aic14609-sup-0001

advertisement

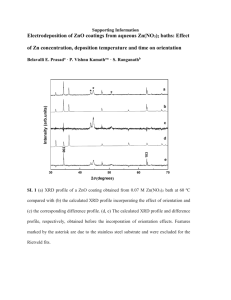

Supporting Information: Facile Fabrication of Spherical Architecture of Ni/Al Layered Double Hydroxide Based on In Situ Transformation Mechanism Fazhi Zhang*, Yue Zhang, Caili Yue, Rong Zhang, and Yanmin Yang State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing 100029, China E-mail: zhangfz@mail.buct.edu.cn 1 Figure S1. SEM images of the samples prepared using only BAA and concentrated ammonia aqueous solution as raw materials, with different reaction times 0.5 min (a), 1 min (b), 10 min (c), and 24 h (d) at reaction temperature 60 °C. 2 Figure S2. XRD patterns of the samples prepared using only BAA and concentrated ammonia aqueous solution as raw materials, with different reaction times 0.5 min (a), 1 min (b), 10 min (c), and 24 h (d) at reaction temperature 60 °C. XRD pattern of boehmite crystal (JCPDS No. 83-2384) is included for comparison. 3 Figure S3. SEM images and XRD patterns of two production samples obtained with Al(NO3)3/Ni(NO3)2 (a) and BAA/Ni(NO3)2 (b) as raw materials. Concentrated ammonia aqueous solution is used as alkali source and the other reaction conditions are the same as those in Figure 1. Both XRD patterns show characteristic reflections of LDH phase with carbonate anions intercalated into the gallery for the two LDH samples. 4 Figure S4. SEM images and XRD patterns of two product samples obtained with urea at 120 ºC (a) and NaOH at 60 ºC (b) as alkali source. BAA and nickel acetate are used as raw materials and the other reaction conditions are the same as those in Figure 1. Both XRD patterns show characteristic reflections of LDH phase with carbonate anions intercalated into the gallery for the two LDH samples. 5 Figure S5. XPS spectra of Al 2p (a) and Ni 2p (b) for LDH spherical architectures obtained with different reaction times. The other reaction conditions are the same as those in Figure 1. 6 Figure S6. SEM images and XRD patterns for the production samples obtained with different reaction temperature: 50 ºC (a), 70 ºC (b) and 90 ºC (c). The other reaction conditions are the same as those in Figure 1. SEM image and XRD pattern of LDH spherical architecture obtained with reaction temperature 60 ºC is shown as Figure 1b. 7 Figure S7. SEM images and XRD patterns for the production samples obtained with different dosage of concentrated ammonia aqueous solution: 5 mL (a), 25 mL (b), and 40 mL (c). The other reaction conditions are the same as those in Figure 1. SEM image and XRD pattern of LDH spherical architecture obtained with concentrated ammonia aqueous solution dosage 15 mL is shown as Figure 1b. 8 Figure S8. N2-sorption isotherm and pore size distribution (inset) of LDH spherical architecture and powder sample. 9 Table S1. Specific surface areas and pore parameters of LDH spherical architecture and powder sample. Sample Used alkali BET surface Average pore source area (m2 g-1) diameter (nm) LDH spherical architecture ammonia 284 3-5 LDH powder NaOH 152 7-15 10