Summary of Feasibility Study

advertisement

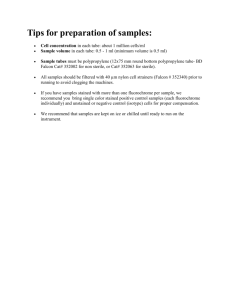

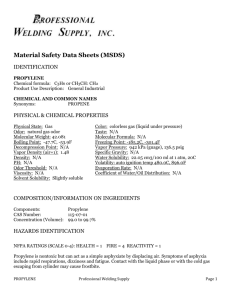

Industrial Development and Summary of Feasibility Study Page 1 of 3 Gas to Polypropylene Project (GTPP)1 Renovation Organization of Iran To be presented to the Industry Development Committee Form Issuing Authority: □ Department of Industrial Investment Development □ Department of Advanced Industrial Development 1. Project introduction and Purpose: Propylene and polypropylene production based on using gas feed and passage through the intermediate product methanol Gas, together with air and water, is first turned into synthesized gas in a process that takes place in the reformers, and then changed into methanol. In fixed-bed reactors, Methanol is converted first into propylene, gasoline, and liquefied gas, as well as a small amount of ethylene, with the ethylene being used as a copolymer together with propylene to produce polypropylene 2. Types and characteristics of the products The project’s saleable products are methanol, dimethyl ether, propylene, liquefied petroleum gas, gasoline 90-95 octane, polypropylene (polypropylene, liquefied natural gas, and gasoline are the end products) 3. Market analysis Major consumers: Southeast Asia, China Demand (present): 90 million tons for polypropylene (the main product) and 125 million tons for propylene in 2015 Demand (future): 110 million tons for polypropylene and 150 million tons for propylene in 2020 Domestic production (at present): 943 thousand tons of propylene and 1105 thousand tons of polypropylene Ongoing projects: 1940 thousand tons of propylene and 750 thousand tons of polypropylene Imports and Exports: 65 thousand tons of imports and 255 thousand tons of exports in 2013 Forecast on project capacity and product composition: 600 thousand tons of propylene and 6 thousand tons of methanol per day, and 165 thousand tons of gasoline and 63 thousand tons of LPG per year Percent of actual market shares held by leading vendors and producers (polypropylene) 1. LyondellBasell: 10 %; 2. Sinopec: 7.8%; 3. Brasscom: 6.2%; 4. SABIC: 5.4%; 5. PetroChina: 4.7%; 6. Reliance: 4.3%; 7. Borealis: 4.3%; 8. Total: 4.25%; 9. ExxonMobil: 3.6%; 10. Formosa Plastics: 3.6% Forecast on total product cost: Considering the price of natural gas as 10 cents per cubic meter and an investment of 1.5 billion dollars for the integrated GTPP complex and LURGI process, the total product cost for polypropylene would be about 900-920 dollars per ton (taking by- products into account) Selling price of the product: 1450 dollar Selling price of the similar foreign product: 1450 dollars Gas to polypropylene 1 Industrial Development and Summary of Feasibility Study Report Renovation Organization of Iran Page 2 of 3 Gas to Polypropylene Project (GTPP) To be presented to the Industry Development Committee 4. The desired production method and technology 1. In the reformers, natural gas, together with water vapor, is changed into synthesized gas which is converted into raw methanol and then into pure methanol in the reactor 2. Methanol is first converted into DME (dimethyl ether) in the primary reactors, and the mixture of DME and methanol is then converted into propylene in three fixed-bed reactors. Propylene, methanol, and DME are separated from the mixture, uncombined methanol and DME are returned to the initial stage of the process, and propylene and other products are purified. 3. The propylene and ethylene produced in the reactors are converted into polypropylene (with various grades) and packaged Methane technology: Topsoe-Lurgi MTP technology: Lurgi P.P technology: Basell, JP Morgan Chase & Co, Mitsui, Sumitomo 5. Physical dimensions of the project Project location: On the northern shores of the Persian Gulf and the Oman Sea , or along the coast of the Caspian Sea Land area: About 4 million square meters Floor area: - Production: Exposed units in a total area of 50,000 square meters (the exact figures shall be determined during the engineering phase) - Service Section (Warehouses, repair & maintenance, etc.): Approx. 50,000 square meters - Offices: Approx. 5000 square meters Infrastructure facilities required for the project: - Water: 40,000 cubic meters per day - Electricity: 70 megawatts ( varies according to process type) - Gas: 1750 million cubic meter per year - Transportation infrastructure: Export port Size and composition of human resources in the project: Operation and repair: 1280; ancillary services 50 ; administrative : 150 Industrial Development and Summary of Feasibility Study Report Renovation Organization of Iran Gas to Polypropylene Project (GTPP) To be presented to the Industry Development Committee 6. Economic dimensions of the project Estimate of investment requirements: - Foreign currency: 1,350,000,000 dollars - Domestic currency: 2420 billion rials Estimate of fixed investments: - Foreign currency: 1100 million dollars - Domestic currency: 2420 billion rials 7. Forecast on the economic indicators of the project Index/Indicator Project Index Production break - even point 65% of the capacity Payback period 4 years I.R.R 25% N.P.V (at interest rate of 25%) 532,000,000 dollars 8. Project schedule 1. Start of engineering phase: 2016 2. Start of unit construction: 2017 3. Year of starting operation: 2019 9. Final evaluation 1. The project will be cost effective only as a GTPP project. 2. The project site must be by the sea to have access to water and gas 3. Since all products are exported, easy access to export terminals must be provided 4. The Southeast Asian and Chinese markets are the first target areas of the project Page 3 of 3