Sample Lab Report II

advertisement

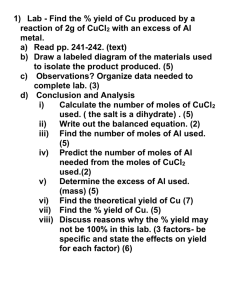

CHE 115 LAB #8 Name: Matt Wilhelm Date 11/8/2011 Experiment 8: Coordination Chemistry Purpose In this experiment a coordination compound was made by reacting copper ions with a common ligand, ammonia, and the percent yield of the reaction was determined. A sample of copper sulfate pentahydrate was obtained and massed. This sample was dissolved in water and then reacted with ammonia and 95% ethanol. After the reaction, using a vacuum filtration system the solid product was collected on a vacuum filter. During this process the substrate was washed with ethanol/ammonia and 95% ethanol to completely dry solid. Once the product was dried completely the mass of the product was recorded. This value was then used to calculate the percent yield, theoretical yield and actual yield of the reaction. This process utilizes the ionic properties of the solid being used in the reaction as well as the chemical and physical properties of coordination compounds to obtain the results portrayed in the experiment. Procedure Procedure is listed in CHE 115 Lab General and Analytical Chemistry III Laboratory Manual Fall Quarter 2011, DePaul University Experiment 8. There were no deviations from the procedure listed in the Lab Manual. Data and Results Table 1, Raw Data Mass of CuSO4 ٠ 5H2O (g) Mass of beaker (g) Mass of beaker & product (g) Mass of product (g) Molar mass [Cu(NH3)4]SO4٠ 5H2O (g/mol) Percent yield [Cu(NH3)4]SO4٠ 5H2O 1.553 g 31.48 (g) 32.5204 (g) 1.0404 (g) 245.772 (g/mol) 68% *The above data was collected and calculated during the experiment. The percent yield of the product was 68%. Experimental Description The synthetic process observed during the experiment was the dissolution of CuSO4٠ 5H2O and the synthesis of [Cu(NH3)4]SO4٠ 5H2O. This process began by massing out a sample of copper (CuSO4 ٠ 5H2O), for this experiment the mass used was 1.558 grams. This copper sample was then dissolved in approximately 5.0 mL of water. Once this solid was dissolved 5 mL of 15 M ammonia was added to the solution and covered with a watch glass so that no evaporation will impact the results. The solution was light purple after adding the ammonia. Next and under a hood, 8 mL of 95% ethanol was added to the solution and stirred with a glass rod. The solution turned dark purple at this point. Once the solution was mixed properly it was cooled in an ice bath for 10 minutes with a watch glass covering it. During the process the solution is able to react and the solid forming is able to precipitate. During this process the vacuum filtration system was set up. The filter paper was moistened so that no precipitate will get through the filter and into the filtration beaker. Once the solution had cooled for 10 minutes, the solution was slowly poured onto the filter paper set up in the filtration device. The filtration device began sucking the liquid and aqueous material through the filter while the filter paper collected the solid. The color of the filtrate was dark bluish/purple and the solid forming on the filter paper appeared to be a light bluish/purple color. The color of the filter paper was similar but lighter than the initial copper sample (CuSO4 ٠ 5H2O). As the product was finishing filtering it was then washed with 10 mL of 1:1 ethanol/ammonia solution. Using a Pasteur pipet small portions of this wash solution were added to top of filter paper. After the 10 mL of the ethanol/ammonia solution was finished the product was washed once again with 4.5 mL of 95% ethanol. During this process the solid forming is able to be isolated as the wash substances are stripping any unnecessary ions from the surface of the solid. The solid was then dried for an additional 10 minutes. Using a spatula the solid collected on the beaker was scraped into a pre-weighed beaker. The initial and final beaker weights can be seen in Table 1. The final weight of the substance collected in the beaker was established by using a mass by difference method shown below in the calculations section. Using the final weight of the substance the theoretical yield, percent yield and actual yield of the solid formed [Cu(NH3)4]SO4٠ 5H2O were calculated. Calculations Theoretical Yield To calculate the theoretical yield of [Cu(NH3)4]SO4٠ 5H2O from the starting amount of CuSO4 ٠ 5H2O the mass of the sample of CuSO4 ٠ 5H2O must be divided by the molecular mass of CuSO4 ٠ 5H2O. This value is the moles of theoretical yield and must then by multiplied by the molecular weight of the product, this will reveal the theoretical yield. 1.5528 g CuSO4 ٠ 5H2O (g) / 249.7 g/mol = 0.006218662 moles theoretical 0.006218662 moles theoretical x 245.772 g/mol = 1.5284 g theoretical yield Actual Yield The actual yield was found using a mass by difference technique. The mass of the beaker was obtained. The product was the placed into the beaker and weighed again. The initial weight of the beaker without the product was subtracted from the weight of the beaker and the product. [Mass beaker + Product] – [Mass beaker] = Actual Yield (g) 32.520 g – 31.480 g = 1.040 g Percent Yield The percent yield of the product was established by using the theoretical yield and the actual yield obtained above. The actual yield was divided by the theoretical yield. This value was then multiplied by 100% and the resulting value is the percent yield. [Actual Yield g] / [Theoretical Yield g] = Percent Yield % 1.0404 g / 1.52837 g = 0.680 x 100% = 68% Discussion Based upon the color of the filtrate it is not possible to obtain a 100% yield on this reaction. For starters, obtaining 100% yield in any reaction performed by hand or imperfect machines is not likely as there are many ways in which failure to achieve 100% yield can happen. With respect to the color of the filtrate, it doesn’t appear likely to obtain 100% yield. The color of the initial substrate was a definitive bright light blue color. The color of the filtrate was a darker blue and the color of the solid collected on the filter was a lighter blue. With this being said, the color on the filter and the color of the filtrate had similar appearances in places. The color of the filtrate is obviously part of the compound that is not forming the solid and is definitively different from the color of the solid forming on the filter. The color of the substance on the filter is more similar to the initial compound used although there appears to be components of each substance both in the filter and filtrate. With this being said it appears that some of the solid was able to get through the filter and some of the liquid or aqueous material was dried to the filter. This means it is unlikely to get a 100% yield as there is may be solid lost in the beaker through the filter or imbedded on the filter itself. In addition, it is also possible that some of the solution evaporated during the initial mixing phase even though a watch glass was used.