PROJECT INFORMATION DOCUMENT (PID) CONCEPT STAGE

advertisement

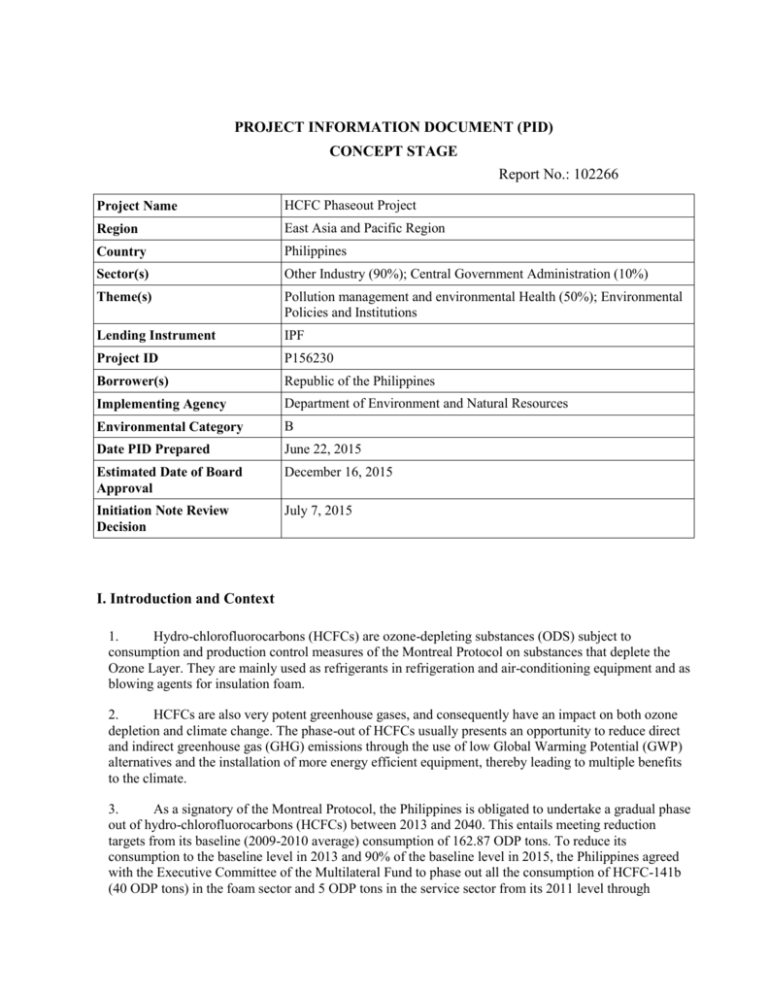

. PROJECT INFORMATION DOCUMENT (PID) CONCEPT STAGE Report No.: 102266 . Project Name HCFC Phaseout Project Region East Asia and Pacific Region Country Philippines Sector(s) Other Industry (90%); Central Government Administration (10%) Theme(s) Pollution management and environmental Health (50%); Environmental Policies and Institutions Lending Instrument IPF Project ID P156230 Borrower(s) Republic of the Philippines Implementing Agency Department of Environment and Natural Resources Environmental Category B Date PID Prepared June 22, 2015 Estimated Date of Board Approval December 16, 2015 Initiation Note Review Decision July 7, 2015 . I. Introduction and Context 1. Hydro-chlorofluorocarbons (HCFCs) are ozone-depleting substances (ODS) subject to consumption and production control measures of the Montreal Protocol on substances that deplete the Ozone Layer. They are mainly used as refrigerants in refrigeration and air-conditioning equipment and as blowing agents for insulation foam. 2. HCFCs are also very potent greenhouse gases, and consequently have an impact on both ozone depletion and climate change. The phase-out of HCFCs usually presents an opportunity to reduce direct and indirect greenhouse gas (GHG) emissions through the use of low Global Warming Potential (GWP) alternatives and the installation of more energy efficient equipment, thereby leading to multiple benefits to the climate. 3. As a signatory of the Montreal Protocol, the Philippines is obligated to undertake a gradual phase out of hydro-chlorofluorocarbons (HCFCs) between 2013 and 2040. This entails meeting reduction targets from its baseline (2009-2010 average) consumption of 162.87 ODP tons. To reduce its consumption to the baseline level in 2013 and 90% of the baseline level in 2015, the Philippines agreed with the Executive Committee of the Multilateral Fund to phase out all the consumption of HCFC-141b (40 ODP tons) in the foam sector and 5 ODP tons in the service sector from its 2011 level through implementation of the Stage I HCFC Phase-out Project which is currently being implemented by UNIDO and UNEP. 4. The goal of this project is to reduce its HCFC consumption to 65% of the baseline level or 105.87 ODP tons by January 1, 2020 in line with its obligations under the Montreal Protocol. Country Context 5. According to the latest official data reported by the Philippines, the total HCFC consumption in 2013 was 136.69 ODP tons, which is well under the Montreal Protocol’s maximum allowable consumption level of 146.58 ODP tons in 2015. To achieve the next obligation, a reduction of at least 30.82 ODP tons should be addressed by this proposed Project. 6. The Philippines does not produce any HCFCs. Demand of HCFCs is met through imports. In 2013, more than 2,100 MT of HCFCs were imported. Preliminary import data shows a slight increase of HCFC imports to more than 2,400 MT of HCFCs in 2014. However, consumption of HCFC-141b MT decreased from 408.67 MT in 2013 to 390.64 MT in 2014 attributed to the efforts of the on-going Stage I HCFC Phase-out Project which focuses on phasing out HCFC-141b in the foam sector. Sectoral and Institutional Context 7. The Philippines National HCFC Phase-out Management Plan prepared in 2011 reveals that HCFC use in ODP tons was somewhat equally distributed in the manufacturing and servicing sectors. The manufacturing sector includes refrigeration and air-conditioning manufacturers, foam producers, electronic and metal processing, and fire protection industries. For the service sector, HCFC is used for service and maintenance of air-conditioning and refrigeration equipment. Since the on-going Stage I HCFC Phase-out Project will completely eliminate the use of HCFC in the foam sector by end of 2015, the proposed Project will focus its phase-out activities in other manufacturing sectors with priority given to refrigeration and air-conditioner manufacturers. 8. The Department of the Environment and Natural Resources (DENR) is empowered by the Government of the Philippines as an executing agency for the implementation of the Montreal Protocol. The Environment Management Bureau (EMB) of DENR is assigned as the national coordinator for the implementation of the Montreal Protocol. Through the DENR-EMB, the Philippine Ozone Desk (POD) was established to serve as a focal point whose main responsibility is the control and monitoring of imports and export of all ozone depleting substances. The POD is financially supported by the MLF through UNEP. In addition, a Project Management Unit (PMU), established to facilitate and coordinate ODS phase-out activities under the Stage I HCFC Phase-out Project, is also financed by the MLF through UNEP. Relationship to CAS 9. The Country Partnership Strategy for the Republic of the Philippines for the period FY2015 – 2018 lays out the World Bank Group’s program and development solutions to promote inclusive growth, reduce poverty and support shared prosperity in five engagement areas. The development objectives of the proposed Stage II HCFC Phase-out Project are specifically linked to “Engagement Area 4 – Resilience to Climate Change, Environment and Disaster Risk Management”. 10. The proposed project will focus on elimination of HCFC use in the refrigeration and airconditioning manufacturing industry by introducing an alternative refrigerant which not only has low global warming effect but will also improve the energy efficiency performance of these products. Therefore, the proposed project will transform refrigeration and air-conditioning markets in the Philippines to higher energy efficient products and with low global warming refrigerants. . II. Proposed Development Objective(s) Proposed Global Environmental Objective(s) 11. The project development objective is to reduce the HCFC consumption in the air conditioning and refrigeration manufacturing sectors in compliance with the Philippines’ obligation under the Montreal Protocol. Key Results 12. The HCFC consumption will be limited to the level not exceeding 146.58 ODP tons during 2016 – 2019 and 105.87 ODP tons from 2020 – 2024. Carbon dioxide (CO2) emission reduction from the use of lower GWP alternatives and the amount of ODP reduction will be captured through result indicators. . III. Preliminary Description Concept Description 11. The proposed project can be considered as a continuation of the Philippines ODS Project as it will build on the infrastructure and capacity established under the ODS project (i.e., POD, PMU, and Land Bank – the financial agent of the previous ODS project) to deliver the required assistance to beneficiaries and stakeholders primarily in the sectors similar to the previous ODS Project. The proposed project is designed to address a specific reduction target (i.e., 2020 35% HCFC consumption reduction target) in accordance with the agreed phase out schedule with the Multilateral Fund rather than a project that would encompass multiple reduction targets and complete HCFC phase-out. The project implementation period will be about 5 – 6 years. 12. The project will provide technical and financial assistance to eligible manufacturers, primarily in the refrigeration and air-conditioning sectors, to redesign their products and retrofit their manufacturing processes in order to adopt non-ozone depleting and low global warming technologies. The project will also finance technology transfer that may be required by the beneficiary enterprises. To ensure sustainability of HCFC phase-out and to transform the markets to non-ozone depleting and low global warming technologies, technical assistance to strengthen monitoring and enforcement capacity and to revise relevant safety and energy efficiency standards, will be provided to relevant government agencies, non-government agencies, and standard bodies and/or agencies. The project will also build capacity in the service industry by providing training on the maintenance and servicing of equipment using the new technology. A. Description Component 1: Investment in HCFC Consumption Reductions (US$2.3 million) 13. The project will finance conversion of manufacturing facilities from HCFC technologies to nonozone depleting and low global warming technologies. While facilities using HCFCs are commercial refrigerator, air-conditioner, electronics, metal processing, fire-fighting equipment manufacturers, the project will give priority to HCFC phase-out in the refrigeration and air-conditioning manufacturing sectors as these sectors consume the largest percentage of the annual HCFC consumption in the manufacturing sector and early HCFC phase-out in these manufacturing sectors will reduce the build-up of HCFC equipment installation in the country and future demand of HCFC for servicing this equipment. 14. To eliminate the use of HCFC in the refrigeration and air-conditioning manufacturing processes, low GWP alternatives such as R-290 (propane), HFC-32, and others (if any) will be considered. Selection of alternatives will take into account safety, performance, and climate impact. 15. Based on the survey conducted in 2011, there are about 21 air-conditioner manufacturers and 8 commercial refrigerator manufacturers in the Philippines. A few of them may not be eligible as they are 100% owned by foreign enterprises from developed countries. Eligibility of the air-conditioner and commercial refrigerator manufacturers will be confirmed during appraisal. For eligible enterprises, the project would finance replacement or retrofit of product design and testing, acquisition of manufacturing equipment including new refrigerant leak detectors, vacuum pumps, refrigerant storages, refrigerant charging units, refrigerant transfer pumps and piping, pressure gauges, refrigerant recovery and recycling machines, brazing machines and air booster compressors, safety devices, and others. Component 2: Technical Assistance (US$0.5 million) 16. The objectives of the technical assistance component are to expedite transfer of manufacturing technology of R-290 and/or HFC-32 refrigeration and air-conditioning technologies, and to ensure safe use and handling of new products. Depending on the final choice(s) of technologies, technical study tours and technical workshops on the design and manufacturing of R-290 and HFC-32 equipment will be financed. Other technical assistance activities could include revisions of appliance standards, building codes, modifications of energy efficiency and safety laboratories, technical training for new and on-thejob refrigeration and air-conditioning technicians involved in manufacturing, installation and services of new alternative products. Component 3: Project Management (US$0.2 million) 17. The project will continue to finance the PMU that has been established within DENR-EMB by the previous ODS project and is currently implementing the Stage I HCFC Phase-out Project financed by UNEP. Assessment of the PMU’s role and responsibility will be conducted. A review and restructuring of the PMU is anticipated in order to ensure that the roles and responsibilities of the PMU are compatible with the new business needs. The project will explore reengagement of the Land Bank of the Philippines (LBP) as a financial agent of the Project. 20. The project will finance technical assistance to EMB-PMU and LBP, if applicable, for managing, supervising, monitoring and reporting on the implementation of Components 1 and 2 of the Project. It will also finance technical assistance to EMB-PMU for the development of sector-specific regulations and policy, such as, inter alia, rules governing HCFC imports and exports, and the ban on the use of HCFC in air-conditioners and refrigerators. . IV. Safeguard Policies that Might Apply Safeguard Policies Triggered by the Project Environmental Assessment OP/BP 4.01 Yes No TBD X Natural Habitats OP/BP 4.04 X Forests OP/BP 4.36 X Pest Management OP 4.09 X Physical Cultural Resources OP/BP 4.11 X Indigenous Peoples OP/BP 4.10 X Involuntary Resettlement OP/BP 4.12 X Safety of Dams OP/BP 4.37 X Projects on International Waterways OP/BP 7.50 X Projects in Disputed Areas OP/BP 7.60 X . . V. Financing (in USD Million) Total Project Cost: 3.0 Financing Gap: 0.00 Financing Source Total Bank Financing: 3.0 Amount Borrower OTF Grant (Montreal Protocol) 3.0 Total 3.0 . . VI. Contact point . World Bank . Contact: Title: Tel: Email: Viraj Vithoontien Senior Environmental Specialist 473-6303 vvithoontien@worldbank.org Contact: Title: Tel: Email: . Borrower/Client/Recipient . Name: Contact: Title: Tel: Republic of the Philippines Cesar Purisima Secretary of Finance 632 523-9220 Email: cpurisima@dof.gov.ph; cvpurisima@yahoo.com . . . Implementing Agencies Name: Department of Environment and Natural Resources Contact: Atty. Analiza Rebuelta-The Title: Tel: Email: Undersecretary 632 925-8277 annateh86@yahoo.com . . VII. For more information contact: . The InfoShop The World Bank 1818 H Street, NW Washington, D.C. 20433 Telephone: (202) 458-4500 Fax: (202) 522-1500 Web: http://www.worldbank.org/infoshop