STANLOW

advertisement

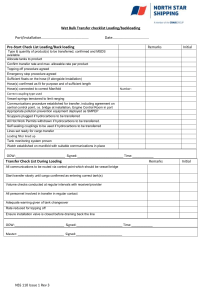

Stanlow Site Requirements www.shell.com/chemicals/transport Version 17 June 2014 Stanlow site requirements, version 17 1. Name of Installation: STANLOW See also General Requirements 2. Physical address of location Essar Oil (UK) Limited, Stanlow Manufacturing Complex, PO Box 3, Ellesmere Port, Cheshire CH65 4HB England 3. Opening hours The Traffic Office is open 07:00 - 18:00 hours Monday - Friday. Drivers should report to the Traffic Office to collect their loading notes before proceeding to the weighbridge and gantries for vehicle inspection and loading. Saturday loadings at the Stanlow 35 gantry will only be permitted by joint approval between Shell/Essar in exceptional circumstances. Timings will be confirmed but are likely to be restricted to 0:800am –11:00am. Details will be agreed when permission is given. First and last loading times at the gantries are as follows: Product First Load (Hours) Last Load (Hours) Alcohols (1) Neodene*(2) 07:00 08:00 18:00 15:00 Momentive* 08:00 15:00 * Subject to load scheduling 1. Except for twin pot vehicles when the last loading slot is 1600. 2. Except for C6/8/10/12/14/16/18/2022 Ionol & C14/16 blends When the last loading slot is 1600. 3. Except for ‘Deep Sea’ road barrels when vehicles should report to the Traffic Office by 1600. 2 Stanlow site requirements, version 17 * The vehicle should report to the Traffic Office 30 minutes before the agreed loading slot time. If a product is not available for collection the customer will be advised 2 days prior to the collection date by the relevant customer service centre. 4. Life Saving Rules. From July 1, 2009 The Site’s Life-Saving Rules have been fully enforced. The Life-Saving Rules set out clear and simple “do’s and don’ts” covering activities with the highest potential safety risk. They are not new. Most people comply with them every day – but there are still breaches taking place. The Life-Saving Rules help to make sure that rules are followed and people are protected. Compliance with the Life Saving Rules is mandatory, and the Life Saving Rules are applicable to all operations under Essar’s operational and / or governance control. Each reported noncompliance will be investigated. And failure to comply will result in disciplinary action, up to and including termination of employment for Essar employees, or for employees of contractors or sub-contractors, removal from the site and disqualification from future Essar work. Supervisors are held accountable to communicate and ensure compliance. If you choose to break the rules, you choose not to work for Essar or at Essar. 3 Stanlow site requirements, version 17 The 12 Life-Saving Rules are: Work with a valid work permit when required Conduct gas tests when required Verify isolation before work begins and use the specified life protecting equipment Obtain authorisation before entering a confined space Obtain authorisation before overriding or disabling safety critical equipment Protect yourself against a fall when working at height Do not walk under a suspended load Do not smoke outside designated smoking areas No alcohol or drugs while working or driving While driving, do not use your phone and do not exceed speed limits Wear your seat belt Follow prescribed Journey Management Plan 4 Stanlow site requirements, version 17 5. Driver’s responsibilities On their initial visit to this site drivers will undergo a general site induction, together with a specific induction for the area where they will be loading, and will then be issued with a driver’s loading passport. On return visits, drivers will be required to produce a valid and in date loading passport, ADR vehicle certificate of approval, *certificate of approval for old tanks (pre 2004) is only allowed for UK collections, ADR licence, photo identity card, SQAS approved cleaning certificate (valid for 6 weeks from date of issue) or previous Shell POD and a **defensive driver training certificate **(SCE contracted hauliers) for vehicle reception staff. Passports are renewable after 3 years when the driver will be required to undergo refresher inductions. All hoses, seals, valves, covers and earthing points on the vehicle are to be operated by the driver under supervision by the loading operator/vehicle inspector. Loading should not commence until the operator has carried out the vehicle inspection and the driver preloading checks have been carried out under the gantry and the loader confirms that loading can commence. In the event of any loading or first aid incident at the Stanlow site, the driver must immediately report the incident and details to the loading operators/vehicle inspectors. Drivers should be able to understand English. 5 Stanlow site requirements, version 17 6. Contact requirements All communication regarding the collection should be made direct to the Traffic Office (exts 4710/4714). Late arrival of vehicles: Due to the large number of vehicles loading at Stanlow, it is necessary to plan ahead. Therefore every effort should be made to meet the given date and/or loading slot time and any change or delay should be advised to the CRC in the satellite or hub or the load slot scheduler at Stanlow, for vehicles arriving late against a booked loading slot. It is highly likely that late arrivals will not be loaded. 7. Contact details General and hazardous products Dangerous Goods Safety Adviser, Mike Collins (MCDGSA) Telephone: +44-(0)1480-810884 The British Isles emergency response number is: Telephone: +44-(0)1235-239-670 General and for Stanlow Site rules Tracy Hughes – South Chemicals Production Unit Manager, CMS/00/11Stanlow Telephone: +44-(0)-151-350-4170 8. Special requirements of this location Drivers must adhere to the Stanlow Site Rules, this Stanlow Site Requirements document and the Essar Life Saving Rules at all times. Personal Protective Equipment must be carried & worn within the gantry loading areas: Safety helmet which is “in date”, safety spectacles, non vented safety goggles (BS EN 166 345B) must be carried & immediately available, one piece proban overalls, safety boots (not rigger boots), safety gloves. With effect from 1/7/14 it will become a site requirement for entry into all plant areas that chin straps on safety helmets must be “at the ready”. “At the ready” means already attached to a safety helmet, or carried and ready to be attached. 6 Stanlow site requirements, version 17 The use of a chinstrap should be considered as a control measure when conducting a 4 Whats or making out a clearance, when routine work underneath equipment is being carried out, or when climbing structures in windy conditions where there is a risk that a helmet without a strap could fall off. Vehicle mounted radios/telephones are to be switched off whilst on site. Mobile telephones are not allowed to be taken into plant control rooms, auxiliary rooms or plant areas (including loading areas). Smoking is not allowed on site, except in authorised designated areas. Smoking is not allowed in vehicle cabs whilst on site. Lighters, matches and electronic cigarettes are banned from site. Unauthorised passengers including children under the age of 16 years and animals are not permitted to enter the site. The site speed limit is up to 20 mph (30 km/h). As pedestrians use site roads, this speed limit must be observed and extreme care taken. The minimum driving standards to be complied with are ‘the rules of the highway code’. Dipped headlights must be used at all times whilst on site. All loads must be well secured. Should an accident occur or in the event of any emergency (fire/accident/spillage) it should be reported immediately to an Essar employee. Vehicles presenting for loading at this location will be subject to a vehicle inspection by trained vehicle inspectors in order to check the safety integrity of the vehicle/driver combination. Instructions in writing* a. SCE contracted hauliers must supply their own ‘Instructions in writing’ document. Customer collect vehicles are expected to provide their own ‘Instructions in writing’ document and substance identification labeling. Acceptance of non ADR/UN tank barrels at Essar Stanlow will only be allowed for the carriage of dangerous goods within the UK Mainland. 7 Stanlow site requirements, version 17 b. Tractor Requirements Meet full ADR requirements. Exception for Momentive Chemicals non hazardous packed product collections. Batteries: vented case. Master Switch: If to the rear of the cab, must be secured to a As near to the battery as possible. Earthing Point: For bulk vehicles only the earthing point must be a brass or stainless steel clearly marked lug permanently welded to the vehicle. Exhausts: To be forward mounted or, if extending to the rear of the cab, must be facing to the side. Rear facing emission will not be permitted. All exhausts protruding from the cab rear to be suitably protected and wiring to meet ADR standards i.e. protected by seamless and waterproof casing. Only a requirement for ADR loads (bulk and packaged) but, exhaust pipe must be located a minimum of 100mm from the fuel tank for all load types. Electrical Wiring: All wiring must be insulated/protected. Fire Screen/ Thermal Shield: It is a requirement that all vehicles be fitted with a fire screen/thermal shield that encases rear of the engine and the gearbox. 8 Stanlow site requirements, version 17 Working at Height: Vehicles must meet the standards of Safe Working Height legislation with respect to access/egress when the driver applies labels. All loading activities are to be carried out from within the gantry safety cages Vehicles fitted with mobile handrails will not be permitted to load and will be rejected at the loading gantry. c. Insurance All hauliers collecting from Essar Supply Locations in the UK must have a minimum of Sterling £3 million of general third party liability insurance cover whilst on Essar Group property. 9 Stanlow site requirements, version 17 d. Product Collection Procedures i) Bulk Liquid Collections: Bulk vehicles presenting at Stanlow to load product will not be allowed to proceed if they are already carrying cargoes of non Shell product or that were previously loaded with a food cargo. Tanks must be fitted with a dipstick or other means of accurately determining the loaded volume i.e. ullage bar/calibration chart. Evidence of tank cleanliness, that is cleaning station certificate giving details of last load, must be available for inspection. ii) Collection of Bags on pallets: (24 tonnes) demand a a) On European Exports, full loads 13.5 metre trailer and that we load only from the side (for safety reasons) unless the trailer has been approved for rear loading. Therefore hauliers need to be aware that the driver will have to prepare his trailer (especially if it is a tilt-type trailer) prior to loading. 10 Stanlow site requirements, version 17 b) For deep sea export containers 590 bags will be loaded as follows: 10 x 40, 8 x 20, 2 x 15. c) Vehicles may not be loaded that already have been part loaded outside of Stanlow. e) Loading slots: A system of pre-booked loading slots are in operation at Stanlow for: i) Collections of: Neodene® Roy Clarke Tel: +44-(0)-151-350-4765 Momentive Andy Morrison Tel: +44 (0)-151-350-4306 A loading slot should be requested when product availability is confirmed. Hauliers should not be sent to Stanlow before a loading slot has been confirmed. Loading slots should be booked before 1500 hours for collection the following day and are booked on a first come, first served basis. If a vehicle presents for loading more than 30 minutes later than the allocated slot it will not be sent in to load. www.shell.com/chemicals/transport Version 17 June 2014 Stanlow Site Requirements Approved by: Tracy Hughes| South Chemicals Production Unit & Chemicals Logistics Manager | Essar Oil (UK) Limited | 31st October 2013 | 11 Stanlow site requirements, version 17 12 Shell Chemicals Europe BV PO Box 8610 3009 AP Rotterdam The Netherlands Tel: +31 10 231 7000 Internet http://www.shell.com/chemicals Disclaimer The information contained in this publication is, to the best of our knowledge, true and accurate, but any recommendations or suggestions that may be made are without guarantee, since the conditions of use are beyond our control. Furthermore, nothing contained herein shall be construed as a recommendation to use any product in conflict with existing patents covering any material or its use. Shell Chemicals The expression “Shell Chemicals” refers to the companies of the Shell Group of companies that are engaged in the chemical businesses. Each of the companies that make up the Shell Group of companies is an independent entity and has its own separate identity.