confined space entry program - University of Wisconsin Oshkosh

advertisement

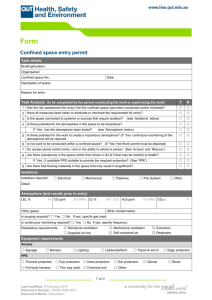

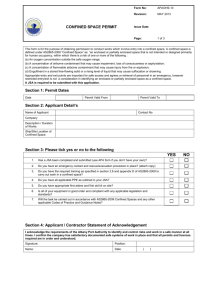

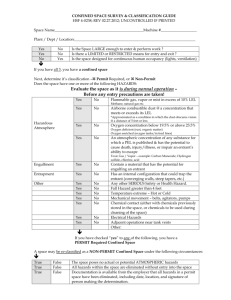

University of Wisconsin Oshkosh CONFINED SPACE ENTRY PROGRAM I. PURPOSE The purpose of this written program is to protect the health and safety of employees who enter confined spaces and/or are assigned to serve as attendants or rescue personnel. II. APPLICATION This program is applies to all employees, who are authorized to enter a confined space, All employees assigned to serve as attendants and/or provide assistance during a CS emergency rescue and to employees who serve as CS Entry Supervisors and/or CS Entry Program Administrators. III. AUTHORITY AND REFERENCE Occupational Safety and Health Administration (OSHA) 29 CFR 1910.146. Dept. of Safety and Professional Services (Chapter SPS 332) IV. RESPONSIBILITY FOR COMPLIANCE A. The CONFINED SPACE ENTRY (CSE) PROGRAM ADMINISTRATOR for the University of Wisconsin - Oshkosh is Evan Schwalbe. The responsibilities of this individual shall include: 1. Conducting/coordinating hazard assessments. 2. Determining the classification (permit required/non permit space) and location of each confined space. 3. Identify and maintain a record of all confined spaces in the work area. 4. Coordinating the posting of appropriate danger/caution signs by each confined space. 4. Supervising the selection and use of respirators in conjunction with the Respiratory Protection Program Administrator 5. Supervising the medical screening of respirator users. 6. Conducting/coordinating supervisory and employee training and 1 maintaining all training records. B. C 7. Conducting an annual evaluation of the overall program to determine its continued effectiveness. 8. Consulting employees and their authorized union representatives on the development and implementation of the CSE Program MANAGERS AND SUPERVISORS are responsible for: 1. Actively supporting the CSE Program and providing funding to purchase equipment when needed. 2. All new and modified processes, equipment, and facilities shall be evaluated prior to installation to identify new confined spaces. Whenever possible, confined spaces should be eliminated through design, or engineering changes made to facilitate entry and rescue. 3. Ensure all assigned personnel are knowledgeable of all aspects of the CSE Program. 4. Ensure their employees comply with all elements of CSE Program. 5. Ensure appropriate PPE and equipment is properly utilized and maintained. CONFINED SPACE ENTRY (CSE) SUPERVISOR(S) The Confined Space Entry (CSE) Supervisors for the University of Wisconsin - Oshkosh campus are Buildings and Grounds Superintendent Chuck Hermes, Mechanical Trade Supervisor Rick Vandrisse, Structural Supervisor Jim Luther, and Heating Plant Supervisor Evan Schwalbe, Occupational Safety Office Mark Haddock 2 V. PROGRAM ELEMENTS A. DEFINITIONS 1. ACCEPTABLE ENTRY CONDITIONS - conditions that must exist in a permit 2. 3. 4. 5. space to allow entry and to ensure that employees involved with a permit-required confined space can safely enter and perform work. ATTENDANT - an individual stationed outside the “permit-required” confined space who has had specific training and monitors the authorized entrants inside the space. AUTHORIZED ENTRANT - employee who is authorized to enter a permit-required space. BLANKING OR BLINDING - absolute closure of a pipe, line, or duct by fastening across its bore a solid plate that completely covers the bore and can withstand the maximum upstream pressure. CONFINED SPACE - a space that meets all the following criteria: a. is large enough to bodily enter and perform work; b. has limited means of entry and egress; c. is not designed for continuous employee occupancy; and d. has one of four hazardous characteristics (e.g., hazardous atmosphere, engulfment, entrapment, or other safety/health hazard). Examples may include tanks, silos, boilers, pits, bins, manholes, electrical vaults, grease traps, and hoppers. 6. ENGULFMENT - surrounding and effective capture of a person by a liquid or finely divided solid substance (i.e sand, corn. grain, sawdust etc). 7. ENTRY - a person's intentional passing through an opening into a permit-required confined space. 8. ENTRY PERMITS - a written or printed document that allows and controls entry into a permit space. 9. ENTRY SUPERVISOR - person responsible for: a. determining if acceptable conditions are present before entering a permit space; b. for authorizing entry; 3 c. coordinating and supervising all entry operations; and d. terminating entry. NOTE: An entry supervisor also may serve as an attendant or as an authorized entrant, as long as that person is trained and equipped as required by this section for each role he or she fills. Also, the duties of entry supervisor may be passed from one individual to another during the course of an entry operation. 10. HAZARDOUS ATMOSPHERE - an atmosphere that may expose employees to the risk of death, incapacitation, impairment of ability to self-rescue, injury, or acute illness from one or more of the following causes a. Flammable gas, vapor, or mist in excess of 10 percent of its lower flammable limit (LFL): b. Airborne combustible dust at a concentration that meets or exceeds it LFL. Vision is obscured at a distance of 5 feet or less. c. Atmospheric oxygen concentration below 19.5 percent or above 23.5 percent. Oxygen concentrations above or below normal background outside the space shall be investigated. d. Atmospheric concentration of any substance above recommended guidelines (TLVs) or regulatory limits (PELs) whichever is lower. Permissible exposure limit are published in Subpart G, Occupational Health and Environment Control, or in Subpart Z, Toxic and Hazardous Substances, of 29 CFR 1910. e. Any other atmospheric condition that is immediately dangerous to life or health. 11. IMMEDIATELY DANGEROUS TO LIFE OR HEALTH (IDLH) - any condition that poses an immediate threat to life or a delayed threat to life, or that would cause irreversible adverse health effects, or interfere with an individual's ability to escape unaided from a permit space. 12. ISOLATION - process by which a permit space is removed from service and completely protects against the release of hazardous energy or material into the space. 13. LOWER EXPLOSIVE LIMIT (LEL) - the lowest concentration of gas or vapor, expressed in percent by volume in air that burns or explodes if an ignition source is present at room temperature. 14. LINE BREAKING - intentional opening of a pipe, line, or duct that is or has been carrying flammable, corrosive, or toxic material, an inert gas or any fluid at a volume, pressure, or temperature capable of causing death or serious physical harm. 4 15. NON PERMIT CONFINED SPACE- A confined space that does not contain or have the potential to contain an atmospheric hazard or any other serious safety or health hazard. 16. OXYGEN DEFICIENT ATMOSPHERE - an atmosphere containing less than 19.5% oxygen. 17. OXYGEN ENRICHED ATMOSPHERE - an atmosphere containing more than 23.5% oxygen. 18. PERMISSIBLE EXPOSURE LIMIT (PEL) - the airborne concentration of a hazardous material that must not be exceeded over a specified time or instantaneously. This value is established by the Occupational Safety and Health Administration (OSHA). 19. PERMIT-REQUIRED CONFINED SPACE - a confined space that has one or more of the following characteristics: a. Contains or has the potential to contain a hazardous atmosphere; b. Contains a material with the potential to engulf someone who enters the space; c. Has an internal configuration that might cause an entrant to be trapped or asphyxiated by inwardly converging walls or by a floor that slopes downward and tapers to a smaller cross section; and/or d. Contains any other recognized serious safety or health hazards. 20. PROHIBITED CONDITION - any condition in a permit space that is not allowed by the permit during the period when entry is authorized. 21. RESCUE SERVICE - personnel designated to rescue employees from permit spaces. 22. RETRIEVAL SYSTEM - equipment used for a non-entry rescue of persons from permit spaces (i.e., tripod). 23. TESTING - process by which hazards that may affect entrants of a permit space are identified and evaluated. 24. THRESHOLD LIMIT VALUE (TLV) - the airborne concentration of a hazardous material that should not be exceeded over a specified time or instantaneously. This value is established by the American Conference of Governmental Industrial Hygienists (ACGIH). 25. WELDING/CUTTING PERMIT - written authorization to perform operations that can provide a source of ignition (e.g., welding, cutting, burning, or heating) or a hazardous atmosphere. 5 B. Hazard Evaluation 1. All confined spaces in the work area shall be identified and properly labeled. An annual survey of confined spaces shall be conducted. 2. All obvious hazards and the predictable hazards that each space represents shall be identified and documented in the hazard identification form. 3. Alternate work practices shall be evaluated that will prevent entry into the space. C. Confined Space Classification 1. Based on the definitions provided above, spaces should be classified as: a. Confined Space – full permit required for entry. b. Not a confined space as it does not meet the definition of a confined space. 2. Confined spaces shall be properly labeled. D. Confined Space Program 1. Necessary measures shall be implemented to prevent unauthorized entry. 2. All hazards shall be identified and evaluated prior to entry. 3. Acceptable entry conditions shall be identified to include: a. Oxygen – greater than 19.5% and less than 23.5%. Oxygen levels should be similar to outdoor background, if not; reason for discrepancy should be investigated. b. Flammable vapors – less than 10% of the Lower Flammable Limit c. Toxic vapor concentrations – below regulatory and/or recommended limits d. Space isolation, including the proper execution of lockout/tagout procedures. e. Permit completion 4. Permit a. The permit should list 1. 2. 3. 4. 5. 6. Specific permit space identification Purpose and date of entry Duration of authorization Authorized entrants by name Name of attendant and entry supervisor Actual hazards of the identified space 6 7. Control and isolation methods used 8. Acceptable entry conditions 9. Air monitoring results 10. Rescue plan 11. Communication procedures 12. Equipment to be provided 13. Other permits being used b. It should be displayed in a conspicuous location near the point of entry. c. At the conclusion of the task or the work shift, whichever occurs first, it should be canceled and filed. Permits should be retained for one year and used for the annual review of the confined space operations program. 5. Personnel Roles a. Entry Supervisor – The Entry Supervisor is: Knowledgeable of the hazards that may be encountered during entry and informing the entrants about the hazards, including information on the mode, signs, or symptoms and consequences of exposure. Ensures that the CSE Permit is completed prior to each entry. Verifies that the proper atmospheric tests have been conducted and that all procedures and equipment are in place before signing the CSE Permit. Ensures the safe conditions are kept throughout the entry. Terminates the entry and cancels the permit when needed. Verifies that rescue personnel are available and that the means for summoning them or other emergency personnel is available and operable in the event that an emergency occurs. Removes unauthorized individuals who have entered or who attempt to enter the confined space. Determines whenever responsibility for a permit space entry operation is transferred and at intervals dictated by the hazards and operations performed within the space, and that entry operations remain consistent with terms of the entry permit. Maintains completed entry permits, and equipment calibration records. Provides employees and their authorized union representative(s) an opportunity to observe the atmospheric testing of the CS. NOTE: An entry supervisor also may serve as an attendant or as an authorized entrant, as long as that person is trained and equipped as required by this section for each role he or she fills. Also, the duties of entry supervisor may be passed from one individual to another during the course of an entry operation. 7 b. Authorized Entrants – The Authorized Entrant(s): Knows the recognized hazards that may be faced during entry. Uses and maintains the proper PPE and other equipment. Will not enter a confined space unless an attendant is ready to execute the attendants’ duties. Communicates with the attendant as necessary. Alerts the attendant when hazardous conditions are detected, identified, or suspected. Exits the confined space immediately whenever: o ordered to do so by other entrants, the attendant or the CSE Supervisor. o warning signs/symptoms are identified, o prohibited conditions are identified, o an evacuation alarm on the sampling devise is activated. o as other conditions dictate. Complying with all other aspects of the CSE program. c. Attendant – The Attendant: Knows the hazards that may be faced during entry, including information on the mode, signs or symptoms, and consequences of the exposure. Knows the possible behavioral effects of the hazard exposure in the authorized entrants. Maintains an accurate count of authorized entrants in the confined space and ensures that the means used to identify the authorized entrants accurately identifies who is in the space. Remains outside the confined space during entry operations until relieved by another attendant. Communicates with authorized entrants as necessary to monitor entrant status and to alert entrants of the need to evacuate the confined space. Monitors activities inside and outside the confined space to determine if it is safe for authorized entrants to remain in the space and orders the authorized entrants to evacuate the space immediately under any of the following conditions: o If the attendant detects a prohibited condition. o If the attendant detects a behavioral effect of the hazard exposure in an authorized entrant. 8 o If the attendant detects a situation outside the confined space that could endanger the authorized entrants; or o If the attendant cannot effectively and safely perform all the duties required. Summons rescue and other emergency services as soon as the attendant determines that entrants need assistance to escape from the confined space hazards. Takes the following actions when an unauthorized person(s) approach or enter a confined space while entry is underway: o Warns the unauthorized person(s) that they must stay away from the confined space. o Advises the unauthorized person(s) that they must exit immediately if they have entered the confined space. o Informs the authorized entrants and the entry supervisor if an unauthorized person(s) have entered the confined space. Performs non-entry rescues as specified in Section (D.9.a,b,c,d) Performs atmosphere testing as needed. Performs no duties that might interfere with the attendant's primary duty to monitor and protect the authorized entrants. 6. Labeling and Warning Signs a. When using warning signs or placards for the identification of Confined Spaces, all types shall be printed both in English and (if applicable) in the predominant language of any non-English reading employees. b. Signs shall include, but not necessarily be limited to, the following information: DANGER: PERMIT REQUIRED CONFINED SPACE - DO NOT ENTER UNLESS AUTHORIZED DANGER: CONFINED SPACE – AUTHORIZED PERSONNEL ONLY 7. Air monitoring a. Spaces that have been identified, as potentially having a hazardous atmosphere shall have air monitoring conducted to quantify airborne levels of hazardous substances and safety and health hazards. b. Monitoring should be performed in a representative cross-section of the space. c. Air monitoring equipment should be properly calibrated. 9 d. If air monitoring indicates a hazardous atmosphere, measures should be implemented to protect employees from the hazardous atmosphere; Oxygen levels shall be measured first and compared to outdoor background oxygen levels. The oxygen level is between 19.5% and 23.5%. The concentrations of flammable gas, vapors, or mists are below 10% of their Lower Flammable Limits (LFL). The concentration of airborne combustible dust does not exceed 10% of the Lower Flammable Limit (LFL). Note: An indication of this condition is if the dust obscures vision at a distance of 5 feet. The level of airborne hydrogen sulfide (H2S) is below 10 parts per million (ppm). Toxic air contaminates are less than the OSHA Permissible Exposure Limit (PEL). Note: If the substance does not have a PEL, use the Threshold Limit Value (TLV) established by the American Conference of Governmental Industrial Hygienists (ACGIH). Atmospheric concentrations of toxic substances are below what is considered as IDLH. The level of carbon monoxide (CO) is less than 35 ppm. Entry into a confined space is not allowed if monitoring indicates deficiency in any of these categories. Respirators or a self-contained breathing apparatus (SCBA) shall not to be used to allow entry into deficient atmospheres. In order to achieve and maintain a safe atmosphere, one or more actions may have to be taken to render the space safe for human occupancy. This could include: System Isolation - precautions taken to prevent release of material and/or energy into the space. This can be achieved through blinding, blanking, disconnecting, lockout/tagout, or removal of incoming pipes or related energy sources. Space Ventilation - purging, inserting, flushing, or otherwise ventilating the space with fresh air. The replacement air will displace the contaminated air allowing for safe entry. This can be accomplished by removing ports and openings or by mechanically ventilating the vessel. Hazard Separation - where there is a possibility of external hazards, the space may require barricades to protect the entrants from falling objects or from unauthorized entry. 10 7. Ventilation a. Continuous mechanical ventilation is required when: 1. 2. 3. 4. Toxic contaminant concentration is questionable. There is a potential for a flammable atmosphere to develop inside the space. It is needed to maintain acceptable entry conditions. A toxic atmosphere is produced as part of a work procedure, such as welding, cutting, etc. b. During ventilation, blowers shall be at an adequate distance from the opening and the air intake shall be placed in an area that will only draw in fresh air. c. Mechanical ventilation may not be necessary when the configuration of a confined space allows for favorable natural ventilation, demonstrated through documented air monitoring. Whenever ventilation is used, employees shall: Keep the blower controls at least 10 feet from the CS, and out of the wind or downwind from the entrance to the CS. Use a ventilation blower that is designed to be intrinsically safe if the possibility of an explosive atmosphere could exit. Ensure that the exhaust systems are designed and placed so that they protect employees in the surrounding area from being contaminated. Ensure that the ventilation system is fully operational. Ensure that contaminated air is not recirculated into the CS. Purge the ventilation hose outlet for at least one-minute (at street level if possible) before inserting the hose into the confined space. Note: Forced ventilation may not be used in lieu of monitoring. Consideration must also be given to the possibility of static discharge that could be a source of ignition. 8. Safety Equipment A review of the additional safety equipment that is needed for safe entry shall be conducted. This equipment may include: a. b. c. d. Personal Protective Equipment Respirators Lighting Equipment Ladders - Any ladder used for confined space entry must extend three feet above the opening. 11 e. Fall protection is required when entering spaces that are not equipped with access to the confined space and exceeds a five foot vertical drop. The retrieval system may be used to meet the fall protection requirement for the authorized entrant if the system is equipped with a locking device. f. Ventilation equipment g. Air monitoring equipment 9. Emergency Procedures a. The authorized entrant entering a confined space shall wear a full body harness, with a retrieval line attached at the center of the entrant’s back near shoulder level, or above the entrant’s head (for vertical rescue). A retrieval line may not be used if it is believed that it will not provide any assistance in rescue. Therefore, provisions for entry rescue shall be in place. b. A mechanical device shall be available to retrieve personnel from vertical type permit spaces with depths greater than 5 feet unless the mechanical retrieval system would not contribute to the rescue of the entrant. Equipment operated by hydraulics or electricity is forbidden. c. Rescue equipment shall be made available on site unless an outside rescue service or in-house service with the capability to standby is available. d. UW - Oshkosh encourages self-rescue or non-entry rescue when the emergency allows it. The Oshkosh Fire Dept. will be contracted with for rescue services. A rescue program will be set up with the fire dept. before rescues can be performed. E. Contractor Provisions 1. UW - Oshkosh Contractors should have a written confined space program in place, including proper training of Contractor personnel. 29 CFR 1910.146 Confined Space Entry 2. UW - Oshkosh should provide Contractor with information on the potential hazards of the site’s confined spaces. 3. All Contractors work should comply with UW – Oshkosh safety and emergency procedures. F. Program Evaluation The Confined Space Operations program should be evaluated on an annual basis by Department Management or designee with the assistance of the Staff Occupational Health and Safety Team. Appendix C, Confined Space Checklist TRAINING A. Employees who are required to perform confined space entry work are required to be trained to the extent that they acquire the understanding, knowledge, and skills necessary for the safe performance of their duties. 12 B. Training should be provided prior to performing any confined space work. C. DSPS requires CPR/AED certification training be completed by Entrants, Attendants and Supervisors. D. Refresher training is recommended annually. However, it is required when confined space entry procedures change or deficiencies are noted during the annual program evaluation. RECORDKEEPING A. Training records should be maintained by the Facilities Management Office Supervisor until superseded. B. Cancelled permits should be maintained by the Confined Space Administrator for one year and made available during the annual evaluation of the program. C. Equipment records (preventive maintenance inspections, corrective actions) should be maintained by the Confined Space Administrator. D. Monitoring equipment records (calibration and service) should be maintained by the Confined Space Administrator. REFERENCES A. 29 CFR 1910.146 Confined Space Entry B. 29 CFR 1910. 147 Control of Hazardous Energy C. NIOSH Pocket Guide to Chemical Hazards APPENDIX A, CONFINED SPACE SURVEY FORM APPENDIX B, CONFINED SPACE HAZARD ASSESSMENT AND ENTRY PERMIT APPENDIX C, CONFINED SPACE CHECKLIST APPENDIX D, RECLASSIFICATION OF CONFINED SPACES 13