Designing & Building a Massively Modular Data Center Scalable

advertisement

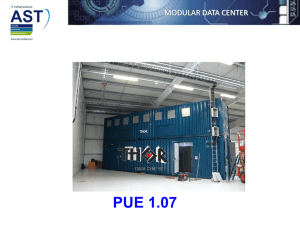

Designing & Building a Massively Modular Data Center Scalable Design on an Expedited Timeline for CyrusOne The presentation will be a combination of slides showing the modular design and the innovative approach CyrusOne took to build a scalable data center in a condensed timeframe. Additionally, a video showing a 3-D fly-through of the building information model will be shown, as part of the discussion of prefabrication use and modular equipment integration. In his new post as chief technology officer of CyrusOne, Kevin Timmons is advancing a design approach called “Massively Modular.” This phrase reflects the ambitions of CyrusOne, which has super-sized its approach to colocation facilities with the development of a one-million square foot campus in Chandler, Arizona, near Phoenix. But CyrusOne also seeks to position modularity as an approach to a phased deployment of space using highly-standardized elements, rather than the use of factory-built containerstyle enclosures. This undertaking is all under the limitations of a strict, aggressive timeline. CyrusOne selected JE Dunn as a building partner in January, and the data center is scheduled to be completed before the end of this year. This expedited timeline is crucial for clients of colocation provider CyrusOne who hope to be occupying the space by 2013. What Does ‘Modular’ Mean? – This portion of the presentation and the concept of a modular colocation data center will be led by Kevin Timmons Kevin Timmons will discuss the definition of modular and why this approach is what CyrusOne clients and potential clients are demanding. He will address the scalable design for the entire campus plan, focusing on the work that is being done with the first of several buildings. When fully executed, this scalable plan will ensure that new facilities can be erected on the campus in a timeframe of less than 16 weeks. Kevin and team will review the massive amounts of city and utility planning that went in to designing this scalable, multi-stage deployment of traditional data center space. For CyrusOne, modular means incremental deployment of space that leverages the company’s supply chain to support a repeatable approach that slashes cost and time to market. The key concept is flexibility. The ability to massively scale a large facility gives CyrusOne a ton of flexibility. It is modular without the constraints of small footprint. It’s paying for the common elements up front. The first implementation of that vision is taking place in Carrollton, Texas, where CyrusOne has just completed the first phase of its project, bringing 5 megawatts of raised-floor space online in about 14 weeks. The most current project to realize this modularity is right in Phoenix’s backyard in Chandler, Arizona. This facility will be nearing completion at the time of the 7x24 Exchange Fall Conference in Phoenix. Equipment Plugs In to Perimeter – The equipment and technical specifications will be discussed by Ed Downey with JE Dunn Construction and Mike Connell with Corgan Associates Architects. This portion of the presentation will cover the application of prefabrication units, the equipment that is being installed, the overall design of the building with office space in the front with a beautiful façade, coupled with functional design and features in the back of the building. The pre-construction work that was done to allow for the scalability and modular design approach will also be highlighted in this portion of the presentation. The design will use almost the entire interior of the building for technical space, adding mechanical equipment to support power and cooling to the perimeter of the facility as needed. This approach gives CyrusOne the freedom to deploy new space in large or small increments, and cool the space with either overhead ducting or under-floor airflow, depending upon the end-user requirement. With the cooling system CyrusOne is using, there will be no CRACs on the floor, which leads to the wide open areas and a more flexible use of the interior. Some of the challenges were to provide a 40,000 square foot data hall without any column disruptions to the space. We accomplished this by providing a 110’ wide by 380’ long data hall without any columns. We also designed the cooling system around the use of a 60,000 cfm Indirect Evaporative Cooling Unit (IDEC) with an additional chilled water coil to provide back-up cooling if water is not available. Each ~40,000 square foot hall will be provided with (18) of these IDEC units, but the modularity of the design allows the project to install these on an as needed basis so that if the I.T. loads are not at the 150W/SF (Average Design Density) we will not have stranded capacity. All of these units can be added without impacting the day to day use of the data center space since they are physically set outside of the building. We are also working to make the Electrical rooms as modular as possible with the installation of (4) separate electrical rooms and each room will contain (1) Mitsubishi 750kVA / kW UPS Module in a Distributed Redundant configuration. Each one of these rooms can handle an additional UPS Module when the loads in the data hall require the total UPS Capacity to 6 MW (Average 150W/SF). For future phases we are working to create a modular electrical room that will be built off site and shipped to the facility for just in time delivery. The distribution from the electrical rooms to the data floor is also being planned early in the process so that we can take advantage of the economies to install the 400kVA STS/PDU feeders underground to various locations in the data hall so that minimal disruptions are needed to install these additional units to provide the full 6MW UPS distribution to the data hall. Since CyrusOne offers both colocation services and custom suites, the company can support requirements ranging from a cabinet to 6 megawatts per data hall and more. The company expects to deploy space in phases of between 2.5 megawatts to 6 megawatts. Project Planning & Integrated Project Delivery – Kevin Timmons & Ed Downey The final portion of the presentation will cover the timeline and order of events necessary to pull off a modular design in a condensed time frame. The use of building information modeling was critical to prefabrication and a fast-moving timeframe. During this portion of the presentation, a 3-D visual flythrough of the facility will demonstrate how the work was done to specification and the vendor/partner selection process that ultimately led to a successful shortened time frame of design and construction.