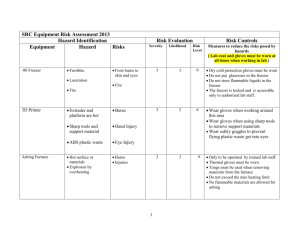

SRC equipment risk assessment 2013

SRC Equipment Risk Assessment 2013

Equipment

-80 Freezer

3D Printer

Ashing Furnace

Hazard Identification

Hazard Risks

Frostbite

Laceration

Fire

Frost burns to skin and eyes

Fire

Extruder and platform are hot

Sharp tools and support material

ABS plastic waste

Hot surface or materials

Explosion by overheating

Burns

Hand Injury

Eye Injury

Burns

Injuries

Risk Evaluation Risk Controls

Severity Likelihood Risk

Level

3 3

Measures to reduce the risks posed by hazards

( Lab coat and gloves must be worn at all times when working in lab )

9

Dry cold protection gloves must be worn

Do not put glassware in the freezer

Do not store flammable liquids in the

freezer

The freezer is locked and is accessible only to authorized lab staff.

2 2 4

Wear gloves when working around this area

Wear gloves when using sharp tools to remove support materials

Wear safety goggles to prevent flying plastic waste get into eyes

3 3 9

Only to be operated by trained lab staff.

Thermal gloves must be worn

Tongs must be used when removing

materials from the furnace

Do not exceed the max heating limit

No flammable materials are allowed for ashing

1

Atomic Absorption

Spectrophotometer

Hazardous radiation from flame/hollow cathode/D2 lamp

Acetylene explode

Heat from burner head

Eye damage

Burns

Gas leak

3

Atomic Force

Microscope

Autoclave

Laser Radiation

Eye damage

3

Heat/Steam

Contamination with bio-hazardous substances

Explosion

Burns

Infections

Eye/body injuries

3

3

3

3

9

Students must be guided by trained lab staff

Never directly view the flame/hollow cathode/D2 lamp.

Acetylene gas pressure should not exceed 15psi

Perform periodic gas leak test

If removing burner head ,allow sufficient time for the burner head to cool

Preventive maintenance should be done

9 yearly

Do not stare into the beam or view directly with optical instruments

(Magnifiers)

Users must be guided by trained lab staff

9

Only to be operated by trained lab staff

Thermal gloves must be worn

The chamber lid must be properly closed

before operation.

Never use autoclave for explosive/combustible/oxidizing

/flammable substances.

Daily maintenance is essential.

Preventive maintenance should be done annually

2

Biosafety Cabinet

Exposure to UV light

Exposure to

Microorganisms

Burns

Infections

Drilling Machine

Flying Chips

Eye/body injuries

3

Bunsen burner

Heat/Flame

Gas leak

Burns

Fire

Centrifuge

Digital Force Gauge

Samples leaks

Samples imbalance

Flying test substance

Aerosols, chemicals and microorganisms contamination

Machine malfunction

Eye/body injuries

3

3

3

3

3

3

2

3

3

9

Users must be trained and strictly follow safety laboratory practices

Do not stand near when the UV is on.

Turn off UV before use

Do not use flammable/combustible/ explosive substances in the unit.

Preventive maintenance should be done annually

9

Wear thermal gloves if necessary

If gas is smelt, turn off tap and report

immediately

Do not have or use flammable/volatile/explosive substances near the flame.

6

Users must be trained

Never fill the centrifuge tubes above the

max limit

Never exceed the max speed

Centrifuge tubes must be balanced

9

Use appropriate protective shield/mask ( depending on the test substance) to prevent injury caused by flying test substance.

Users must be guided by trained lab staff

9

Always secure the workpiece on the vice

Wear goggles

Student must be guided by trained lab staff

3

Electrophoresis System

Electric shock

Short-circuiting

Toxic chemicals used

Fractional

Distillation/Reflux

System/Rotary

Evaporator

Fume Hood

Release of evaporating content

Flask falling off or cracking of glassware

Injuries

Protein gel is toxic

Inhalation of toxic fume.

Injuries

3

3

flammable liquids

hazardous fumes/substances

Fire/Explosion

Exposure to hazardous substances

3

2

3

3

6

Polyacrylamide gel can only be casted by trained lab staff or to purchase commercially.

Metal components should not be touched.

Electrodes must be connected to their respective sockets.

Student must be guided by trained lab staff

9

Student must be guided by trained lab staff

Do not operate near flammable vapour or exposed flame.

To be done in fume hood with the front door down

Heating mantle is used instead of naked

flame.

The equipment should not be left unattended when the process is going

on.

Greater care should be exercised when handling ignitable or organic substances.

Check setup before starting the process.

9

Ignition sources to be kept out of fume hood

Containers of flammable liquids to be kept sealed except during decanting.

Preventive maintenance should be done annually

4

Gas Cylinder

(Flammable)

Gas leak

Falling Gas cylinder

Fire

Body injuries

3

Heating Mantle

High Voltage DC

Power Supply for

Electro-spinning

High temperature

High voltage

Risk of burns due to touching hot surface

Low risk of electrocution due to spillage of water or solvents on heating mantle

Electric Shock

2

3

3

3

9

Store outside the laboratory and well ventilated place

Must always be firmly secured with clamp and never left unsupported.

No chemicals are allowed to store together with the gas cylinders

Proper pressure limits for the compressed gas system must be observed to prevent leaks and explosions

Correct pressure regulator to be used

Check gas leak regularly

Always use smaller cylinder if possible

6

Do not leave heating mantle switch on

when unattended.

Do not place near flammable/volatile/explosive

substances.

Ensured the apparatus is electrically checked on regularly.

2 6

Student must be guided by trained lab

staff

Do not touch metal parts of the setup when the equipment is turned on

Always discharge the load after each operation

5

Homogenizer

Contact with rotating shaft, homogenizer head

Irritating noise

High power

Cuts/Injuries

Elevated noise affect hearing

Exposure to hazardous materials

3

Hot Bead Sterilizers

Heat

Hot plate

Burns 2

High temperature

Risk of burns due to touching of hot plate

Low risk of fire due to ignition of oil or chemicals being heated

Low risk of electrocution due to spillage of water or solvents on hot plate.

3

6

3

2

3

9

Training in safe operation and guided by trained lab staff

Protected goggles must be worn.

Chamber must be fully closed when in use.

Switch off when cleaning.

Hearing protection is required for longer time or higher speed.

Reduce operation time and speed if possible.

4

Metal ware must not be left too long in the hot bead sterilizer.

9

Thermal gloves must be worn if necessary

Do not leave hot plate switch on when unattended.

Do not place the hot plate near flammable/volatile/explosive

substances.

Avoid heating oil bath or chemicals to

too high temp

Ensured the apparatus is electrically checked on regularly.

HPLC

Incubator

Infrared Lamp

Laminar Flow

Hazardous substances including flammable, irritant solvents used and testing materials

Exposure to hazardous substances

Fire can occur in the present of ignition sources

3

Heat

Danger of fire with low flash points chemicals

Burns

Fire

Heat

Explosive if it contacts with water as the lamp tends to be very hot when in use.

Exposure to UV light

Microorganisms

Burns

Injuries

Burns

Infections

2

3

3

3

2

3

3

9

Student must be guided by trained staff

Awareness of possible exposure to hazardous substances

No ignition sources or hot plate near the equipment.

Routine maintenance should be done

Preventive maintenance should be done annually

4

Do not place incubator near volatile/flammable/explosive substances

Thermal gloves should be worn if the

9 temperature setting is above 45 deg C

Do not allow contact with water and place away from the water sources.

Switches should turn off after use.

9

Users must be trained and strictly follow safety laboratory practices.

Do not stand near the hood when UV light is on

Turn off UV light before removing the

front covers

Do not use flammable/volatile/explosive

substances in the unit

Daily maintenance by lab staff is essential.

Preventive maintenance should be done annually

7

Laser

Microwave Oven

Burns

Leakage of Microwave radiation

Burns

Pose hazard to health

3

Milling Machine

Optical fibres

Optical Tweezers

Laser Radiation

Hazardous voltages

Cutters

Eye Damage

Electric Shock

Injuries

Broken fibres pieces are sharp and could penetrate the skin

Laser Radiation

Injuries

Eye Damage

3

3

3

3

3

3

2

2

3

9

Wear laser safety Eye goggles.

Class 3b laser users to be guided by licensed lab staff

The laser apparatus when not in use should be locked and is accessible only to authorized lab staff.

9

Thermal gloves must be worn.

Bottles/containers should not be closed tightly.

Seals to be checked regularly

Stay at least an arm’s length away from the front of an operating microwave oven

6

Student must be guided by trained lab staff

Materials to be milled must be held securely.

Eye protection must be worn

After switching off the machine, always wait at least 5 minutes before removing the rear cover to access the electrical panel

6

Handle optical fibres as glass.

Fibres should be disposed carefully and not left lying on the bench.

9

Wear laser safety Eye goggles.

Student must be guided by trained lab staff

8

Oven –Dry Heat

High temp

Pump

Electric shock

Scalpels/Blades/Syringe needles

Sharp objects

Injuries

Cuts

Puncture

Scroll Saw

Burns

Fire

Flying object

eg. sharp chip

Chuck key,

wrenches &

workpiece

Eye/body

injuries

Inhale dust

3

3

3

3

2

3

3

3

9

Wear thermal gloves when removing hot items from the oven

Never use oven to evaporate flammable or combustible chemicals

Do not place the oven near volatile/flammable/explosive substances.

6

Strictly follow the instructions.

Lab staff guided is essential

9

Lab staff supervision is essential

To emphasize the danger of sharp objects to students.

Used sharps should not be bent or broken, and must be disposed into sharp waste container

Syringe with needle is only allowed to use when necessary and lab staff

supervision is required

Issue to students only when necessary

Only lab staff are accessible to the storage box.

9

Student must be guided by trained lab staff

Ensure the chuck keys and wrenches are removed before operating the machine

Use clamps or vices to secure workpiece

Goggles and mask must be worn

9

Shaking Incubator

Spilling of Chemicals or Microorganisms

Broken glass

Chemicals or microorganism contamination

Cuts

3

Soldering irons

Electric shock

Heat from melted component.

Burns

Injuries

Sonicator

Vibration

Hearing impairment

3

Thermometer

UV transilluminator

Mercury vaporized from broken

thermometer.

Broken pieces

UV radiation

Toxic vapor inhalation from broken

thermometer

Cuts

Harmful to eyes

Skin burns

3

3

3

2

3

2

3

3

6

Flasks or bottles should not be overfilled or over-tighten.

Ensure the flasks or bottles are secured

Place objects on the platform in a stable condition

Do not overload the shaker or exceed the equipment’s specification.

9

Lab staff should ensure the equipment and cables are maintained in good conditions

Suitable eye protection should be worn

Students are not allowed to operate this process

6

Student must be guided by trained lab staff

Minimize sample sonication time

Perform in fume hood if necessary

Ear protection if needed

9

All breakage, accidents and spillage must be reported immediately to

teachers or lab staff.

Follow mercury spillage SOP

9

Lab staff supervision is essential.

Full face shield should be worn

UV lamp must be off after use

10

Vacuum Concentrator

Vacuum Oven

Toxic or flammable vapours

Toxic volatile substance

Implosion

Heat

Broken glass

Inhalation of toxic vapours

Fire if presence of ignition sources.

Burns

Cut

Hazardous fume evolved

Intoxication

Explosion

3

3

2

3

6

The equipment must not be used to evaporate low flash points substances.

When evaporating flammable liquids,volatile liquids or explosive liquids , a cooling trap should be used to ensure condensation and separation of the vapour

Student must be guided by trained lab staff

9

Lab staff supervision is essential

Thermal gloves must be worn

Do not place or dry explosive, flammable, corrosive and combustible materials around or in the oven.

Do not seal the glassware

Door gasket will degrade at high temp

Vortex mixer

Water-Bath

Samples leak

Electric shock

Heat

Exposure to

hazardous substances

Injuries

Scalding

2

2

2

2

Emergency procedures and first aid kit must be in place.

Lab users to be aware of where nearest firefighting equipment is located & emergency phone number.

after some time, check frequently.

Check Vacuum pump frequently

4

Users are to ensured tubes sealed properly

4

Fill the bath with water to the recommended height.

“HIGH TEMP, DO NOT TOUCH” sign should be displayed if the temperature

setting is higher than 60 deg C.

Off the water-bath if not in use.

11

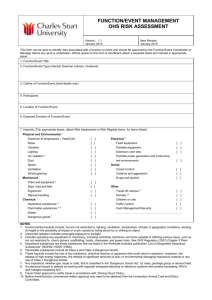

Experiment Risk Assessment

Equipment Chemicals and Processes

1. Experiments assessment

Possible hazardous

Risks of operating equipment

Risk

Level

2. Use of biohazardous substances

3. Use of Hazardous chemicals

Exposure to infectious substances

Acute or chronic

Infections

Exposure to hazardous chemicals

Acute or chronic

Health effects from chemical exposures

Measures to reduce the risks posed by hazards

Lab coat and gloves must be worn at all times when working in lab

To modify the experimental procedure if higher risk is involved.

Students must read and understand the safety rules before doing experiment

All students users must be trained before commencing of their experiments.

Proper operation of equipment should be followed.

Users must always follow safety regulations strictly

Lab coat and gloves must be worn at all times when working in lab

Restrict work to the BSL-1 microorganisms. Tissues, blood or body fluids from human or vertebrates are not allowed to use.

Microorganisms of unknown pathogenicity or from unknown sources must not be used

All used apparatus contaminated with microorganisms and culture media must be autoclaved after the experiment

Students must be trained ,strictly follow safety laboratory practices and

guided by trained lab staff

Associated signs use to demonstrate hazards.

Work to be done in biosafety cabinet

Washing of hands after process is completed

Disposal as per Laboratory Safety Manual.

Lab coat and gloves must be worn at all times when working in lab

Assessment prior to use if this chemical must be used or if a less dangerous chemical can be substituted.

Students must be trained and strictly follow safety laboratory practices

MSDS must be accessed prior to usage

Associated signs use to demonstrate hazards.

Prepare chemicals in the appropriate work station e.g. fume hood

Washing of hands after process is completed

Disposal as per Laboratory Safety Manual