Break-up and bounce of TiO 2 agglomerates by impaction

advertisement

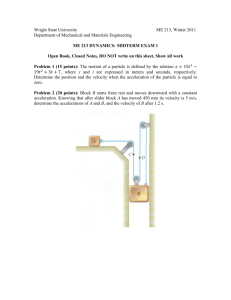

SUPPLEMENTAL INFORMATION Break-up and bounce of TiO2 agglomerates by impaction Ihalainen M.1,2, Lind T.1, Arffman A.3, Torvela T.2 and Jokiniemi J.2,4 1 Paul Scherrer Institut, Department of Nuclear Energy and Safety, 5232 Villigen, Switzerland Department of Environmental Science, University of Eastern Finland, P.O. Box 1627, 70211 Kuopio, Finland 3 Tampere University of Technology, Department of Physics, P.O. Box 692, 33101 Tampere, Finland 4 VTT Technical Research Centre of Finland, Fine Particles, P.O. Box 1000, FI-02044 VTT, Espoo, Finland 2 Figure S1 Schematic of the MOUDI nozzle In the simulations, the geometry of the nozzle was estimated using information provided by the MOUDI manufacturer (MSP Corporation) and information extracted from scanning electron microscope images of the nozzle. The shape of the nozzle can be divided into two sections: a wide cylindrical section and a narrow cylinder at the bottom of the nozzle (Fig. S1). The narrow section of the nozzle had an average diameter of 55 m, as determined by scanning electron microscopy. The flow field was simulated using ANSYS Fluent 12.1.4 software, and the particle tracking and collection efficiency were computed using a separate MATLAB script. All of the simulations were performed in two dimensions (using axi- and plane-symmetric equations) for compressible flow. Rectangular meshes consisting of approximately 250,000 computation cells were used. A boundary layer was created for the collection plate, and a higher density mesh was used to model the interior and outlet of the nozzle. The flow was modeled as turbulent using the SST-k-ω-turbulence transfer model and the advanced wall treatment of ANSYS Fluent. The magnitude of the non-dimensional wall coordinate y+ was maintained on the order of unity, which was required for the advanced wall treatment. The Reynolds numbers of the nozzle were on the order of a few hundred, and the flow was in a Reynolds number range over which simulations have been shown to produce accurate results (Arffman et al., 2011). A second order upstream scheme was used to discretize the flow equations. The boundary conditions consisted of fixed pressures at the inlet and outlet boundaries of the domain. These boundary conditions are presented in the section on impaction parameters. The particles were released from the nozzle inlet plane, and the aerodynamic focusing effect at the inflow was neglected in the simulations. The particle trajectories were calculated using the CFD simulated gas phase data. The following simple adaptive Eulerian method was used to calculate the trajectories: v( x1 , y1 ) v( x0 , y0 ) a( x0 , y0 )dt ( x1 , y1 ) v( x0 , y0 )dt ( x0 , y0 ) , (S1) where v and a denote the two-dimensional particle velocity and acceleration, respectively, at a given location (x0,y0) and at the location (x1,y1) after a time step dt. The particle acceleration can be estimated from the drag force Fd, which is given for spherical particles as follows: Fd ,s 3 vd Cc (d ) , (S2) where is the gas viscosity, and Δv is the differential velocity between a particle of diameter d and the gas medium. Cc denotes the Cunningham slip correction factor for the particle. An impactor classifies particles according to their aerodynamic size, i.e., a spherical particle of unit density is assumed to have the same terminal velocity under gravity as the original particle. Therefore, the particle acceleration under the flow field can be modeled as follows: a 18 v . d a2Cc (d a ) 0 (S3) Particle tracking simulations can be used to obtain the impaction velocities of particles as a function of their aerodynamic diameter. However, real particles may have an irregular shape: thus, electrical mobility diameters must be converted to aerodynamic diameters. The conversion equation is given below (Kelly and McMurry, 1992): d a db Cc (db ) eff Cc (d a ) 0 , (S4), where ρeff denotes the effective density of the particles, and ρ0 denotes the unit density. The effective density is the average density of a particle with a mechanical mobility diameter db. This effective density can be measured using a APM and a DMA. First, the APM is used to determine the particle mass, mp, and then the electrical mobility diameter is measured using SMPS. The following equation describes the effective density: eff mp (1/ 6) db3 . (S5) For singly-charged particles, the electrical mobility diameter is equal to the mechanical mobility diameter db. The electrical mobility diameters were measured with the DMA and substituted into Eq. (S5) for db. The effective density ρeff was measured using the aerosol particle mass analyzer (APM) and the DMA and substituted for the density parameter in Eq. (S5). Figure S2. The simulated impaction velocities of the aerosols used in this study as a function of A) the pressure difference over the jet plate and B) the stokes number. The ratios of impaction velocity to the average jet velocity in relation to the square of Stokes’ number are shown in Fig S2. The impaction angles are shown in Fig. S3. The impaction angles were close to the 90° for all the cases when the impaction velocity was 100 m/s or larger. In the cases of smaller impaction velocities, the impaction angle was still rather perpendicular for the cases where the effective density was higher. The impaction angle was still above 85° in the worst case used in the measurements of this study. Figure S3. The simulated impaction angles as a function of the impaction velocity. Figure S4. A) The simulated ratio of the impaction velocity to the average gas jet velocity as a function of particle effective density. Several pressure differences over the jet plate were simulated and the average jet velocity is shown in the legend. B) The impaction velocity and the maximum particle velocity for the case of average jet velocity 298 m/s (maximum gas velocity 334 m/s). The diameter of the simulated particle was 250 nm. The numerical simulation results for the ratio of the impaction velocity to the average jet velocity are shown in Fig. S4. The particle size was constant 250 nm, however, the effective density of the particle was varied. The average jet velocity was also altered with the varying pressure difference over the jet plate. Two major factors affect the impaction velocity; the acceleration at and after the nozzle and the deceleration near to the impaction plate. As the density of the particle increases, the amount of deceleration near to the impaction plate decreases due to the inertia of the particle. At the same time, the maximum velocity of the particle decreases due to the inertia in the acceleration phase. The effect of inertia on deceleration is the major factor with lower densities (Fig. S4B). Furthermore, with the higher values of density (near 1000 kg/m³ for the simulated particles in Fig. S4B) the decreasing maximum particle velocity limits the impaction velocity, leading to decreasing impaction velocities. The impaction velocity reaches its maximum at the turning point. As the average jet velocity decreases, there is an increase in the effective density for the maximum impaction velocity (Fig. S4A). Simulated impaction angles for different particle sizes at two jet velocities are shown In Fig. S5. Two different types of particles were simulated; one with a fractal structure (an effective density similar to the TiO2 basic case) and the other as a spherical particle with constant density 733 kg/m³, which was also the effective density of the basic case 250 nm particles. When the particle size was large enough, in this study about 250 nm, the impaction took place at near to a 90 degrees angle. At lower particle sizes, the impaction angle started to decline until it reached close to zero values. At zero values the particles will basically pass by the impaction plate without any impaction. Fig. S5 illustrates the effect of the fractal structure of the agglomerate in the simulations. The particle density was the same in both density cases for the 250 nm particles. However, as the particle size was decreased, the effective density of the fractal particles increased resulting in much smaller particles to impact at high impaction angles. Figure S5. The simulated impaction angles for particles with constant density of 733 kg/m³ and with size dependent effective density (fractal dens.). Two different average gas jet velocities (206 and 121 m/s) are shown here. Arffman, A., Marjamaki, M., Keskinen, J. (2011). Simulation of low pressure impactor collection efficiency curves. J.Aerosol Sci. 42, 5:329-340.