Enterprise PDM

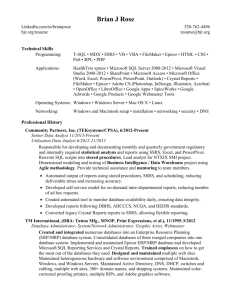

advertisement

Enterprise PDM Integration Survey Purpose The purpose of this document is to provide a baseline for an integration discussion. The document is broken down into three sections. The first section, Enterprise PDM, is an overview of the common Enterprise PDM integration points for review. The second section, Needs Assessment, is meant to be completed by the customer and is useful to get an overview of how the customer will reap the benefits of the potential integration. The third section, PLM/MRP/ERP Capability, is meant to be filled out by either an internal to customer application specialist, application consultant provided by customer, or the application vendor themselves. Table of Contents Purpose ......................................................................................................................................................... 1 Enterprise PDM ............................................................................................................................................. 2 Export to Excel .......................................................................................................................................... 2 XML File Import/Export............................................................................................................................. 2 Direct API Programming............................................................................................................................ 3 Direct SQL Extraction ................................................................................................................................ 3 Distribution Files ....................................................................................................................................... 3 Needs Assessment ........................................................................................................................................ 4 PLM/MRP/ERP Description ....................................................................................................................... 4 Part Numbering......................................................................................................................................... 4 Bill of Materials ......................................................................................................................................... 4 Part Attributes/Meta-Data/Properties ..................................................................................................... 4 PLM/MRP/ERP Capability ............................................................................................................................. 5 Part Numbering......................................................................................................................................... 5 Bill of Materials ......................................................................................................................................... 5 EPDM Integration Survey Page 1 of 5 Enterprise PDM SolidWorks Enterprise PDM has a few generally accepted methods of integrating data into other systems. These range from the very basic and manual (or out of the box) to the more complicated, automated and expensive. The best way to integrate applications is to fully discuss what you want to get from the integration, what the value of that is to the company, and the cost of that piece. Many times companies have scaled back on a full integration based upon the cost to value justification. Export to Excel Every Assembly and Named BOM has an export option to extract the current BOM View into Microsoft Excel. The formatting of the data can be controlled through setting up different Views. A View will not only determine which columns to show for the items’ properties, but also what those column names should be. It’s quite easy to get an exported file to transform the columns to an acceptable import format through this way. Advantage: Cost. This is an out of the box solution that takes a minimal amount of time to construct the customized BOM View for export. Disadvantage: This is a manual data extraction and also requires a manual data import into the other system. The format for import into the other system might not be acceptable. XML File Import/Export XML is a structured text document that is becoming the standard for importing/exporting information between different business systems. Enterprise PDM provides an option for both import and export that allows the files to be created at a pre-determined event. For example, when an assembly is released through an Enterprise PDM workflow, the XML file of the full BOM structure and associated properties can be automatically created into a pre-determined directory. Additionally an XML file can be created by the other system into a pre-determined directory that Enterprise PDM can read in. This is commonly used for importing properties from the other system (like cost and vendor information). Advantage: Cost. This is an out of the box solution that takes a minimal amount of time to construct the property mapping and events for export. Disadvantage: Older business systems typically cannot read XML files. Additionally the XML syntax differs commonly between systems and a middleware “translator” might need to be created to modify the PDM XML into the PLM/MRP/ERP XML file. Some systems cannot import indented bill of materials. EPDM Integration Survey Page 2 of 5 When this is the case the “translator” application might read in one PDM XML file and create multiple PLM/MRP/ERP XML files. Direct API Programming Enterprise PDM comes with a full API (application programming interface) layer than can be utilized to automate the data extraction process. Advantage: More control can be obtained on the exact information you want to extract. Disadvantage: Cost and complexity. The API is meant to automate common Enterprise PDM tasks; it can be used for data extraction but does take a little more work to do so. The more complex the solution, the more costly the maintenance will also be. Direct SQL Extraction Enterprise PDM utilizes Microsoft SQL as the database backbone. The database is kept open for query building and report extraction. Custom SQL queries can be built to extract data directly from the database for import into other systems. Typically there needs to be an application layer for the PLM/MRP/ERP system controlling the extraction. Advantage: More control can be obtained on the exact information you want to extract. Disadvantage: Cost and complexity. The database structure isn’t guaranteed to not change between releases so a testing development effort will be required prior to upgrades. Depending on the PLM/MRP/ERP application, the complexity can be fairly high. Distribution Files Distribution files are the versions of the CAD documents that you want distributed to the rest of the organization. Many times this means that the CAD files are converted to STEP files and the CAD drawings are printed to PDF format. Some PLM/MRP/ERP applications will then either want to hyperlink to these documents, or attach them directory. GoEngineer has helped customers with a simple tool to allow configuration of how, when, and where these files are created. Additionally Enterprise PDM has a unique ability to support standard Windows hyperlinks. These are special hyperlinks that allow the PLM/MRP/ERP application to link to the latest release of the associated document by opening up the Enterprise PDM system to get the file. This assumes that the end user of the hyperlink as a thick client of Enterprise PDM installed. EPDM Integration Survey Page 3 of 5 Needs Assessment The following section is meant to help the customer determine what type of integration is going to be the most beneficial to their business processes. Feel free to deviate from the questions/sections listed here, this is meant as a guideline to help the conversation. Priority of each of the integration points will also need to be determined. PLM/MRP/ERP Description What PLM/MRP/ERP application is currently being utilized? o What version/release? o Are you actively receiving support from the PLM/MRP/ERP vendor? Please provide a brief overview of all the areas of the business that are utilizing the PLM/MRP/ERP application. Part Numbering How do you currently handle part number generation from the Engineer’s perspective? If there is more than one type, please describe each. o Example: We have vendor parts that are auto-assigned a VEN-XXXX number in the ERP system with a second field for the mfg. part number. Manufactured parts are autoassigned the next number in the general sequence. Do you see Enterprise PDM being used to create the Part Number? Bill of Materials Overall, what portion of your product BOM do you plan on having in Enterprise PDM? o Example: We make electro-mechanical devices. About 80% of our item numbers are mechanical and the other 20% electrical. We only plan on keeping the mechanical BOM in Enterprise PDM based upon the CAD structure. Do you want the BOM to be able to be pushed from Enterprise to ERP? Is there a release process in ERP that is followed prior to manufacturing? Please describe when in your release process would the BOM be pushed from Enterprise into the PLM/MRP/ERP system. o Example: There are two times a BOM push will need to happen. The first is for new product introduction release from Eng. for review to MFG. The second is upon an ECO change to an existing product and the CCB review process is approved. Part Attributes/Meta-Data/Properties What relevant data needs to be pushed from the Enterprise PDM system into the PLM/MRP/ERP system? o Example: Part Number, Material, Weight, MFG. Part Number EPDM Integration Survey Page 4 of 5 What relevant data needs to be pulled from the PLM/MRP/ERP system and pushed into Enterprise PDM? o Example: Cost, Vendor PLM/MRP/ERP Capability Part Numbering If part number generation is managed by the ERP application, what kind of automated methods does it have for creating items with new part number and returning a part number (i.e. API calls, etc…). Please be as descriptive as possible. If no option exists to automate the part number generation in PLM/MRP/ERP and the part number is going to be created in ERP, then it will be a manual step for Engineering to generate the item in ERP, and give the part number back to the CAD/PDM object. Is this acceptable? Bill of Materials What import options does the ERP application have for items and BOM’s? Please be as descriptive as possible. o Example: Excel, CSV, Tab delimited, XML Does it take two different imports, one for items and one for the BOM structure of those items? o Does the BOM import fail if the items do not exist? Can the import process receive structured BOM’s or only Flattened BOM’s? o Flattened BOM only contains a single level of items. So for a full assembly you would have multiple BOM imports in flattened, one for each level. If this is the case, does the order of import impact the success of the import? Do you need position numbers in the BOM? How is the level of object set for import format? o Example: In the CSV file for import, the first column labeled Level needs to start at 1 for the top level BOM object (the parent) and then each consecutive level counts up from there. Can XML files be used for import? o Do you have the schema required? o Are there stipulations for import when using this method? Can the BOM import create new BOM’s or only modify existing ones? Can the BOM import redline an existing BOM? o Does it only do this when just the changes are imported? Or can it import a full BOM and recognize the additions, modifications, and deletions? If possible, please provide examples of import formats for review. EPDM Integration Survey Page 5 of 5