Technical Description

advertisement

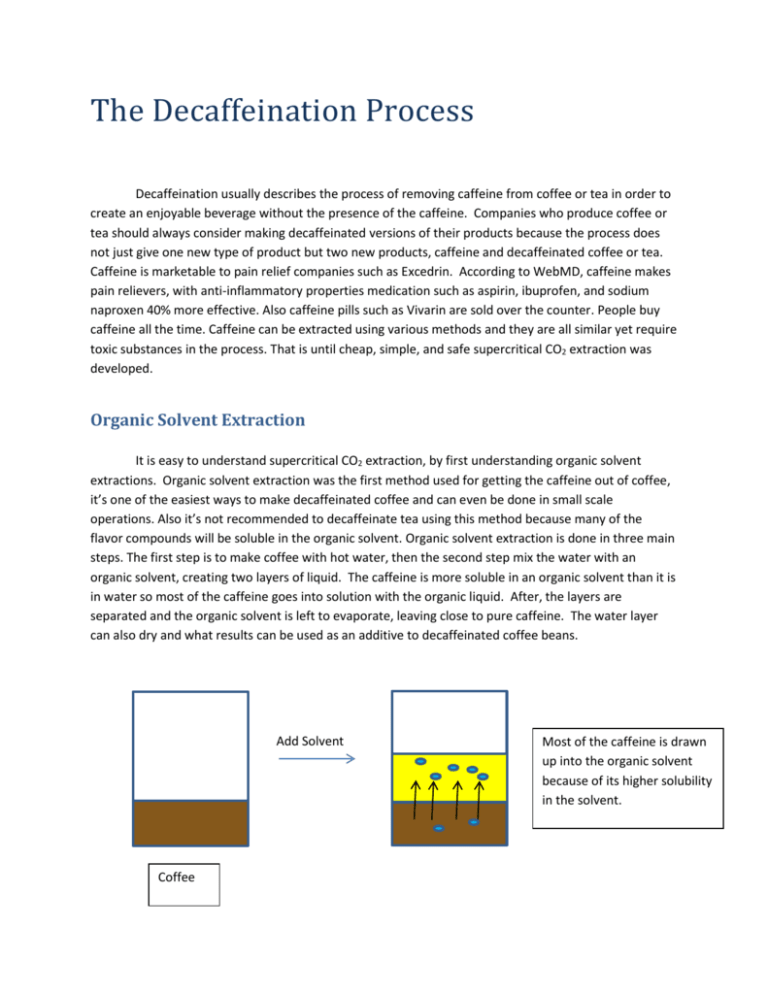

The Decaffeination Process Decaffeination usually describes the process of removing caffeine from coffee or tea in order to create an enjoyable beverage without the presence of the caffeine. Companies who produce coffee or tea should always consider making decaffeinated versions of their products because the process does not just give one new type of product but two new products, caffeine and decaffeinated coffee or tea. Caffeine is marketable to pain relief companies such as Excedrin. According to WebMD, caffeine makes pain relievers, with anti-inflammatory properties medication such as aspirin, ibuprofen, and sodium naproxen 40% more effective. Also caffeine pills such as Vivarin are sold over the counter. People buy caffeine all the time. Caffeine can be extracted using various methods and they are all similar yet require toxic substances in the process. That is until cheap, simple, and safe supercritical CO2 extraction was developed. Organic Solvent Extraction It is easy to understand supercritical CO2 extraction, by first understanding organic solvent extractions. Organic solvent extraction was the first method used for getting the caffeine out of coffee, it’s one of the easiest ways to make decaffeinated coffee and can even be done in small scale operations. Also it’s not recommended to decaffeinate tea using this method because many of the flavor compounds will be soluble in the organic solvent. Organic solvent extraction is done in three main steps. The first step is to make coffee with hot water, then the second step mix the water with an organic solvent, creating two layers of liquid. The caffeine is more soluble in an organic solvent than it is in water so most of the caffeine goes into solution with the organic liquid. After, the layers are separated and the organic solvent is left to evaporate, leaving close to pure caffeine. The water layer can also dry and what results can be used as an additive to decaffeinated coffee beans. Add Solvent Coffee Most of the caffeine is drawn up into the organic solvent because of its higher solubility in the solvent. Step 1: Brewing the Coffee The first step is to brew the coffee in hot water. This form of extraction is called solid/liquid extraction. This step is necessary because the organic solvent cant ionize the caffeine but water can. When the caffeine is ionized the C=O bonds become (C=O-H)+ bonds but not all the caffeine does this at once and therefore takes flow of the water through the coffee beans to continually remove the caffeine from the solids. This can be looked at as a process that breaks loose the caffeine and allows the organic solvent to reach the caffeine particles. Sigmaaldrich.com + H Non Ion Form Ion Form (This product is favored and can exist in an organic solvent) (This is the only for that can exist in water.) Step 2: Adding the Organic Solvent to the Water The second step is adding an organic solvent. Caffeine would be more soluble in any type of organic solvent, for example gasoline could be used as the organic solvent described in the process. Though any solvent will work the best solvents for this process would be benzene, or toluene using the “like dissolves like” property, which is simple as it sounds, since they both contain a ring structure they look similar, and it can be assumed that benzene will disolve caffeine. When the organic solvent is added it allows caffeine which is more stable in the non ion form (especially when it is left to cool for awhile). Therefore the caffeine goes into solution with the benzene and leaves the water phase. If only pure caffeine is desired and not decafe coffee, then table salt (NaCl) is be added to the water layer, which is more soluble in water than caffeine and therefore drives the caffeine out of solution of the water resulting in a higher percent yeild. In summary an organic chemical is used to pull caffeine from the water. Benzene Step 3: Final Sepparation During this step the organic layer is sepparated from the water layer by siphoning off the top layer. The bottom layer would normally be the water layer which, most of the time more dense than organic materials. This is not always the case because the amount caffeine that is in solution changes the density of the liquid it is contained in. Therefore when the liquids are separated it is verified that the product stream is infact still the organic phase. This is done by a person who drops a drop of water into a test of the solution for every new batch of coffee or tea being processed. If the drop does not for a bubble in the solution it can be verified that the process is still running smoothly. If not then the organic layer needs to be diluted before it can finish processing. This problem is rare though, because most coffee’s and teas have a set amount of caffeine that can be considered beforehand. Therefore when the liquids are separated it is verified that the product stream is infact still the organic phase. Also if only pure caffeine is desired the extraction can be done multiple times over the water layer. In plants this is done by having a flowing organic layer over a flowing water layer going in opposite directions through a recycled stream this will result in what can be considered 99.9% yeild of pure caffeine plus other chemicals after evaporation. Because of cost concerns and enviormental concerns the evaporated organic solvent is recollected and recycled to use again by cooling the gas in a cooling chamber after it evaporates. To completely purify the caffeine this is heated to 235 degrees celcius which causes caffeine to sublimate into a gas, the caffeine goes up into the air to hit a coolant where it recrystalizes into virtually pure caffeine. Otherwise you only want a one time pass of organic layer over the caffeine to preserve the flavor of the coffee which still removes about 80% of the caffeine. The flavors remain in the water and can be mixed back into the ground coffee beans that were used to brew the coffee in. Super Critical CO2 Extraction Now that you understand what an extraction process entails, it will be easier for you to understand a supercritical extraction. The super critical extraction uses CO2 as both the water and the organic solvent. The CO2 acts like water in that it will dissolve organic chemicals, yet it will not dissolve things like dirt, or combusted parts of the coffee bean. It breaks lose the caffeine from the bonds that hold it to the coffee bean but a lot the other things that are absorbed during a water extraction are left in the bean, some of these in which give the bean flavor which is imported for decaffeinated coffee. Supercritical extraction is a great way to ensure there are no poisonous chemicals present in the process of decaffeination, though high pressures are necessary which can also be somewhat dangerous but as long as proper safety valves are in place the process is very safe. Not only is it safe, but it is also a simple two-step process. CO2 is added to a chamber with coffee in it, then a lower pressure chamber is opened causing the caffeinated CO2 to flow into the chamber where it is allowed to evaporate (which is a very fast process, CO2 is a gas at room temperature and atmospheric pressure, which leaves just pure caffeine. Super critical extraction can be done with any polar chemical including water, yet the thermodynamic properties of the substance need to be considered. The easiest supercritical condition to make is to pressurize CO2 to about 250-300 bar at room temperature. Supercritical fluids are essentially gases that act like liquids (they dissolve things) yet retain they still flow through objects like fabric easily without adsorbing to the surfaces. These properties make the caffeine easy to get out of the solid form of the bean; also what is good is that CO2 dissolves polar molecules, (molecules that contain hydrogen), which makes it better at dissolving caffeine. The only problem is that it still dissolves the natural acids and alcohols (though at a much slower rate) that are present in the coffee and extracting all the caffeine will result in loss of flavor. Thus this is fixed by making the process a relatively fast process. healthpsych.psy.vanderbilt.edu Caffeine is released from the solid under high pressure CO2. Caffeine saturated CO2 is drawn into a separate chamber. The chamber is set to atmospheric pressure, and the caffeine falls out.