- Sangtech Technologies

advertisement

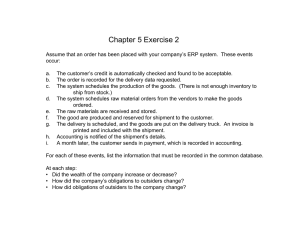

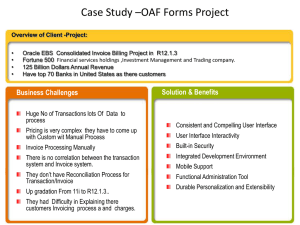

S-ERP-IPIM Integrated Production & Inventory Management (IPIM) is for Manufacturing and Trading Company Providing Following Details- IPIM -Means 1) Immense Peace In Mind – Presenting Unique Integrated Software package & well updated stock of finished goods or Semi-finished or Stock of any value addition or Processed or Unprocessed-Raw or Discrete stock makes Customer real King who is always well informed about his holding. Material 2) Software helps in - Sales planning & Raw Material planning- gives full control of all the Business Process. 3) Hassel free Production & Inventory process. 4) Local Invoice or Transfer, Export Invoice or Excise Invoice facility makes Invoice system very strong. 5) Automatic Excise duty or Export Duty credit makes system robust. 6) S-ERP-IPIM Customized Tracker helps in Tracking of any Item or Product Detail, Customer or Supplier Transaction, Any relevent Docs using this Integrated software make system really useful . 7) System generated Purchase Order on the basis of preset Reorder level & variable saves time. 8) Purchase Order can be linked to MRN to make entry into the system and reconcile the Ord_Qty with Recd_Qty and updating Back Order Status. IPIM – Outer world Interfaces-[Part-I] 1) Software Interfaces helps in – Material Resource planning & Production planning System. 2) S-ERP-IPIM’s IPIM can give alert on Excess Stock, Shortage of stock, Precious issue alert to designated person for the Safety and smooth running of the Manufacturing unit, system may use the technique of Auto SMS , Auto Mailing, Auto calling, Auto switch off or any other integrated device. 3) Any Inventory Item can be GPS track enabled. 4) Software can be linked to external devices through any advance connector or RS232 Connector supported device like Weighing Machine, Temperature Controller. 5) For any particular Item Biometric Security is placed. 6) Bar Code enabled Inventory saves time. 7) Software can be used on online - Remote terminal for real life experience. IPIM Advantages (I) 1) Help Organization Managing Production and Material Management in a single system. 2) Latest Finished Product, Semi finished, Particular Manufacturing – Process Stock, Raw Material Stock Status, Updated Inventory Category Wise or Product Category wise stock etc at any point of time. Fast moving vs Slow moving status alert. 3) Integrated Product planning, Sales, Purchase & accounting Help maintaining sufficient stock. 4) Accurate Production, Sales, Purchase forecast avoids incorrect purchase decision which may impact cash flow & Profitability. 5) Operational efficiency through Integration of data so Supply chain become robust even Manufacturer can sell to the Customer directly and Organization adapting to Customers needs. 6) Integrated Manufacturing Execution system with feedback and control, using MES -component to manage Machine Resources, Prioritize Prod-schedule, Control workflow, Managing Labor and Automating Document flow using latest Technology. Sales Order ProcessingSales Order Generated after Status update On 1) Telephonic 2) 3) 4) 5) 6) 7) Scheduled or 3) Verbal Order Status Confirmed-Current Stock -Credit Check -Pricing Negotiate -Back Order Status May start executing Order with -Shipment on Delivery Date -and Coordinate with Production Planning