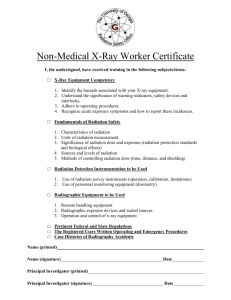

X-ray analytical equipment

PRIOR RISK ASSESSMENT FOR WORK WITH IONISING RADIATION:

WORK WITH X-RAY GENERATING EQUIPMENT

This is a generic assessment for people working with X-ray generating equipment. It must be adapted to local circumstances. There should be a written testing protocol based on this assessment, Work with

Ionising Radiation (Approved Code of Practice and Guidance on IRR99), and AURPO Guidance Notes on Work with Ionising Radiations in Research and Teaching (June 2005 Edition).

Note: all equipment in which electrons are accelerated in a vacuum to an energy of more than 5KeV are potential sources of X-rays and are legally defined as radiation generators. This may include electron microscopes, high voltage rectifiers and thyratrons. The Radiation Protection Officer should be consulted if there is any doubt as to what constitutes X-ray generating equipment.

Radiation doses from X-ray generators can be very high and can give extremely harmful doses in minutes. The following table indicates typical figures for doses produced by X-ray diffraction units etc.

(operating conditions: 40kV, 20 mA)

* Equal to the annual dose limit for a member of the public.

The risk assessment covers work X-ray generating equipment and instruments.

It covers controlled area, supervised area and unclassified area locations.

The main risk is to people using X-ray equipment etc. during teaching and research activities. Other people at potential risk are: visitors etc observing work with X-ray equipment, cleaning staff, maintenance staff, contractors servicing the equipment or other equipment in the area, maintenance staff. Members of the public should not be exposed to risks from this work.

HAZARDS

Radiation exposure

Radiation dose rates to which anybody could be exposed (in microSv/hr) should to be determined on a case by case basis. The limited data currently available from dosimetry does not indicate significant doses to radiation workers.

Failure of control measures.

•

Exposure of operator to significant dose of direct, scattered or reflected radiation from the equipment as a result of inadequate shielding, faulty interlocks or warning signs, an error of judgement or poor working practices.

• Failure to provide adequate information, instruction & training about risks and workplace precautions leading to mishandling of equipment;

• Failure of students or researchers to follow protocols with subsequent exposure to radiation;

•

Failure to detect radiation leakage from the equipment due to poor technique or use of inappropriate or inadequately sensitive monitoring equipment;

•

Failure to take appropriate action on discovering leakage of radiation.

LIKELIHOOD OF EXPOSURE Low if control measures are in place and work is carried out or supervised by competent persons. Moderate if beam alignment etc. takes place with interlock controls partially or completely disabled.

CONSEQUENCES OF EXPOSURE Possibility of erythema, burns and tissue damage in the short term, radiation sickness in the medium term and mutagenic, teratogenic or oncogenic effects in the long term. Injury would be dependent on the energy of the source and extent and duration of exposure.

OVERALL LEVEL OF RISK : Low if control measures are in place and work is carried out or supervised by competent persons.

Non radiation hazards

Possible hazards are:

•

Fire and flood;

• Electrical hazards from equipment;

•

Other equipment related hazards (heat, mechanical hazards, sharp surfaces etc);

• Hazards from manual handling of equipment;

•

Physical hazards in the environment in which the testing takes place e.g.slip, trip & fall, contact hazards.

•

Malicious tampering with equipment

Risks from these hazards should be assessed as part of general laboratory risk management process and suitable control measures should be in place.

CONTROL MEASURES for preventing radiation exposure:

Dose constraints. Doses must be constrained so that in practice, doses received are low.

Dosimetry . Use should be determined on a case by case basis and should be appropriate for the work area and the type of equipment used. Undergraduate students should not attempt work that would involve dosimetry.

Designation of areas as Controlled or Supervised: criteria set out in Regulation 16 of the Ionising

Radiations Regulations should be applied on a case by case basis. Enclosures surrounding x-ray equipment should normally be designated controlled areas.

Registration & designation of workers: Only authorised persons approved by the Department may work with X-ray generating equipment. A list must be kept. Designation as a Classified worker should not normally be required given the activities currently being undertaken in the University.

Laboratory design features:

These must be determined on a case by case basis. Basic laboratory facilities should normally be acceptable. Dedicated shielding and interlocks may be required. Hygiene facilities should be suitable for handling chemical or biological hazards associated with the work. Departments must keep a list of Xray generating equipment together with the location. A copy must be lodged with the University

Radiation Protection Officer.

Access restriction / warning devices / signs, screens etc:

•

This should be as appropriate for the work areas in question;

• Areas where the work takes place must be designated “supervised” or “controlled” as necessary

•

Areas in which X-ray generating equipment is located in should be clearly marked with the radioactive trefoil sign.

Equipment controls / interlocks.

•

All X-ray generators must be fitted with warning lights which read "X-rays on" indicating that the generator is working and generating X-rays. The light unit must be of a fail-to-safe design. It must be visible to the operator and anyone else who enters the room.

• Alterations or modifications to safety devices, particularly to those connected to the shutter, are not permitted.

• The X-ray generator and associated cameras, gonimeters, etc., must be enclosed in shielding and interlocked with the shutter or the power supply in such a manner that the shutter cannot be opened unless the shielding is in place. Interlocks must be designed so that they fail to safety.

•

An emergency panic button for switching off the sources recommended.

•

If it is necessary to override safety interlocks for functions such as beam alignment to take place, there must be a safe system of work describing how risks will be reduced to as low a level as reasonably practicable. Such work may only be carried out by competent and authorised persons and strict security provisions must be applied to keys and other devices.

•

Users must not assume that interlocks are operating properly. If the equipment is in regular use a weekly check should be made to ensure that the interlocks are really preventing beam generation.

If use is irregular then such a check must be made before use.

•

The RPS (or other nominated person) must conduct a monthly survey of X-ray generators and any associated cameras while the generator is running to check that shielding and interlocks are operating properly. Records of checks must be kept and the equipment taken out of service pending further investigation if irregularities are found.

• A competent electrician must check the insides of interlock switches every six months.

•

Particular care must be taken with flat-plate cameras. The RPO must be consulted before cameras of this type are employed.

Safe systems of work (effectiveness & suitability):

• For X-ray generators a competent named person must be appointed (who may be in charge of several generators). The name of the nominated person must be displayed prominently on the generator or nearby. The nominated person is responsible for ensuring that the generator is in good condition, shields and interlocks are in good working order, University and local rules are obeyed and relevant schemes of work are followed.

•

Use of X-ray generating equipment must only be carried out by trained individuals or persons under the direct supervision of competent persons using approved techniques.

•

There should be written protocols for work with X-ray generating equipment that cover normal operation as well as operations where interlocks are over-ridden, assembly of equipment, dismantling equipment, maintenance procedures etc.

• Adjustment operations for which enclosures have to be removed or partially removed and / or interlocks overridden may only be carried out by competent, authorised persons. Areas in which such adjustments are being made may have to be classified as temporary controlled areas.

Suitable monitors must be placed to detect scattered beams while adjustments are made. A preliminary survey would be helpful and temporary screens could be used. Project students may not carry out adjustments of this category.

•

X-ray equipment must be correctly identified with unique identification codes.

• Local Rules appropriate for the work areas visited must be followed.

Personal protective equipment: as appropriate to the area in question and in compliance with Local

Rules.

Monitoring procedures (before during & after experiments):

• Areas where X-ray generators are used should be monitored carefully for radiation escaping containment when the facility is first set up, monthly during normal operation and when adjustments are made with safety features disabled (see above);

•

Monitoring must be done by competent people using appropriate equipment.

Maintenance/testing procedures:

• X-ray generating equipment must be inspected and maintained as necessary. Faulty equipment must not be used but must be repaired or replaced;

• Monitors must be recalibrated by competent persons every year according to supplier’s recommendations.

Disposal of equipment.

Equipment must be disposed of safely and in accordance with relevant legislation.

Training requirements.

•

All persons using X-ray generating equipment must be competent to do so or be directly supervised by competent persons.

•

Competence issues should be referred to the University Radiation Protection Officer where necessary.

Health surveillance including alteration of working conditions of pregnant/breastfeeding workers or other persons at increased risk.

• The need for health surveillance must be assessed on a case by case basis (it is unlikely to be required given the current activities in the University).

• Exposure of pregnant or breastfeeding women to significant doses of radiation must be avoided if practicable and. In any case, must not exceed the dose limits.

DOSE LIMITS: INVESTIGATIONAL LEVEL FOR WORKERS

IRR99 requires a formal investigation to be carried out if any person receives a dose in excess 15mSv for the first time in any calendar year. The regulations also include a facility for an employer to set an

investigation level below this value to encourage keeping doses as low as reasonably practicable. It is not expected that any member of staff will receive an annual exposure in excess of 1mSv per year and the investigation level is set at this value. The RPSs should notify the URPO about any doses that are unexpected or significantly above background. The URPO will instigate a formal investigation if doses

(single or accumulated) exceed the above limits

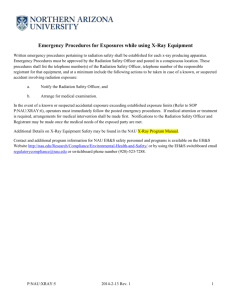

EMERGENCY PROCEDURES AND MITIGATION OF THE CONSEQUENCES OF ACCIDENTS

•

There must be an action plan for specifying action to be taken in the case of suspected significant exposure to radiation or contamination from an x-ray generator;

•

If necessary, the advice of the University Radiation Protection Officer should be sought;

•

People working in the facilities must be instructed in the action to be taken in an emergency;

•

Where practicable, emergency procedures should be tested periodically.

ACTION PLAN

An Action Plan must be drawn up if the risk assessment identifies any actions that is needed to reduce risks to as low a level as is reasonably practicable (ALARP). The plan must specify who will carry out the actions identified, a timescale for completion; and who is responsible for monitoring the completion of the work.