Flowmeters & Regulators: Bourdon Gauge & Thorpe Tube Guide

advertisement

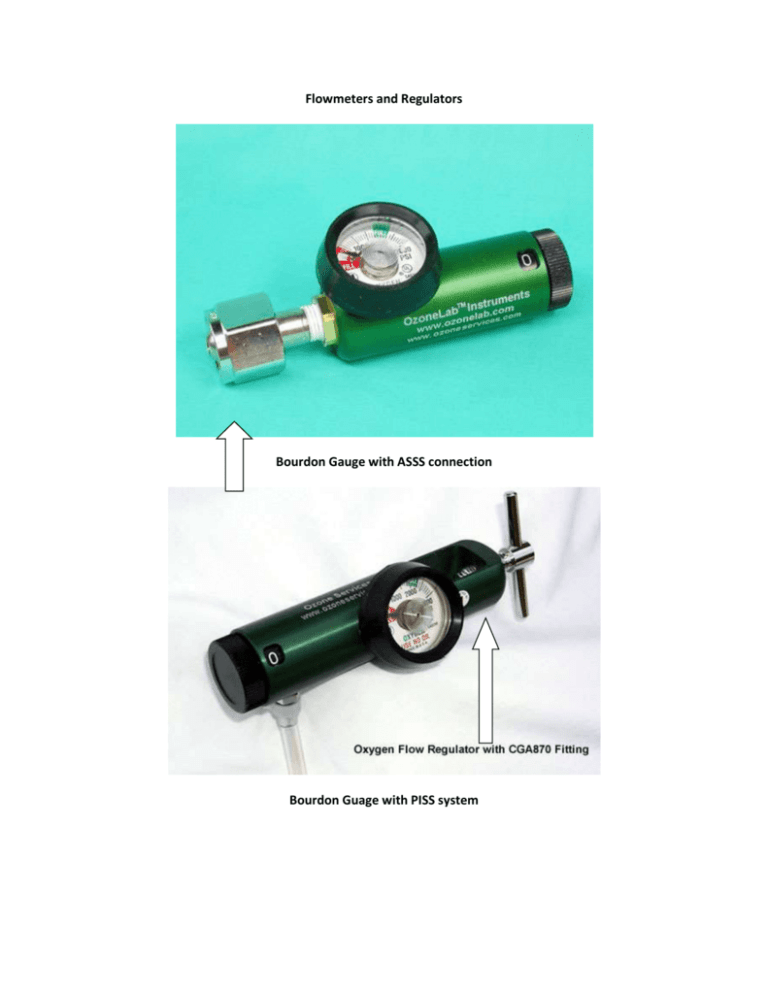

Flowmeters and Regulators Bourdon Gauge with ASSS connection Bourdon Guage with PISS system H tank with ASSS connection and an E tank with PISS system and key Double stage regulator (Bourdon Gauge), 2 pressure relief valves Bourdon Gauge ASSS connection for H tank For continuous aerosol Thrope Tube attached to Pressure reducing regulator (Bourdon) and ASSS connection Thorpe tube attached to bourdon and PISS Oxygen conservation device, attached to a bourdon gauge and PISS system Thorpe tubes with two types of quick connects Quick connect that’s screws in Twist to remove, align pegs with holes Oxygen and Air blender Single stage regulator Zone Valves O2 key and wrench O2 cylinder with handle Concentrator Assembly and Troubleshooting of Flowmeters Assembly 1. Attach the flowmeter to a 50 psig source. Thorpe tubes will have a DISS or quick connect fitting, while Bourdon gauges are usually part of a regulator. 2. Attach the required therapeutic equipment to the DISS fitting on the flow meter. 3. Bourdon gauges measure pressure, and any obstruction can reduce flow substantially while causing an erroneously high reading on the gauge. Be sure to inspect tubing and delivery devices carefully for kinks and other obstructions. 4. Most Thorpe tubes are pressure compensated. This will be noted in the labeling. Also, the float will "jump" when connected to a 50 psig source and the tube is pressurized. The ball in uncompensated Thorpe tubes will not jump when attached to a 50 psig source. Also, uncompensated Thorpe tubes read erroneously low when a distsl obstruction is present. 5. Adjust the flow to the desired setting. In order to read accurately, a Thorpe tube must be vertical. Bourdon gauges function in any position. Troubleshooting 1. Check for leaks: a. At the connection between the flowmeter and the 50 psig source. If this occurs in a regulator, try tightening the connection; if it occurs at a wall outlet, try another flow meter. If a different flowmeter still leaks, the leak is probably in the wall outlet. b. At the connection between the therapy equipment and the flowmeter. c. Within the therapy delivery device. 2. If the flowmeter fails to deliver expected flow or behaves erratically, check the output with a calibrated flow gauge, and if necessary replace it and send it for repair. Terms a. Gas regulator: pressure-reducing valve that uses opposing forces on two side of a diaphragm. Regulators are used in piping systems, on cylinders and inside ventilators to i. Maintain a constant pressure because the pressure from the tanks will decline with use ii. Reduce a high pressure to a lower one. Many regulators reduce the cylinder's 2000 psig to the 50-60 working pressure needed for respiratory care equipment b. Direct action regulators: this regulator operates with a spring-loaded diaphragm that opposes the pressure of the gas. The opposition of the force of the spring and the pressure of the gas keeps the pressure downstream from the regulator at a constant pressure. i. When the poppet is at rest, it is closed against the door that leads to the higher pressure chamber. The lower pressure chamber starts to empty ii. Once the pressure in the lower chamber drops below the spring tension, the diaphragm moves the poppet into the high-pressure chamber. This opens the door. Gas flows from the higher pressure chamber into the lower pressure chamber until it equals the spring tension. iii. Then the poppet closes and the flow stops iv. To keep the pressure constant: if the pressure upstream drops, the poppet opens to allow gas to enter until the pressure equals the spring tension v. The diaphragm position and its regulation of the pressure are determined by the position of the spring. c. Indirect action regulators: works the same way, the gas flows differently d. Single-stage regulators: the regulator reduces the pressure only in one step e. Dual stage regulators: the regulator reduces the pressure with two single stage regulators in series so that the pressure goes from highest to a working pressure. This will have two pressure relief valves f. Multi-stage regulators: more than two single stage regulators in series will have as many stages as there are pressure relief valves. g. Adjustable regulators: Some springs are preset at the factory and others are set by the operator. The regulator in pp. 60 Figure 3-2 is adjustable because the spring is attached to a handle that can be turned to tighten or loosen the tension. h. Preset regulators: will not have the adjustment handle. The tension of each spring will never vary. The regulator in pp. 60 Figure 3-2 is pre-set at the factory. i. Pressure relief valves: when the pressure in a regulator exceeds the appropriate pressure by 50%, the spring disc opens to vent the chamber to the atmosphere. There is one pressure relief valve per reducing stage. Over-pressure tends to happen when there is trash downstream from the regulator causing decreased flow out of the regulator. j. Pressure gauges: manometers are devices used to measure pressure in line or in tanks. In medical gases, these are generally calibrated in psig or in kPa. Can the bourdon gauge be used as a flow meter? Some bourdon gauges have soft copper coils more responsive to lower pressure changes. If these are attached to a dial face that is calibrated in liter/minute, the pressure changes can be converted into a liter flow. a. For it to work properly to display the flow rate, it must have a fixed orifice downstream from the bourdon gauge. A fixed orifice would allow more gas through it as the pressure rises. b. The gauge actually measures the back-pressure created by the restricted orifice. Is the Bourdon gauge an accurate flow meter? The bourdon gauge is an accurate flow meter as long as there are no restrictions down stream. If the line downstream from the regulator was to become occluded the pressure would rise. This rise in pressure would straighten out the copper coil and an erroneously higher flow rate would be displayed. Is the pressure accurate in all conditions? Bourdon gauges on ventilators are exposed to rapid pressure changes. At a respiratory rate of 12 bpm the gauge is rising and falling every 5 seconds. Bourdon gauges will display less accurate pressures in the face of respiratory rates in excess of 12 bpm. [refer: private conversation with electronic experts] Over the last few years, bourdon gauges on ventilators are being replaced by digital monometers with a faster response time. "If the digital monometer has been calibrated, it will always be more accurate than any bourdon gauge." a. Does this device work upside down? Yes, there is no problem with changes in gravity like there are with the other common type of flow meter b. Could Bourdon gauges work in the international space lab? Yes, as long as the cab was pressurized to 760 mmHg [one atmosphere] & if the space lab were heated to room temperature. Explain the structure and the function of the Thorpe Tube. Regulator with thorp tube flow meter: In this device, a variable orifice and a constant pressure will control the flow rate. The 02 flow meter must be placed downstream from a regulator that has reduced the pressure to 50 psig. At a constant pressure, the gas flow will rise as the orifice opens to allow more gas to enter. The orifice is controlled by a needle valve. a. The actual flow rate is measured by the rising of a float. The gas molecules push up on the float until the tube widens enough for them to get around it. As the flow rate increases, the float rises higher. As long as the flow is stronger than gravity the float will stay suspended. b. Can this Thorpe tube be used as a flow meter? Yes, if it is at sea level and room temperature and the appropriate gas is used. c. Is the flow rate accurate in all conditions? No. i. Different gases have different densities and these densities will cause inaccuracies. Flow meters are gas-specific. A 02 flow meter will not be used for compressed air or for C02 delivery. If one uses a 02 flow meter to deliver Helox [02/He mixture] the RCP must make conversions for accuracy. 1. Multiply the 02 liter flow by 1.8 to correct for 80% Helox gas or by 1.6 for 70% Helox mixture ii. The Thorpe tube must be attached to 50 psig,---if it is not, the flow rate will be inaccurate d. Does this work up side down? While the Thorpe tube may not be read when it is turned upside down or on it's side, because the float will move, its flow rate will be constant, but one must turn the Thorpe tube back to upright to read the flow rate. e. The Thorpe tube would be a poor choice for the international space lab because it requires gravity to work. While the needle valve actually changes the flow rate, the float would not be responding properly and the flow meter would not be functional as a monitoring devise. i. One would do better with a bourdon gauge type of flow meter, or one would use a flow restrictor rather than a flow meter. The flow restrictor has several adjustable orifices that can be selected by turning a knob. Differentiate between compensated and non-compensated flow meters 1. Compensated Thorpe tube flow meters are compensated for the back pressure which in the case of the bourdon gauge will cause inaccurate readings 2. The compensated Thorpe tube will read the accurate flow rate as restriction downstream from it rises. As the flow is restricted, the flowmeter will display lower and lower flows. If there is complete occlusion, there will be a zero displayed. If the resistance is removed, the flow will increase. For example: you place a cool humidifier on the nipple of a flow meter set at 5 lpm. Because the humidifier's outlet is not patent, it causes a complete occlusion and the flow rate will drop from 5 lpm to zero. As you adjust the flow rate nothing happens; the float stays at the bottom. Once the humidifier is removed, the flow rate rises back to 5 lpm. 3. The placement of the float inside the Thorpe tube will determine whether your flow meter is compensated or non-compensated. a. An uncompensated flow meter will have a float that is downstream from the valve. This float is subjected to atmospheric pressure i. if there is an obstruction down stream such as attaching an entrainment device onto the flow meter, the back pressure builds up and effects the float. ii. It will rise & record an erroneously high flow rate because the density of the gas under the float has been increased. b. A compensated flow meter will have a float that is upstream from the valve so that the float will be in contact with the wall pressure rather than the atmospheric pressure. c. A quick way to remember the compensated flow meter: Identify the advantages of having a compensated flow meter? a. The flow is accurate in the face of an obstruction down stream. Imagine what would happen if your 02 line became occluded or pinched off? Your patient could become hypoxic. i. The compensated flow meter would show that the flow rate is zero ii. The uncompensated flow meter would display an erroneously high flow rate b. If the ordered flow rate is too high for your device [such as a cool humidifier or an entrainment device], as you increase the flow, the indictor would show that the flow is not increasing as you turn it…this means there is restriction down stream How can I tell I have a compensated flow meter? a. Read the label on the flow meter b. If there's nothing written, you would attach the flow meter to the wall or the tank. As soon as the inlet is in contact with the high pressure, the float [ball] will leap to the top then fall back to the correct flow. i. The uncompensated flow meter's float will not leap up Why can you not use an air flow meter for 02 delivery? you cannot because the DISS connection will not allow you to attach the air flow meter to the 02 outlet you must not: i. because the air flowmeter is dirty and can be a fire hazard as gas enters the regulator ii.. because Thorpe tubes are calibrated for their gas and the flows will not be accurate. Differentiate between flow restrictors and flow meters When some persons go home on 02, you may not trust them to not change the proscribed liter flow. The flow restrictor can be preset & to get a different flow rate, the home care RCP needs to change the flow restrictor's outlet. Some flow restrictors are operated off 50 psig for the hospital or for cylinders but other flow restrictors use 20 psig pressures such as used with LOX [liquid 02 systems]. Flow restrictors are accurate only at their rated pressures What would be an advantage to a flow restrictor? A patient with chronic hypercapnia cannot change his 02 to a dangerous level where he is no longer breathing off his hypoxic drive. With a flow restrictor, the patient will get only his proscribed liter flow--- not more--- not less Because they are so simple to operate, flow restrictors are getting a lot of use in air transport and these are the flow meters of choice in the international space station's hospital.