Diffusing Knowledge from Scientific Industrial Laboratories:

advertisement

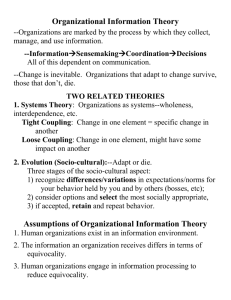

Diffusing Knowledge from Scientific Industrial Laboratories: A Network Approach to the Fuzzy Front-End of Innovation Samir Gupta, Monash University, Australia Elliot Maltz, Willamette University, Oregon, Arch Woodside, Boston College, MA March 2012 Please send correspondence to: Samir Gupta, Department for Marketing, Monash University, Chisholm Tower, 26 Sir John Monash Drive, Caulfield East, Melbourne, Victoria, 3145, Australia, Tel/Fax. +61 3 9903 2492/2900 (email: samir.gupta@monash.edu.au); Elliot Maltz, Atkinson Graduate School of Management, Willamette University, 900 State Street, Salem, Oregon 97301 (Ph: 503-370-6832; Fax: 503-370-3011; email:emaltz@willamette.edu); Arch Woodside, Boston College, Carroll School of Management, Department of Marketing, 450 Fulton Hal, 140 Commonwealth Avenue, Chestnut Hill, MA. USA 02467-3808, Tel/Fax: +1 617 522 3069/6677 (email: woodsiar@bc.edu). 2 Diffusing Knowledge from Scientific Industrial Laboratories: A Network Approach to the Fuzzy Front-End of Innovation March 2012 Abstract 3 The aim of the research is to understand the network of process activities, knowledge creation, and diffusion amongst actors who develop new ideas at the fuzzy front-end of innovation (FFEI). The study focuses on an important generator of industrial innovation – the industrial research laboratory. The research shows that knowledge creation/diffusion in the FFEI is primarily horizontal based on published knowledge, and the use of prior knowledge and exchange of ideas at the conceptual stage through a trial and error process to get product that meets industry specification. These IRLs follow a set of stage gate process activities to the time of patenting the process or product and invite the industry players (vertical) after the patent has taken place to conduct trials at a scaled-up level. The study finds that the FFEI process may yield scientific success without resulting in commercial success; lower levels of uncertainty and equivocality in the FFEI lead to knowledge creation/diffusion within an IRL. The paper offers implications for industry and industry focused research laboratories and direction for future research. Keywords: Fuzzy front-end; network; uncertainty; equivocality; network; knowledge/creation diffusion 4 1. Introduction The lifeblood of most industrial firms is continuous innovation. Without continuous innovation and the accompanying new products generated, industrial firms are forced to compete on price and often struggle to survive (Porter 1980, 1985). R&D laboratories are at the forefront of innovation performing much of the basic research at the fuzzy front-end of the new product development process (Reid and de Brentani 2004). Most research on R&D laboratories focuses on the practicalities of the NDP processes at the firm level, where managers can build structures and systems that will enable innovations within a firm (Crossan and Apaydin 2010). However, fuzzy front-end charactertistics include substantial uncertainty and equivocality resulting in risks of stranded investments and losses for the firm (see Frishammar, Floren, and Wincent 2011). With a renewed emphasis on cost cutting and profit potential, many multinationals are using their internal laboratories for applied research with more concrete profit potential (Kindler 2007). They are increasingly ceding the riskiest part of the development process of basic research at the fuzzy front-end to external R&D laboratories. External R&D laboratories are classifiable as research universities where new knowledge from science precedes publications, supported by a priority-based reward system; or commercial laboratories where ideas are produced for economic ends and encoded in patents and other modes of protection to facilitate appropriability (Murray 2002). Traditionally scholarly studies of external laboratories examine the collaboration between research universities and commercial entities (e.g., Dittrich and Duysters 2007; Un, Cuervo-Cazurra, and Asakawa 2010; van Echtelt, Wynstra, van Weele, and Duysters 2008). The focus of the current study is on the latter relationship where basic research providers have a more explicitly commercial focus. Specifically there exists a set of scientific organizations with laboratories not tied to universities where new ideas and processes are developed with the 5 intent to market these new ideas to businesses. These organizations have limited collaboration with their ultimate customers prior to the actual patenting of the innovation. Once patented, these ideas are sold or licensed to commercial organizations that develop value creating concepts for end-users. We refer to these organizations as “Industrial Research Laboratories (IRL’s).” IRL’s are part of the broader class of organizations which are receiving attention in the literature known as “Knowledge Process Outsourcing (KPO)” firms. KPO firms are companies that have contractual arrangements to provide knowledge-intensive critical activities like research and development (R&D) to entities which would otherwise have completed them in-house (Aggrawal 2007). KPOs create processes, often in conjunction with their contracted partner, that demand advance information search, analytical interpretation and technical skills as well as some judgement and decision making (Nair 2006). However, IRL’s differ from most KPO’s in that they often initiate and develop the outsourcing relationship with their larger, multinational counterparts (MNC’s). As such, they largely control the knowledge diffusion process during the fuzzy front-end of innovation. Network scholars suggest MNC-KPO collaboration is an attempt to enhance firm competencies by engaging with other organizations (Powell, Koput, and Smith-Doerr 1996). The process of knowledge creation and diffusion is central to competence building efforts. However, to our knowledge no studies have focused on the IRL context where the creation and diffusion process may be quite different as the KPO may be both the originator of basic knowledge and the initiator of the knowledge diffusion process. This study attempts to begin to fill this gap in the literature. Given the relatively limited amount of attention paid to these kinds of organizations (IRLs) in the NPD literature we have taken theories in use, approach to our research. We begin by reviewing relevant literature on network collaboration with particular emphasis on 6 how networks operate in the fuzzy front-end of the innovation process. We then draw from one scientific organization (cf. Burgelman 1983) and use a narrative description of the development and dissemination of eight ideas to begin to build theory in a business to business marketing environment. The narrative incorporates extensive interviews from the chief executive of an IRL as well as the lead scientists for the individual projects. Our goal is to describe and understand the network of process activities, resources and actors who develop new ideas in IRL’s and how those may differ from other KPO’s and/or the fuzzy front-end processes described in previous research. Specifically we seek to address the following research questions. How is knowledge created by IRL’s in the fuzzy front-end of the innovation process? How is knowledge diffused by the IRL’s? How are core competencies of the IRL’s and MNC’s affected by the knowledge creation and diffusion process? We begin by developing a more precise specification of our focal construct (IRLs). To do so, we review two related streams of research. The research focuses on KPOs and the fuzzy front-end of the innovation process. 2. IRLs: A Special Class of KPOs Knowledge is now advancing exponentially, such that no firm, whatever its size, can hope to keep up with changing knowledge in all areas. This has led to a trend toward the creation of business networks accompanied by explicit and implicit (i.e., tacit) learning and knowledge-sharing (cf. Hakansson and Ford 2002), both within the structure of a single organization and within the structure of inter-connected organizations. Because it is impossible to predict when and where breakthroughs will occur, industrial firms need to develop and build on their knowledge and core competencies with network partners. This knowledge-competency building-work precedes the stream of research focusing on knowledge processing organizations (KPO’s). KPO firms are companies having contractual 7 arrangements to provide knowledge-intensive critical activities to entities which would otherwise have completed them in-house (Aggrawal 2007). However, that the great bulk of the research adopts the perspective of the focal organization (i.e., multinational companies MNC outsourcing to KPOs). Knowledge about how outsourced organizations benefit strategically is limited (Karlsen, Silseth, Benito, and Welch 2003). Recently, Gupta, Woodside, Dubelaar, and Brandmore (2009) provide a study on the value of the MNC-KPO relationship incorporating insights from both partners in the relationship. They focused on a particular type of KPO, the Clinical Research Organizations (CRO) utilized by the pharmaceutical industry to perform clinical trials on drugs originated and patented by the MNC. Based on this particular context they develop a series of propositions which jointly suggest that the diffusion of knowledge in this relationship over time (a) erodes the current core competencies of MNCs by making them dependent on CROs for certain process activities while freeing up (MNC) resources to focus on new competencies (b) requires MNCs to understand how CROs perform their own internal processes and activities (c) provides benefits to CROs through economies of scale and scope while sustaining a competitive advantage over similar firms (d) requires CROs to monitor the rate of learning in order to be competitive. The focal construct in this study differs from Gupta at al. (2009) CRO’s in at least two important ways. First IRL’s, as the creator of the innovation are at the center of the knowledge creation and diffusion process. As such they are often the initiator of knowledge transfer in the network. Moreover, as they are often the focal organization in the network they have already developed relationships with other entities (e.g., other scientific organizations, government agencies) beyond the MNC. Second, IRL’s operate at a much earlier stage in the innovation process then CROs. In the case of CROs a drug has already been conceptualized and the CRO provides value add through clinical trials or testing of drugs. The IRL, on the 8 other hand, is instrumental in creating and developing the idea for the ultimate product where the industry purchases the patent for the product or the process. As noted earlier, they differ from university laboratories in that they have an explicitly commercial focus and often patent the idea which is the basis for the commercial transaction prior to significant interactions with industry (see types of KPOs in Table 1 below). IRL’s clearly operate at the fuzzy front-end of the innovation process. As such, we turn to research on the fuzzy front-end of innovation. Insert Table 1 here. 3. The Fuzzy Front-end of Innovation (FFEI) The focus here is on organizations creating patentable ideas that can be incorporated into commercially viable products. One stream of research that is of particular interest in our context is the “fuzzy front-end” of innovation (FFEI) based in the New Product Development (NPD) literature. The FFEI initiates the process activities by actors for competence enhancing and competence destroying innovation. Competence-enhancing innovation is innovation building on underlying strengths of existing competencies whereas competence-destroying innovation is innovative change replacing existing competencies (Davis and Devinney 1997). The term “fuzzy” refers to the intangible nature of this particular stage in the NPD process (Jorgensen, Bergenholtz, Goduscheit, and Rasmussen 2011). This literature stream (FFEI) has generally looked at the period between when an opportunity is first considered and when an idea is judged ready for formal development (see Khurana and Rosenthal 1998; Montoya-Weiss and O'Driscoll 2000; Reid and de Brentani 2004). Most researchers (Jorgensen et al. 2011; Khurana and Rosenthal 1997, 1998) have focused their study on firms that innovate, that is develop ideas for their economic ends while others have investigated fuzzy front-end activities from a customer interaction perspective (Alam 2006). 9 The stages of the FFEI have variously been described in many ways in the literature (e.g. Koen, Ajamian, Burkart, Clamen, Davidson, D'Amore, Elkins, Herald, Incorvia, Johnson, Karol, Seibert, Slavejkov, and Wagner 2001). Scholars agree that idea generation and idea development should be included. Some scholars include activities such as market assessment, concept development, feasibility analysis and project planning at the fuzzy front-end of an innovation (see for example Cooper 1994; Khurana and Rosenthal 1997, 1998; Zhang and Doll 2001). Kim and Wilemon (2002) note that the FFEI can be subdivided to develop greater clarity on the topic depending on the managerial goals and the context of the research. Clearly our context will include idea generation and development as our focus is on firms whose primary goal is develop patentable, commercially viable ideas. As such, the processes of interest will involve dealing with a large amount of uncertainty, the difference between the information one has and the information one need needs to complete the project. It is also likely to involve dealing with a significant amount of equivocality, the existence of multiple and conflicting interpretations among project participants (Daft, H., and Trevino 1987). Through the reduction of uncertainty and the resolution of equivocality that knowledge creation and dissemination occur in the FFE and later in the new product development process (see Frishammar et al. 2011). However, it is unclear if IRL’s and their MNC partners consciously engage in structured activities such as market assessment, concept development and product planning during the FFEI or if they use a more organic process to deal with uncertainty and equivocality. Thus, one of the goals of our study is to understand how formal the later stages of the FFEI are for IRL’s. In summary, as a starting point and consistent with the literature we reviewed on KPO’s and the fuzzy front-end of innovation we define an IRL (industrial research lab) as a KPO which operates primarily (although not exclusively) in the idea generation and creation stages of the FFEI and deals with high uncertainty and/or equivocality. As the initiator of the 10 innovation the IRL will be at the centre of knowledge creation and is often the initiator of the knowledge diffusion process. Knowledge creation and dissemination continues in conjunction with the MNC during the more formal stages of NPD and may impact competency enhancement or destruction at the MNC (see Figure 1 below). Insert Figure 1here. The balance of this exposition proceeds as follows. Section 4 provides a description of our research setting. Secttion 5 develops a conceptual framework which incorporates insights from previous literature and the current data collection. 4. Research setting The Central Salt and Marine Chemicals Research Institute (CSMCRI) is one of the divisions of the Council of Scientific and Industrial Research (CRIR). Located in Gujarat India, this IRL is situated on the coast line near the ‘Little Rann of Kutch’ and is involved in developing innovative products that are primarily chemistry based and in particular built around their knowledge of salt. Salt, apart from being an indispensable item of food, is an important raw material for the manufacture of several heavy chemicals, for example, soda ash, caustic soda and chlorine. In addition, salt is used in the food processing industry, such as fish curing, meat packing, dairy products and fruit and vegetable canning. The IRL has several advantages which support a core capability in salt based research. It has a long history of developing processes for developing, transporting and processing saltbased industrial products. Thus, it has an extremely strong knowledge base in this area. It is also located in an area with abundant salt resources giving it easy access to the raw material for research. In its operational activities this IRL is recognized as being at the forefront of discovery, it has several important patents and is one of the top performing national R&D 11 laboratories in India. This gives it easy access to other top performing freestanding research universities and IRL’s. Their reputation also draws significant funding from both public and private sources. As such the setting was nearly idea for our investigation. The IRL was approached and the management willingly cooperated with the researchers. The head of the institute served as the Key Informant and participated in two eight hour interviews conducted over three days. During these interviews the KI explained the nature of the institute and identified specific laboratories within the institute that might be of interest for our study. Following the interviews with the KI, five lead scientists and engineers were interviewed on location. Interviews lasted about an hour. The participants discussed cases of on-going and completed projects that started at the idea generation stage and discussed idea development. They provided the data for the period prior to patent application. The KI, who was the primary conduit to the clients of the IRL, provided additional information about network collaboration with commercial partners both pre and post patent. For the purpose of this paper, projects were selected that were initiated both within CSMCRI and those that were instigated from industry. This provided a basis for understanding how the knowledge diffusion process differed based on the initiator of the project. Table 2 provides a list of those interviewed and the duration of the interviews. Names of the scientists have been omitted for confidentiality reasons. Insert Table 2 here. In summary, through in-depth interviews the authors have developed a series of cases from 1 IRL. The purpose was to develop an understanding of the actors and resources involved in the FFEI in terms of knowledge creation and diffusion and how these processes 12 affect capabilities of the IRL and MNC. The analysis extends the propositions that were developed in prior research (Gupta et al. 2009) and provides further insights into the FFEI in the NPD process. 5. 5.1 Conceptual framework Knowledge creation/diffusion in uncertainty and equivocality network environment As the complexity of innovations increase, firms with R&D expertise seek to collaborate with other industrial research institutes like the IRLs to innovate products and new processes. While some firms outsource non-core yet essential activities to other firms (e.g. Gupta et al. 2009), others like the IRLs innovate products and process by collaborating with actors within its core competencies and at times with actors of likeminded institutions. Empirical evidence from the microcomputer industry provides support for balancing and managing activities within the network (Rothaermel, Hitt, and Jobe 2006). Rothaermel at al. (2006) argue that balancing vertical integration enriches a firm's product portfolio and product success, contributes to overall firm performance of the firm. While studies drawing on social network tradition (e.g. Powell et al. 1996) as well as scholars within the industrial network (Hakansson and Ford 2002) view networks as borderless, self-organizing systems that emerge (Moller and Rajala 2007), others representing the strategic management perspective suggests they are more intentionally created and contain a specific set of organizations with agreed roles (Moller and Svahn 2004, 2009). Moller and Rajala (2007) build a topology of business nets based on the level of determination of the value system, that is, a set of activities carried out by actors in the net. This line of research also draws on “Industrial Marketing and Purchasing (IMP) Group” where scholars’ propose and support the proposition that networks structures needs to be evaluated through the processes, activities and actors who operate in this network environment (cf. Golfetto, Salle, Borghini, and Rinallo 2007). The study here takes the latter 13 approach. As such, our investigation attempts to uncover how the processes, activities and actors interact in terms of knowledge creation and dissemination and how those interactions relate to innovation and commercial success. We then examine how these interactions affect the core competency of the IRL. Arikan (2009) argues knowledge-based theory places emphasis on inter-firm knowledge exchanges among clusters of firms in explaining enhanced knowledge creation within a cluster. This knowledge exchange takes place among cluster firms that take various forms from vertical to horizontal networks (Arikan 2009). This argument is helpful in understanding how IRLs form clusters within (internal networks) and interacts with clusters of other scientific based institutions (horizontal networks) in the FFEI process (for details see Figure 1). Generally, CSMCRI develops new to the world products and processes that they patent and the patents are sold to a number of industries. Scientist 1: “We have developed a polymer membrane that can be used for commercial purposes e.g. production of pure sodium Chloride for medical industry.” Scientist 3: “… like others [divisions] we too innovate and develop new products and processes e.g. bromo-phenols that is used as fire retarders in making TV sets.” Interestingly, while all the projects discussed had similar knowledge creation and dissemination processes (see Figure 1) they were not all explicitly associated with their primary core competence—expertise in salt-based products and processes (see Table 3 for details). Our first case study describes one such project—Bio-Diesel Creation. Bio-Diesel Creation Initial theoretical investigation & lab level experiments CSMCRI developed the purest form of bio-diesel from a shrub called Jatropha Curcas (henceforth will be called Jatropha) that originated in Central America. This project did not 14 involve salt-based expertise or the location advantages in terms of proximity to salt. The project was initiated because Jatropha did grow near the institute; Engineer 1 – Process and Design Cell: “since jatropha grows in this barren land where we are [located] we started doing some work on jatropha. CSMCRI scientists had in-depth local and the knowledge about the plant.” In the beginning CSMCRI did not venture into the project, but having discovered that the shrub was growing in its backyard prompted the engineers and scientific group to investigate whether the oil can be converted into bio-fuel Furthermore the Planning Commission of India also instigated the development of biofuel as priority project for India (Fairless 2007) and it was seen as one way to address a growing emphasis on alternative fuels by a key funder—the Indian Government. Engineer 1 – Process and Design Cell: “Scientists had knowledge about the fuel and had experimented with edible-oils products like sunflower oil … it was already proven the Jatropha contained oil … in academic literature … since everybody is going about finding alternate sources of energy not only in India but everywhere we too got into this field … since we are located in this part [of India] we have identified commonly available non-edible oil, that is jatropha.” Engineer 1 – Process and Design Cell: “… based on the known literature a team was set up to first conceptualize the process and then we [came in] started from laboratory scale [models] … we had done some work already into edible and non-edible oil … in India there is always a scarcity of edible oil so we started work on extracting oil from jatropha.” The process in the laboratory was first initiated to extract the oil and then the scientists and engineering staff proceed to refine the oil after receiving positive results at the laboratory level. A trial and error approach was followed till such time the scientists and engineering staff could bring the quality of the fuel to a benchmark, recognised by the Austrian Fuel Research Institute. 15 Scale Up of Prototype Once the scientists had developed the bio-fuel in the laboratory, the engineering team within the institute was involved in the scale up process activities in the development of biodiesel from this shrub. Most of the conceptual laboratory level tasks were carried out and knowledge creation and diffusion were shared with other teams both within the IRL and some outside institutions. Under these conditions laboratory results were compared and discussed particularly the problems or issued faced at this early part of the process. Some of the issues were discussed with others like minded scientists in other scientific institutions (Horizontal network). This process does build off a portion of their core competence—their reputation as a strong scientific organization. CEO-CSMCRI and Engineer 1 – Process and Design Cell: “… the managing director from Gujarat State Fertilizer Corporation happened to be earlier from this institute … brilliant person and a chemical engineer … very passionate about the plant [Jatropha] we started sharing and exchanging knowledge … the division [laboratory within CSMCRI] coordinator and I were discussing how to develop the product commercially.” CEO-CSMCRI: “They started to evaluate our bio-diesel and said it was good but not a winner …it required a lot of improvement. At this time the process to develop bio-diesel from jatropha was patented “the problem was how to purify the bio-diesel because once you got it, the oil has to be free of all impurities … the problem was when we did this [purification process] the molecules became bigger and bigger … we were able to address this problem and the solution [to this problem] is covered in the patent.” As was seen in many other cases the original investigation within the institute led to useful breakthroughs not foreseen at the beginning of the project. Thus, additional knowledge creation not anticipated at the beginning of the project was achieved. 16 CEO-CSMCRI: “I do not want to go into the specifics but [our knowledge of having gone through the process in the laboratory, knowledge from the literature and what industry players were doing] gave us the lead on purification with water … however, we found that water was the culprit … this is in a sense our biggest innovation … the process came to us suddenly when we were trying to eliminate water … I feel that the innovation was made possible when we lacked the choices … and broke off from what others were doing.” This process was then followed up by scaling up the project. Second Scale Up for Industry Level Evaluation Engineer 1 – Process and Design Cell: “In February 2004, we were asked to make 6000 litres of the fuel to be tested … we got together [scientists and engineering staff members within CSMCRI] and we started to scale up from the laboratory scale to a more bigger scale.” The focus of the production was not only the volume but to process the bio-diesel such that the quality was continuously maintained. The scaled up models was developed producing oil round the clock “the output from the Hyderabad plant and from the Udaipur plant was 10000 litres/per day over the last three years.” Industry was invited to collaborate with CSMCRI and to test the oil and both Daimler-Chrysler and GM showed interest on the product and they tested the product in their laboratories. It is at this point that vertical knowledge networks are created to diffuse the innovation as demonstrated by the company documents cited below. Company documents: “Dear Professor Ghosh, [CEO – CSMCRI] first of all good news: we analysed the two Jatropha samples and they are o.k., congratulation. Compared to the samples of last year the transesterification (trans-certification) is now complete, and the alkali residues are low. Also the oxidation stability is improved likely because of the additive … Kind regards, Dr. Winfried Degen DaimlerChrysler AG” (18 Feb 2004). Having gained experience in producing the highest quality bio-diesel from Jatropha, the scientists are continuing testing and improving the process and technology. 17 Engineer 1 – Process and Design Cell: “We have now set up field stations and DaimlerChrysler [in India] have been running field trials using three cars and they have reported no problems with the car engine … in fact our own [fleet] vehicle we tested the diesel and found that after running 100,000 km we did not even had to add any other substance to blend the diesel (e.g. ethanol) and the engine was as clean as they day of new [purchase].” In summary, the innovation was a scientific success. Engineer 1 – Process and Design Cell: “The uniqueness of the innovation and the development was that (a) the scientists were able to produce a high quality product consistently i.e. the viscosity and the glycerine content met the standards (b) the temperature at which the product was produced and all associated chemical reaction is generally high but they (CSMCRI) was able to produce in ambient temperature so much so “anyone can now manufacture the bio-diesel without in-depth knowledge of chemistry or engineering.” The process of knowledge creation and diffusion provided the team of scientists and engineers the knowledge and skills to develop the bio-diesel product. In addition to this discovery the scientists found potentially valuable by-products from the process. CEO – CSMCRI: The by-product for the ‘oil pods’ could be converted into fuel for oil lamps as the pods contained oil. The other by-product was a paste that was converted into glycerol. The key result for the knowledge creation diffusion was additional innovations that were developed. With the help of micro-biologists the scientists were able to ferment the fuel and produce plastics “… these were by-products that we have patented.” To summarize, during the process before the patent, knowledge creation and diffusion primarily took place with the confines of the scientific community and the engineering staff with prior knowledge of the plant through literature and industry information. Once the patent was successful more actors became involved in the testing phases of the new product development process as depicted in Figure 2. 18 Insert Figure 2 here. However, it is important to note that the project, while a scientific success, has yet to prove out commercially. CEO – CSMCRI: “at that time they [industry] had made some bio-diesel of the quality that made the benchmark ... this is in literature … but we did not know how to do it at a commercial scale.” This was due to the fact, that while jatropha was plentiful, the yield from the process was not sufficient to make it cost effective at commercial scale. This description leads to our first set of propositions in regards to IRL-based networks. P (1a) Knowledge creation/diffusion in the FFEI is primarily horizontal based on published knowledge about the concept, and using prior scientific knowledge and exchange of ideas at the conceptual stage by the actors through a trial and error process to get product that meets industry specification. P (1b) IRLs follow a set of stage gate process activities to the time of patenting the process or product and invite the industry actors shortly before or after the patent has taken place to conduct further trials at an industry scaled-up level. It is at this point that vertical knowledge diffusion takes place. P (1c) The FFEI process may yield scientific success without resulting in commercial success. These propositions are descriptive and provide limited conceptual understanding of why the processes and actors interact as they do and how their interactions lead to commercial success or failure. To provide additional insight we turn to information processing theory. 5.2 Uncertainty, Equivocality and Knowledge Diffusion 19 Uncertainty is a state where actors engaging in activities that are based on less than complete knowledge (Galbraith 1973). While uncertainty necessitates the acquisition of additional information to reduce the influence of actor’s heuristics, equivocality necessitates the exchange of knowledge among organizational actors to address a problem. What is important is that participants develop similar judgements. In the FFEI where new information is supplied which often reveals further complexity equivocality may, in fact increase (Frishammar et al. 2011). Frishammar et al. (2011) argue that actors that face an equivocal situation need prior or cumulative knowledge to move forward in the FEEI process. According to these scholars often front-end decisions need to be made under high equivocality in cases where the innovation newness is high and the industrial firms cannot rely on previous knowledge. This is because the activities prior and during the fuzzy front-end are characterized by significant uncertainty and equivocality. Other scholars suggest a firm possessing strong internal technical capabilities is more likely to be able to process external information and transfer this knowledge into the new product development process (Cousins, Lawson, Petersen, and Handfield 2011). This discussion may be summarized in two competing propositions. P (2a) In the FFEI equivocality will not be reduced through the introduction of additional information. P (2a*) In the FEEI equivocality can be reduced through the introduction of additional information if the firm has strong internal capabilities. Inorganic Materials Our second case study describes innovations from the use of inorganic materials such as zeolite, calcium, and kimberlite. In the development and use of these inorganic materials the scientists used their existing knowledge to provide solutions to industry through a similar process to that discussed in the biodiesel case. The project took advantage of the salt based 20 competence of the IRL. Thus, this team of CSMCRI scientists and engineer were both skilled and had knowledge of the problem and were able to provide solutions to the industry. Scientist 3: “Usually a team is formed to solve the problem … in the initial stage of the project the team consisted one chemist, 2 to 3 scientists and one chemical engineer … we were able to provide solutions to the industry.” Scientist 3: “exploratory work by us indicated that sodium aluminate when reacted with sodium silicate could produce zeolite … this process was developed in the laboratory after which we scaled-up the process … we were very certain that the process will work … presently a unique plant is set up that manufactures zeolite by our method … this product is used in the process of preparing detergents … in Europe the presence of phosphates in zeolite is prohibited … the zeolite produced by us does not contain any phosphate.” In summary, not all FFEI projects exhibit high uncertainty and equivocality. In many cases IRL’s have sufficient internal knowledge bases to create low uncertainty, low equivocality environments. Where they have minimal knowledge lapses they are able to utilize their strong technical knowledge base and horizontal contacts to greatly reduce uncertainty. This focus-process explains why the general process they follow relies on internal and horizontal knowledge creation and dissemination. In general, they do not need much information from outside to make the innovation a scientific success. The internal focus-process explains why the biodiesel project has yet to achieve commercial success. The scientists were outside their core area of expertise. They were able to reduce uncertainty and perceived equivocality through conversations with other scientists. However, because they did not have enough market knowledge they did not have enough vertical communication to make the product a commercial success. They had no expertise in the biodiesel market and didn’t share the scientific knowledge until it was too late. 21 However, we came across other projects where the uncertainty and equivocality was perceived because projects’ frame-of-reference was science, not based on a market-frame. CEO – CSMCRI: “ …where we do have the expertise we are able to address them while other areas we are not so sure … we successfully found a way in separating magnesium compounds from silica … but do not have the knowledge to utilize magnesia-based products [which is outside of what we do].” CEO – CSMCRI: “… we could not come up with a commercially viable technology … so we had to somehow break out [of our current thinking pattern] … we were trying this process [without success] since 1999 … participation within the industry [our scientific community] did not produce the results … we had some potash [not of industrial standard].” This project ultimately succeeded because even though there was significant uncertainty and equivocality it was recognized and the project rested, in part, on the core competence of the CSMSRI. CEO – CSMCRI: “we had some funds to start the research but the government asked us to return the funds … we had to fight to retain the funds … as I had just joined the institute … we were making progress but the uncertainty was there [from the funding aspect as well as from technically coming up with the innovation] we were shooting in the dark …we didn’t have any other experience with potash … we did laboratory tests but the nozzles were getting choked (equivocality)… we were [even] contemplating buying a patent from Jordon who had done some work [reducing the equivocality] … then we had information from an unexpected source … I was in Delhi giving a seminar when Dr. Sabra and Dr Sinha said why are you trying to make KCL, you can make what is known as sulphate of potash instead of chloride of potash … it has a better chemical composition therefore better fertilizer … this fertilizer will give you both potash and sulphur … I was thinking about what he said and trying while flying back to figure in my mind then it fell into place … 22 we can combine all the accumulated knowledge that we had and came up with a solution to the process of manufacturing potash … we did this and the rest is history.” These examples lead us to the following modified set of propositions about the effects of equivocality and uncertainty in the FFEI process. P(2a): Lower levels of uncertainty and equivocality in the FFEI lead to knowledge creation/diffusion within an IRL. P (2b) For projects based on non-core competencies, there may be a difference between perceived and actual uncertainty. P(2c): For projects based on non-core competencies, if the uncertainty is not perceived as science based insufficient vertical knowledge dissemination may occur. P(2d): Higher level of perceived uncertainty and equivocality in the FFEI leads to knowledge creation/diffusion with external players. P(2e): For teams with significant technical expertise facing equivocality, leveraging the scientific community for additional information may result in novel solutions that reduce both uncertainty and equivocality. 5.3 Core competencies in network Prahalad and Hamel (1990) contend that core competencies are the collective learning in the organizations, especially how to coordinate diverse production skills and integrate multiple streams of technologies. They argue core competence is based largely on communication, involvement, and a deep commitment to working in networks. Prahalad and Hamel (1990) claim that collective learning and sharing knowledge constitute core competencies that must unite around individuals within firms. However, their research does not address how core competencies can benefit individual organizations in the network in order to recognize opportunities for blending their functional expertise with those of others in new, interesting ways. Javidan (1998) criticizes the relatively loose application of the core competency concept. He argues that to make core competence concepts more specific, resources - physical, human and organizational – should be used as inputs directed at the firm’s value chain. According to 23 Durand (1998), competence can be connected to (a) the firm’s resources and property and (b) the capabilities of individuals and organizations, knowledge, processes, routines, and culture. Resources alone are frequently not enough to generate competitiveness over other firms. In creating a competitive advantage, a firm needs the ability to make good use of resources – defined as the capability to handle a given matter – and, as the ability grows over time, to utilize the available resources to create new products and processes. Gupta et al. (2009) claim that a firm’s accumulated knowledge base realized through the effective use of internal collaboration represents the firm’s core competency. Kandampully (2002) argues that the continuously updated “amorphous knowledge resource” results from the network partners that represent the firm’s core competency. Consistent with this claim we define core competence in the FFEI as accumulated knowledge gained over time and the ability of the firm to apply this knowledge in order to develop new products and process. Based on this definition we include IRL’s access to resources of recognised accredited agencies that are outside the network as a core competence where knowledge/diffusion and their internal capabilities are constantly challenged in the FFEI. In other words, as discussed in the previous section, CSMSRI’s knowledge and prestige as it relates to industrial salt is a core competence. Prior studies (cf. Gupta et al. 2009) on knowledge-based core competencies in networks claim that the economies of scale and scope benefit organizations like the IRLs rather than the firms that purchase the patent rights. Further investigation using data from CSMCRI indicate that this proposition requires further refinement. For example, in a break through innovation, CSMCRI was able to produce potash from seaweed by using their internal knowledge base and their established network. Potash from seaweed 24 The third case study in the present study describes innovating potash from seaweed. Scientist 2, “To develop a new product, relevant information is gathered from published literature, private discussion with the chemical community of scientists and attendance in [like-minded] conferences … scientists attend about two conferences on average a year [in their domain]. “ …this institute has people with vision and such people are found in the industry.” Scientist 4, “for instance the Gujarat State Fertiliser Corporation was is a chemical engineer and a former employee of this institute had noticed a certain plant growing in the coastal region … he was aware of the work that was in our institution so he extended his collaboration.” Scientist 5, “sometimes while working on a project, ideas on other related projects [as we know what other division are working on – through divisional meetings] are generated and pursued … initially when conceptual models are developed, when tested if found suitable the second phase is carried out, that is, conducting laboratory level experiment.” In this environment while working on a project “ideas on other related products are generated and pursued” and exchange of ideas take place within the IRL. “Initially a theoretical study is made in the laboratory environment, if found suitable [positive results to the hypothesis] then the second phase of the study is undertaken” where laboratory work is carried out prior to the scaling up the project. However, leveraging the core competence is not always successful. In the potash example they had to go outside their existing set of contacts to generate the innovation. In FFEI process for potash, researchers had failed to produce adequate quantity at a reasonable price for use as a fertilizer. CEO – CSMCRI: While the technology and knowhow to produce potash was readily available CSMCRI “I can tell you that … earlier attempts failed … I am not going into 25 that … but we have been trying to produce potash since 1999 … that was most recent, but you could go back to the 1950s” CSMCRI received valuable input to the process not from its ‘regular’ sources, that is, the chemical fraternity, rather the birth of the innovation came from a rather unexpected source “I remember when I joined the institute, a person called Dr. Bhora who is a chemical engineer … working at the Indian Council of Agricultural Research … was very determined to come up [with a process to develop potash] with potash technology … because it was a national requirement … [India] every gram of potash was being imported into the country … India required 3.5 million tons of potash [ever year] … today its about 5 million tons.” Based on external funding (both government and non-government) and knowledge of the scientists were able to patent a process that was cost effective “we ended up making a beautiful technology … the cost of production was reduced … we could with a simple manoeuvre … also utilized local products [sea water] as inputs to manufacture potash.” In sum, the regular process and existing network was not enough. In this case they had to stretch the knowledge diffusion process more horizontally and vertically then their normal practice before the patent was fully and unconditionally enforceable to finalize the innovation. In doing so they faced additional risks and challenges. CEO-CSMCRI: “… they [interested commercial parties] play dirty tricks … they quietly did this although we had a patent … they were blatantly infringing on our work [patent] … we challenged them in court … their patent application was overturned.” However, this broader diffusion of knowledge had a bright side. It strengthened produced by-products that were not anticipated in the original project. The CEO-CSMCRI also stated that at the time of the innovation they discovered that they were able to produce salt that was pure salt “that was found to be very good for the heart … commercial firm (Hindustan Levers) was interested in the product.” While this was 26 an interesting by-product outcome from the study under consideration, the firm was actually more interested in the manufacture of potash.” The broader diffusion also strengthened and stretched their knowledge base in a way that was adjacent to their existing base. While the source of the raw material was in abundance locally the scientists within the IRL worked on a problem when an external source provided input into the problem. Scientist 3, “why not try to make what is known as sulphate of potash instead of chloride of potash … which is a better fertilizer and is twice the value … will give you both potash and sulphur.” These examples lead to the following set of propositions. P(3a): Economies of scope benefits the FFEI process for both the focal IRLs and its partners in the network rather than just the focal IRL as new innovations are sometimes achieved as a by-product of the current scientific work. Prior studies (cf. Gupta et al. 2009) suggest that IRLs need to conduct continuous training, to be flexible and to apply knowledge in order to be competitive. This vertical and horizontal stretch is one example of how this may occur. P(3b): Successful FFEI requires economies of scope (vertical and horizontal stretch) which leads to enhanced core competencies. By-products from primary innovation A supporting focus of the IRL was better utilization of agricultural products from the sea. While cultivating seaweed was not the part of the core competence of the IRL, they began conceptual work on discovering that when seaweed is crushed and blended it left with two products. In this case, an industry client (Pepsi) was the initiator of the project. Work on this residual product was commissioned and a team consisting chemists and microbiologists were engaged. The scientific process involved drying the product in the sun thus eliminating the sea water. The microbiologist found that the seaweed had the property of 27 filtering out the sodium chloride and absorbed only potassium chloride. The CEO and his colleagues realised that the dried power could be used as source of potash which is an essential ingredient in the manufacturing of fertilizer. At this stage the process was patented and sold to Pepsi who began using it for its sugarcane plantation. Thus, unlike the biodiesel example where the commercial application is still in doubt, this project has achieved commercial success. “Pepsi has poured a lot of money into this discovery … we have given them non-exclusive rights of this fertiliser … Pepsi has acknowledge this patent … if the company wants us to do more work we do it ” (CEO – CSMCRI). The patent rights were also sold to another company TATA and they have scaled up the production of the seaweed based fertiliser which is used within the country and is also exported. This success may be because the industry partner initiated the project they maintained significant input into its commercial feasibility and combine their market and operational knowledge with the basic scientific knowledge provided by CSMCRI to create a new and more complete understanding of this new area of science. This increases the scope of the core competence of both the IRL and the MNC. This finding supports the final set of propositions. P(4a): Learning is based on exchange of ideas that are geared more towards competence enhancing processes in the FFEI. P(4b): Projects introduced by the industry partner are more likely to create competence enhancing processes in the FFEI. 6. Managerial implications The study has important implications for firms attempting to manage the knowledge creation and diffusion process for both short term and long term advantage. From the short term perspective, managers in the FFEI process of innovation must try to manage uncertainty and equivocality to achieve not only scientific but also commercially success innovations. Our exploratory study suggests that the key to this is identifying where the knowledge 28 boundaries of the firm lie. For scientists, who are often not interested in the marketability of their innovations, it is important to recognize that for a commercial entity like an IRL commercial success is a must. For markets where the IRL has not demonstrated a core competence, they may wish to involve their industry partners earlier in the process in order to reduce the probabilities that actual equivocality is higher than perceived equivocality. That is, that they truly understand what is required for the innovation to be a commercial success. This suggests that for noncore projects scientific knowledge dissemination may have to be married to the market and operational knowledge of the industry partner. For FFEI projects that rely primarily on core competence the knowledge dissemination process can be more vertical. This will ensure the value add to the IRL is not appropriated by the industry partner prior to the patenting process. This can likely be done at little risk to the commercial success of the innovation. However, from a long term perspective the IRL should be alert to ways they can generate vertical and horizontal knowledge stretch to maximize their economies of knowledge scope and continue to enhance competitive advantage. 7. Discussion The goals for this study include providing ”direct research” (i.e., in situ, see Mintzberg, 1979) findings on (1) how knowledge creation processes occur in IRL’s at the fuzzy frontend of the innovation process; (2) how is knowledge diffuses in and by the IRL’s; and (3) how the knowledge creation and diffusion processes affect core competencies of the IRL’s and MNC’s. This exploratory study provides some insights to answering these issues. Knowledge creation and diffusion appears to be primarily internal and horizontal during the FFEI. We propose this is because for core competency based projects, there is no need to share knowledge vertically and for non-core based projects there is less perceived uncertainty 29 equivocality then actually exists. In other words, as long as the scientists can solve the scientific problem—they are satisfied and don’t see any need to share and compare knowledge with industry partners. Thus, they see limited upset potential of sharing and tremendous risk of sharing before the innovation is patented. However, when they do share, assuming they are working from a position of technical strength they are likely to develop competence enhancing innovations that increase scope economies and ultimately their position in the market. Even when they share from a position where their core competence is not levered they may still benefit by identifying unexpected by products of the project or enhancing scope economies. Thus, knowledge diffusion in the FFEI is proposed to almost always be associated with competence enhancing activities. This finding builds on and modifies previous work in the KPO literature. We also find some support for the equivocality reducing power of new information when technical capabilities of the focal organization are sufficient (i.e. core competence in the area exists). Of course these proposals, while based on a very strong narrative description of one IRL, are still just that, a narrative description of seven cases at a single firm. Much additional work is necessary to undertake. However, at this stage of the KPO literature’s development that the gathering data in-depth at a single firm may be superior to a shallow-breadth survey-report of multiple firms. Future studies should test the validity of our propositions. 30 References Aggrawal, A. (2007). The next big opportunity: Moving up the value chain from BPO to KPO, Knowledge Process Outsourcing (KPO): Origin, Current State and Future Directions (CA: EVS Article ), pp. 4-15. Alam, I (2006). Removing the fuzziness from the fuzzy front-end of service innovations through customer interactions, Industrial Marketing Management, 35, 468-480. Arikan, A. T. (2009). Interfirm knowledge exchange and the knowledge creation capability of clusters, Academy of Management Review, 34(4), 658-676. Burgelman, R. A. (1983). A process model of internal corporate venturing in the diversified major firm, Administrative Science Quarterly, 28(3), 223-244. Cooper, R. G. (1994). Perspective: Third-Generation new product processes, Journal of Product Innovation Management, 11, 3-14. Cousins, P. D., Lawson, B., Petersen, K. J., and Handfield, R. B (2011). Breakthrough scanning, supplier knowledge exchange, and new product development performance, Journal of Product Innovation Management, 28, 930-942. Crossan, M. and Apaydin, M. (2010). A multi-dimensional framework of organizational innovation: A systeatic review of the literature, Journal of Management Studies, 47, 1154-1191. Daft, R. L., H., Lungel. R., and Trevino, L. K. (1987). Message equivocality, media selection and manager performance: Implications for information systems, MIS Quarterly, 11(3), 355-366. Davis, J. and Devinney, T. M. (1997), The Essence of Corporate Strategy (Sydney: Allen & Unwin). 31 Dittrich, K. and Duysters, G. (2007). Networking as a means to strategic change: The case of open innovation in mobile telephony, Journal of Product Innovation Management, 24(6), 510-521. Durand, T. (1998). The Alchemy of Competence, eds G. Hamel, et al. (Strategic Flexibility: Managing in a Turbulent Environment; NY: John Wiley & Sons). Fairless, D. (2007). The little shrub that could - maybe, Nature, 449. Frishammar, J., Floren, H., and Wincent, J. (2011). Beyond managing uncertainty: Insights from studying equivocality in the fuzzy front-end of product and process innovation projects, IEEE Transaction on Engineering Management, 58(3), 551-563. Galbraith, J. (1973). Designing complex organizations (MA: Addison-Wesley). Golfetto, F., et al. (2007). Opening the network: Bridging the IMP tradition and other research perspectives, Industrial Marketing Management, 36, 844-848. Gupta, S., Woodside, A., Dubelaar, C., Bradmore, D (2009). Diffusion knowledge-based core competencies for leveraging innovation strategies: Modelling outsourcing to knowledge process organizations in pharmaceutical networks, Industrial Marketing Management, 38, 219-227. Hakansson, H. and Ford, D. (2002). How should companies interact in business networks, Journal of Business Research, 55, 133-139. Javidan, M. (1998). Core Competence: What does it mean in practice, Long Range Planning 31(1), 60-71. Jorgensen, J. H., et al. (2011). Managing inter-firm colloboration in the fuzzy front-end: Structure as a two-edged sword, International Journal of Innovation Management, 15(1), 145-63. 32 Kandampully, J. (2002). Innovation as the core competency of a service organization: The role of technology, knowledge and networks, European Journal of Innovation Management, 5(1), 18-26. Karlsen, T., et al. (2003). Knowledge, internationalization of the firm, and inward-outward connections, Industrial Marketing Management, 32, 385-396. Khurana, A. and Rosenthal, S. R. (1997). Integrating the fuzzy front-end of new product development, Sloan Management Review, 38(2), 103-1119. --- (1998). Towards holistic "front-ends" in new product development, Journal of Product Innovation Management, 15(1), 57-74. Kim, J. and Wilemon, D. (2002). Focusing the fuzzy front-end in new product development', R&D Management, 32(4), 269-279. Kindler, Jeffrey (2007). Billion dollar pills, The Economist. Koen, P., Ajamian, G., Burkart, R., Clamen, A., Davidson, J., D’Amore, R., Elkins, C., Herald, K., Incorvia, M., Johnson, A., Karol, R., Seibert, R., Slavejkov, A., and Wagner, K. (2001). Providing clarity and a common language to the fuzzy front-end, Research Technology Management, [volume ?] March-April, 46-55. Mintzberg, H. (1979). An emerging strategy of ‘direct’ research. Administrative Science Quarterly, 24(4), 582–589. Moller, K. K. and Svahn, S. (2004). Crossing East-West boundaries: Knowledge sharing in intercultural business networks, Industrial Marketing Management, 33, 219-228. Moller, K. K. and Rajala, A. (2007). Rise of strategic nets - new modes of value creation, Industrial Marketing Management, 36, 895-908. Moller, K. K. and Svahn, S. (2009). How to influence the birth of new business fields network perspective, Industrial Marketing Management, 38, 450-458. 33 Montoya-Weiss, M. and O'Driscoll, T. (2000). From Experience: Applying performance support technology in the fuzzy front-end, Journal of Product Innovation Management, 17, 143-161. Murray, F. (2002), Innovation as co-evolution of scientific and technological networks: Exploring tissue engineering, Research Policy, 31, 1389-1403. Nair, C. (2006). From BPO to KPO, The Hindu. Powell, W. W., Koput, K. W., and Smith-Doerr, L. (1996). Interorganizational collaboration and the locus of innovation: Networks of learning in biotechnology, Administrative Science Quarterly, 41(1), 116-139. Prahalad, C. K. and Hamel, G. (1990). The core competence of the Corporation, Harvard Business Review, 68(3), 79-91. Quinn, J. B (2000). Outsourcing Innovation: The new engine of growth, Sloan Management Review, 41(4), 13-28. Reid, S. and de Brentani, U (2004). The fuzzy front-end of new product development for discontinuous innovations: A theoritical model, Journal of Product Innovation Management, 21, 170-84. Rothaermel, F., Hitt, M. A., and Jobe, L. A. (2006). Balancing vertical integration and strategic outsourcing: Effects on product portfolio, product success and firm performance, Strategic Management Journal, 27, 1033-1056. Un, C. A, Cuervo-Cazurra, A., and Asakawa, K. (2010). R&D colloborations and product innovations, Journal of Product Innovation Management, 27, 673-689. van Echtelt, F., et al. ( 2008). Managing supplier involvement in new product development: A multiple-case study, Journal of Product Innovation Management, 25(2), 180-201. Zhang, Q. and Doll, W. (2001). The fuzzy front-end and success of new product development, European Journal of Innovation Management, 4(2), 95-112. 34