Microsoft Word 2007 - UWE Research Repository

advertisement

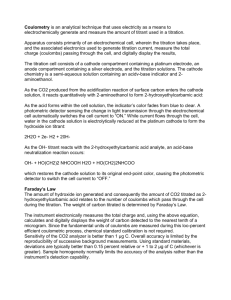

1 Water formation at the cathode and sodium recovery using Microbial fuel cells (MFCs) 2 Iwona Gajdaa, John Greenmana,b, Chris Melhuisha, Carlo Santoroc,d, Baikun Lic,d, Pierangela 3 Cristianie, Ioannis Ieropoulosa,b* 4 5 6 7 8 9 10 aBristol Robotics Laboratory, Block T , UWE, Bristol, Coldharbour Lane, Bristol BS16 1QY bSchool cDepartment of Civil and Environmental Engineering, University of Connecticut, 261 Glenbrook rd, Storrs, CT 06269, USA dCenter eRSE of Life Sciences, UWE, Bristol, Coldharbour Lane, Bristol BS16 1QY for Clean Energy Engineering, University of Connecticut,44 Weaver rd, Storrs, CT 06269, USA – Ricerca sul Sistema Energetico S.p.A., Environment and Sustainable Development Dept., Via Rubattino 54, 20134 Milan, Italy *ioannis.ieropoulos@brl.ac.uk 11 12 Abstract 13 Microbial Fuel Cells (MFCs) utilise biodegradable carbon compounds in organic waste to 14 generate electric current. The aim of this work was to enhance MFC performance by using 15 low cost and catalyst (platinum)-free cathode materials. The results showed that the range of 16 Pt-free cathodes including activated carbon, plain carbon fibre veil with and without 17 microporous layer (MPL) in two-chamber MFC generated power with simultaneous catholyte 18 generation in the cathode chamber. This is the first time to report a clear catholyte formation 19 on the cathode half cell, which was directly related to MFC power performance. The 20 importance of this phenomenon may be attributed to the oxygen reduction reaction, water 21 diffusion and electroosmotic drag. The synthesised catholyte in situ on the open-to-air 22 cathode appeared to be sodium salts (9% concentration), which was recovered from the 23 anolyte feedstock containing sludge and sodium acetate. An overlooked benefit of catholyte 24 formation and accumulation contributes greatly to the overall wastewater treatment, water 25 recovery, bioremediation of salts and carbon capture. 26 Keywords: Microbial Fuel Cell (MFC), carbon veil cathodes, Microporous Layer (MPL), 27 electroosmotic drag, oxygen reduction reaction, wet scrubbing 28 1. Introduction 29 The world of the 21st century is facing shortages in fresh water as well as increased electricity 30 demand, which is inspiring the development of new, alternative technologies of wastewater 31 treatment and power generation. One of the most promising solutions, addressing both 32 challenges, is the Microbial Fuel Cell (MFC) technology, whose bio-catalytic activity of 33 microbes digesting organic matter allows the direct generation of electricity [1]. Biomass in 34 wastewater contains a significant amount of energy, and its utilisation as a power source may 35 have an important role in helping to secure a sustainable future. The most attractive aspect of 36 the process is that the generation of electricity from wastewater is resulting in cleaner waste. 37 The Microbial Fuel Cell (MFC) comprises an anode and a cathode chambers, separated by a 38 proton selective membrane. The electrons are generated by the metabolic pathways of the 39 microbes digesting biomass into CO2, electrons and protons. For each electron that is 40 produced, an equivalent proton must be transported to the cathode through the electrolyte, 41 which sustains the current flow. The oxygen reduction reaction (ORR) at the 42 membrane/cathode interface consumes oxygen and generates water or hydrogen peroxide. 43 According to Kinoshita [2], under alkaline conditions, the H2O2 is then transformed from both 44 electrochemical and chemical processes [2]. 45 Peroxide pathway in alkaline solutions 46 O2 +H2O +2e- → HO2- +OH- 47 Followed by reduction of peroxide: 48 HO2- + H2O +2e- → 3 OH- 49 or decomposition : 50 2 HO2- - → 3 OH- + O2 51 Air cathode MFCs are the most promising configuration for practical applications including 52 wastewater treatment and power generation due to their improved electrical power output and 53 operational simplicity [3]. However, the ORR of a working MFC in comparison to chemical 54 fuel cells is limited due to the MFC neutral pH and ambient operating temperature. Overall, 55 the cathode is being usually the limiting factor for power generation, which hinders the 56 overall system performance. [4, 5]. The utilization of platinum as a cathode catalyst would 57 certainly enhance the overall performances but it would elevate the total MFC cost. 58 Unfortunately, the platinum would have also been poisoned by a non-sterile environment in a 59 relatively short amount of time [6]; therefore there is a critical need for low-cost catalysts for 60 future long-term MFC applications. Materials with high surface area and different surface 61 treatments have been used to increase the rate of ORR and improve the overall MFC 62 performance. For example, granular graphite, micro-porous layer and activated carbon, have 63 been reported to support cathodic oxygen reduction due to the very large specific surface area 64 [7-9] and high porosity that would also improve the water management. 65 In Proton Exchange Membrane Fuel Cells (PEMFCs) the water management is critical for 66 achieving high performance. The polymer exchange membrane requires to be sufficiently 67 hydrated to maintain high ionic conductivity. During fuel cell operation, water molecules 68 migrate through the membrane due to electro-osmotic drag and diffusion and water is also 69 being generated at the cathode/membrane interface due to the ORR. If the water generated is 70 not removed, cathode flooding may hinder the oxygen transport on the catalyst active sites 71 and severely penalize the output [10]. In PEMFCs, the liquid water transport mechanism is 72 one of the most dominant parameter influencing the performance of the cathode and current 73 density-based loss distribution [11]. Water is also essential for the operation of MFC, 74 providing an electrolyte bridge between anolyte, membrane and the cathode, however, there 75 are very few MFC works studying water production (via oxygen reduction), water transport 76 from the anode and its sufficiency for supporting cathode reaction [12]; thus, in the open to 77 air cathode design an external supply of water is necessary [13]. In addition, it has been found 78 that in MFCs cations, other than protons, are more likely to complete the circuit via 79 transportation from the anode to the cathode [14] allowing their recovery from wastewater. 80 With the ionic movement that will drag water molecules through electroosmosis, water also 81 can be recovered. Similar concept has been recently utilized for bioelectrochemical systems 82 with the purpose of desalinization of water [15]. Moreover it has also been recognised that 83 the flooding of the cathode is a negative factor in MFCs [16] attributing it to hindered oxygen 84 mass transfer by catalyst sites filled with water and pursuing a direction of development for 85 anti-flooding binders [17]. However, from the wastewater treatment point of view, the 86 formation and accumulation of catholyte might serve as a huge advantage to the MFC 87 technology if catholyte flooding is correctly managed. This can be achieved through the 88 cathode electrode design and its configuration within the reactor. The generated or 89 transported water from the anolyte to the cathode chamber in the MFC system plays an 90 important role in wastewater treatment as an additional waste cleanup method, synthesis and 91 bioremediation (recovery) of elements. 92 This work aims to: (i) explore the water transport phenomenon in the dual-chamber MFC 93 system in relation to power production in order to understand the mechanism of catholyte 94 flow on carbon porous electrodes as an opportunity for biosynthesis, remediation and 95 recovery of useful components from the wastewater. (ii) Present for the first time the 96 catholyte formation in situ on the range of carbon based cathode electrodes; and (iii) analyse 97 the produced catholyte in terms of its salt composition and other elements from the anodic 98 wastewater, and its potential for carbon capture in wet scrubbing open to air cathode MFCs. 99 100 2. Materials and Methods 101 2.1.MFC design and operation 102 Twelve tested MFC reactors comprised 25mL anode chambers and 25mL cathode chambers 103 as previously described [18] separated by a cation exchange membrane (CMI Membranes 104 International, USA). Already established and well matured anodes were used from previous 105 MFC experiments, which have been running for at least 6 months under pseudo steady-state 106 conditions. Anode electrodes were made from carbon fibre veil with a carbon loading of 107 20g/m2 (PRF Composite Materials, Poole, Dorset, UK) and had a total macro surface area of 108 270cm², folded into 3D rectangular cuboids (geometric surface area of 36cm2) in order to fit 109 into the chamber and be fully suspended in the anolyte fluid. The cathode electrodes were 110 used as shown in Table 1 and placed in transparent MFC chambers with 2 vents (0.3mm 111 diameter) at the top. The anolyte was recirculated using a 16-channel peristaltic pump (205U, 112 Watson Marlow, UK) with a flow rate of 47mL/h. The tubing was made of silicone, its length 113 was 40cm from the pump to the MFC, 40cm from the MFC to the 1L anolyte reservoir and 114 90cm from the reservoir back to the pump, periodically supplemented with fresh sludge 115 mixed with 20mM sodium acetate as a carbon-energy (C/E) source, in order to maintain C/E- 116 replete conditions and avoid having the anode as the limiting half-cell. 117 2.2.Cathode electrodes preparation 118 The same folded carbon veil electrode used for the anode was used as the control for the 119 cathode (CV) and was the only type of 3D cathode electrode used. Microporous layer on 120 carbon cloth and on carbon veil was prepared as previously described [19]. Activated carbon 121 (activated charcoal, BET area of 802 m2g-1, Calgon, Pittsburgh, PA) was prepared with a 122 loading of 60±2 mgAC cm-2 and PTFE (20%wt) were mixed using a blender and pressed on a 123 30% wt PTFE treated carbon cloth (Fuel Cell Earth) that was used as the current collector in 124 MFCs. The AC cathodes were prepared under pressure force (1400 psi) for 2 minutes and 125 then heated at 200°C for 1 hour [20]. 126 The cathode chamber had the additional hollow space at the bottom and included a syringe to 127 allow the collection of the catholyte produced (see Fig.2). All 12 MFCs were divided in 4 128 experimental groups of identical triplicates (Table 1). No catalysts or buffers were used. 129 Table 1. Types of electrodes in the open to air cathode half cells. Electrode Name Electrode Type Cathode type, size CV Carbon veil (Control) folded 3Dimensional (folded), 270cm2 MPL Carbon cloth with Microporous layer 2D 10cm2 CV MPL Carbon veil with Microporous layer 2D 10cm AC Activated carbon on carbon cloth 2D 10cm2 130 131 2.3. Measurement and Calculation 132 Voltage (V) was measured in millivolts (mV) and monitored using an ADC-24 Channel Data 133 Logger (Pico Technology Ltd., Cambridgeshire, U.K.), recorded data were processed using 134 GraphPad Prism® version 5.01 software package (GraphPad, California, U.S.A.). Current in 135 amperes (A) was determined using Ohm’s law, I=V/R, where (R) is the external resistor load 136 in ohms (Ω). Power in watts (W) was calculated using Joule’s law P=IV. Polarisation 137 experiments were performed by connecting a variable resistor, with a range between 138 30,000Ω-10Ω. Resistance was changed every 3 minutes, with data recorded every 30 139 seconds. Anodes were inoculated with anaerobic activated sludge provided by the Wessex 140 Water Scientific Laboratory (Saltford, UK). Sludge was mixed with 20mM acetate and used 141 as feedstock. Anodes were connected to the 16-channel peristaltic pump (205U, Watson 142 Marlow, Falmouth, UK) with the use of silicon tubing and 1L of anolyte bottle to maintain 143 anolyte recirculation at flow rate of 47 mL/h. 144 2.4. Analysis of the accumulated catholyte”water” 145 The pH was measured with Hanna 8424 pH meter (Hanna, UK) and the conductivity with 146 470 Jenway conductivity meter (Camlab, UK). Dry weight of precipitated salts was 147 determined by drying 0.5mL of catholyte over 48h and weighing the dry mass. Samples were 148 prepared for SEM microscopy by sputter coating in gold using an Emscope SC500 sputter 149 coating unit. Images were observed and captured using a Philips XL30 scanning electron 150 microscope (SEM). Energy dispersive x-ray (EDX) analysis was performed (Philips XL30 151 SEM) and it was used to determine elements present in precipitated cathodic salts. Detection 152 limits are typically 0.1-100%wt. The ICP-OES (Varian Inc. Vista-Pro ICP-OES using Axial 153 Plasma) was used for metal analysis of the catholyte samples. GC-MS was performed to 154 determine organic compounds in the collected catholyte by liquid extraction 1:1 with ethyl 155 acetate. XRD (X-ray Diffraction) analysis on precipitated salts from the catholyte was 156 determined using powder measurements, performed on a Bruker D8 Advance Diffractometer 157 with the results being analysed using EVA software package (Bruker, UK). For the single 158 crystal measurement, a unit cell check was performed on a Bruker Microstar Cu-anode 4- 159 circle diffractometer with the results being analysed with APEX II (Bruker, UK) 160 3. Results and Discussion 161 3.1. Polarisation experiments of cathode materials 162 To assess the maximum power point (MPP), a polarisation experiment was performed; Fig.1 163 presents the polarisation data where the maximum power recorded for the different electrodes 164 was: AC 498μW; MPL 419 μW; CVMPL 313 μW and CV121 μW. From these, it can be 165 concluded that the 2D pressed cathode type materials such as AC, MPL, MPL CV are 166 performing 4, 3.4, and 2.5-fold better, respectively compared to the control 3D cathode (CV). 167 The improved performance might have been due to the higher specific surface area of the 168 activated carbon in AC and MPL and the better contact with the PEM, which might have 169 resulted in an improved ORR rate. MPL Power MPL Voltage CV Power CV Voltage 600 400 AC Power AC Voltage 500 300 400 300 200 Voltage[mV] Power[W] CV MPL Power CV MPL Voltage 200 100 100 0 0 1000 2000 4000 5000 0 6000 Current (µA) 170 171 172 3000 Figure 1. Polarisation data of all tested MFCs (mean value of tiplicate MFCs) 173 3.2. Catholyte accumulation 174 Catholyte formation on the surface of the cathode electrode was first observed as droplets, 175 visible to the naked eye (Fig. 2, left) and further on as accumulation of the catholyte from all 176 the tested MFCs. The newly formed catholyte was consistently clear in colour (Fig.2, right) 177 and when evaporated left a residue suggesting high salt content, which is soluble in water 178 (Fig.2, centre). At the same time, anolyte loss was observed. To explore the catholyte 179 accumulation phenomenon, all MFCs were connected to 2.4kΩ, 1.2kΩ, 600Ω and 300 Ω 180 resistors. The 300Ω resistor was chosen as the closest to the internal resistance for MPP, 181 which was derived from the polarisation experiment. The catholyte was collected after 72h of 182 steady state MFC operation under external load conditions. The dry mass of collected 183 precipitant was estimated on the basis of evaporation of collected catholyte samples of equal 184 volumes. The maximum salt concentration calculated for each cathode (see Figure 3) was 185 shown to be: CV 40.1 g/L, AC 57.2 g/L, MPL 93.8g/L, CV MPL 86.2 g/L and shows 186 correlation with power performance. 187 Figure 2. MFC with droplets of water forming on the cathode and collected liquid in the syringe(left), cathode chamber dissassembled with salts percipitation(centre),catholyte liquid collected (right). Salt concentration[g/L] 60 100 40 0 1200 1200 2400 CV MPL AC Power[W] Salt concentration[g/L] 100 60 100 1200 Resistance value[] 2400 Power[W] Salt concentration[g/L] 300 100 80 200 60 100 40 0 300 600 1200 Salt concentration[g/L] 80 200 300 600 300 600 Resistance value[] Salt concentration[g/L] Power[W] 40 2400 40 191 60 100 Resistance value[] 300 0 80 200 0 300 600 100 Salt concentration[g/L] 80 200 Power[W] Salt concentration[g/L] 300 100 Salt concentration[g/L] Power[W] CV Power[W] Power[W] MPL 300 Power[W] 188 189 190 2400 Resistance value[] 192 193 Figure 3. Salt concentration in produced catholyte calculated by dry mass of salts evaporated from the catholyte formed in all 4 experimental MFC groups under various load conditions. 194 3.3. Relationship between catholyte accumulation and power generation of MFCs 195 Voltage and produced catholyte “water” were monitored during a 72h period at each resistor 196 value. In terms of cathode material, the highest power was recorded for AC 262μW, MPL 197 159μW, MPL CV 152μW at 300Ω and CV 88μW at 600Ω (Figure 4). Catholyte 198 accumulation was recorded after 72h under each resistance value. The data show that water 199 was produced from all cathode materials, at different levels, and was dictated by the level of 200 power as well as by the cathode material. The maximum current was produced from AC 201 934μA, MPL 728μA, CV MPL 712μA and CV 540μA. In terms of power generation, the best 202 performing cathode was the activated carbon (AC) with a maximum power density of 203 262mW/m2 (normalised to the total macro cathode surface area). The relationship between 204 power generation and the catholyte accumulation is shown in Figure 4, as a function of 205 external resistance. CV Power[W] Catholyte produced[mL] 300 2.5 Power[W] 1.0 100 0.5 0 300 600 1200 2400 2.0 200 1.5 1.0 100 0.5 0.0 0 300 600 Resistance value[ ] AC Power[W] Catholyte produced[mL] 2.5 Power[W] 1.5 1.0 100 0.5 1200 Resistance value[ ] 0.0 2400 0.0 Power[W] 2.5 2.0 200 1.5 1.0 100 0.5 0 300 600 1200 2400 Water produced[mL] 200 300 600 2400 Catholyte produced[mL] 300 Water produced[mL] 2.0 0 1200 Resistance value[ ] Power[W] CV MPL 300 2.5 Water produced[mL] 1.5 Water produced[mL] 2.0 200 Power[W] Catholyte produced[mL] 300 Power[W] MPL 0.0 Resistance value[ ] 206 207 Figure 4. Power average over 72h period in relation to amount of catholyte collected after 208 72h steady state response under various external resistances: 2.4kΩ, 1.2kΩ, 600Ω and 300Ω. 209 These findings seem to be similar to the previously reported water loss through the 210 membrane, which was also dependent on the value of the external load resistance, suggesting 211 that the major water transport phenomena is related to electro-osmotic drag of water through 212 the membrane [12, 21]. However, this has only been reported as a loss of anolyte volume and 213 furthermore this is the first time that newly synthesised catholyte of such volumes, is actually 214 collected from MFCs. This has also been reported for chemical PEM fuel cells [22], which 215 traditionally employ water management techniques to avoid flooding and improve 216 performance. This data shows that water formation actually improves power generation 217 which has an opposite effect to the conventional notion of cathode flooding and showing 218 cathode half cell architecture as flowing system. 219 220 3.4. Analysis of the accumulated catholyte 221 3.4.1. Conductivity and pH CV pH 100 Conductivity[mS/cm 2] pH 40 11 20 10 300 600 1200 Conductivity[mS/cm 2] 60 11 40 10 300 600 AC pH 2 Conductivity[mS/cm ] 100 pH 60 40 11 20 300 600 1200 Resistance value[ ] 2400 0 pH Conductivity[mS/cm 2] 100 80 12 60 40 11 20 10 300 600 1200 2400 Conductivity[mS/cm 2] 12 13 Conductivity[mS/cm 2] 80 10 2400 pH CV MPL 1200 Resistance value[ ] Resistance value[ ] 13 100 80 12 0 2400 pH Conductivity[mS/cm 2] 60 Conductivity[mS/cm 2] 80 12 13 pH MPL 13 0 Resistance value[ ] 222 223 Figure 5. Conductivity and pH values of catholyte collected after 72h under various external 224 load conditions: 2.4kΩ, 1.2kΩ, 600Ω and 300Ω. 225 The conductivity and pH behaved in a similar manner, with the highest conductivity and pH 226 recorded for the highest power levels and water volumes. The pH of the collected samples in 227 the range of 10.6-12.7 suggests high caustic content; Figure 5 shows the measured pH and 228 conductivity values of the collected catholyte from MFCs under the different resistance loads. 229 The data suggest that improved power generation and subsequent higher ion exchange rate 230 between the anode and the cathode drives the OH- accumulation on the cathode surface, 231 therefore the more power produced by the MFC, the more caustic catholyte is collected. The 232 higher reaction rates at MPT (300Ω) would suggest that CO2 buffering (reacting with OH-) 233 would be suppressed compared with the lower power generation (i.e. slower reaction rates) 234 recorded under 2.4kΩ or 1.2kΩ. As previously reported, in the aqueous cathode half cells, 235 high pH of the catholyte is generating a large membrane pH gradient between the anolyte and 236 the catholyte, causing a significant potential loss [23], which could be compensated by the 237 increase in cathodic conductivity [24]. In the present study the excess of catholyte is 238 constantly removed from the cathode surface by gravity (Fig 2) preventing cathode flooding, 239 salt precipitation and high pH gradient build-up, therefore not affecting the MFC 240 performance. 241 3.4.2 EDX and SEM analysis 100 80 Cathode surface % 60 40 Catholyte precipitation 20 0 242 Na Si S K Ca Al 243 244 245 Figure 6. EDX profile representing % of detected elements in precipitated salts from the electrode surface and the evaporated liquid sample(left) and SEM image of the catholyte crystals(right). 246 Given that the anolyte contained 20mM sodium acetate, it would be expected to find sodium 247 in the precipitated salts. The precipitated salts were crystalline, transparent or white and 248 soluble in water (Fig 2 and Fig 6). The EDX analysis of the salts that precipitated on the 249 surface of the electrode and from the evaporated catholyte solution, show 96.7% and 93.6% 250 sodium content, respectively. This suggests that cations such as sodium (from sludge and 251 sodium acetate feedstock) are being recovered from the anode to the cathode. 252 3.4.3 GC MS and ICP OES analysis 253 The GC-MS analysis detected no organic content in the collected liquid. With the exception 254 of Na, which was off-scale for all the samples, and K which was off-scale for AC, the ICP 255 OES profile is shown in Figure 7. The analysis showed varying amounts of potassium, 256 magnesium and calcium primarily, depending on cathode material, and very small amounts of 257 aluminium and zinc. Although the data were not directly proportional with the level of power 258 produced by each material, the highest peaks were recorded from the most powerful AC 259 cathode. 260 261 Figure 7. Detected trace elements in catholyte samples (mg/L) by ICP OES. Sodium was off 262 the measurable scale in all tested samples (*), as well as Potassium in sample AC (*). 263 3.4.4 XRD analysis 264 X-ray diffraction pattern analysis of all crystallised catholyte samples, appear to be made up 265 from very similar materials. Analysis using single crystal X-ray diffraction suggests that the 266 primary component of the material has a monoclinic cell of a = 21.0, b = 3.5, c =10.7 β = 267 106.41. A database search of materials with a known unit cell of this value with a Na content, 268 suggests a mineral phase known as Trona or Na3H(CO3)2.H2O. 269 Recent developments in the field of BES research have shifted from power production to 270 chemical synthesis, where the energy is stored as chemicals in the cathode and valuable 271 compounds are produced. Here, it is suggested that it may be possible to integrate both 272 energy generation and chemical synthesis as it appears that both processes are inherently 273 linked. The recovery of caustic soda from wastewater and acetate solution used as anolyte has 274 been previously reported [25], by using an energy-consuming MEC and a catholyte 275 containing NaCl. Here, as no catholyte solution was used, the electricity produced by the 276 MFCs is directly linked to the synthesis of caustic catholyte in situ. Similar carbonate salt 277 deposits were previously reported on the cathode electrode-membrane assembly, however 278 this accumulation was hindering the overall MFC performance [26]. Similarly, in cases of 279 single chamber membrane-less MFCs, the biocathode, free of platinum, seemed to be limited 280 by carbonate deposits other than pH higher than 10 [27, 28]. Here, it is suspected that the salt 281 accumulation is prevented due to the effective water transport and production, which removes 282 salts away from the membrane by hydrodynamic flow and is washing away potentially 283 accumulating salts off from the cathode surface. Therefore, the catholyte flow in the present 284 MFC may be also beneficial in keeping the cathode pores free of precipitants as well as it 285 could enhance the water management of the membrane. 286 287 3.5. Significance of catholyte accumulation to environmental cleanup 288 In principle, the catholyte production is mainly due to the water transport and thus the volume 289 of catholyte produced should equal the volume of anolyte lost (minus evaporative losses) 290 considering negligible the contribution of water produced through ORR due to low current 291 generation. Figure 5 shows that up to 2mL of catholyte can be produced over 3 days of 292 operation, from a 25mL sludge filled anode, which theoretically suggests that it would take 293 (for example) 16 days to produce 10.6mL of clear catholyte. If by the end of this period the 294 anolyte is completely depleted (which we expect to be the case), this would suggest a 40% 295 recovery rate with a 60% evaporation rate. This is only a prediction based on visual 296 inspection of anolyte evaporative losses, and further work is required to validate this 297 phenomenon. Apart from sodium which was added as sodium acetate in the feedstock, the 298 other detected elements through the ICP OES analysis included potassium, magnesium and 299 calcium (Fig. 7). It is therefore suspected that these cations must have come from the 300 wastewater through the PEM, and in effect this demonstrates a type of recovery. This would 301 be valuable in extracting useful elements from highly polluted/toxic waste streams. 302 303 3.6. Sodium recovery through bioproduction 304 It has already been hypothesised that a 25mL anolyte could produce 10.6mL of catholyte. 305 This would be the equivalent of 426L of catholyte recovered from 1m3 of anolyte. Taking 306 into account the concentration (5-9%) and composition (90% sodium) of salts in the obtained 307 catholyte, it may be suggested that in theory, 45-81g of sodium per L of catholyte can be 308 recovered, which would be the equivalent of 19.1-34.5kg of salts from 1m3 of anolyte, at 309 larger scale. The analysis of the salt deposits suggests the mineral trona 310 Na3(CO3)(HCO3)•2H2O or Na2CO3-NaHCO3:2H2O which is one of the natural forms of 311 sodium carbonate and it is a double salt of sodium carbonate and sodium bicarbonate. Its 312 potential could be quite high, due to the abundance and low price of sodium-precursors that 313 are normally used in the production of battery components [29]. 314 315 3.7. Control of catholyte alkalinity 316 The typical pH of the collected catholyte throughout the experiment was 10.6-12.7. During 317 the experiment the cathode chamber was closed with only 2 open to air vents left at the top of 318 the reactor. As it was observed by obstructing the vents and preventing the ambient air to 319 flow through the chamber, the pH of the catholyte collected subsequently increased to >13. 320 This indicates that by limiting the air flow and consequently the CO2 flux and its buffering 321 properties, it is possible to affect the alkalinity of the catholyte. Moreover, elevating the 322 already high pH of the catholyte simply by limiting the air flow is suggesting the possible use 323 of the synthesised caustic solution as disinfectant and may prevent biofouling of the 324 membrane by limiting the growth of biofilm on the cathode side [30]. 325 326 3.8. Carbon capture 327 Removal of gaseous components through contact with a liquid is known as “wet scrubbing”. 328 Carbon dioxide absorption from atmospheric air using alkaline solution has been explored in 329 the 1940s [31] and used at large/industrial scales [32]. In the air extraction process, alkaline 330 sodium solvent reacts chemically with the entrapped CO2. Therefore, it is suspected that in 331 the present MFC cathode, an air flow (and consequently its CO2 content) played an important 332 role in controlling the alkalinity of the caustic catholyte formed in the porous open to air 333 cathode, and the further formation of sodium salts such as: trona, carbonate and bicarbonate 334 of sodium. Furthermore, it has already been proposed that an addition of CO2 is an important 335 pre-condition for the formation of trona deposits [33]. Sodium carbonate is commonly 336 employed in the (i) glass and ceramic, (ii) petroleum, (iii) aluminium, (iv) paper, (v) soap, 337 (vi) detergent and (vii) caustic soda industries. With the proposed MFC set up, caustic 338 solution (and its carbonate content) may be directly synthesised on the MFC cathode to 339 capture atmospheric CO2 and allow sodium recovery from the anolyte. This would allow the 340 MFC to be a truly carbon negative technology. 341 342 Conclusions 343 It has been shown for the first time that Microbial Fuel Cells have the ability to synthesise 344 and extract useful elements on different catalyst-free carbon-based cathodes with the 345 important advantage of electricity generation during this process. The level of power 346 performance depends on the cathode material used however the in situ synthesis of catholyte 347 appears to be independent of the electrode material used and it shows a significant correlation 348 with its electrical performance. This is the first time that carbon-capture via chemical 349 synthesis of liquid catholyte containing valuable minerals, actually improved (and not 350 hindered) the power generation of MFCs, which strongly demonstrates the benevolent 351 potential of the MFC technology. 352 Acknowledgement 353 The work was funded by the Engineering and Physical Sciences Research Council EPSRC 354 CAF EP-I004653/1 and EP/L002132/1. Authors would like to thank Dr David Patton, Mr 355 Paul Bowdler from the University of the West of England and Dr Christopher H. Woodall 356 from the University of Bristol for the valuable expertise and analysis of the catholyte 357 samples. 358 References 359 360 [1] R.M. Allen, H.P. Bennetto, Microbial fuel-cells:Electricity production from carbohydrates, Appl. Biochem. Biotechnol. 39/40 (1993) 27-40. 361 [2] K. Kinoshita, Carbon: electrochemical and physicochemical properties, (1988). 362 363 364 [3] Park, D.H. and Zeikus, J.G. (2003) Improved fuel cell and electrode designs for producing electricity from microbial degradation. Biotechnology and Bioengineering [online]. 81 (3), pp.348-355. 365 366 [4] R. Holze, W. Vielstich, The Kinetics of Oxygen Reduction at Porous Teflon‐Bonded Fuel Cell Electrodes, J. Electrochem. Soc. 131 (1984) 2298-2303. 367 368 [5] H. Rismani-Yazdi, S.M. Carver, A.D. Christy, O.H. Tuovinen, Cathodic limitations in microbial fuel cells: An overview, J. Power Sources. 180 (2008) 683-694. 369 370 371 [6] C. Santoro, A. Stadlhofer, V. Hacker, G. Squadrito, U. Schröder, B. Li. Activated Carbon Nanofibers (ACNF) as cathode for Single Chamber Microbial fuel cells (SCMFCs). Journal of Power Sources, 243 (2013) 499-507 372 373 [7] S. Freguia, K. Rabaey, Z. Yuan, J. Keller, Non-catalyzed cathodic oxygen reduction at graphite granules in microbial fuel cells, Electrochim. Acta. 53 (2007) 598-603. 374 375 376 [8] C. Santoro, A. Agrios, U. Pasaogullari, B. Li, Effects of gas diffusion layer (GDL) and micro porous layer (MPL) on cathode performance in microbial fuel cells (MFCs), Int J Hydrogen Energy. 36 (2011) 13096-13104. 377 378 379 [9] H. Dong, H. Yu, X. Wang, Q. Zhou, J. Feng, J. A novel structure of scalable air-cathode without Nafion and Pt by rolling activated carbon and PTFE as catalyst layer in microbial fuel cells. Water Res. 46 (2012) 5777-5787. 380 381 [10] L. Yu, W. Chen, M. Qin, G. Ren, Experimental research on water management in proton exchange membrane fuel cells, J. Power Sources. 189 (2009) 882-887. 382 383 [11] D. Natarajan, T. Van Nguyen, Three-dimensional effects of liquid water flooding in the cathode of a PEM fuel cell, J. Power Sources. 115 (2003) 66-80. 384 385 386 [12] J.R. Kim, G.C. Premier, F.R. Hawkes, R.M. Dinsdale, A.J. Guwy, Development of a tubular microbial fuel cell (MFC) employing a membrane electrode assembly cathode, J. Power Sources. 187 (2009) 393-399. 387 388 389 [13] F. Zhang, K.S. Jacobson, P. Torres, Z. He, Effects of anolyte recirculation rates and catholytes on electricity generation in a litre-scale upflow microbial fuel cell, Energy & Environmental Science. 3 (2010) 1347-1352. 390 391 [14] R.A. Rozendal, H.V. Hamelers, C.J. Buisman, Effects of membrane cation transport on pH and microbial fuel cell performance, Environ. Sci. Technol. 40 (2006) 5206-5211. 392 393 [15] C. Forrestal, P. Xu, Z. Ren, Sustainable Desalination using a microbial capacitive desalination cell, Energy and Environmental Science 5, 2012, 7161-7167. 394 395 [16] Wilkinson, S. (2000) “Gastrobots”—Benefits and Challenges of Microbial Fuel Cells in FoodPowered Robot Applications. Autonomous Robots 9 (2), pp.99-111. 396 397 398 [17] F. Zhang, G. Chen, M.A. Hickner, B.E. Logan, Novel anti-flooding poly (dimethylsiloxane)(PDMS) catalyst binder for microbial fuel cell cathodes, J. Power Sources. (2012). 399 400 [18] I. Gajda, J. Greenman, C. Melhuish, I. Ieropoulos, Photosynthetic cathodes for Microbial Fuel Cells, Int J Hydrogen Energy. (2013). 401 402 403 [19] C. Santoro, Y. Lei, B. Li, P. Cristiani, Power generation from wastewater using single chamber microbial fuel cells (MFCs) with platinum-free cathodes and pre-colonized anodes, Biochem. Eng. J. 62 (2012) 8-16. 404 405 406 407 [20] C. Santoro, K. Artyushkova, S. Babanova, I. Ieropoulos, M. Grattieri, P. Cristiani, S. Trasatti, B. Li, P. Atanassov. Parameters Characterization and Optimization of Activated Carbon (AC) Cathodes for Microbial Fuel Cell Application. Bioresource Technology, Under review 408 409 [21] L. Zhuang, S. Zhou, Y. Wang, C. Liu, S. Geng, Membrane-less cloth cathode assembly (CCA) for scalable microbial fuel cells, Biosensors and Bioelectronics. 24 (2009) 3652-3656. 410 411 412 [22] Y.H. Park, J.A. Caton, An experimental investigation of electro-osmotic drag coefficients in a polymer electrolyte membrane fuel cell, Int J Hydrogen Energy. 33 (2008) 7513-7520. 413 414 415 [23] R.A. Rozendal, H.V. Hamelers, K. Rabaey, J. Keller, C.J. Buisman, Towards practical implementation of bioelectrochemical wastewater treatment, Trends Biotechnol. 26 (2008) 450-459. 416 417 418 [24] R. Rozendal, T. Sleutels, H. Hamelers, C. Buisman, Effect of the type of ion exchange membrane on performance, ion transport, and pH in biocatalyzed electrolysis of wastewater, Water Science and Technology. 57 (2008) 1757-1762. 419 420 421 [25] K. Rabaey, S. Butzer, S. Brown, J. Keller, R.A. Rozendal, High current generation coupled to caustic production using a lamellar bioelectrochemical system, Environ. Sci. Technol. 44 (2010) 4315-4321. 422 423 424 [26]T.H Pham, J.K. Jang, H.S. Moon, I.S. Chang, B.H. Kim, Improved performance of microbial fuel cell using membrane-electrode assembly, Journal of microbiology and biotechnology. 15 (2005) 438-441. 425 426 [27] P. Cristiani, M. Carvalho, E. Guerrini, M. Daghio, C. Santoro, B. Li, Cathodic and anodic biofilms in single chamber microbial fuel cells, Bioelectrochemistry. 92 (2013) 6-13. 427 428 429 [28] C. Santoro, M. Cremins, U. Pasaogullari, M. Guilizzoni, A. Casalegno, A. Mackay, B. Li, Evaluation of Water Transport and Oxygen Presence in Single Chamber Microbial Fuel Cells with Carbon-Based Cathodes, J. Electrochem. Soc. 160 (2013) G3128-G3134. 430 431 [29] M.D. Slater, D. Kim, E. Lee, C.S. Johnson, Sodium‐Ion Batteries, Advanced Functional Materials. (2012). 432 433 [30] J. Xu, G. Sheng, H. Luo, W. Li, L. Wang, H. Yu, Fouling of proton exchange membrane (PEM) deteriorates the performance of microbial fuel cell, Water Res. 46 (2012) 1817-1824. 434 435 [31] N.A. Spector, B.F. Dodge, Removal of carbon dioxide from atmospheric air, Trans. Am. Inst. Chem. Eng. 42 (1946) 827-848. 436 437 [32] K.S. Lackner, P. Grimes, H. Ziock, Capturing carbon dioxide from air, (2001) In: 24th Annual Technical Conference on Coal Utilization, Clearwater, FL. 438 [33] S. Earman, F.M. Phillips, B.J. McPherson, The role of “excess” CO2 in the formation of 439 trona deposits, Appl. Geochem. 20 (2005) 2217-2232.