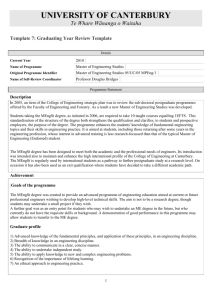

Bachelor of Engineering with Honours

advertisement

(09) UC/12 BE(Hons)(Chemical and Process) /1 UNIVERSITY OF CANTERBURY Te Whare Wānanga o Waitaha Template 2: Qualification Change -2012 Proposal Description R Purpose of the proposal To create a Minor in Bioprocess Engineering as part of the BE(Hons) Chemical & Process Engineering degree. Justification Bioprocess engineering is an important sub-discipline in chemical engineering but the job market is not consistently strong enough to justify a new, more specialised degree, as some chemical engineering programmes overseas have implemented. Chemical and Process Engineering (CAPE) has three out of nine research-active academics with a speciality in bioprocess engineering, with two other academics with some interests in this area. Therefore, the proposal aligns well with the present strengths of the Department and is not contingent on the availability of just one staff member. This minor supports employment in a number of large process industries in New Zealand including dairy, food processing and environmental engineering. Minor areas such as pharmaceuticals and biological health care products are growing also. There are strong employment opportunities in this area overseas, including in Asia, from where we draw a portion of our undergraduate students and to where many return after graduation. There may also be benefits to students who intend to pursue postgraduate research in the bio-related area. We believe this programme will not dramatically compete with other programmes at Canterbury, as CAPE is the only engineering degree programme at Canterbury that incorporates applied biology into its degree programme explicitly in parallel to applied physics and chemistry. It will compete, in some fashion, with degree programmes available at Massey but as our programme is based on an accredited BE at its core, it is not a direct overlap. It will compete, in some fashion, with degree programmes available at Massey, however our programme is an optional specialisation within the broader Chemical and Processing Engineering endorsement compared to their two separate endorsements and is therefore not a direct overlap. We believe the applied biology features of our degree contribute to the high relative percentage of women graduating with a BE in Chemical & Process Engineering. With regard to research, this programme does complement on-going research in the Department. Many of the individual research projects associated with ENCH 495 will integrate and complement on-going postgraduate research in the Department. Some students who have completed the focus have stayed on for postgraduate degrees or gone on to study at other institutions. The students have been doing this specialty since 2005. By creating the Minor, it will be acknowledged on their transcript. Students have been requesting this feature. Prior to this, the department has just been issuing a letter indicating the specialty. Acceptability This area of specialisation was discussed with our Industrial Advisory Board prior to creating the second bioprocess engineering elective in 2007, and informally at subsequent meetings, and has always received strong support. The fact that is does not overly specialise the students and does not dilute the core chemical engineering degree makes it particularly acceptable to the board. As it fits within the elective structure of our degree, it has no significant accreditation implications. Goals of the programme The goal of the minor is to provide a focus in bioprocess engineering. This area uses more microbiology, molecular biology, biochemistry and bioseparations than the standard chemical engineering graduate would normally be 1 (09) UC/12 BE(Hons)(Chemical and Process) /1 exposed to as part of their required courses. The student achieves this speciality by taking specific electives within the Department and completing required project work that has a bioprocess component. This develops both the fundamental and the applied aspects of bioprocess engineering. These courses build on the required course, ENCH 281 ‘Principles Of Biology For Engineers’, which all CAPE graduates must take. Graduate profile A more in-depth understanding of microbiology, molecular biology and biochemistry compared to the standard chemical engineering graduate and an ability to integrate these scientific principles within a traditional chemical engineering design and separation framework. Understand the principles and strategies of bioseparation processes Apply scale-up principles of bioseparation processes, especially in chromatography Understand the basic fermentation technologies associated with submerged microbial, tissue culture applications and solid state fermentations An ability to carry out a preliminary process design of an engineering facility incorporating both fermentation technology and bioseparation processes as part of a chemical engineering capstone design project Perform an individual research project that focusses one or more aspects of bioprocess engineering. Outcome statement No change to the outcome of the existing BE(Hons) degree, now recognising already established pathway Programme overview Entrance into 1st Pro Chemical & Process Engineering in year 2 Pass ENGR 281 - ‘Principles Of Biology For Engineers’ (15 pt required course) in year 2 Pass ENGR 407 - Bioprocess Engineering 1 (15 pt elective course) in year 3 Pass ENCH 482 – Bioprocess Engineering 2 (15 pt elective course) in year 4 Pass ENCH 494 – Process Engineering Design 3 in year 4 (30 pt required course) with an approved bioprocess project focus Pass ENCH 495 – Research Project in year 4 (30 pt required course) with an approved bioprocess project focus Note – 407 and 482 represent two of the three 15 point technical electives permitted as part of the degree requirements for Chemical & Process Engineering. Proposed teaching/delivery methods Lecture based classes for ENGR 407 and ENCH 482 Group project work for ENCH 494. This project will have a bioprocess theme and have the same milestones as groups not completing the bioprocess stream. Individual project work for ENCH 495 where the student will be supervised by a member of the academic staff in CAPE on a bioprocess-related project. Assessment procedures Tests, assignments and examinations for lecture based material in ENGR 480 and ENCH 482 Project reports as part of ENCH 494 and ENCH 495. Predicted student numbers/EFTS Students have had the ability to focus on this specialty since 2007. Since this time, we have averaged between 10-20 students completing all the requirements on an annual basis. Resources 2 (09) UC/12 BE(Hons)(Chemical and Process) /1 Existing resources in the Department, no new courses or other resources required. Plans for monitoring programme quality The normal monitoring as part of the Chemical & Process Engineering BE degree. Annual department reviews Feedback from course surveys, Staff/student liaison meetings and the Industrial Advisory Board Accreditation reviews by IPENZ and ICHEME on a 5 yearly cycle University reviews on a 5 yearly cycle Calendar Form New Qualification Regulations UC Calendar 2012 Page 3. Engineering Disciplines and Minors (b) The degree may also be completed with a Minor that denotes sub-specialisation within an engineering discipline Chemical and Process Engineering 17. Minor in Bioprocessing Engineering (a) ENCH 281 Principles of Biology for Engineers (b) ENGR 407 Bioprocess Engineering 1 (c) ENCH 482 Bioprocess Engineering 2 (d) ENCH494 Process Engineering Design 3* (e) ENCH 495 Research Project* *Note: ENCH494 Process Engineering Design 3 and ENCH495 Research Project must be taken with an approved bioprocess engineering focus as approved by the Director of Studies. 3