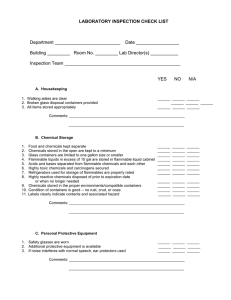

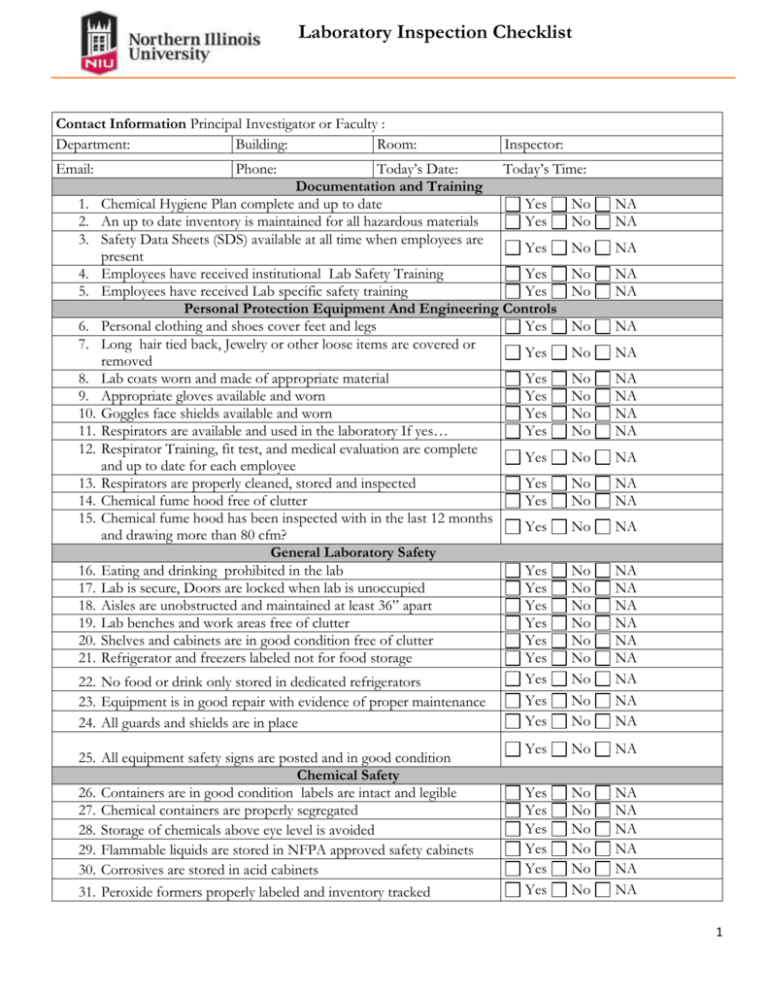

Laboratory Inspection Checklist

advertisement

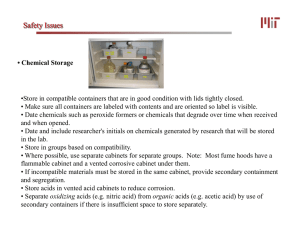

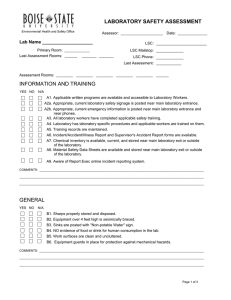

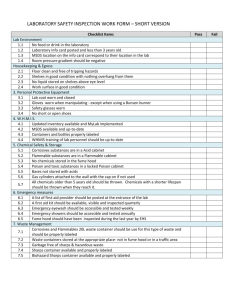

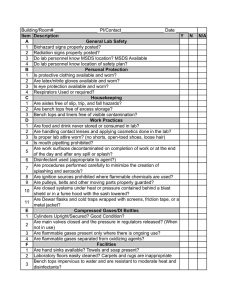

Laboratory Inspection Checklist Contact Information Principal Investigator or Faculty : Department: Building: Room: Email: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. Inspector: Phone: Today’s Date: Today’s Time: Documentation and Training Chemical Hygiene Plan complete and up to date Yes No An up to date inventory is maintained for all hazardous materials Yes No Safety Data Sheets (SDS) available at all time when employees are Yes No present Employees have received institutional Lab Safety Training Yes No Employees have received Lab specific safety training Yes No Personal Protection Equipment And Engineering Controls Personal clothing and shoes cover feet and legs Yes No Long hair tied back, Jewelry or other loose items are covered or Yes No removed Lab coats worn and made of appropriate material Yes No Appropriate gloves available and worn Yes No Goggles face shields available and worn Yes No Respirators are available and used in the laboratory If yes… Yes No Respirator Training, fit test, and medical evaluation are complete Yes No and up to date for each employee Respirators are properly cleaned, stored and inspected Yes No Chemical fume hood free of clutter Yes No Chemical fume hood has been inspected with in the last 12 months Yes No and drawing more than 80 cfm? General Laboratory Safety Eating and drinking prohibited in the lab Yes No Lab is secure, Doors are locked when lab is unoccupied Yes No Aisles are unobstructed and maintained at least 36” apart Yes No Lab benches and work areas free of clutter Yes No Shelves and cabinets are in good condition free of clutter Yes No Refrigerator and freezers labeled not for food storage Yes No Yes No No food or drink only stored in dedicated refrigerators Yes No Equipment is in good repair with evidence of proper maintenance Yes No All guards and shields are in place 25. All equipment safety signs are posted and in good condition Chemical Safety 26. Containers are in good condition labels are intact and legible 27. Chemical containers are properly segregated 28. Storage of chemicals above eye level is avoided 29. Flammable liquids are stored in NFPA approved safety cabinets 30. Corrosives are stored in acid cabinets 31. Peroxide formers properly labeled and inventory tracked NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA Yes No NA Yes Yes Yes Yes Yes Yes No No No No No No NA NA NA NA NA NA 1 Compressed and Cryogenic Gas Safety 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. Gas cylinders are stored upright and are properly secured Caps are properly secured when on in use Flammable gases are stored separately form oxidizers Cryogenic and flammable gases are stored in well ventilated areas Proper regulators in use Cylinders moved using cylinder trucks with regulators removed and caps secured Waste Management Waste are not disposed via trash or drains unless approved by EH&S Storage containers are appropriate for the waste and are in good condition Waste containers are properly labeled with date and contents Waste container lids are tightly closed unless adding waste Emergency Planning & Response Employees are familiar with building evacuation procedures location of fire alarms and exits Employees are familiar with the location and used of fires extinguishers Spill control equipment available employees are familiar with their use Safety shower and eyewash accessible Safety shower tested within the past year Eyewash tested monthly Emergency procedure and phone numbers clearly posted Yes No NA Yes Yes Yes Yes No No No No NA NA NA NA Yes No NA Yes No NA Yes No NA Yes Yes No No NA NA Yes No NA Yes No NA Yes No NA Yes Yes Yes Yes No No No No NA NA NA NA Comments 2

![B. ANNUAL CAMPUS EHS INSPECTION CHECKSHEET [ BIO / CHEM ] Methodist University | Office of Environmental Health and Safety](http://s2.studylib.net/store/data/011933406_1-402b18c49141c7240c4a4d3fd3fc4396-300x300.png)