Lab#4

advertisement

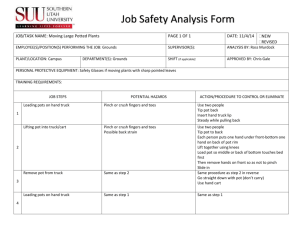

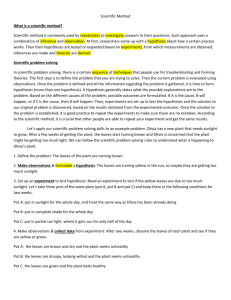

Prescott, Arizona Campus Department of Electrical and Computer Engineering EE 402 Control Systems Laboratory Fall Semester 2014 Lab Section 51: Thurs 9:10 – 11:50 am Lab Section 50: Thurs 1:25 – 4:05 p.m. in KEC 122 Lab Instructor: Dr. Stephen Bruder Lab 04 Introduction to the MS 150 Servo System Date Experiment Performed: Thursday, October 02, 2014 Instructor’s Comments: Comment #1 Comment #2 Date Report Submitted: ??, 2014 Group Members: Student # 1 Name & Email Student # 2 Name & Email Grade: EE 402 Control Systems Lab Fall 2014 1. GETTING STARTED Configure your workstation as shown in Figure 1 below. Do NOT turn on the power until the lab instructor checks your wiring!!! Note that you will be using the voltmeter on the Reduction Gear Tacho Unit (GT150X) as required. Also, terminal 1 of the servo amp is being driven by the pot and terminal 2 is grounded. +15V - 15V I/O Signal Figure 1 MS150 starting configuration Rotate the pot on the attenuator unit fully counter-clockwise to position “0,” next, adjust the load unit to position “0” (i.e., no loading), and then turn on the power supply. The motor should not spin. Slowly rotate the knob on the pot clockwise until the motor just begins to spin. Record this minimum voltage ( Vmin ). Vmin ??? Volts Carefully increase the pot and confirm that the motor spins faster as you increase the input voltage and slower as you decrease it. Set the input to 1 Volt and count the number of rotations of the output pot in a 1-minute interval. Confirm that 30× this number is about the rpm reading you are reading on the tachometer. Please record both values. Measured input voltage = ?? Volts, rotations / min = ??, tach rpm = ??. Names of Students in the Group Page 2 of 7 EE 402 Control Systems Lab Fall 2014 2. MOTOR SPEED AND TORQUE CHARACTERISTICTS For the next two experiments we will use the starting configuration of Figure 1. 1.1. Motor Speed Characteristics As we saw in the pre-lab, the motor speed varies approximately linearly with the applied input voltage. Using the tachometer to measure the motor speed (in rpm) and the voltmeter (also on the GT150X) to measure the applied input voltage, complete the table below and insert a plot of the motor speed in rad/s vs input voltage into Figure 3. It is difficult to get exact input voltages so simply get close to the prescribed levels and record your actual value (e.g., 1.05 V for 1 V). Vin Speed Speed (Volts) (rpm) (rad/s) Desired Actual 0.5 1 1.5 2 2.5 Figure 2 Motor speed vs input voltage See the MS150 Book 1 page 41 for an example of what to expect for this plot. Figure 3 Plot of motor speed vs input voltage Estimate of the slope of the plot Kg Names of Students in the Group speed ???? (rad/s)/V input voltage Page 3 of 7 EE 402 Control Systems Lab Fall 2014 1.2. Motor Torque Characteristics In this experiment, we will be determining the effect of increasing the load torque on the motor’s speed for two different fixed input voltages. First, fix the input voltage at 0.5 V and record the motor’s speed. Set the load unit to “0” (no load) and vary as indicated in Figure 5. Please try to center the disk in the cavity of the magnet as well as you can. Figure 4 Load unit unloaded (left), partially loaded (center), and fully loaded (right) Use the provided approximate “brake scale1” column in order to calculate the load torque at each brake position. Note that the brake scale is given at 1000 rpm and must be converted based on your measured speed. Brake Position 0 1 2 3 4 5 6 7 8 9 10 Input Voltage = 0.5 V Load Motor Speed Torque (rpm) (rad/s) (Nm) Input Voltage = 1.0 V Load Motor Speed Torque (rpm) (rad/s) (Nm) Brake Scale (Nmm at 1000 rpm) 0 4 12 20 40 56 70 81 110 142 160 Figure 5 Motor speed vs load torque for two different input voltages Plot both speed (rad/s) vs load torque (Nm) curves together and insert them into Figure 6. See the MS150 Book 1 page 41 for an example of what to expect for this plot. 1 See MS150 book 1 page 46. Names of Students in the Group Page 4 of 7 EE 402 Control Systems Lab Fall 2014 Figure 6 Plot of motor speed vs load torque 3. ERROR CHANNEL INVESTIGATION In this portion of the lab, we will be generating and calibrating the error signal formed between the Output V V Vout R f 1 2 R1 R2 Potentiometer (OP150K) & Input Potentiometer (IP150H) using the Operational Amplifier (OA150A) as a comparator. Figure 7 A simple comparator Recall the operation of an Op. Amp. configured as a comparator (see Figure 7). 1.3. Set the Offset of the Comparator to Zero Configure your Op Amp unit as shown in Figure 8. Rotate the feedback selector on the Op. Amp. to the 100 kΩ resistor setting. Apply power (±15V & GND) to the Op. Amp. Unit (QA150A) and measure the output (terminal 6) voltage with no input connection. Adjust the “Zero Set” knob to achieve as close to zero volts as you can. This will Figure 8 Setting the Offset to 0 accomplish the task of setting the comparator offset to zero. Names of Students in the Group Page 5 of 7 EE 402 Control Systems Lab Fall 2014 1.4. Zeroing the Input and Output Pots Connect the Power Supply, Op. Amp, Input pot, and Output pot as shown in Figure 9. You will still need to power the GT150X (use it as a voltmeter) To Voltmeter Figure 9 Error channel calibration configuration Be certain to connect the polarity of power to the input pot and output pot as shown (i.e., they intentionally have opposite polarities). - Starting with the input pot, rotate the knob on the front face to set the pot to 0 and then “adjust” the cursor until the voltage on terminal 3 is zero (ask for help as this may involve a crescent wrench). Note do NOT rotate this pot beyond ±150 as this will compromise your calibration!! - Transferring attention to the output pot, carefully turn the motor shaft (DO NOT TRY TO ROTATE THE OUTPUT POT DIRECTLY) so as to rotate the dial on the output pot to zero. Measure the voltage on terminal 3. If this voltage is not ~0V, rotate the motor shaft to achieve a voltage of 0 V and record the output pot angle ( 0 =??). This will be your offset angle for the remainder of the lab. Also, rotate the output pot to read 0 and record the voltage ( V0 =?? Volts). BE SURE TO SUBTRACT THIS OFFSET ANGLE FROM ALL OUTPUT POT ANGLES!!!! Names of Students in the Group Page 6 of 7 EE 402 Control Systems Lab Fall 2014 1.5. Calibrating the Error Factor (Ke) We now seek to determine the error factor, Ke , Input Angle + - Voltage Error Angle Output Angle which has units of volts/degree. With the output potentiometer at a fixed value, we will vary the input potentiometer to experimentally determine the error Figure 10 The error factor (Ke) factor. Fill in the table below and plot the error voltage (Op. Amp. output voltage) vs input angle in deg. Each column of the table corresponds to a different output pot angle. Input Pot (Degrees) Amplifier Output V0 (Volts) O/P Pot @ –60 O/P Pot @ –30 O/P Pot @ 0 O/P Pot @ 30 O/P Pot @ 60 –60 –30 0 30 60 Figure 11 Error voltage vs Input pot angle for various output pot angles. Plot each column of the “Amplifier Output” against the “Input Pot” angle (in deg) all on the same graph (please include a legend and remember to subtract 0 from the O/P pot angle). Next, compute the slope of these lines and then the average slope across all of the lines. Figure 12 Plot of the error voltage vs input angle for multiple output angles The average slope is the error factor, Ke . K e ??? volts/degree Names of Students in the Group Page 7 of 7