full press release

advertisement

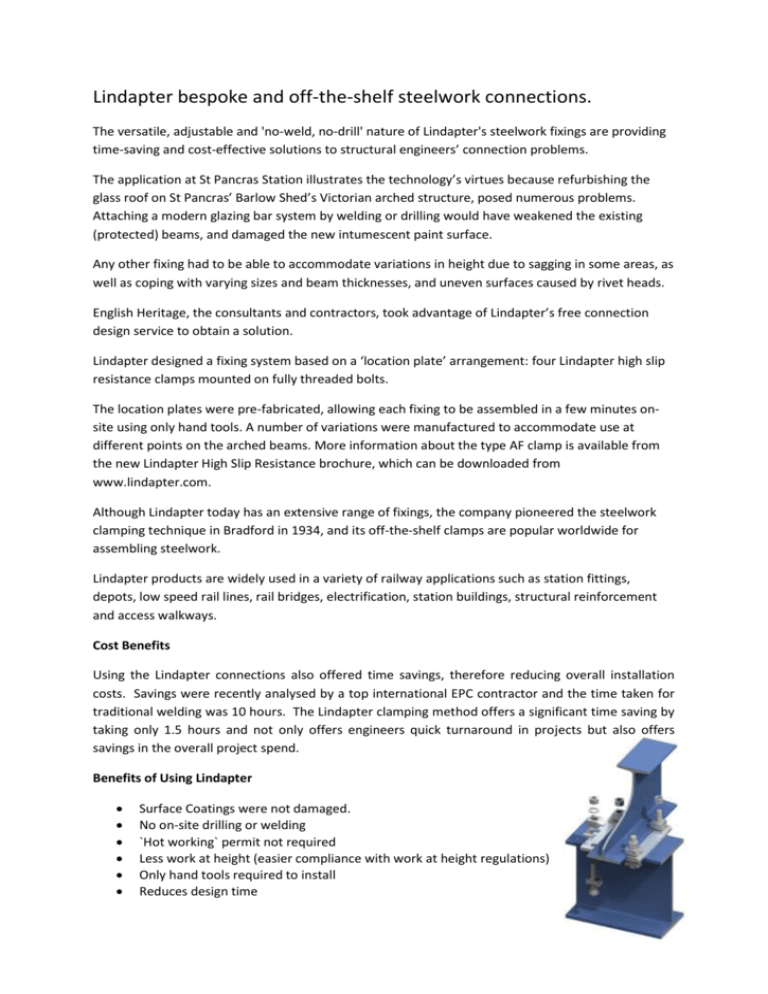

Lindapter bespoke and off-the-shelf steelwork connections. The versatile, adjustable and 'no-weld, no-drill' nature of Lindapter's steelwork fixings are providing time-saving and cost-effective solutions to structural engineers’ connection problems. The application at St Pancras Station illustrates the technology’s virtues because refurbishing the glass roof on St Pancras’ Barlow Shed’s Victorian arched structure, posed numerous problems. Attaching a modern glazing bar system by welding or drilling would have weakened the existing (protected) beams, and damaged the new intumescent paint surface. Any other fixing had to be able to accommodate variations in height due to sagging in some areas, as well as coping with varying sizes and beam thicknesses, and uneven surfaces caused by rivet heads. English Heritage, the consultants and contractors, took advantage of Lindapter’s free connection design service to obtain a solution. Lindapter designed a fixing system based on a ‘location plate’ arrangement: four Lindapter high slip resistance clamps mounted on fully threaded bolts. The location plates were pre-fabricated, allowing each fixing to be assembled in a few minutes onsite using only hand tools. A number of variations were manufactured to accommodate use at different points on the arched beams. More information about the type AF clamp is available from the new Lindapter High Slip Resistance brochure, which can be downloaded from www.lindapter.com. Although Lindapter today has an extensive range of fixings, the company pioneered the steelwork clamping technique in Bradford in 1934, and its off-the-shelf clamps are popular worldwide for assembling steelwork. Lindapter products are widely used in a variety of railway applications such as station fittings, depots, low speed rail lines, rail bridges, electrification, station buildings, structural reinforcement and access walkways. Cost Benefits Using the Lindapter connections also offered time savings, therefore reducing overall installation costs. Savings were recently analysed by a top international EPC contractor and the time taken for traditional welding was 10 hours. The Lindapter clamping method offers a significant time saving by taking only 1.5 hours and not only offers engineers quick turnaround in projects but also offers savings in the overall project spend. Benefits of Using Lindapter Surface Coatings were not damaged. No on-site drilling or welding `Hot working` permit not required Less work at height (easier compliance with work at height regulations) Only hand tools required to install Reduces design time Site adjustable (easier and faster re-alignment) Power not required Independently approved and guaranteed safe working loads Industry leading approvals Comprehensive technical support by experienced Lindapter Engineers Lindapter is a world market leader of steelwork fixings with international references since 1934. Lindapter’s product range covers all aspects of fixing to or suspending from structural steelwork. As a premium British manufacturer, Lindapter have industry leading product approvals, including a list of Network Rail approved products in its rail brochure. As well as steelwork fixings, the Lindapter range includes floor fixings, service supports and cavity fixings. Lindapter offers the highest standard of customer service, extensive technical support with a free design service for bespoke connections and off-the-shelf solutions from a world-wide distributor network. For more information visit www.lindapter.com , call +44 (0)1274 521 444 or email enquiries@lindapter.com