Interview with Greg Marble 1-13

advertisement

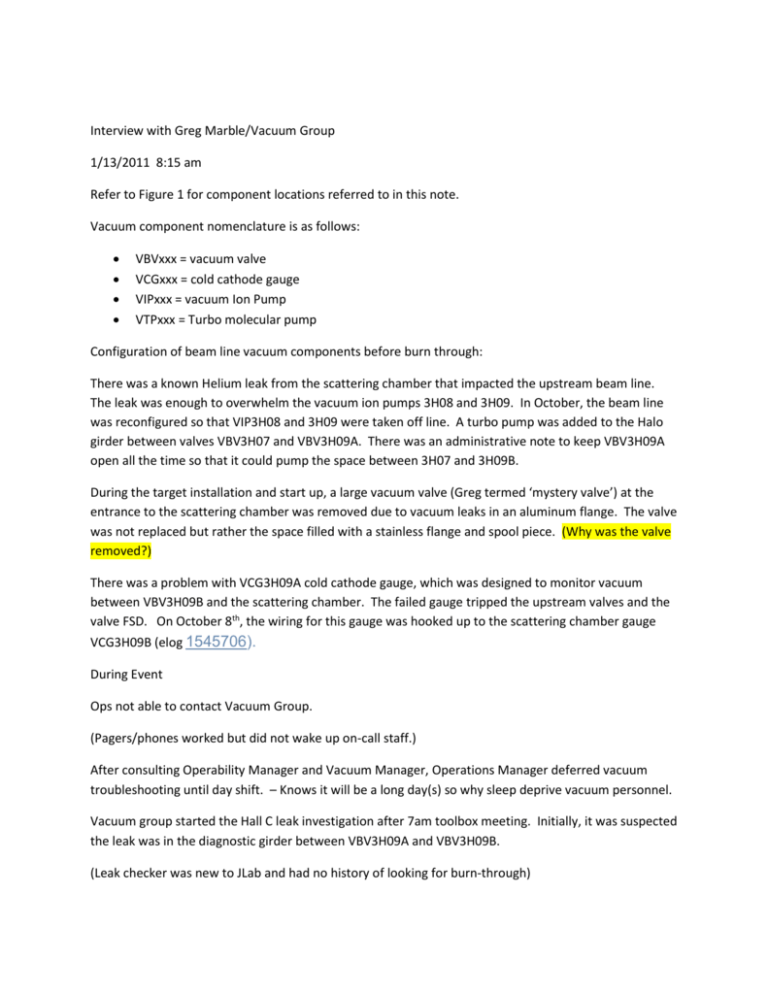

Interview with Greg Marble/Vacuum Group 1/13/2011 8:15 am Refer to Figure 1 for component locations referred to in this note. Vacuum component nomenclature is as follows: VBVxxx = vacuum valve VCGxxx = cold cathode gauge VIPxxx = vacuum Ion Pump VTPxxx = Turbo molecular pump Configuration of beam line vacuum components before burn through: There was a known Helium leak from the scattering chamber that impacted the upstream beam line. The leak was enough to overwhelm the vacuum ion pumps 3H08 and 3H09. In October, the beam line was reconfigured so that VIP3H08 and 3H09 were taken off line. A turbo pump was added to the Halo girder between valves VBV3H07 and VBV3H09A. There was an administrative note to keep VBV3H09A open all the time so that it could pump the space between 3H07 and 3H09B. During the target installation and start up, a large vacuum valve (Greg termed ‘mystery valve’) at the entrance to the scattering chamber was removed due to vacuum leaks in an aluminum flange. The valve was not replaced but rather the space filled with a stainless flange and spool piece. (Why was the valve removed?) There was a problem with VCG3H09A cold cathode gauge, which was designed to monitor vacuum between VBV3H09B and the scattering chamber. The failed gauge tripped the upstream valves and the valve FSD. On October 8th, the wiring for this gauge was hooked up to the scattering chamber gauge VCG3H09B (elog 1545706). During Event Ops not able to contact Vacuum Group. (Pagers/phones worked but did not wake up on-call staff.) After consulting Operability Manager and Vacuum Manager, Operations Manager deferred vacuum troubleshooting until day shift. – Knows it will be a long day(s) so why sleep deprive vacuum personnel. Vacuum group started the Hall C leak investigation after 7am toolbox meeting. Initially, it was suspected the leak was in the diagnostic girder between VBV3H09A and VBV3H09B. (Leak checker was new to JLab and had no history of looking for burn-through) Leak Check showed beamline up to VBV3H09B was OK. Decided that the Scattering Chamber had vacuum of 10-5, considered good enough. (No new Leak). (Two TMPs on chamber were enough to pull maintain vacuum readings at gauge positions. Pumps were pumping air the whole time.) Valve 3H09A buggered in order to allow halo turbo pump to pump on upstream beam line. (Had trapped Helium from former SC leak). Attempted to open VBV3H07 and 3H09B using normal EPICS controls - resulted in immediate trip and valves shutting. Vacuum Group decided NOT to bugger valve 3H09B, since vacuum on both sides read OK but order of magnitude different. Would only make job of turbo pump harder. THIS DECISION BASED ON ERRONIOUS ASSUMPTION THAT VCG3H09A WAS READING SPACE BETWEEN 09B VALVE AND TARGET SC. 12/17/10 Hole found Hall C and Vacuum needed to warm up target chamber to get rid of iceball before repairs to cross. (The mystery valve would have isolated this section enough to allow work to proceed.) 12/19/10 Target warm, able to get in and replace cross. No leak check performed (Interest of time) Hall C decided to run warm (not cool down target) Week of 1/3/11 Hall C opens SC and repairs suspected source of leak (Instrumentation connector feed through). Vacuum greatly improved but some residual leak is still suspected. (VCG 3H09A still buggered) VCG3H09A replaced. Now reading in correct position. Present configuration Ion pumps still OFF Helium leak much smaller, but still present. Figure 1 Hall C Beamline Vacuum Around Target