Fast Crop Stock Plants

advertisement

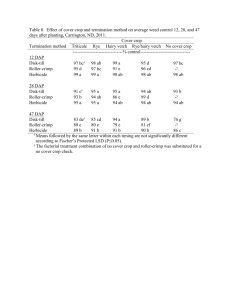

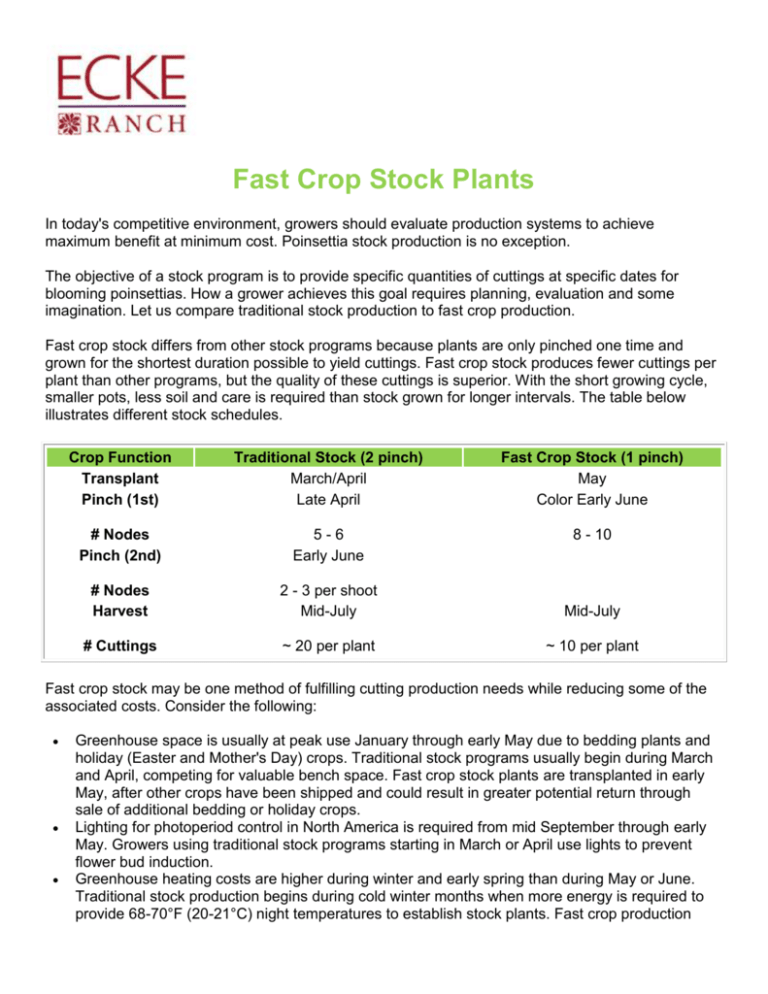

Fast Crop Stock Plants In today's competitive environment, growers should evaluate production systems to achieve maximum benefit at minimum cost. Poinsettia stock production is no exception. The objective of a stock program is to provide specific quantities of cuttings at specific dates for blooming poinsettias. How a grower achieves this goal requires planning, evaluation and some imagination. Let us compare traditional stock production to fast crop production. Fast crop stock differs from other stock programs because plants are only pinched one time and grown for the shortest duration possible to yield cuttings. Fast crop stock produces fewer cuttings per plant than other programs, but the quality of these cuttings is superior. With the short growing cycle, smaller pots, less soil and care is required than stock grown for longer intervals. The table below illustrates different stock schedules. Crop Function Transplant Pinch (1st) Traditional Stock (2 pinch) March/April Late April Fast Crop Stock (1 pinch) May Color Early June # Nodes Pinch (2nd) 5-6 Early June 8 - 10 # Nodes Harvest 2 - 3 per shoot Mid-July Mid-July # Cuttings ~ 20 per plant ~ 10 per plant Fast crop stock may be one method of fulfilling cutting production needs while reducing some of the associated costs. Consider the following: Greenhouse space is usually at peak use January through early May due to bedding plants and holiday (Easter and Mother's Day) crops. Traditional stock programs usually begin during March and April, competing for valuable bench space. Fast crop stock plants are transplanted in early May, after other crops have been shipped and could result in greater potential return through sale of additional bedding or holiday crops. Lighting for photoperiod control in North America is required from mid September through early May. Growers using traditional stock programs starting in March or April use lights to prevent flower bud induction. Greenhouse heating costs are higher during winter and early spring than during May or June. Traditional stock production begins during cold winter months when more energy is required to provide 68-70°F (20-21°C) night temperatures to establish stock plants. Fast crop production begins during May when the heat load required for these same temperatures, and therefore the associated costs are considerably lower. Reduced production time for fast crop also reduces the labor input per unit required for these poinsettias. Traditional programs require more inspection time and spraying for insect or disease pests, watering, spacing, pinching and other operations requiring the attention of production staff and growers. Additional savings result from the reduced quantity of fertilizers, pesticides and other material costs associated with a longer production cycle. Fewer cuttings produced per stock plant result in higher quality of cuttings. These cuttings are larger and more uniform than cuttings produced from multiple pinch stock plant programs, assuming good cultural and environmental management is provided by the grower for either program. Given the benefits identified for fast crop production, it is only fair to consider the negative aspects too: Fast crop plants produce about 1/2 the total number of cuttings per plant when compared to traditional programs, resulting in double the initial cutting quantity and costs. The short production cycle for fast crop stock does not allow recovery from serious production difficulties, minimizing the margin of error allowed. Growers should not limit poinsettia stock programs to one system only. This 'all or nothing' approach may be easier to manage, but the extra effort of combining traditional and fast crop programs can be a win-win situation. 1. Cutting production requirements peak during a few short weeks in the summer. To produce enough cuttings during this peak without sacrificing their size and quality places an excessive burden on traditional stock plants. Supplying for this peak also goes beyond the economic viability for fast crop stock alone. However when the programs are combined, production is accomplished at a lower total cost. For example, to produce the cuttings during a few weeks of the cycle, traditional stock would require an excessive number of stock plants resulting in a higher cost to the grower for more greenhouse space, heat, labor, etc. By combining the programs, a smaller base of traditional stock plants can produce the majority of cuttings needed, while a group of fast crop stock provides the balance. 2. Novelty colors or cultivars may not warrant the production cost associated with traditional stock plants or the cost of purchasing summer cuttings to fill needs. Fast crop stock may be an ideal program to supply the quantity of cuttings needed without committing long term space and care. 3. Fast crop stock allows the grower flexibility in meeting production requests than from traditional stock program. This flexibility can be an asset in today's market where the ability to start a program later in the spring season based on customer feedback can be an important program feature. Consider the potential improvements that might be gained through the use of fast crop stock and focus your sights on success. Guidelines for Blooming Another benefit of fast crop programs is the opportunity to make good quality blooming plants out of the stock plants. Because fast crop stock grown for a shorter duration and given limited pinching, plants can be made into compact 2-pinch forms or grouped to create larger specimen plants. Stock plants scheduled in the traditional 2-3 pinch program are more likely to have an excessive number of shoots and damaged foliage, resulting in blooming plants of lesser quality. Some guidelines for using fast crop stock for blooming plants: 1. Select the best stock plants for blooming, discard any weak or damaged plants. 2. Stock may have to be cut down to reduce the total number of shoots. As these plants are generally grown to 10+ nodes, the total height and shoot count may be excessive double pinch forms. Trim back the plant using care to shape the plant and allow uniform side shoots from which new growth will emerge. The final cutback date should be similar to the pinch date used for a 6 1/2" pinched plant of the same cultivar in your location. 3. Specimen plants (multiple plants per pot) should be created by selecting for uniformity in height, shoot size and root system development. 4. Keep only as many stock plants as you have finishing space to accommodate. o Double pinch forms required approximately 2 square feet per plant. o Three plants combined in 10"+ containers require a minimum of 3 square feet per plant. ©2011 Ecke Ranch