Mr - QSEN

advertisement

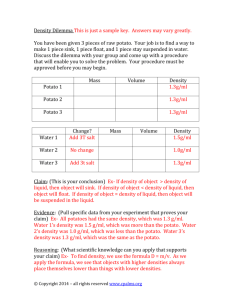

Mr. Potato Head Simulation Instructions & Teaching Points Beth Murphy, MD Eric Alper, MD Eric Dickson, MD (*Inventor) Simulation Summary: A bus filled with 16 Potato Head family members is in a terrible crash! At the scene of the accident, Emergency Medical Services arrives to find only scattered body parts. Luckily, one of the family members was carrying a photo album with a photo of each family member. There are men, women, children, and pets on the bus. A health care team is waiting in the emergency room to correctly assemble as many family members as possible in 7 minutes. On the health care team, two of the members are designated “Implantation Specialists” (a.k.a. trauma surgeons). Only they can “implant” the parts into the potato bodies. The number of correctly assembled Potato Heads and the number of errors are tracked through each PDSA cycle. Page 2 Educational Goals: 1. Participants will understand concepts of Lean Process Management including “waste”, non-value added work, elimination of non-value added tasks in a work process, role of “the system” in quality, and importance of team based care. 2. Participants will understand steps in a PDSA cycle. 3. Participants will understand that with small changes in system, both quality and efficiency can be improved. 4. Applying insights gained from this interactive and fun exercise, participants will be energized to bring new Quality Improvement skills and knowledge back to their clinical settings to begin or enhance improvement efforts. Target Audience: 1. Medical Students, Residents, Faculty, Nurses, other health care providers and team members 2. Anyone! Has been done successfully with 9 year olds at summer camp, as well as industrial engineers! Number of Participants Needed: 1. Ideal number is 7-8 members per team 2. Has been done with as few as 4 participants, or 125 students in teams of 8-10 members. Page 3 Materials Needed: 1. Parts for 16 assembled Mr. Potato Heads. (1 bag per team) a. Purchase different sizes and types of Potato Heads to demonstrate patient variety. There are adult sized, “child” sized, and even pets (cats/dogs). There are many different types of Mr. Potato Head (traditional, Toy Story, Star Wars, Sports Teams, Holiday versions (Santa, Valentine’s Day, Halloween, Valentine’s Day). In addition to toy/department stores, you can find these online at EBay, etc. b. Keep extra parts that come with each kit to demonstrate “waste” in system! c. Assemble 16 different Potato Head family members wearing various accessories and take photos as below. 2. Laminated Photos of assembled Potato Heads. (4”x6” or 5”x7” work best; if bigger, takes up too much space on table) 3. Canvas tote bag (“THE BUS”) to keep one “set” of 16 Potato Heads, extra parts, and laminated photos. 4. One table per team. 5. Quality Inspection Table/Area 6. Stopwatch Concepts to Review before Beginning Simulation: 1. Core Concepts of Lean Process Management: 1. 2. 3. 4. 5. Derived from Toyota Production System Efficiency and Quality are both important Every step in process should add “Value” Eliminate all “waste” from the system Each member of the team is valued for their input AND their ideas for improving the process 2. Components of PDSA Cycle: Page 4 Before Beginning the Simulation: 1. Ask for 3 volunteers and have them come up front and turn away from the crowd. Demonstrate that each of them has no additional formal training in Mr. Potato Head assembly and are therefore equally trained providers. 2. At the front of the room set Up “Three Systems” Description SYSTEM 1 Volunteer should have a photo of the assembled Potato Head and all of his/her parts arranged in an organized fashion for quick assembly. Provide only the parts that are needed, right side parts on right side of body/left side on left side etc. SYSTEM 2 Volunteer should have a photo of the assembled Potato Head and all of his/her parts in one pile. SYSTEM 3 Volunteer should have a photo of the assembled Potato Head and bag filled with all of his/her parts PLUS many other miscellaneous parts. (Usually this is the parts for the 14 other Potato Heads not used in Systems 1 & 2 above, along with all of the extra parts.) Photo 3. Assign one volunteer to each of the “Systems.” 4. Ask volunteers to assemble their Mr. Potato Heads as quickly as possible. Using a stopwatch, record the assembly time for each “System”. a. Typically System 1 takes approximately 20-30 seconds to complete and System 2 approximately 30-45 seconds. System 1 & 2 volunteers are usually done while system 3 volunteer has barely found one or two pieces. Don’t make System 3 volunteer finish. It could take all day. 5. Talk with the group about the concepts of “waste” in a system and value-added work. System 1 is comprised of almost all value added work (assembling Mr. Potato Head). System 2 has some waste/non-value added work as the provider Page 5 has to search for parts in the pile. The additional time needed for this assembly represents “non-value” added work. System 3 is filled with waste/non-value added work as the provider spends most time searching for parts due to all of the extra parts/clutter (aka waste). 6. Ask for examples of non-value added work in their current health care settings. Some examples might include finding forms and equipment, documentation requirements, regulatory requirements, tasks needed to support another area. 7. Note: If a system designed with no waste (i.e. System 1 above) allows for assembly of each Potato Head in 25 seconds, then in the full simulation below, all 16 Potato Head family members should be able to be assembled in less than 7 minutes. (25 sec x 16 potatoes = 400 seconds (6.67 minutes)) Simulation: 1. Set up Scenario: A bus filled with 16 Potato Head family members is in a terrible crash! At the scene of the accident, Emergency Medical Services arrives to find only scattered body parts. Luckily, one of the family members was carrying a photo album with a photo of each family member. There are men, women, children, and pets on the bus. A health care team is waiting in the emergency room to correctly assemble as many family members as possible in 7 minutes. On the health care team, two of the members are designated “Implantation Specialists” (a.k.a. trauma surgeons). Only they can “implant” the parts into the potato bodies. The number of correctly assembled Potato Heads and the number of errors are tracked through each PDSA cycle. GOAL: Correctly assemble as many “patients” as possible in 7 minutes 2. Describe Simulation Roles: Implantation Specialists (2): The only team members who may assemble “patients” Providers/Practice staff (2-6): assembling “patients” May perform any function other than Observers: (If team sizes big enough) Observers record highlights of each PDSA cycle on the recording sheet. Observers may not communicate with the team during the PDSA cycle. Observers may communicate and share observations with the team during the QI discussion phase. 3. PDSA Cycles Page 6 Round 1: Give the groups 1- 2 minutes to organize themselves and assign roles. Place one closed bag (aka “bus”) with photos inside on each table. Begin the first round of the simulation. Stop the simulation at 7 minutes. Announce when 3.5 minutes has passed and when one minute is left. Completed Potato Heads must be inspected for quality. If you have a very large group of participants, you can have an inspection area where someone keeps track of # assembled, # correct, # errors, etc. If you have just one table of participants, the completed Potato Heads can be brought to simulation leader to inspect. Record each team’s results at the front of the room after each round. For example: PDSA 1 Team 1 2 3 # Built 5 4 2 # Inspected 5 3 2 # Passed 3 2 2 # Rejected 2 1 2 At the completion of the first round, share a just a couple of observations about things you noticed in the groups, noise level of the groups, level of chaos, physical organization of parts and team members, communication between team members, decision making etc. Remind participants that they are doing PDSA cycles. So far, they have done Plan, Do, and Study. Now they need to Act by making changes and seeing if it results in any improvement. Round 2: Change the bags between groups so there are new “patients” to work with. Remind learners they don’t see the same patients each day. Give the groups 2 minutes to talk among themselves to make changes in how they put the Mr. Potato Heads together. If you are using the observer roll, this is when the observer can share what they observed and make recommendations to the group. Stop the simulation at 7 minutes. Be sure to record the number of Mr. Potato Heads built, inspected, passed and rejected. Record round 2 results at the front of the room. Take 2 – 3 minutes to ask each group for one thing they noticed about how their team worked and then observe the difference in the number of Mr. Potato Heads built, inspected, passed and rejected. Round 3: Change bags between groups again and add a twist if you want. Stop the simulation at 7 minutes, record the numbers and finish up with a discussion on lessons learned. The final discussion period is where you can Page 7 tie up the specific teaching points you want to emphasize and help the group think about how they might apply lessons learned to their clinical setting or improvement effort. Additional Variations for the 3rd simulation: Ask two members of the team to move to another team – representing float staff, staff covering vacations or new hires There’s been a layoff! Remove 1-2 members of a team and have them only observe. Participants may find that the team is more efficient with fewer people (although we always ask for more help!) Move the “implantation specialists” to another team – representing new providers. Add a constraint such as the inspectors – representing common bottlenecks such as registration, rooming, immunization Promote a quiet or shy person to leadership role Ask the most vocal/natural leader to stand back and observe. Require one team to adopt a different approach of used by another team Session Review/Key Teaching Points Learned What I Learned from Mr. Potato Head: 1. The system is a critical determinant of performance; usually more significant than the skills or efforts of the people. 2. Good communication is essential for a high-functioning team. 3. Good ideas for improvement can come from anyone on the team. 4. Data is essential to drive improvement efforts. 5. Repeating PDSA cycles is a valuable process in Quality Improvement. 6. Efficiency is enhanced when waste is reduced. 7. All steps should add value. Strive to eliminate all steps that do not add value. Page 8 8. With very simple changes in system, you can improve both quality and efficiency! 9. QUALITY IMPROVEMENT CAN BE FUN! Additional Attachments: 1) Power Point Slides 2) Inspection Reporting Sheet Created: Jeanne.mcbride@umassmemorial.org 11/30/10 Revised: Elizabeth.Murphy@umassmemorial.org 6 UMass Residents Doing Mr. Potato Head exercise in April 2011 1/23/14 Inspection Table