c4f_annexiitechspeciiitechoffer_en

advertisement

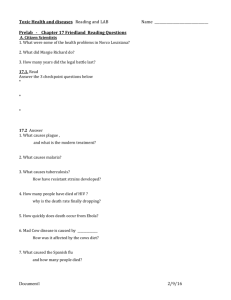

ANNEX II + III: TECHNICAL SPECIFICATIONS + TECHNICAL OFFER Contract title : Supply and Installation of a Water Treatment Plant at Desrruisseaux p 1 /… Publication reference : EuropAid/136389/IH/SUP/LC Column 1-2 should be completed by the Contracting Authority Column 3-4 should be completed by the tenderer Column 5 is reserved for the evaluation committee Annex III - the Contractor's technical offer The tenderers are requested to complete the template on the next pages: Column 2 is completed by the Contracting Authority shows the required specifications (not to be modified by the tenderer), Column 3 is to be filled in by the tenderer and must detail what is offered (for example the words “compliant” or “yes” are not sufficient) Column 4 allows the tenderer to make comments onits proposed supply and to make eventual references to the documentation The eventual documentation supplied should clearly indicate (highlight, mark) the models offered and the options included, if any, so that the evaluators can see the exact configuration. Offers that do not permit to identify precisely the models and the specifications may be rejected by the evaluation committee. The offer must be clear enough to allow the evaluators to make an easy comparison between the requested specifications and the offeredspecifications. 2013.1 Document1 Page 1 of 11 1. 2. 3. 4. 5. Item Number SpecificationsRequired SpecificationsOffered Notes, remarks, ref to documentation Evaluation Committee’s notes 2013.1 Document1 Page 2 of 11 1 25 metric tonnes - 1.4mm Filter Media Grain Shape Effective Size Uniformity Coefficient Sub-Round 1.35 – 1.50mm 1.30 to 1.60 Sub-Angular 1.51 – 1.65mm 1.30 to 1.60 Material Type US Sieve Size Maximum % Coarse 8 and larger 20% w/w (retained) Fine 18 and smaller 1.5% w/w (passed) - - - 2013.1 Document1 The filter media shall predominately be siliceous material that will resist degradation during handling and use. Crushed gravel is not acceptable. (Sub-Round) grains are essentially round with smooth surfaces (non-angular). (Sub-Angular) grains are essentially sub-angular with multifaceted smooth edges. The effective size is the diameter of the tenth percentile grain (D10) by weight. The uniformity coefficient is the diameter of the sixtieth percentile grain by weight divided by the diameter of the tenth percentile by weight (D60/D10). The effective size and uniformity coefficient are determined by a dry, 10-minute automatic sieve shaker procedure on a 500-800 gram sample with U.S. Sieve Nos. 8,10,12,14,16,18 as well as a pan. Specific Gravity - dry specific gravity must be greater than 2.5 Hardness - minimum 6.0 on Moh's Hardness scale (ref. Testing and Inspection of Engineering Materials; McGraw-Hill Cook Co., New York; 3rd Edition; Page 209). Page 3 of 11 - 2013.1 Document1 Page 4 of 11 1. 2. 3. 4. 5. Item Number SpecificationsRequired SpecificationsOffered Notes, remarks, ref to documentation Evaluation Committee’s notes - - 2 2 - Lamellas Gravity Settler Unit* - 3 - - 2013.1 Document1 * Fabricated from ASTM A-36 Steel. Minimum tank thickness shall be 1/4" 2 - Flash Mixer - 6 Tank assembly including Floc Drive Flash mix tank support columns Floc/Flash mix support frame Mixer propeller and shaft Flash mixer drive 2 - Sludge Hopper - 5 Each Lamella shall provide a minimum 570 ft2 of effective projected area Lamella Tank assembly Lamella support columns 2 - Floc& Flash Mixer* - 4 and Inspection of Engineering Materials; McGraw-Hill Cook Co., New York; 3rd Edition; Page 209). Acid Solubility - less than 5% total loss in mass after a 30-minute immersion in a hydrochloric acid (HCl) solution made by combining equal volumes of water and standard reagent grade 12.1N (approx.) HCl. General - must be in accordance with AWWA Standard B-10001 Inline flash static mixer 2 - Stage Mixer Page 5 of 11 1. 2. 3. 4. 5. Item Number SpecificationsRequired SpecificationsOffered Notes, remarks, ref to documentation Evaluation Committee’s notes - 7 2 - Tank - 8 Fabricated from ASTM A-36 Steel. Minimum tank thickness shall be 1/4" 4 - Low range turbid meter - - - 2013.1 Document1 Shall be a variable slow speed mixer comprised of a paddle type mixer with a hollow shaft gear reducer The retention time for 3-stage flocculation tank shall be 20minutes The turbid meter shall be a microprocessor-based, continuous reading, on-line nephelometric instrument The turbidity monitoring system shall include one or two turbid meter(s) and one interface unit. The turbid meter shall measure turbidity in the range of 0.001100 NTU Accuracy shall be ±2% of reading or ±0.015 NTU (whichever is greater) from 0 to 40 NTU; ±5% of reading from 40 to 100 NTU Displayed resolution shall be 0.0001 NTU from 0 to 9.999 NTU and 0.001 NTU from 10.000 to 9.999 NTU Repeatability shall be better than ±1.0% of reading or ±0.002 NTU (whichever is greater). The turbid meter shall meet all design and performance criteria specified by USEPA method 180.1 or European equivalent Light shall be directed through the surface of the sample and the detector shall be immersed in the sample, eliminating glass windows and flow cells. Optical components shall be mounted in a sealed head assembly that can be removed for calibration/ service without disturbing sample flow. The turbid meter body shall be constructed of corrosion-resistant polystyrene. Page 6 of 11 1. 2. 3. 4. 5. Item Number SpecificationsRequired SpecificationsOffered Notes, remarks, ref to documentation Evaluation Committee’s notes - - - - 9 4 - Electromagnetic meters - 2013.1 Document1 An internal bubble removal system shall be included to vent entrained air from the sample stream. Calibration of the turbid meter shall be either formazin-based (20 or 1 NTU) or instrument comparison-based calibration method. User selectable signal averaging, bubble removal, alarm and recorder output hold, and self-test diagnostics shall be provided. Connections between the turbid meter(s) and the controller shall be “plug and play.” The Interface unit shall allow operators to control sensor and interface functions with menu-driven software and shall provide data logging of measurement data. The interface unit shall have a built-in data logger with the capacity to store data on 15-minute intervals for up to 6 months. The interface unit shall be housed in a NEMA-4X (indoor) industrial metal/plastic enclosure. The DC power supply shall be housed in the interface unit The DC power supply shall automatically accept input in the range of 100 to 230 Vac, 50/60 Hz. All system components shall be ETL listed to UL 61010A-1, certified to CSA C22.2 No. 1010.1, and CE certified by manufacturer to EN 61010-1. All system components shall be CE certified by the manufacturer to EN 61326 (industrial levels) for immunity and emissions, Class A. All system components shall meet FCC Part 15 for North America and Canadian Interference-Causing Equipment Regulation ICES-003, and CISPR 11 Class A levels for rest of the world. Low Range Turbid meter with Controller Accuracy: ±0.2% of rate from 1 to 33 ft/sec. Repeatability: ±0.1% Page 7 of 11 1. 2. 3. 4. 5. Item Number SpecificationsRequired SpecificationsOffered Notes, remarks, ref to documentation Evaluation Committee’s notes 10 4 - Controllers - 11 Mounting: Sensor, Wall or Panel Keypad: 3 Internal Keys LCD Display: Graphic Display Backlight: Yes 4-20mA Output: Y Pulse/Frequency/Alarm Output: 2 assignable Empty Pipe Detection: Yes Interface: RS485, PC, Hand Terminal Batch Function: Yes Power Supply: 90-265VAC, 10-35VDC, 18-63VDC/15-45VAC Enclosure: Aluminium or Plastic (panel version) NEMA 6 1 - Chemical Feed (Pre-Engineered, Chemical Metering Systems Pre-Packaged and Self-Contained Chemical Feed Systems with redundancy) - 2013.1 Document1 Temperature (Process): +0 to 60ºF (PP), -05 to 79.4ºF (Ebonite), -20 to 100ºF (PTFE Compact), -4 to 302ºF (PTFE Remote) Pressures to: 5600 PSI Liner Material: PTFE, Ebonite or Polypropylene Flow Tube: 304 S.S. Body Material: Carbon steel with two-part epoxy coating (S.S. optional) Electrode Material: 316 S.S. Number of Electrodes: 2 (3rd grounding electrode optional) Environmental Rating: NEMA 6 Fluid Conductivity: 5 μS/cm (min) Connections: ANSI Flange Single and Multiple Pump Configurations Panel Material: Polypropylene or Fiberglass Process Piping Material: PVC Page 8 of 11 1. 2. 3. 4. 5. Item Number SpecificationsRequired SpecificationsOffered Notes, remarks, ref to documentation Evaluation Committee’s notes - - 12 Process Connections: 1/2” NPT Power: 115/220 VAC Multi-Function Controller Flow meters Integral leak containment with optional Tubing Rupture Detector relay output that can start a back-up pump and/or signal an operator remotely via an autodialer. Supply Tank Level Monitoring Tanks On-Line Analysers Corp Stops with Solution Tube Assembly Suitable for base or wall mounting Flow rates to 50 GPH, pressures to 100 PSI Rugged industrial TEFC motors. Seal-less pumping technology. No check valves – few moving parts. Peristaltic Pump with NEMA 4x Controller Back pressure and Pressure Relief Valves 500ml Calibration Cylinder Pulsation Dampener Diaphragm Protected Pressure Gauge Suction Wye Strainer PVC Ball Valves Leak-proof Tubing Connectors 1 - Flocculation testing equipment - Lab Stirrer, 4-Paddle Jar Tester with 2L Beakers Tester 2013.1 Document1 Jar testers to utilize four operator-programmable memory banks Built on a powder-coated steel uni-frame chassis Page 9 of 11 1. 2. 3. 4. 5. Item Number SpecificationsRequired SpecificationsOffered Notes, remarks, ref to documentation Evaluation Committee’s notes - - Each memory bank should be able to run independently in any one of the memories, continuously, at a selected speed or automatic transition from a fast mix/long run, or any combination or speeds and times desired to replicate actual plant conditions and operation Provides reliable, diffused sample illumination Operates on 24DC with a power supply that works with 100 to 240VAC electrical sources Dimensions: 394X768X235mm (15.5X30.2X9.3inches) Jars(6) 13 Clear plexiglass, square jar with sample delivery port for monitoring flocculation. Measures 21X12.7X12.7cm (8.3X5X5inches) with a capacity of 2L. Suitable for use with six-unit gang Includes tubing, stopper, clamp and 50mL graduated beakers 1 - Micro pipette - - Two-stage plunger dispenser which ensures high accuracy and precision in pipetting techniques and facilitates last drop dispensing Tip cone accepts both micro and ultra micro pipet tips Micropipette should be autoclavable and colour-coded for easy identification *Surface finish - All structural and tank stresses to be within the allowable limits as shown in Steel Construction Manual of the American Institute of Steel, latest edition or the European equivalent. Weldments shall be designed and performed in general conformance with AWS design standards. Continuous welds shall be used for all seal or structural support welds and intermittent welding for stiffener welds 2013.1 Document1 Page 10 of 11 - All seal welds shall be visually inspected and at a minimum be dye penetrated tested Primer and paint shall be applied in accordance with coating manufacturer's recommendations Stainless steel, nickel, Monel, Lead, Hastelloy, galvanized steel, rubber, Plastic, fiberglass surfaces, and fasteners shall not be painted All other appurtenances including motor, reducer, etc. shall be supplied with the manufacturer's standard finish *Carbon Steel Surface Paint - Exterior Surfaces: Sandblasted in accordance with the Steel Structures with the Steel Structures Painting Council Surface Preparation SP-6 Method, latest edition to obtain a profile of 15.-3.0 mils, on all non-wetted surfaces. The base coat shall be Carboguard 890 High Performance, Cycloaliphatic Amine Epoxy Mastic Coating, White (S800) applied at 4.0-5.0 mils DFT. The finish coat shall be Carbocrylic 3359 DTM Single Component, Water Based High Gloss Terpolymer Acrylic Coating, Safety Blue (S150) applied at 3.0-5.0 mils DFT Total DFT shall be 7.0 mils minimum average Interior Surfaces: Sandblasted in accordance with the Steel Structures with the Steel Structures Painting Council Surface Preparation SP-10 Method, latest edition to obtain a profile of 15.-3.0 mils, on all wetted surfaces. The base coat shall be Carboguard 891 High Performance, Cycloaliphatic Amine Epoxy Mastic Coating, White (S800) applied at 6.0-8.0 mils DFT. The finish coat shall be Carboguard 891, Solids, Polyamine Epoxy Coating, Light Blue (0100) applied at 6.0-8.0 mils DFT. Total DFT shall be 8.0 mils minimum average 2013.1 Document1 Page 11 of 11