BSysE 595 Class Project Xin Gao

advertisement

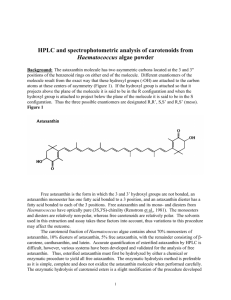

BSysE 595 Class Projcet Xin Gao 11212457 BSysE 595 Class Project Project name Maximize the yield of Astaxanthin in the Haematococcus pluvialis growth Project description Astaxanthin is a carotenoid. It belongs to a larger class of phytochemicals known as terpenes, which are built from five carbon precursors; isopentenyl diphosphate and dimethylallyl diphosphate [1]. It is currently used as a feed supplement for seafood and animals [2]. The primary use for humans is as a food supplement [2], which is a high-value product. Researches showed that, due to astaxanthin's potent antioxidant activity, it may be beneficial in cardiovascular, immune, inflammatory and neurodegenerative diseases. Some research supports the assumption that it may protect body tissues from oxidative and ultraviolet damage through its suppression of NF-κB activation. Astaxanthin can be found in microalgae, yeast, salmon, trout, krill, shrimp, crayfish, crustaceans, and the feathers of some birds [1]. It is difficult to synthetize astaxanthin artificially, because synthetic astaxanthin always contains a mixture of stereoisomers [3]. Another method is extracting it from the shellfish [4]. However, this method is limited by the low content of astaxanthin in the shellfish, also the product yield and purity are not satisfied enough, which cause the high cost. Some researchers [5] use yeast to product the astaxanthin, such as Phaffia rhodozyma, Rhodotorula rubra and Rhodotorula glutinis. But, now the highest yield is only 0.3% of the dry cell weight and small condition changes will easily affect the accumulation of astaxanthin during the fermentation, such as temperature, pH value, dissolved oxygen, carbon and nitrogen sources and so on. All in all, these are not the perfect method for this project. In this project, Haematococcus pluvialis, one kind of the microalgae, was chosen to product the astaxanthin. Haematococcus pluvialis can produce the astaxanthin as high as 4% of the dry cell weight [3]. The current limitations are: 1). this kind of microalgae grows slowly, requires longer time; 2). it is also sensitive to environmental changes and susceptible to other algae, bacteria and pollutions; 3). the yield of 4% of dry cell weight is not ideal enough. So, it is necessary to optimize the culture conditions to grow the Haematococcus pluvialis faster and research the maximum biomass and then improve the product yield by changing the light intensity, temperature, nutrient, etc. Objectives 1. Find the optimal environment for growing the Haematococcus pluvialis faster and also it can reach the maximum biomass. 2. Improve and maximize the product yield of the astaxanthin. BSysE 595 Class Projcet Xin Gao 11212457 3. Learn to use the MATLAB COBRA toolbox to calculate the flux balance analysis and analyze the metabolic engineering. 4. Try to find the optimal model by using the function of the dynamic flux balance analysis. Research methods Two main methods and software will be applied in this project, one is minitab for the mathematic and statistic analysis to find the optimal environment for growing the Haematococcus pluvialis faster and also reach the maximum biomass, using the ANOVA (analysis of variance) table based on the actual experimental data. The other one is the MATLAB COBRA toolbox, this will be used for the calculation of the flux balance analysis and analyze the metabolic engineering. Also, the optimal model by using the function of the dynamic flux balance analysis will be tested. Time line Task Timeline Prepare the Haematococcus pluvialis in the reactors 02/10/2013 Literature review 02/15/2013 Change different culture conditions 03/05/2013 Optimize the culture conditions (ANOVA) 03/20/2013 Calculate the flux balance analysis (COBRA) 04/05/2013 Improve and maximize the product yield (ANOVA) 04/10/2013 Analyze the metabolic engineering (COBRA) 04/26/2013 Establish and find the optimal model (COBRA) 04/30/2013 Project report 05/03/2013 Reference 1. Yousry M. A. Naguib. Antioxidant Activities of Astaxanthin and Related Carotenoids. J. Agric. Food Chem., 2000, 48 (4), pp 1150–1154. 2. P. Stepnowski, G. Ólafsson, H. Helgason, B. Jastorff. Recovery of astaxanthin from seafood wastewater utilizing fish scales waste. Chemosphere. 2004, 54(3), pp 413–417. BSysE 595 Class Projcet Xin Gao 11212457 3. Makio Kobayashi, Toshihide Kakizono, Shiro Nagai. Astaxanthin production by a green alga, Haematococcus pluvialis accompanied with morphological changes in acetate media. Journal of Fermentation and Bioengineering. 1991, 71(5), pp 335–339. 4. W. Miki, K. Yamaguchi, S. Konosu. Comparison of carotenoids in the ovaries of marine fish and shellfish. Comparative Biochemistry and Physiology Part B: Comparative Biochemistry. 1982, 71(1), pp 7–11. 5. Eric A. Johnson and Michael J. Lewis. Astaxanthin Formation by the Yeast Phaffia rhodozyma. Microbiology. 1979, 115(1), pp 173-183.