Copper is Purified by Electrolysis

advertisement

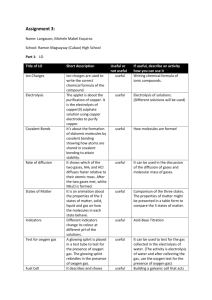

Some Metals have to be Extracted by Electrolysis Metals that are more reactive than carbon have to be extracted using electrolysis of molten compounds. An example of a metal that has to be extracted this way is aluminium. However, the process is much more expensive than reduction with carbon because it uses lots of energy. Copper is Purified by Electrolysis Copper can easily be extracted by reduction with carbon. The ore is heated in a furnace- this is called smelting. However, the copper produced this way is impure – and impure copper doesn’t conduct electricity very well. This isn’t very useful because a lot of copper is used to make electrical wiring. So electrolysis is also used to purify it, even though its quiet expensive. The product is very pure copper, which is a much better conductor. Electrolysis is the breaking down of a substance using electricity. It requires a liquid to conduct the electricity called the electrolyte. In the image on the left this is the electrolysis of copper. The electrons are pulled off copper atoms at the anode, causing them to go into copper sulphate electrolyte solution as Cu2+ ions. Cu2+ ions near the cathode gain electrons and turn back into copper atoms. The impurities are dropped at the anode as sludge, whilst pure copper atoms bond to the cathode. The cathode starts as a thin piece of pure copper and more pure copper adds to it. The anode is just a big lump of impure copper which will dissolve. Copper-rich Ores are in Short Supply The supply of copper rich ores is limited, so it’s important to recycle as much copper as possible. The demand for copper is growing and this may lead to shortages in the future. Scientists are looking into new ways of extracting copper from low- grade ores (ores which contain small amounts of copper) or from the waste that is currently produced when copper are extracted. Examples of new methods to extract copper are bioleaching and phytomining.