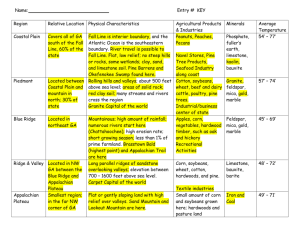

Background on Value Web Component: Logistics/Distribution

advertisement

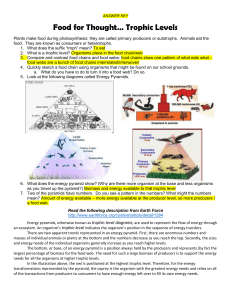

Background on Value Web Component: Logistics/Distribution/Storage Background Logistics and storage are important components of the value chain that ensure the value of the crop at harvest is not lost by the time it gets to the end-user. In the U.S., soybeans are primarily sold to three markets: (1) protein and oil processing, (2) food-grade processing, which makes products for human consumption and (3) export, which eventually leads to processing (categories 1 and 2) in the importing countries. The quality attributes by which grain is sold are physical characteristics (soundness and purity), intrinsic attributes and uniformity1. Physical characteristics include percent of trash and foreign materials including other grains, split seeds, moisture, test weight, heat damage, mechanical and mold damaged kernels. Intrinsic attributes refer to the chemical properties of the beans. Typically the protein and oil contents and fatty acid profiles are the primary intrinsic properties of importance in trade. Uniformity refers to the physical and chemical variability of a bulk. These properties are used to determine the value of the crop when traded in various markets because they affect storage, processing and end-use performance to varying degrees. Most of the soybeans produced in the U.S. are sold as commodity soybeans to processors who crush them, producing oil and soybean meal (protein). Commodity soybeans are typically shipped either from on-farm storage to country or river elevators, or directly from on-farm storage to the processor. Emerging markets include soybeans grown for food-grade processing, non-GMO beans or specialty varieties such as Monsanto’s Vistive® Gold or DuPont Pioneer’s Plenish high oleic. The high oleic soybeans offer better oil stability without hydrogenation, which provides an oil that is healthier for consumers. Soybeans grown for these markets typically command a premium, which can only be gained through a wellmanaged identity preservation (IP) program. As this market grows and larger volumes of foodgrade and specialty varieties come to market, the challenges in IP will increase, especially with respect to planting, storage, handling and logistics from the seed supplier to the farmer to the processor to the end user. This results in additional costs that will require price premiums to compensate for these additional services and management activities. Limitations to Value Realization The value of food-grade and specialty soybean varieties can only be gained through ensuring their identity and end-use quality are preserved throughout the value chain from production to processing. Because the majority of the U.S. grain logistics infrastructure was built for high-throughput commodity grains and oilseeds, there is an additional cost associated with preserving identity during harvesting and handling. Elevators are typically not efficient at IP and the costs and risks of managing the system tend to be high. On-farm storage offers a better option, but farmers need to be educated on the techniques and equipped with the proper tools in order to ensure that quality is maintained during the storage period. Another IP issue is how the value of the soybean crop can be captured effectively by pricing based on its composition, primarily the protein, oil and amino acid profiles. This is the basis for the “Estimated Processed Value” of soybeans, a concept developed by Iowa State University. An understanding of how weather and genetics affect composition, and how to preserve quality throughout the value chain are important in capturing the component value. Photo credit: www.unitedsoybean.org Problem Overview The U.S. grain handling and logistics infrastructure is designed to efficiently handle high volumes of commodity grain and oilseeds. Most farmers, however, are not equipped or trained to handle IP grains. IP requires extra levels of management and auditing to ensure that the identity and value of the specialty variety is maintained throughout the value-chain. While farms offer a better choice and less risk for IP, Example of Complex Issue Affecting Logistics/Storage/Distribution the use of information technology (IT) and smart technologies in management and inventory tracking has not yet been fully realized since the introduction of IP grains in the U.S. and global markets. Additionally, the storability and handling performance of new varieties, which may deviate in physical and intrinsic properties from commodity soybean varieties, should be determined so that they can be properly handled and stored. There is very little information available on differences in properties such as kernel size, shape and density, among varieties. Differences in such attributes could affect processing efficiency, storage capacity, and the quality of the end products. Changes in color and other physical attributes of soybeans during storage are not well understood. Research towards a solution IP costs must be reduced or captured in the pricing to farmers in order to grow the market for specialty grains. Additionally, the storage characteristics of specialty varieties must be compared with those of commodity soybeans to determine whether there are differences that require special management in production and handling. Research on physical and chemical properties and on storage and handling characteristics of specialty and food grade soybean varieties will provide insight into how to better handle and store these varieties to preserve their quality. Effects of storage conditions on physical and chemical attributes need to be identified along with factors that cause seeds to split. Research on the incorporation of IT and smart tracking technologies that lead to efficient IP and marketing is needed especially as the specialty market volume increases. Chemical properties of soybeans should be mapped with respect to growing location so that the industry can better understand how variability is impacted by weather conditions. Technology systems that map component value in soybeans from the field to the bin should be developed as part of an integrated IP management system. Production practices may also vary relative to fertility or pest management, especially if the end use is for human consumption. Research into emerging markets (economics) for food grade soybeans, organic, and non-GMO varieties based on soybean functionality (genetics) cuts across the value web and should include the effect of production, storage and handling conditions on end-use quality. Storage research should include nonchemical control and management of stored insect pests (entomology & ag. engineering), prevention of mold growth (plant pathology & ag. engineering), and reduction of split beans. Finally, research must be integrated with extension outreach to producers and others in the industry. Feedback from stakeholders through Extension, research collaboration, forums, and other interactions is essential to identify the key issues confronting the industry as they arise. References [1] USSEC. 2008. How the global oilseed and grain trade works. 2008. U.S. Soybean Export Council.