Chapter 5 5.1 Calculate the fraction of atom sites that are vacant for

advertisement

Chapter 5

5.1 Calculate the fraction of atom sites that are vacant for lead at its melting temperature of

327°C (600 K). Assume an energy for vacancy formation of 0.55 eV/atom.

5.12 For both FCC and BCC crystal structures, there are two different types of interstitial sites.

In each case, one site is larger than the other and is normally occupied by impurity atoms.

For FCC, the larger one is located at the center of each edge of the unit cell; it is termed an

octahedral interstitial site. On the other hand, with BCC the larger site type is found at 0

1

2

1

positions—that is, lying on {100} faces and situated midway between two unit cell

4

edges on this face and one-fourth of the distance between the other two unit cell

edges; it

is termed a tetrahedral interstitial site. For both FCC and BCC crystal structures, compute

the radius r of an impurity atom that will just fit into one of these sites in terms of the

atomic radius R of the host atom.

5.15 What is the composition, in atom percent, of an alloy that consists of 30 wt% Zn and 70

wt% Cu?

5.34 Cite the relative Burgers vector–dislocation line orientations for edge, screw, and mixed

dislocations.

5.37 (a) For a given material, would you expect the surface energy to be greater than, the same

as, or less than the grain boundary energy? Why?

(b) The grain boundary energy of a small-angle grain boundary is less than for a highangle one. Why is this so?

5.38 (a) Briefly describe a twin and a twin boundary.

Chapter 6

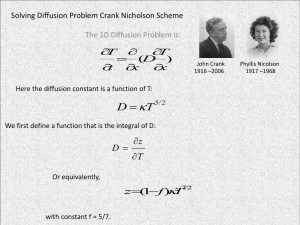

6.1 Briefly explain the difference between self-diffusion and interdiffusion.

6.3 (a) Compare interstitial and vacancy atomic mechanisms for diffusion.

(b) Cite two reasons why interstitial diffusion is normally more rapid than vacancy

diffusion.

6.4 Briefly explain the concept of steady state as it applies to diffusion.

6.5 (a) Briefly explain the concept of a driving force.

(b) What is the driving force for steady-state diffusion?

Steady-State Diffusion

6.8 A sheet of BCC iron 1 mm thick was exposed to a carburizing gas atmosphere on one side

and a decarburizing atmosphere on the other side at 725C. After having reached steady

state, the iron was quickly cooled to room temperature. The carbon concentrations at the

two surfaces of the sheet were determined to be 0.012 and 0.0075 wt%, respectively.

Compute the diffusion coefficient if the diffusion flux is 1.4 10-8 kg/m2-s. Hint: Use

Equation 5.12 to convert the concentrations from weight percent to kilograms of carbon

per cubic meter of iron.

6.9 When a-iron is subjected to an atmosphere of hydrogen gas, the concentration of hydrogen

in the iron, CH (in weight percent), is a function of hydrogen pressure, pH 2 (in MPa), and

absolute temperature (T) according to

27.2 kJ / mol

CH 1.34 10 2 pH 2 exp

RT

(6.16)

Furthermore, the values

of D0 and Qd for this diffusion system are 1.4 10-7 m2/s and 13,400

J/mol, respectively. Consider a thin iron membrane 1 mm thick that is at 250C.

Compute the diffusion flux through this membrane if the hydrogen pressure on one side of

the membrane is 0.15 MPa (1.48 atm) and that on the other side is 7.5 MPa (74 atm).

Non-Steady Diffusion

6.11 Determine the carburizing time necessary to achieve a carbon concentration of 0.45 wt% at

a position 2 mm into an iron–carbon alloy that initially contains 0.20 wt% C. The surface

concentration is to be maintained at 1.30 wt% C, and the treatment is to be conducted at

1000C. Use the diffusion data for g-Fe in Table 6.2.

6.12 An FCC iron-carbon alloy initially containing 0.35 wt% C is exposed to an oxygen-rich

and virtually carbon-free atmosphere at 1400 K (1127C). Under these circumstances the

carbon diffuses from the alloy and reacts at the surface with the oxygen in the atmosphere;

that is, the carbon concentration at the surface position is maintained essentially at 0 wt%

C. (This process of carbon depletion is termed decarburization.) At what position will the

carbon concentration be 0.15 wt% after a 10-h treatment? The value of D at 1400 K is 6.9

10-11 m2/s.

6.16 Cite the values of the diffusion coefficients for the interdiffusion of carbon in both α-iron

(BCC) and γ-iron (FCC) at 900°C. Which is larger? Explain why this is the case.

6.17 Using the data in Table 6.2, compute the value of D for the diffusion of zinc in copper at

650ºC.