UDOT PM & RM Program

advertisement

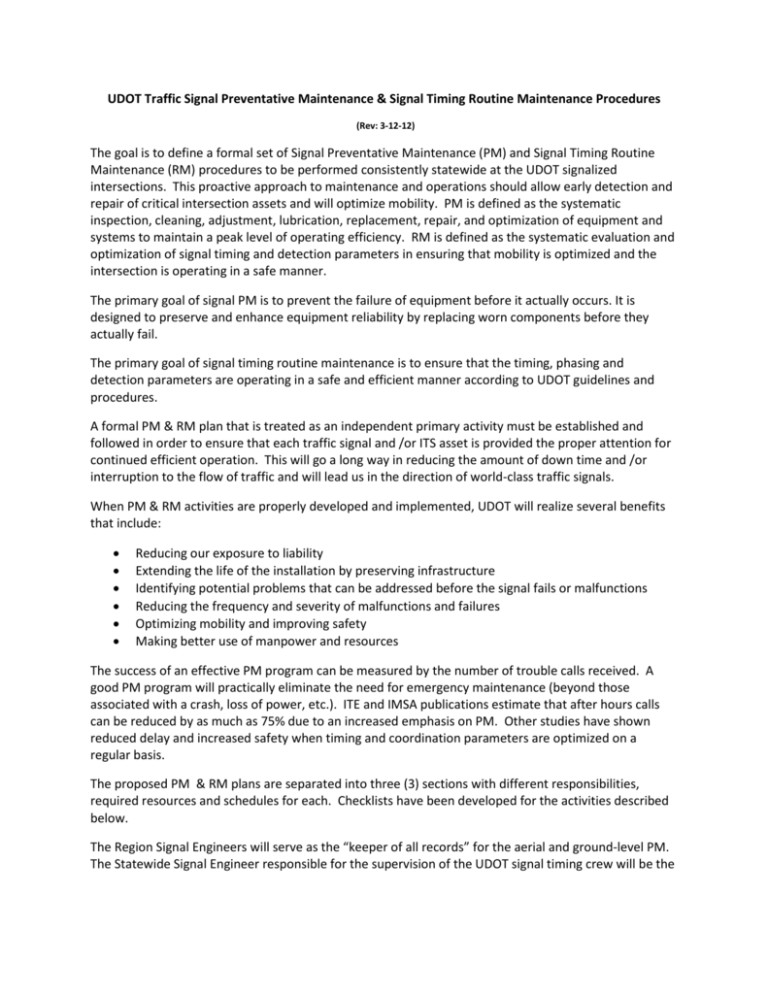

UDOT Traffic Signal Preventative Maintenance & Signal Timing Routine Maintenance Procedures (Rev: 3-12-12) The goal is to define a formal set of Signal Preventative Maintenance (PM) and Signal Timing Routine Maintenance (RM) procedures to be performed consistently statewide at the UDOT signalized intersections. This proactive approach to maintenance and operations should allow early detection and repair of critical intersection assets and will optimize mobility. PM is defined as the systematic inspection, cleaning, adjustment, lubrication, replacement, repair, and optimization of equipment and systems to maintain a peak level of operating efficiency. RM is defined as the systematic evaluation and optimization of signal timing and detection parameters in ensuring that mobility is optimized and the intersection is operating in a safe manner. The primary goal of signal PM is to prevent the failure of equipment before it actually occurs. It is designed to preserve and enhance equipment reliability by replacing worn components before they actually fail. The primary goal of signal timing routine maintenance is to ensure that the timing, phasing and detection parameters are operating in a safe and efficient manner according to UDOT guidelines and procedures. A formal PM & RM plan that is treated as an independent primary activity must be established and followed in order to ensure that each traffic signal and /or ITS asset is provided the proper attention for continued efficient operation. This will go a long way in reducing the amount of down time and /or interruption to the flow of traffic and will lead us in the direction of world-class traffic signals. When PM & RM activities are properly developed and implemented, UDOT will realize several benefits that include: Reducing our exposure to liability Extending the life of the installation by preserving infrastructure Identifying potential problems that can be addressed before the signal fails or malfunctions Reducing the frequency and severity of malfunctions and failures Optimizing mobility and improving safety Making better use of manpower and resources The success of an effective PM program can be measured by the number of trouble calls received. A good PM program will practically eliminate the need for emergency maintenance (beyond those associated with a crash, loss of power, etc.). ITE and IMSA publications estimate that after hours calls can be reduced by as much as 75% due to an increased emphasis on PM. Other studies have shown reduced delay and increased safety when timing and coordination parameters are optimized on a regular basis. The proposed PM & RM plans are separated into three (3) sections with different responsibilities, required resources and schedules for each. Checklists have been developed for the activities described below. The Region Signal Engineers will serve as the “keeper of all records” for the aerial and ground-level PM. The Statewide Signal Engineer responsible for the supervision of the UDOT signal timing crew will be the “keeper of all records” for the signal-timing RM. A copy of the aerial, ground-level and signal-timing PM and RM reports will be forwarded to the Traffic Signal Operations Engineer monthly. AERIAL PM: This activity includes maintenance items that require the utilization of a bucket truck and closing of a lane in order to properly perform the work. Examples include but are not limited to the following: Group replacement of all signal LED’s (including pedestrian heads), straightening and tightening signal heads, ensuring signal hoods, back plates, end caps and upper hand-hole covers are in place, and cleaning the cameras (both video and CCTV) and traffic signal lenses. This activity will be performed every four years as part of the current LED replacement schedule until Year 2016, where this activity will be modified to be performed annually. To keep on track, the regions need to go at the following rate: Region 1: 7 intersections per month Region 2: 10 intersections per month Region 3: 5 intersections per month Region 4: 2 intersections per month Ground-Level PM: This activity includes maintenance items that do not require the use of a bucket truck or taking of a traffic lane to accomplish. Examples include but are not limited to the following: cleaning / evaluating the physical condition of the cabinets; analyzing vehicle and pedestrian detection; checking cabinet power, wiring, switches, UPS, breakers, relays, flashers, load switches, BIU’s; MMU/conflict monitor testing; testing preemption; pull-boxes; cabinet filter replacement; etc. This activity should be performed annually at the following rate: Region 1: 28 intersections per month Region 2: 40 intersections per month Region 3: 20 intersections per month Region 4: 8 intersections per month Signal-Timing RM: This activity includes signal timing items. Examples include but are not limited to the following: drawing a sketch of the intersection; measuring the crosswalks for pedestrian clearance time; checking critical timing parameters, such as the yellow, red clearance, minimum green; updating controller firmware; checking time-clocks; optimizing timing, coordination and detection parameters, etc. This activity should be performed every three years at the following rate: Region 1: 10 intersections per month Region 2: 13 intersections per month Region 3: 6 intersections per month Region 4: 3 intersections per month Total: 32 intersections per month (timing PM in all regions is done by Signal Timing crew)