Reliable feed process for heavy workpieces

advertisement

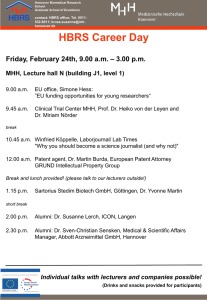

Press release by KASTO Maschinenbau GmbH & Co. KG 1/2 Title: Reliable feed process for heavy workpieces Topic: The new KASTOwin F 10.6 with moveable material support table Reliable feed process for heavy workpieces The sawing technology specialist KASTO is extending its product portfolio: The KASTOwin F 10.6 fully automatic band sawing machine is now available with a moveable material support table. This makes it possible to feed in and position heavy, bulky stock such as ingots, large tools or offset shafts easily and reliably. A versatile, robust and economical standard solution for a wide range of sawing applications – these are the properties that have already made the KASTOwin series of band saws, which was were first launched in 2014, extremely popular with many of the company’s customers. To expand the range of possible applications and simplify the sometimes laborious task of handling large workpieces, KASTO has decided to extend this product family: The KASTOwin F 10.6, which has a cutting range of 1,000 x 1,060 millimetres, is now available with a moveable material support table. The saw is particularly suitable for steel manufacturers, steel traders and largescale toolmakers. Using the table, it is possible to feed, for example, ingots, permanent moulds or materials with pre-forged geometries simply and reliably in a way that meets process requirements. The support length of the table is 2,600 millimetres, while the table has a travel distance of 3,700 millimetres and a bearing capacity of up to 18 tonnes. It can travel at a speed of up to three metres per minute – and do so with exceptional positional accuracy. The table is moved in the longitudinal direction by two linear guides, each equipped with four lubricated linear roller bearings. Precision feed is achieved by means of a zero-play ball screw spindle, while a hydraulic horizontal vice mounted on the outfeed side of the saw band holds the workpiece in place. Like all the models in the KASTOwin range, the saw excels thanks to its robust steel construction, a cutting accuracy of ±0.1 millimetres per 100 millimetres of cutting length, as well as cutting speeds of up to 150 metres per minute. To respond to special requirements, KASTO offers an extensive range of accessories for the KASTOwin F 10.6. This includes a laser to depict the projected cutting trajectory, a travelling hydraulic horizontal vice at the end of the table, support surfaces with wearing plates and infrared remote control. A wide range of individual stop, alignment and clamping devices are also available for the saw. 2,419 characters, including spaces Contact partner for enquiries: Public relations: KASTO Maschinenbau GmbH & Co. KG – Stephanie Riegel-Stolzer, Member of the Management Board – Industriestraße 14 – 77855 Achern, Germany – Tel. +49 7841 61-387 – Fax +49 7841 61-70 387 – press@kasto.com – www.kasto.com Text and editing: a1kommunikation Schweizer GmbH – Oberdorfstr. 31A – 70794 Filderstadt, Germany – Tel. +49 711 945 4161-4 – Fax +49 711 504 343 83 – info@a1kommunikation.de – www.a1kommunikation.de Picture credits: KASTO Maschinenbau GmbH & Co. KG Reprinting free - copy requested Press release by KASTO Maschinenbau GmbH & Co. KG 2/2 Title: Reliable feed process for heavy workpieces Topic: The new KASTOwin F 10.6 with moveable material support table Picture captions: Picture 1: The new KASTOwin F 10.6 is suitable for heavy, bulky stock such as ingots, large tools or offset shafts. Picture 2: The saw possesses an electrically driven material support table which can be used to position the large workpieces quickly and reliably to meet process requirements. About KASTO: KASTO Maschinenbau GmbH & Co. KG, based in Achern-Gamshurst, Germany, specialises in sawing and storage technology for bar stock. The company is a global leader in the manufacture and sale of metal-cutting saws and semi-automatic and automatic storage systems for bar stock and sheet metal. It is also a leading manufacturer of automatic handling systems for metal bars, sheet metal and pre-cut parts. One of Europe’s oldest family-owned companies, KASTO celebrated its 170th anniversary in 2014. In the course of its successful history it has registered 160 patents, delivered more than 140,000 sawing machines to all parts of the world and installed more than 1,700 automatic storage facilities. In addition to a branch in Schalkau, Thuringia, KASTO has subsidiaries in England, France, Singapore and the USA. In 2014 the company’s roughly 700 employees achieved revenues of about 120 million euros. Contact partner for enquiries: Public relations: KASTO Maschinenbau GmbH & Co. KG – Stephanie Riegel-Stolzer, Member of the Management Board – Industriestraße 14 – 77855 Achern, Germany – Tel. +49 7841 61-387 – Fax +49 7841 61-70 387 – press@kasto.com – www.kasto.com Text and editing: a1kommunikation Schweizer GmbH – Oberdorfstr. 31A – 70794 Filderstadt, Germany – Tel. +49 711 945 4161-4 – Fax +49 711 504 343 83 – info@a1kommunikation.de – www.a1kommunikation.de Picture credits: KASTO Maschinenbau GmbH & Co. KG Reprinting free - copy requested