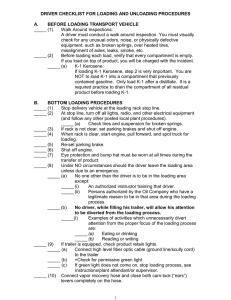

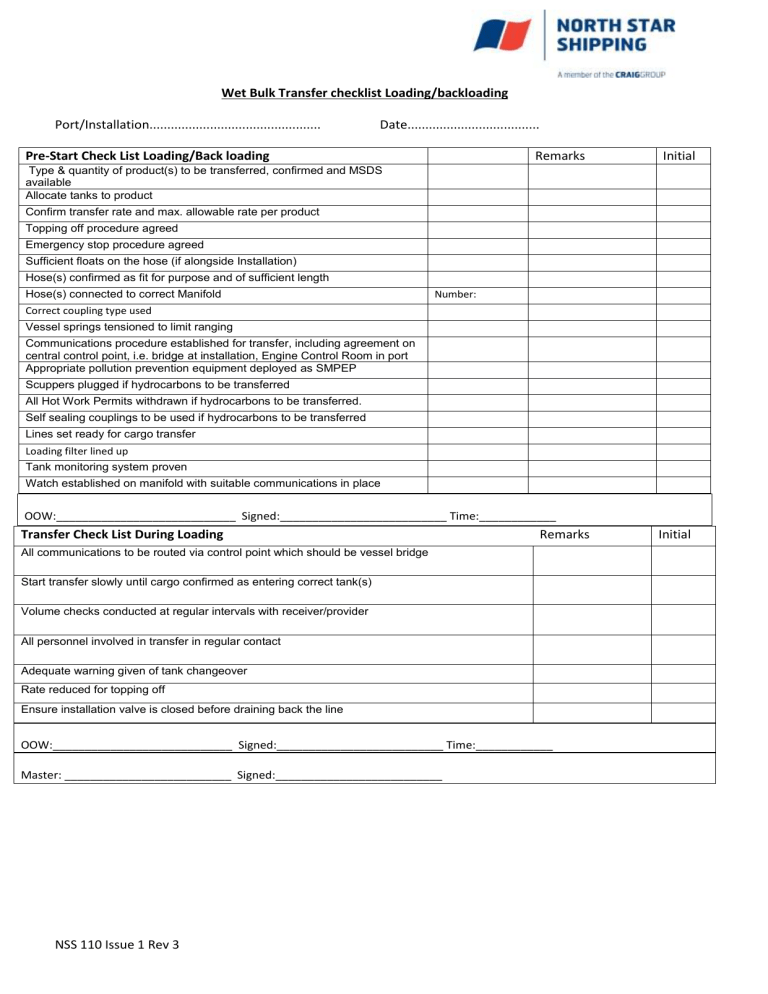

Wet Bulk Transfer checklist Loading NS 110.rev

Wet Bulk Transfer checklist Loading/backloading

Port/Installation................................................ Date.....................................

Pre-Start Check List Loading/Back loading

Type & quantity of product(s) to be transferred, confirmed and MSDS available

Allocate tanks to product

Confirm transfer rate and max. allowable rate per product

Topping off procedure agreed

Emergency stop procedure agreed

Sufficient floats on the hose (if alongside Installation)

Hose(s) confirmed as fit for purpose and of sufficient length

Hose(s) connected to correct Manifold

Correct coupling type used

Vessel springs tensioned to limit ranging

Number:

Remarks

Communications procedure established for transfer, including agreement on central control point, i.e. bridge at installation, Engine Control Room in port

Appropriate pollution prevention equipment deployed as SMPEP

Scuppers plugged if hydrocarbons to be transferred

All Hot Work Permits withdrawn if hydrocarbons to be transferred.

Self sealing couplings to be used if hydrocarbons to be transferred

Lines set ready for cargo transfer

Loading filter lined up

Tank monitoring system proven

Watch established on manifold with suitable communications in place

OOW:____________________________ Signed:__________________________ Time:____________

Transfer Check List During Loading

All communications to be routed via control point which should be vessel bridge

Remarks

Start transfer slowly until cargo confirmed as entering correct tank(s)

Volume checks conducted at regular intervals with receiver/provider

All personnel involved in transfer in regular contact

Adequate warning given of tank changeover

Rate reduced for topping off

Ensure installation valve is closed before draining back the line

OOW:____________________________ Signed:__________________________ Time:____________

Master: __________________________ Signed:__________________________

NSS 110 Issue 1 Rev 3

Initial

Initial