Quantum Dots: Nanoparticles with Outstanding Fluorescent

advertisement

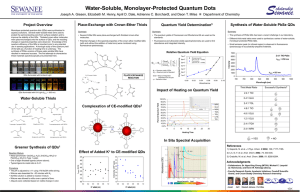

Journal of Materials Chemistry – Review QUANTUM DOTS: NANOPARTICLES WITH OUTSTANDING FLUORESCENT PROPERTIES Libor Janu1, Jana Chomoucka2,3, Jana Drbohlavova2,3, Marketa Ryvolova1,3, Pavlina Sobrova1, Vojtech Adam1,3, Pavel Kopel1,3, Jaromir Hubalek1,2, Rene Kizek1,3,* 1 Department of Chemistry and Biochemistry, Faculty of Agronomy, Mendel University in Brno, Zemedelska 1, CZ-613 00 Brno, Czech Republic 2 Department of Microelectronics, Faculty of Electrical Engineering and Communication, Brno University of Technology, Technicka 10, CZ-616 00 Brno, Czech Republic 3 Central European Institute of Technology, Brno University of Technology, Technicka 3058/10, CZ-616 00 Brno, Czech Republic *Corresponding author: Rene Kizek, Department of Chemistry and Biochemistry, Mendel University in Brno, Zemedelska 1, CZ-613 00 Brno, Czech Republic; E-mail: kizek@sci.muni.cz; phone: +420-54513-3350; fax: +420-5-4521-2044 1 Journal of Materials Chemistry – Review Abstract Current issue solved in the area of quantum dots (QDs) synthesis and application, is to find highly luminescent semiconductor nanocrystals, which are easy to prepare, biocompatible, stable and soluble in aqueous solutions. These are made up of 100–100 000 number of atoms typically range in size from 1 to 10 nm in diameter. The most popular types of QDs include CdTe, CdSe, ZnSe, ZnS, however also other semiconductor metals such as In, Ga, and many others can be used. QDs play an important role mainly in the imaging and as fluorescent probes for biological sensing (DNA, proteins, peptides, and drugs). QDs designed for biological applications are mainly applied in colloidal form. To date, two original approaches have been reported for the preparation of colloidal QDs: synthesis of hydrophobic QDs and aqueous synthesis routes. Hydrophobic QDs are insoluble in aqueous solution, they cannot be directly employed in bioapplications and require further surface modification to achieve water solubility, biocompatibility and stability. On the other hand, the aqueous synthesis route produces QDs with excellent water solubility, biological compatibility, and stability. Besides the applications as simple sensors, the main function of the QDs based on their exceptional fluorescent properties in the biochemical and biomedical research area is their use as unique fluorescent labels. Various specific labeling strategies are known and most of these approaches are based on bioconjugation with other biomolecule exhibiting some specific affinity to the target compound. Keywords Quantum Dots; Synthesis; Glutathione; Applications 2 Journal of Materials Chemistry – Review Content 1. Introduction 2. Synthesis of hydrophobic QDs Solubilization of hydrophobic QDs 3. Aqueous synthesis of QDs 3.1 QDs synthesis in reflux condenser 3.2 Microwave irradiation synthesis 3.3 Microemulsion synthesis 4. Glutathione as a QD capping agent 4.1 CdTe QDs capped with GSH 4.2 CdSe QDs capped with GSH 4.3 CdS QDs capped with GSH 4.4 Zn-based QDs capped with GSH 5. Characterization of QDs 6. Applications of QDs 6.1 QDs toxicity and biocompatibility 6.2 In vitro applications 6.3 In vivo applications 6.4 Quantum dots and nanocomposites in cancer detection and therapy 7. Conclusion 3 Journal of Materials Chemistry – Review 1. Introduction Typically, QDs are represented by nanocrystallites or atomic clusters consisted of few hundreds to few millions of atoms, but only a small number of electrons (≤ 100) are free based on metallic (Ni, Co, Pt, Au) 4 1-3 . QDs can be or mostly on broad scale of semiconductor materials, particularly from periodic group II-VI (CdTe, CdSe, CdS, ZnSe, ZnS, PbS, PbSe, PbTe, SnTe) (Fig. 1). Moreover other semiconductor elements from III-V group such as In, Ga, and many others can be used for QDs fabrication (InP) 5. With conventional optical spectroscopy, the focused laser beam has a typical diameter of ∼100 μm, which for dot densities of ∼1010–1011 cm−2, results in the simultaneous excitation of ∼106–107 quantum dots. As a consequence, the resultant spectra are inhomogeneously broadened owing to unavoidable fluctuations in dot size, shape, and composition 6. Because of their reduced size, QDs behave differently from bulk solids due to the quantum-confinement effects that are responsible for their remarkably attractive properties intermediate between compounds and single molecules, namely intensive photoluminescence. The QDs fluorescent properties arise from the fact, that their excitation states/band gaps are spatially confined (Fig. 2). The quantum confinement effects occur, when the nanoparticle radius is lower than one of these magnitudes: ae, ah and aexc (Bohr radius of electron, hole and exciton, respectively). In other words, the physical size of the band gap determines the photon’s emission wavelength, which can vary from UV to NIR wavelengths (400–1350 nm). For example, larger QDs having smaller band gaps emit red light, while smaller QDs emit blue light of higher energy 7. These effects depend not only on the core size, but also on the chemical composition of the core. Therefore there is not a clear line to say that a nanoparticle is a QD or not if one regards only its size (e.g. Bohr radius for InAs is 36 nm, while 4 Journal of Materials Chemistry – Review for CuCl only 0.7 nm). Recently, also emission-tuneable QDs covering the range from yellow-tored 8 and white light emitting ZnSe QDs doped with Mn2+ ions were prepared 9. The electrons in the quantum dot belong to the conduction band of the semiconductor. The conduction electron density is low, the mean electron-electron distance being of the order of 10 nm. Electron transport through a quantum dot is studied by connecting the quantum dot to surrounding reservoirs. The fact that the charge on the electron island is quantized in units of the elementary charge e regulates transport through the quantum dot in the Coulomb blockade regime. If the dot is fully decoupled from its environment, it confines a well defined number N of electrons. For weak coupling, deviations due to tunnelling through the barriers are small, leading to discrete values in the total electrostatic energy of the dot. This energy can be estimated by N(N-1)e2/(2C), where C is the capacitance of the dot. Thus the addition of a single electron requires energy Ne2/C, which is discretely spaced by the charging energy e2/C 10. QDs play an important role mainly in the imaging and as highly fluorescent probes for biological sensing that have better sensitivity, longer stability, good biocompatibility, and minimum invasiveness. The long lifetime in the order of 10–40 ns increases the probability of absorption at shorter wavelengths and produces a broad absorption spectrum 11 . Most interest in QDs is focused on the core-shell structure rather than on the core structure 12. Regardless of a core/shell structures, it is the size of the core nanocrystal which determines the emission wavelength of the QDs. For example, CdS QDs is used to generate ultraviolet and blue emission, CdSe is used to span most of the visible spectrum, CdTe is well suited for the red and near infrared region and PbS and PbSe have been used to create cores that emit in the near infrared. The shell greatly improves the QY and stability of the core nanocrystals. 5 Journal of Materials Chemistry – Review Majority of sensing techniques employing QDs in biological systems are applied in solution (colloidal form). Up to present days, the most frequently used approaches have been reported on the preparation of colloidal QDs: synthesis of hydrophobic QDs with subsequent solubilization step, direct aqueous synthesis or two-phase synthesis. Compared to hydrophobic or two-phase approaches, aqueous synthesis is reagent-effective, less toxic and more reproducible. Furthermore, the products often show improved water-stability and biological compatibility. The current issue solved in the area of QDs synthesis is to find highly luminescent semiconducting nanocrystals, which are easy to prepare, biocompatible, stable and soluble in aqueous solutions. Thus, the semiconductor core material must be protected from degradation and oxidation to optimize QDs performance. The other problematic issue is high reactivity of QDs cores, which suffer from very strong unspecific interactions with macromolecules leading to the particle aggregation and fluorescence variation. Shell growth and surface modification enhance the stability and increase photoluminescence of the core. And the last, but probably most important is the QDs toxicity (mainly because of their toxic heavy metal composition), which can be greatly reduce by surface modification as well. The protecting layer should also hinder the creation of reactive oxygen species (ROS) such as free radicals (hydroxyl radical: •OH and superoxide: O2•-) and singlet oxygen (1O2), which are known to cause irreversible damage to nucleic acids, enzymes, and cellular components such as mitochondria and both plasma and nuclear membranes 5. As results from above mentioned, the key step in QDs preparation ensuring the achievement of above mentioned required properties is QDs functionalization. Coating of inorganic surface of QDs should provide two functions, a chemical and physical stabilization of the QDs as well as the ability to modify them for a wide range of applications by attaching certain surface groups 13. 6 Journal of Materials Chemistry – Review Most of these approaches are based on bioconjugation with some biomolecule 14 . Many biocompatible molecules can be used for this purpose, especially those compounds possessing the surface amino and carboxyl functional groups. Glutathione (GSH), member of thiol compounds family, as the only one carries both these functional groups. GSH coated QDS can be further modified, for example with biotin giving biotinylated-GSH QDs which can be employed in specific labelling strategies 15 . Namely, these biotin functionalized GSH coated QDs has high specific affinity to avidin (respectively streptavidin and neutravidin) 16. 2. Synthesis of hydrophobic QDs The synthesis of the most frequently used semiconducting colloidal QDs, consisted of metal chalcogenides (sulphides, selenides and tellurides), is based either on usage of organometallic precursors (e.g. dimethylcadmium 17 , diethylzinc salts of inorganic and organic acids (e.g. stearate 18 ), metallic oxide (e.g. CdO 20, 21 , acetate 22, 23 , nitrate 24 19 ) or metallic ). The sources of chalcogenide anion are usually pure chalcogen elements (e.g. S, Se, Te). Whatever precursor is used, the resulted QDs are hydrophobic, but their quantum yields (QY) are higher (in the range of 20–60 %) compared to QDs prepared by aqueous synthesis route (below 30 %). However, the trend is to avoid the usage of organometallic precursors, because they are less environmentally benign compared to other ones, which are more preferable 25. The most common approach to synthesis of colloidal hydrophobic QDs is the controlled nucleation and growth of particles in a solution of organometallic/chalcogen precursors containing the metal and the anion sources. The method lies in rapid injection of a solution of chemical reagents into a hot and vigorously stirred coordinating organic solvent (typically trioctylphosphine oxide (TOPO), trioctylphosphine (TOP) or hexadecylamine (HDA) 26) that can 7 Journal of Materials Chemistry – Review coordinate with the surface of the precipitated QDs particles 27. Consequently, a large number of nucleation centres are initially formed at about 300 °C. The coordinating ligands in the hot solvents prevent or limit subsequent crystal growth (aggregation) via Ostwald ripening process (small crystals, which are more soluble than large ones, dissolve and reprecipitate onto larger particles), which typically occurs at temperatures in the range of 250–300 °C 28 . Further improvement of the resulting size distribution of the QDs particles can be achieved through selective preparation 29 . Because these QDs are insoluble in aqueous solution and soluble in nonpolar solvents only, further functionalization with various organic molecules possessing thiol, carboxy or amino groups is required to achieve their solubilization. However, this inconveniency is compensated with higher QY of these QDs as mentioned previously. Solubilization of hydrophobic QDs Solubilization of QDs is inevitable for many biological and biomedical applications. The process of transformation from hydrophobic to hydrophilic QDs is difficult and demanding multiple steps. It requires sophisticated surface chemistry alteration. Current solubilization strategies without affecting key properties are mostly based on exchange of the original hydrophobic surfactant layer (TOP/TOPO) capping the QDs with hydrophilic one or the addition of a second layer 30. The strategies are shown in Fig. 3. However, in most cases, the surface exchange results in not only broadening of the size distribution but also reductions in QY from 80 % in the organic phase to about 40 % in aqueous solution 31. The first technique involves ligand exchange (sometimes called cap exchange). The native hydrophobic ligands are replaced by water-soluble bifunctional molecules in which one end connects to QDs surface and the other end is hydrophilic and may also be reactive to 8 Journal of Materials Chemistry – Review biomolecules. This may be achieved using surface anchoring thiol-containing molecules (e.g. sodium thioglycolate, glutathione 12, etc.) or more sophisticated ones (e.g. based on carboxylic or amino groups such as oligomeric phosphines, dendrons and peptides) to bind to the QDs surface and hydrophilic end groups (e.g. hydroxyl and carboxyl). Nevertheless, this approach can negatively alter the chemical and physical states of the QDs surface and cause a dramatic decrease in the quantum efficiency. For example, Jin et al. modified the surface of hydrophobic CdSeTe/CdS QDs with GSH in tetrahydrofuran-water solution and these QDs exhibited the QY only of 22% 32 . Moreover, thiol-based molecules (e.g. mercaptopropionic acids 33 ) may form disulphides over time and come off from the QDs surface and finally QDs aggregate and precipitate out of water. And next, most of water-soluble bifunctional molecules are expensive and instable. The second strategy employs polymerized silica shells with polar groups using a silica precursor (functional organosilane molecules containing –NH2 or –SH, e.g. 3-aminopropyltriethoxysilane 5 ) during the polycondensation to insulate the hydrophobic QDs. Silica coating enhances the mechanical stability of colloidal QDs and protects them against oxidation and agglomeration. The other advantage of silica encapsulation is QDs chemical stability over a much broader pH range compared to carboxy-terminated ligands, which limit the QDs dispersion to basic pH. The procedures creating a controllable silica layer (coating) around hydrophobic QDs core are relatively complicated regarding to the other strategies. The simple way to encapsulate QDs with silica is reverse microemulsion method, which is described in details below. The third method maintains the native ligands on the QDs and uses variants of amphiphilic diblock and triblock copolymers and phospholipids to tightly interleave the alkylphosphine ligands through hydrophobic interactions 34, 35 . Aside from rendering water solubility, these 9 Journal of Materials Chemistry – Review surface ligands play a critical role in insulating, passivating and protecting the QD surface from deterioration in biological media 14. Phospholipids can encapsulate QDs by forming oil-in-water micelles through interaction between their hydrophobic ends and the surface ligands of QDs and provide water-solubility via hydrophilic exterior ends. A more promising approach is to use long chain-length amphiphilic polymers to form micelle-like structures and hence to transfer the hydrophobic QDs into water. For example, Tortiglione et al. transferred hydrophobic TOP/TOPO-capped CdSe/ZnS QDs into aqueous solution by wrapping up them in an amphiphilic polymer shell (diamino-PEG 897) 36. Das and colleagues employed block copolymer spheres for encapsulation of CdS QDs in an aqueous emulsion polymerization process. First, stable dispersions of CdS QDs in water were prepared using a polymer dispersant, either poly(acrylic acid) or a random copolymer having an average of ten acrylic acid and five butyl acrylate units. These polymer dispersants were prepared by reversible addition-fragmentation chain transfer polymerization. Then, the CdS QDs dispersed in water were encapsulated in a polystyrene shell using an emulsion polymerization process 37 . This strategy is generally better than the ligand exchange because there is no direct interaction with the QDs surface atoms, which can preserve the original quantum efficiency to a highest extent. Moreover, the polymer’s large number of hydrophobic side chains strengthens the hydrophobic interaction to form more steady structures and consequently more stable water-soluble QDs. And finally, these amphiphilic polymers are commercially available and cheap that make them better materials than other molecules such as peptides and phospholipids in large-scale preparation. 3. Aqueous synthesis of QDs 10 Journal of Materials Chemistry – Review The second and more utilized way is the aqueous synthesis producing directly water soluble QDs with excellent biological compatibility and stability (usually more than two months)38. Compared with organic phase synthesis, QDs synthesized in aqueous way exhibit good reproducibility, low toxicity, and are less expensive. Basically, the fabrication process of water-soluble QDs takes place in reflux condenser (usually in a three-necked flask equipped with this reflux condenser). This synthesis route usually consists in reaction of heavy metal (Zn, Cd, etc.) precursor with chalcogen precursors. Ordinary used precursors of heavy metals easily dissolving in water are acetates, nitrates or chlorides. The chalcogen precursors can be either commercial solid powders (e.g. Na2TeO3 in the case of CdTe QDs) or freshly prepared before using in reaction procedure, e.g. H2Te (preparation by adding sulphuric acid dropwise to the aluminium telluride (Al2Te3) 39) or NaHTe (forming by reaction of sodium borohydride (NaBH4) with Te powder 40, 41) in the case of CdTe QDs. However, NaHTe and H2Te are unstable compounds under ambient conditions; therefore the synthesis of CdTe QDs generally has to be performed in inert reaction systems. Since Na2TeO3 is air-stable, all of operations can performed in air, avoiding the need for an inert atmosphere. The synthetic pathway is thus free of complicated vacuum manipulations and environmentally friendly. Nevertheless the procedure in water phase needs very long reaction time ranging from several hours to several days. Recently, new strategies employing microwave-assisted (MW) synthesis, which seems to be faster compared to the reflux one, were published as well (see below). The other disadvantages of QDs synthesized through aqueous route are the wider FWHM (the full width at half maximum) and lower QY which can be attributed to defects and traps on the surface of nanocrystals 42 . These defects can be eliminated by the selection of capping agents. The process of functionalization involves ligand exchange with thioalkyl acids such as thioglycolic 11 Journal of Materials Chemistry – Review acid (TGA) 43 , mercaptoacetic acid (MAA) 44 , mercaptopropionic acid (MPA) 45, 46 , mercaptoundecanoic acid (MUA) 47, mercaptosuccinic acid (MSA) 48 or reduced GSH 49, 50. From these ligands, GSH seems to be very perspective molecule, since it provides an additional functionality to the QDs due to its key function in detoxification of heavy metals (cadmium, lead) in organism 51 . Thus, GSH QDs as biological probe should be more biocompatible than other thiol-capping ligands. 3.1 QDs synthesis in reflux condenser This synthesis route usually consists in reaction of heavy metal (Zn, Cd; Fig. 1) precursor with chalcogen precursors. Ordinary used precursors of heavy metals easily dissolving in water are acetates, nitrates or chlorides. The chalcogen precursors can be either commercial solid powders (e.g. Na2TeO3 in the case of CdTe QDs) or freshly prepared before using in reaction procedure, e.g. H2Te (preparation by adding sulphuric acid dropwise to the aluminium telluride (Al2Te3) 39) or NaHTe (forming by reaction of sodium borohydride (NaBH4) with Te powder 40, 41) in the case of CdTe QDs. However, NaHTe and H2Te are unstable compounds under ambient conditions; therefore the synthesis of CdTe QDs generally has to be performed in inert reaction systems. Since Na2TeO3 is air-stable, all of operations can performed in air, avoiding the need for an inert atmosphere. The synthetic pathway is thus free of complicated vacuum manipulations and environmentally friendly. 3.2 Microwave irradiation synthesis Reflux methods for QDs synthesis require long reaction times and often result in a large number of surface defects on synthesized QDs with low photoluminescence QY, therefore some other 12 Journal of Materials Chemistry – Review more sophisticated approaches were investigated. Microwave synthesis was found to be very effective since it provides high-quality QDs in one-pot and in shorter time 52, 53 (Fig. 4). The process is based on rapid homogeneous heating realized through the penetration of microwaves. Compared to conventional thermal treatment, this way of heating allows the elimination of defects on QDs surface and produces uniform products with higher QY 54. The sizes of QDs can be easily tuned by varying the heating times. The QDs growth stops when the MW irradiation system is off and product is cooled down. From chemical point of view, the most frequent types of QDs synthesized using microwave irradiation are CdTe, CdSe, CdS, Zn1−xCdxSe and ZnSe. As usual, these QDs can be functionalized with various thiol ligands such as MPA, MSA 55 , TGA, 1-butanethiol, 2- mercaptoethanol 56 or GSH 57. However, thiol ligands can be also used as sulphur source in onestep MW synthesis of QDs. Qian et al. reported on a seed-mediated and rapid synthesis of CdSe/CdS QDs using MPA, which was decomposed during MW irradiation releasing S2- anions at temperature of 100 °C 58. In this step, only CdSe monomers were nucleated and grown by the reaction of NaHSe and cadmium chloride. The initial core was rich in Se due to the faster reaction of Se with Cd2+ compared to S. The amount of released S2- anions increased, when the temperature rose to 140 °C which resulted in formation of alloyed CdSeS shell on the surface of CdSe nanocrystals. As prepared, QDs showed the QY up to 25 %. Traditionally, GSH was used as thiol-capping agent for CdTe QDs in the work of other research group 57 . Highly luminescent, water-soluble, and biocompatible CdTe QDs were synthesized in one-pot through reaction of Cd2+–GSH complex (using cadmium chloride as Cd source) with freshly prepared NaHTe in a sealed vessel under MW irradiation at 130 °C in less than 30 min. The prepared nanocrystals possessed excellent optical properties and QY above 60 %. It is worth 13 Journal of Materials Chemistry – Review to note, that CdTe nanocrystals were tightly capped by Cd2+–GSH at a lower pH value (compared to other thiol ligands, e.g pH 11.2 in the case of MSA 55 ), which inhibited the growth of the nanocrystals. With the decrease of the pH value, the growth rate slows dramatically. Similar approach for one-step synthesis of GSH-capped ZnSe QDs in aqueous media was employed in the work of Huang et al. 53 . The process was based on reaction of air-stable Na2SeO3 with aqueous solution consisted of zinc nitrate and GSH. Then NaBH4 as reduction agent was added into the above solution with stirring. The pH was set to value of 10 by addition of NaOH. The mixture was then refluxed at 100 °C for 60 min under MW irradiation (300 W). The obtained QDs (2–3 nm), performed strong band-edge luminescence (QY reached 18%). 3.3 Microemulsion synthesis The microemulsion synthesis belongs to other non-refluxed method for fabrication of watersoluble QDs, which is simple, inexpensive and highly reproducible method enabling excellent control of QDs size and shape 59 . This control of particle size is achieved simply by varying water-to-surfactant molar ratio. Nevertheless, the microemulsion synthesis gives relatively low yield of product; even large amounts of surfactant and organic solvent are used compared to bulk aqueous precipitation. The key point of this procedure is extraction of the nanoparticles from microemulsion into aqueous phase and to maintain their structural and surface features. In order to reach feasible yields of nanoparticles, the higher concentration of precursors in microemulsion should be used, which leads to much larger particle density inside the reverse micelles. In this synthesis way, various thiol ligands are employed for QDs coating, for example mercaptoacetic acid, mercaptopropionic acid and GSH 49 . Briefly, the typical microemulsion synthesis of CdSe QDs can be described as follows: Se powder is added to Na2SO3 solution 14 Journal of Materials Chemistry – Review under continuous nitrogen bubbling at higher temperature forming Na2SeSO3 (sodium selenosulphate). Subsequently, this precursor was mixed with reverse micelle system prepared by dissolving AOT (sodium bis(2-ethylhexyl) sulphosuccinate) in n-heptane. Similar microemulsion was prepared with Cd(NO3)2. Finally, these two microemulsions were vortex-mixed which leaded to formation of CdSe QDs inside the reverse micelles. In the second step, a shell of CdS was created by addition of (NH4)2S microemulsion under vortex-stirring. The last step consisted in core-shell QDs stabilization using thiol ligands aqueous solution, which is added to solution of QDs. The process is accompanied with colour change of organic phase (initially orange–red) to translucent. This colour change indicated the complete transfer of thiol-capped QDs into the aqueous phase. The CTAB is another molecule which can be used to cap QDs forming a micelle. This surfactant is known to create spherical micelle in the aqueous medium, where the nucleation and growth of the QDs takes place in the cavity of the CTAB micelle 60. 4. Glutathione as a QD capping agent GSH is a linear tripeptide synthesized in the body from 3 amino acids: L-glutamate, L-cysteine, and glycine. These functional groups provide the possibility of being coupled and further crosslinked to form a polymerized structure 61. Thiol group of cysteine is very critical in detoxification and it is the active part of the molecule which serves as a reducing agent to prevent oxidation of tissues 50. Besides its thiol group is acting as a capping agent, each GSH molecule also contains one amine and two carboxy groups 62 . GSH is presented in almost all living cells, where it maintains the cellular redox potential. The liver, spleen, kidneys, pancreas, lens, cornea, erythrocytes, and leukocytes, have the highest concentrations in the body, ordinary in the range from 0.1 to 10 mM. It belongs to powerful anti-viral agents and antioxidants for the protection of 15 Journal of Materials Chemistry – Review proteins, which neutralizes free radicals and prevents their formation. Moreover, it is considered to be one of the strongest anti-cancer agents manufactured by the body. GSH important role is also in the liver for detoxification of many toxins including formaldehyde, acetaminophen, benzpyrene and many other compounds and heavy metals such as mercury, lead, arsenic and especially cadmium, which will be discussed later concerning the toxicity level of Cd-based QDs. GSH is involved in nucleic acid synthesis and helps in DNA repairing 63 . It slows the aging processes; however its concentration decreases with age. GSH must be in the reduced form to work properly. Reduced GSH is the smallest intracellular thiol (-SH) molecule. Its high electrondonating capacity (high negative redox potential) combined with high intracellular concentration (milimolar levels) generate great reducing power. This characteristic underlies its potent antioxidant action and enzyme cofactor properties, and supports a complex thiol-exchange system, which hierarchically regulates cell activity. 4.1 CdTe QDs capped with GSH Xue et al. synthesized GSH-capped CdTe QDs by mixing the solutions of cadmium acetate and GSH and following injection of NaHTe solution under argon atmosphere and heating 64 . After refluxing, QDs were precipitated with an equivalent amount of 2-propanol, followed by resuspension in a minimal amount of ultrapure water. Excess salts were removed by repeating this procedure three times, and the purified QDs were dried overnight at room temperature in vacuum. These GSH-QDs showed excellent photostability and possessed high QY (42 %) without any post-treatment. The authors conjugated the QDs with folic acid and studied how these labelled QDs can specifically target folic acid receptor on the surface of human hepatoma and human ovarian cancer cell to demonstrate their potentially application as biolabels. 16 Journal of Materials Chemistry – Review Another GSH-functionalized QDS, namely CdTe and CdZnSe, were prepared by Ali et al. 51. The first mentioned were synthesized from H2Te and CdCl2, while in the second case NaHSe, ZnCl2, H2Se were used. Both types of GSH-capped QDs were coupled with a high-throughput detection system, to provide quick and ultrasensitive Pb2+ detection without the need of additional electronic devices. The mechanism is based on selective reduction of GSH-capped QDs in the presence of Pb2+ which results in fluorescence quenching that can be attributed to the stronger binding between heavy metal ions and the surface of GSH capping layer. Also Goncalves and colleagues employed the simple experimental procedure for GSH-capped CdTe QDs fabrication and investigated the fluorescence intensity quenching in the presence of Pb2+ ions 65. Briefly, they mixed CdCl2 and GSH aqueous solutions with freshly prepared NaHTe solution and the mixture was refluxed up to 8 h. The same reactants for synthesis of GSH-capped CdTe QDs were used by Cao M. et al. 66 and Dong et al. 67. Cao and co-authors studied QDs interactions (fluorescence quenching) with hemecontaining proteins and they found their optical fluorescence probes can be used for the selective determination of cytochrome c under optimal pH value. While Dong et al. used their GSH-CdTe QDs as fluorescent labels to link bovine serum albumin (BSA) and rat anti-mouse CD4, which was expressed on mouse T-lymphocyte and mouse spleen tissue. The authors demonstrated that CdTe QDs-based probe exhibited much better photostability and fluorescence intensity than one of the most common fluorophores, fluorescein isothiocyanate (FITC), showing a good application potential in the immuno-labelling of cells and tissues. Wang and colleagues reported on preparation of three kinds of water-soluble QDs, MAA-capped CdTe QDs, MAA-capped CdTe/ZnS and GSH-capped CdTe QDs, and compared the change of their fluorescence intensity (quenching) in the presence of As (III)68. Arsenic (III) has a high 17 Journal of Materials Chemistry – Review affinity to reduced GSH to form As(SG)3 thus the fluorescence of GSH coated QDs is reduced significantly in the presence of As (III). MAA-capped CdTe QDs were prepared through reaction of CdCl2 and MAA with subsequent injection of freshly prepared NaHTe solution under vigorous magnetic stirring. Then the precursor solution was heated and refluxed under N2 protection for 60 min. Finally, cold ethanol was added and MAA-CdTe QDs were precipitated out by centrifugation. Similar procedure was used for GSH-capped CdTe QDs synthesis with only one difference: the precipitation process was repeated for three times in order to eliminate free GSH ligands and salts in the GSH-CdTe QDs colloids. MAA-capped CdTe/ZnS QDs were prepared also similarly. When the CdTe precursor was refluxed for 30 min, ZnCl2 and Na2S were added slowly and simultaneously to form ZnS shell. After another 30 min, the products were separated by the addition of cold ethanol and centrifugation. Different thiol ligands, including TGA, L-cysteine (L-Cys) and GSH for capping CdTe QDs were also tested by Li Z. et al. 69 . The starting materials were identical as in previous mentioned studies, i.e. NaHTe and CdCl2. The luminescent properties of CdTe QDs with different stabilizing agents were studied by using fluorescence spectra, which showed that CdTe QDs with longer emission wavelength (680nm) can be synthesized more easily when L-Cys or GSH is chosen as stabilizing agents. Moreover, the authors found that the cytotoxicity of TGA-QDs is higher than that of L-Cys- and GSH-CdTe. Ma et al. also prepared CdTe QDs modified with these three thiol-complex, namely TGA, L-cys and GSH and investigated the interactions of prepared QDs with BSA using spectroscopic methods (UV-VIS, IR and fluorescence spectrometry) 70. Tian et al. 31 used for the first time GSH and TGA together to enhance stability of water soluble CdTe QDs prepared using NaHTe and CdCl2. The author prepared different-sized CdTe QDs 18 Journal of Materials Chemistry – Review with controllable photoluminescence wavelengths from 500 to 610 nm within 5 h at temperature of 100 °C. When the molar ratio of GSH to TGA is 1:1, QY of the yellow-emitting CdTe (emission maximum at 550 nm) reached 63 % without any post-treatment. The synthesized CdTe QDs possess free carboxyl and amino groups, which were successfully conjugated with insulin for delivery to cells, demonstrating that they can be easily bound bimolecularly and have potentially broad applications as bioprobes. Yuan et al. replaced NaHTe with more convenient Na2TeO3 for preparation of CdTe QDs, namely they used CdCl2 and Na2TeO3, which were subsequently mixed with MSA or GSH as capping agent 50 . The prepared QDs were tested for glucose detection by monitoring QDs photoluminescence quenching as consequence of H2O2 presence and acidic changes produced by glucose oxidase catalysing glucose oxidation, respectively. The authors found that the sensitivity of QDs to H2O2 depends on QDs size: smaller size presented higher sensitivity. The quenching effect of H2O2 on GSH-capped QDs was more than two times intensive than that on MSA-capped QDs. 4.2 CdSe QDs capped with GSH Compared to CdTe QDs, GSH-capped CdSe QDs are much readily prepared. Jing et al. synthesized TGA-capped CdSe QDs using CdCl2 and Na2SeO3, and they used these QDs for hydroxyl radical electrochemiluminescence sensing of the scavengers 71. The research group of Dong, mentioned in synthesis of CdTe QDs, also prepared two kinds of highly fluorescent GSH-capped CdSe/CdS core-shell QDs emitting green and orange fluorescence at 350 nm excitation by an aqueous approach 72 . The authors used these QDs as fluorescent labels to link mouse anti-human CD3 which was expressed on human T-lymphocyte. 19 Journal of Materials Chemistry – Review Compared to CdSe QDs, they found a remarkable enhancement in the emission intensity and a red shift of emission wavelength for both types of core-shell CdSe/CdS QDs. They demonstrated that the fluorescent CdSe/CdS QDs exhibited much better photo-stability and brighter fluorescence than FITC. 4.3 CdS QDs capped with GSH Also thiol-capped CdS QDs are less studied in comparison with CdTe QDs. MPA belongs to the most tested thiol ligands for capping these QDS 73 . Liang et al. synthesized GSH-capped CdS QDs in aqueous solutions from CdCl2 and CH3CSNH2 (thioacetamide) at room temperature 74. In this synthesis procedure, GSH was added in a final step into previously prepared CdS QDs solution. The obtained GSH coated QDs were tested as fluorescence probes for determination of Hg2+ with high sensitivity and selectivity. Under optimal conditions, the quenched fluorescence intensity increased linearly with the concentration of Hg2+. Merkoci et al. employed another preparation process: GSH and CdCl2 were first dissolved in water with subsequent addition of TMAH (tetramethylammoniumhydroxide) and ethanol. After degassing, HMDST (hexamethyldisilathiane) was quickly added as sulphide precursor, giving a clear (slightly yellow) colloidal solution of water soluble CdS QDs modified with GSH 75 . The authors used these QDs as a model compound in a direct electrochemical detection of CdS QDs or other similar QDs, based on the square-wave voltammetry of CdS QDs suspension dropped onto the surface of a screen printed electrode. This detection method is simple and low cost compared to optical methods and it will be interesting for bioanalytical assays, where CdS QDs can be used as electrochemical tracers, mainly in fast screening as well as in field analysis. 20 Journal of Materials Chemistry – Review Thangadurai and colleagues investigated 5 organic thiols as suitable capping agent for CdS QDs (diameter of 2–3.3 nm), namely 1,4-dithiothreitol (DTT), 2-mercaptoethanol , L-Cys, methionine and GSH 76 . The QDs were prepared by a wet chemical method from Cd(NO3)2 and Na2S. Briefly, the process started with addition of capping agent aqueous solution to the solution of Cd(NO3)2 and stirred for 12 h at room temperature and under dry N2 atmosphere. In the second step, Na2S solution was added dropwise and stirred for another 12 h. The CdS prepared with and without coating appeared greenish yellow and dark orange, respectively. The authors revealed the CdS QDs being in cubic phase. According to FT-IR studies, they suggested two different bonding mechanisms of the capping agents with the CdS. DTT was found to be the best capping agent for CdS from all tested thiols because of lower grain size in cubic phase and good fluorescence properties with efficient quenching of the surface traps. Jiang et al. prepared GSH-capped aqueous CdS QDs with strong photoluminescence (QY of 36 %) using CdCl2 and Na2S by typical procedure 71. The excitation spectrum was broad ranging from 200 to 480 nm. These QDs were conjugated with BSA and tested as fluorescence probes. The results demonstrated that the fluorescence of CdS QDs can be enhanced by BSA depending on BSA concentration. 4.4 Zn-based QDs capped with GSH Generally, the QDs fluorescent colour can be tuned by changing their size which depends mainly on reaction time. There is also another option how to tune the colour of QDs emission without changing the QDs size using alloyed QDs, which is the most frequently used approach for Znbased QDs. Alloyed QDs are traditionally fabricated in two step synthesis route, for example by incorporation of Cd2+ into very small ZnSe seeds 77 . Subsequent stabilization of these QDs is usually ensured with thiol compounds. Cao et al. prepared water-soluble violet–green emitting 21 Journal of Materials Chemistry – Review core/shell Zn1−xCdxSe/ZnS QDs using N-acetyl-l-cysteine (NAC) as a stabilizer 78 . ZnS shell provided reduction of Zn1−xCdxSe core cytotoxicity and increase of QY up to 30 %, while NAC resulted in excellent biocompatibility of these QDs. Liu and colleagues synthesized alloyed ZnxHg1−xSe QDs capped with GSH in one step process by reacting a mixture of Zn(ClO4)2, Hg(ClO4)2 and GSH with freshly prepared NaHSe 79 . The fluorescent colour of the alloyed QDs can be easily tuned in the range of 548–621 nm by varying the Zn2+:Hg2+ molar ratio, reaction pH, intrinsic Zn2+ and Hg2+ reactivity toward NaHSe, and the concentration of NaHSe. These GSH-capped Zn0.96Hg0.04Se QDs possessed high QY (78 %) and were applied for sensing Cu2+. Ying et al. synthesized another type of alloyed QDs, namely GSHcapped Zn1-xCdxSe QDs with tuneable fluorescence emissions (360–700 nm) and QY up to 50 %80. Lesnyak and colleagues demonstrated a facile one-step aqueous synthesis of blueemitting GSH-capped ZnSe1-xTex QDs with QY up to 20 % 81. Deng et al. examined two other thiol ligands beside GSH, MPA and TGA, for stabilization of ZnSe and ZnxCd1-xSe QDs synthesized by water-based route 82. A typical synthetic procedure for ZnSe QDs started with mixing Zn(NO3)2, thiol molecule and N2H4 (hydrazine), which was used to maintain oxygen-free conditions, allowing the reaction vessel to be open to air. In the next step, freshly prepared NaHSe solution was added to the flask with vigorous stirring and the pH was adjusted to 11 using 1 M NaOH. The mixture was refluxed at temperature close to 100 °C which resulted in light blue solution as ZnSe QDs grew. The prepared QDs possessed tuneable and narrow photoluminescence (PL) peaks ranging from 350 to 490 nm. The authors found that MPA capping agent gave rise to smaller ZnSe QDs with a high density of surface defects, while TGA and GSH produced larger ZnSe QDs with lower surface defect densities. According to absorption spectra, the growth was more uniform and better controlled with linear two-carbon 22 Journal of Materials Chemistry – Review TGA (QDs size of 2.5 nm) than with GSH, which is branched bifunctional molecule. Concerning ZnxCd1-xSe QDs, the preparation was performed in a reducing atmosphere by addition of Cd-thiol complex directly to ZnSe QDs solution. The PL peaks changed from 400 to 490 nm by changing the Zn to Cd ratio. Fang et al. fabricated water-dispersible GSH-capped ZnSe/ZnS core/shell QDs with high QY up to 65 % 83. In the first step, GSH-capped ZnSe core was synthesized by mixing zinc acetate with GSH solution. The pH of solution was adjusted to 11.5 by addition of 2 M NaOH. Subsequently, fresh NaHSe solution was added at room temperature. The system was heated to 90 °C under N2 atmosphere for 1 h which resulted in formation of ZnSe core with an average size of 2.7 nm. In the second step, ZnS shell was created in reaction of as-prepared ZnSe core with shell precursor compounds (zinc acetate as zinc resource and thiourea as sulphur resource) at 90 °C. In comparison to the plain ZnSe QDs, both the QY and the stability against UV irradiation and chemical oxidation of ZnSe/ZnS core/shell QDs have been greatly improved. 5. Characterization of QDs The most important characterization of QDs dealing with their optical properties is usually provided by UV-VIS and photoluminescence spectroscopy, which offer fast, non-destructive and contactless option. Besides monitoring the excitation, absorption and emission spectra, which are usually applied for calculation of quantum yield, band gap studies can be also carried out by optical diffuse reflectance spectra measurement. Size of QDs can be calculated from absorption edges using Henglein empirical curve, which relates the wavelength of the absorption threshold to the diameter of QDs 37 . In particular cases, the Fourier transformed infrared (FTIR) spectroscopic measurements are also necessary 84 . Raman spectroscopy, as one of the best non- 23 Journal of Materials Chemistry – Review destructive techniques, can be employed for QDs characterization as well, since it allows to probe the active optical phonon modes and to explore the confined electronic structure of QDs 60, 85. As mentioned before, the optical properties (fluorescence emission) of QDs can be fine-tuned by the QDs size, which is a key parameter that determines the spectral position and purity of photoluminescence. QDs size and morphology (shape and structure) are generally calculated using conventional techniques like scanning electron microscopy (SEM), transmission electron microscopy (TEM), and dynamic light scattering (DLS) studies. For these measurements, QDs are usually transformed to powder form either by simple drying of QDs solution or by precipitation (for example with ethanol), centrifugation and final drying. Besides these techniques, field flow fractionation, which belongs to high resolution liquid chromatography-like elution methods for separating and sizing, can be also successfully employed for QDs size distribution analysis 86 . The structure of QDs is usually analysed by X-ray diffraction (XRD) 87 and the elemental composition of QDs can be studied by energy dispersive X-ray analysis (known as EDS, EDX or EDAX) 84 . Other techniques, like inductively coupled plasma atomic emission spectrometry (ICP-AES), was used for analysis of QDs as well, namely for the metal ions content in final QDs 88. Recently, also electrochemical methods were applied to the study of QDs behaviour 89-91. 6. Applications of QDs In the 1970s and early 1980s, understanding the photophysical properties of semiconductor structures was important for a broad range of computer and electronic applications. It was hypothesized that the physical properties of structures in an intermediate size range (between single atoms and bulk) could be tuned by alteration of size and shape. For electronics and 24 Journal of Materials Chemistry – Review computer applications, such a system allows an engineer to synthesize a large set of nanometresized building blocks for constructing faster and smaller computer chips or more efficient lightemitting devices. Very soon it was realized that these nanometre size structures can have significantly much more applications. Nowadays a wide range of QDs utilizations are found in the biological, biochemical and biomedical areas. Besides the applications as simple sensors 92-94, the main function of the QDs based on their exceptional fluorescent properties in the biochemical and biomedical research area is their use as unique fluorescent labels 95-97 . Utilization of QDs for various purposes are shown in Fig. 5). 6.1 QDs toxicity and biocompatibility To use QDs in biology, it is extremely important to deal with the biocompatibility and toxicity. However, very few studies have examined the toxicity of these nanomaterials 98-100 . Moreover, the toxicity of nanomaterials is highly complicated, due to the diversity of materials. In sharp contrast to conventional hazardous materials, the attention has to be paid to the nanoparticlespecific problems; including the fact that surface of nanomaterials is highly active due to the large surface area, and surface to volume ratio. In addition, it is necessary to exclude the effect of solubility and possible contamination, which also would decrease the validity of any toxicity testing 99. In 2006, Hardman reviewed the toxicity of QDs as a function of physicochemical and environmental factors 101 . QDs size, charge, concentration, outer coating bioactivity (capping material, functional groups), as well as oxidative, photolytic, and mechanical stability have each been shown to be determining factors of QDs toxicity. In vitro studies suggest certain QDs types may be cytotoxic. 25 Journal of Materials Chemistry – Review To improve the biocompatibility, it is needed to passivate or cap the QDs with a layer of ZnS or CdS. The ZnS or CdS improve the fluorescence QY of the QDs and protect them against photooxidation (which is important for minimizing cytotoxicity and for enhancing photostability). The ZnS shell has larger band gap energy than CdSe, eliminating the core’s surface defect states. Also, the ZnS shell has a similar bond length to the CdSe, minimizing crystal-lattice strain and allowing epitaxial growth. Even with advances in synthesis, obtaining biomedically useful QDs is still problematic due to differences in optical properties from batch to batch. From one synthesis to the next, QDs with different QYs and fluorescence spectra may be produced. Moreover, further functionalization is needed for incorporation of required chemistry. Various surface modification techniques were developed to ensure the specific bioconjugation. This is usually achieved by decorating QDs with proteins, peptides, nucleic acids, or other biomolecules that mediate specific interactions with living systems. Surface engineering is thus crucial not only for tuning the fundamental properties of nanomaterials and for rendering them stable and soluble in different environments, but also for creating nanoparticle–biomolecule hybrids capable of participating in biological processes. Such hybrids should combine useful properties of both materials involved, i.e. optical properties of the nanocrystals and biological functions of ligands attached 95 . One of these strategies utilizes the biotin-avidin (respectively streptavidin and neutravidin) interaction known for its very high specificity. Modification of QDs by the streptavidin proved a very successful method evaluated in numerous publications 104 15, 95, 102- and due to this success, streptavidin-QDs are nowadays also commercially available. In addition, biotin-functionalized QDs were developed to exploit the same interaction. Recent achievements in merging nanoparticle encapsulation and bioconjugation steps and design of pre-functionalized surface coatings promise to provide more compact, stable, and 26 Journal of Materials Chemistry – Review biocompatible nanoparticles with controlled density and orientation of ligands attached. Amphiphilic polymers with a maleic anhydride backbone are being actively explored for this purpose. In organic anhydrous solvents, such polymers encapsulate TOPO-coated QDs and introduce reactive anhydride groups on the surface. In basic aqueous buffers, anhydride rings are quickly hydrolysed, yielding negatively charged carboxylic acid groups and rendering QDs water soluble 105 . More importantly, anhydride groups are highly reactive towards amine-containing molecules, thus allowing covalent conjugation of a variety of biomolecules to the polymer chains without the need for post-encapsulation modification 106, 107. Choice of the bioconjugation approach depends on availability of ligands with suitable functional groups and on specific application requirements. However, common design criteria involve preserved QDs photo-physical properties and ligand biofunctionality, controlled ligand orientation and binding stoichiometry, compact probe size, and good stability in physiological environment. As these criteria can be satisfied in only few specific cases, improvement of existing bioconjugation techniques and design of novel application specific water-solubilization and bioconjugation approaches remains an active area of research. With the development of stable and biofunctional QDs probes, these materials will become nanoscience building blocks with flexible properties that could be further optimized for specific applications including biomedical imaging, detection, and nano-therapeutics 108. 6.2 In vitro applications In vitro literally means “in glass”. The conditions of the experiment are artificial and simulate what might happen in vivo. In the last decade, surface engineering and bio-functionalization techniques have transformed semiconductor nanocrystals into complex cellular probes capable of 27 Journal of Materials Chemistry – Review interaction with biomolecules and direct participation in biological processes. In 1998, two seminal science papers first demonstrated that semiconductor nanoparticles could be made watersoluble and used as biological imaging probes 109, 110 . One approach utilized silica shell encapsulation chemistry in order to produce QDs for a single-excitation dual-colour cell staining 109 . When derivatized with trimethoxysilylpropyl urea and acetate groups, green QDs preferentially labelled the cell nucleus, and when derivatized with biotin, red QDs labelled Factin filaments pre-treated with phalloidin-biotin and streptavidin. The second paper was the first to demonstrate the ligand-exchange approach to QDs water solubilization 110 . Subsequent conjugation of transferrin produced QDs probes that were endocytosed by live HeLa cells resulting in punctate cell staining, while IgG bioconjugates were used in an aggregation-based immunoassay. Since then, a multitude of surface engineering techniques for QDs solubilization and biofunctionalization have been developed, enabling application specific design of QDs probes. Such probes have found their use in a variety of in vitro applications, such as histological evaluation of cells and tissue specimens, single molecule detection and real-time tracking, longterm live-cell imaging, and study of intracellular processes. Moreover, QDs can be employed as optical labels that probe dynamic biological processes, such as biocatalysed reactions or structurally induced biomolecular transformations using fluorescence resonance energy transfer (FRET) or electron-transfer quenching as photophysical probing mechanisms (Fig. 5). 6.3 In vivo applications The characterization and analysis of biomolecules and biological systems in the context of intact organisms is known as in vivo research. The in vivo approach involves experiments performed in the large system of the body of an experimental animal. Compared with the imaging in vitro, 28 Journal of Materials Chemistry – Review QDs imaging in vivo faces different challenges caused by the increase of complexity of multicellular organism, and also caused by the accompanying increase in the size. There are four main kinds of in vivo imaging applications with QDs: biodistribution of QDs in vivo, in vivo vascular imaging, in vivo tracking of QDs, and in vivo tumour imaging (Fig. 5). Utilization of nanomaterials, particularly nanoparticles for the in vivo monitoring of cell transplantation is one of near future appealing application. Currently MRI provides low resolution and no difference between original and transplanted cells is registered. Any cells can be labelled – stem cells, Langerhans cells, tumour cells, etc. Incorporation of the contrast agents into the cells can be done by either phagocytosis or conjugation of the contrast agent to the cell surface via antibody interaction with the receptor. Labelled cells can be transplanted into the animal as well as bacteria. This method is available especially for bacterial screening avoiding time-consuming procedures and it is advantageous in clinical diagnosis and environmental monitoring. A new and exciting direction of research for QDs is their application as a contrast agent for in vivo imaging 34, 111-113 . Organic fluorophores and chemiluminescence probes are currently the most commonly used optical probes for animal imaging. However, a limitation of optical contrast agents is the lack of available probes that emit in NIR emission range (> 650 nm). The NIR emitting window is appealing for biological optical imaging because of the low tissue absorption and scattering effects in this emission range. The bounds of the NIR optical window for animal imaging are typically set at 650–900 nm. Since the optical properties of QDs can be tuned by size and composition, it should be possible to prepare a series of NIR-emitting QDs for animal imaging 114. CdTe, CdTeSe, InPAs, PbS, and PbSe have been successfully synthesized with NIR emission 115, 116. For most investigations of in vivo imaging, QDs are usually directly injected into 29 Journal of Materials Chemistry – Review the live animal intravenously or subcutaneously and thereby are delivered into the bloodstream. The behaviour of QDs in vivo is very interesting because they have to interact with the components of plasma, blood cells, and the vascular endothelium. 6.4 Quantum dots and nanocomposites in cancer detection and therapy Imaging application. It is generally accepted idea that the future treatment for cancer relies on early detection of cancer lesions, as well as efficient and specific delivery of drugs to the cancer cell site 117 . The detection of stage 1 cancer is associated with > 90% 5-year survival rate while conventional anatomic imaging typically cannot detect cancers until they reach > 1 cm diameter. Molecular imaging, especially with QDs covalently linked to biorecognition molecules such as peptides, antibodies, nucleic acids, or small-molecule ligands, is expected to play an important role in future cancer diagnosis. QDs inside cells are particularly useful for cell tracking to study cell division and metastasis. Because of the QDs high stability and multicolour emission, QDs can act as unique markers for tracking cancer cells in vivo during metastasis — a critical issue in the development of effective cancer therapies. Whole-body NIR optical imaging is a powerful technique that allows the observation of complex biological phenomena with minimum invasiveness. The absorption of light by tissues in the NIR region is limited as compared with that in the UV and VIS regions. Thus, light can penetrate several centimetres below the body surface, and internal fluorophores can be observed easily. In the NIR region autofluorescence from tissues is also limited, so that the fluorescence of an introduced fluorophore can be more clearly visualized 118, 119 . Kim et al. presented a study where NIR QDs emitting at 850 nm were used as markers in sentinel lymph node mapping, a major procedure in cancer surgery, whereby the lymph node closest to the organ affected is monitored for the presence of roaming cancer 30 Journal of Materials Chemistry – Review cells 120 . Also, other authors have reported an elegant study using QDs to simultaneously track different populations of cells in lung tissue 119. They have used the major features of QDs and the high resolution of fluorescence, combined QDs and emission spectrum scanning multiphoton microscopy to develop a mean to study extravasations in vivo. Briefly, to examine the cell metastasis in a natural tissue environment, a mixed population was injected into the tail vein, extracted and fixed lung tissues, and then emission-scanning microscopy was used to distinguish both populations of cells in the whole tissue sample. Thus, there exists a broad range of characterization methods and alternative strategies that researchers may follow, such as the use of emission spectrum scanning microscopy allowing simultaneously tracking of several different QD-tagged populations of cells in the same living organism. An important aspect to be considered on developing new strategies for cancer detecting and treatment is the QD-target conjugate efficiency on reaching the site in vivo assays. Biomolecule labelling application. Interestingly, some authors have reported on the approach of using engineered-coated QDs that ‘disguises’ the host system as the surfaces are covered by a synthetic peptide, a tactic inspired nature and found in plants and yeasts. Synthetic phytochelatinrelated peptides were used as an organic coat on the surface of colloidal CdSe/ZnS semiconductor nanocrystals synthesized from hydrophobic coordinating TOPO solvents. The peptides are designed to bind to the nanocrystals via a C-terminal adhesive domain 121 . It was demonstrated that through a surface chemistry approach using bioconjugation the process is suitable for targeting and detecting individual protein receptors in living cells. Hence, a picture can be envisioned in which cancer diagnosis and patient management could be considerably improved. For instance, patients at high risk of breast or colorectal cancer would be injected with the color-coded QDs with the engineered antibodies specific for cancer-associated cell surface 31 Journal of Materials Chemistry – Review markers before being submitted to mammography or colonoscopy. In case it is needed, the biopsy would be conducted using the tissue already labelled by the QDs under fluorescence microscopy 122 . Immunofluorescence labelling using QDs showed different staining patterns between normal and cancer cells 123 . Detection of ovarian cancer marker CA 125 in various specimens using streptavidin-conjugated QDs 124. In addition, a very promising realm of cancer research based on the detection of genetic polymorphisms is discussed. Briefly, QDs can be used for the simultaneous detection of multiple single nucleotide polymorphisms (SNPs). QDs have been used in assays for detection of SNPs of cytochrome p450 and the human p53 tumour suppressor gene; a gene that has been suggested as being involved in over half of the known human cancers. For the reasons expounded above, in the future, a reasonable scenario may be envisaged where polymers, biomolecules, and QDs will be conjugated in a completely integrated hybrid nanostructured composite system aiming to address a large number of problems and challenges faced by the biomedical community. Therapeutic application. Recent advances in surface modification of QDs have enabled their potential application in cancer imaging 125 . Conjugation of QDs with biomolecules, including peptides and antibodies, could be used to target tumours in vivo. QDs with NIR emission could be applied to sentinel lymph node mapping to aid biopsy and surgery 126 . For diagnosis and imaging of breast cancer, an assay that could accurately quantify several cancer-related proteins simultaneously on single tumour sections or small tumour specimens could offer clear advantages over standard immuno-histochemical methods 127 . With this approach, Wu et al. 128 showed specific ERBB2 labelling of fixed ERBB2-positive breast-cancer cells and human ERBB2positive breast-cancer xenografts. Although this method is easy to use and highly effective for 32 Journal of Materials Chemistry – Review single staining of cell proteins, it is not optimal for multiplex protein detection. Al-Hajj et al. 129 have shown simultaneous multiplex detection of six breast cancer proteins by use of direct conjugation of QDs to antibodies on fixed paraffin-embedded tumour samples. Recently, Hassan and collaborators have published a fine review considering the QDs as a ‘nanomedicine toolbox’. With respect to cancer detection and therapy some important examples based or specific targeting ligands were summarized, for instance: detection of Her2 (hairy-related 2) on SK-BR-3 breastcancer cells by employing humanized anti-Her2 antibody, a biotinylated goat anti-human IgG, and streptavidin coated QDs 128. 7. Conclusion QDs, tiny light-emitting nanocrystals, have emerged as a new promising class of fluorescent probes for biomolecular and cellular imaging. In comparison with organic dyes and fluorescent proteins, QDs have unique optical and electronic properties such as size-tuneable light emission, improved signal brightness, resistance against photobleaching, and simultaneous excitation of multiple fluorescence colours. The biomedical applications of nanoparticles are rooted in the advanced functional design, and have been realized in preclinical experimental diagnosis. In the end, they will contribute to personalized clinical treatment based on molecular profiles of each individual patient. The development is rapid and multidirectional, but at present is still in its early stages. The main applications of nanoparticles can be divided into several major directions: diagnostic molecular imaging, delivery of drug and gene, and targeted therapy. Acknowledgements 33 Journal of Materials Chemistry – Review Financial support from CEITEC CZ.1.05/1.1.00/02.0068, IGA IP MENDELU 2012, GA CR 102/10/P618 and NANOSEMED GA AV KAN208130801 is highly acknowledged. The author P.S. is „Holder of Brno PhD Talent Financial Aid“. 34 Journal of Materials Chemistry – Review Captions for Figures Figure 1 The most commonly used semiconductor metals Zinc, cadmium, indium, gallium, arsenic, selenium, tellurium and sulphur for QDs synthesis. Figure 2 Photo of CdTe QDs of different size illuminated by UV light. QD were prepared according to Duan et al. 54 . Cadmium chloride solution (CdCl2, 0.04 M, 4 ml) was diluted to 42 ml with ultrapure water, and then trisodium citrate dihydrate (100 mg), Na2TeO3 (0.01 M, 4 ml), MPA (119 mg), and NaBH4 (50 mg) were added successively under magnetic stirring. The molar ratio of Cd2+/MPA/Te was 1:7:0.25. 10 ml of the resulting CdTe precursor was put into a Teflon vessel. CdTe QDs were prepared at 95°C for various times according to desired colour (10 min. – green, 30 min. yellow, 120 min. – red) under microwave irradiation (400 W, Multiwave3000, Anton-Paar GmbH, Austria). After microwave irradiation, the mixture was cooled 50 °C and the CdTe QDs sample was obtained. Figure 3 The most common surface modification approaches used for bio applications. Antibodies, single strands of nucleic acids, double strands of nucleic acids, proteins, peptides and small organic molecules are often used. Figure 4 35 Journal of Materials Chemistry – Review Scheme of simple microwave assisted QDs synthesis. For other details, please, see caption for Figure 2. Figure 5 Applications of QDs in chemical, biomedical and diagnostic area. QDs can be applied for biosensing, biomarker mapping, real time cell growth monitoring, drug delivering, gene delivering, detection and diagnostics, molecular imaging, and targeted therapy. 36 Journal of Materials Chemistry – Review References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. L. Eaves, Nature, 1992, 357, 540-540. P. Matagne and J.-P. Leburton, Quantum Dots: Artificial Atoms and Molecules, American Scientific Publishers Stevenson Ranch, California, 2003. R. C. Ashoori, Nature, 1996, 379, 413-419. M. A. Ghanem, P. N. Bartlett, P. de Groot and A. Zhukov, Electrochem. Commun., 2004, 6, 447-453. Y. Q. Wang and L. X. Chen, Nanomed.-Nanotechnol. Biol. Med., 2011, 7, 385-402. M. S. Skolnick and D. J. Mowbray, Ann. Rev. Mater. Res., 2004, 34, 181-218. R. J. Byers and E. R. Hitchman, Prog. Histochem. Cytochem., 2011, 45, 201-237. D. E. Nam, W. S. Song and H. Yang, J. Mater. Chem., 2011, 21, 18220-18226. P. T. Shao, H. Z. Wang, Q. H. Zhang and Y. G. Li, J. Mater. Chem., 2011, 21, 1797217977. S. M. Reimann and M. Manninen, Rev. Mod. Phys., 2002, 74, 1283-1342. G. P. C. Drummen, Int. J. Mol. Sci., 2010, 11, 154-163. R. Gill, L. Bahshi, R. Freeman and I. Willner, Angew. Chem.-Int. Edit., 2008, 47, 16761679. A. F. E. Hezinger, J. Teßmar and A. Göpferich, Eur. J. Pharm. Biopharm., 2008, 68, 138152. W. B. Cai, A. R. Hsu, Z. B. Li and X. Y. Chen, Nanoscale Res. Lett., 2007, 2, 265-281. M. Ryvolova, J. Chomoucka, L. Janu, J. Drbohlavova, V. Adam, J. Hubalek and R. Kizek, Electrophoresis, 2011, 32, 1619-1622. J. Chomoucka, J. Drbohlavova, P. Babula, V. Adam, J. Hubalek, I. Provaznik and R. Kizek, in Eurosensor XXIV Conference, eds. B. Jakoby and M. J. Vellekoop, Elsevier Science Bv, Linz, 2010, pp. 922-925. H. Mattoussi, G. Palui and H. B. Na, Adv. Drug Deliv. Rev., 2011, in press http://dx.doi.org/10.1016/j.bbr.2011.03.031. C. Carrillo-Carrión, B. M. Simonet and M. Valcárcel, Anal. Chim. Acta, 2011, 703, 212218. Z. Wan, W. Luan and S.-T. Tu, J. Colloid Interface Sci., 2011, 356, 78-85. T. Kjällman, H. Peng, C. Soeller and J. Travas-Sejdic, Curr. Appl. Phys., 2008, 8, 308311. X. Liu, Y. Jiang, C. Wang, S. Y. Li, X. Lan, Y. Chen and H. Zhong, J. Cryst. Growth, 2010, 312, 2656-2660. Z. Li, Y. M. Du, Z. L. Zhang and D. W. Pang, React. Funct. Polym., 2003, 55, 35-43. M. Majumder, S. Karan and B. Mallik, J. Lumines., 2011, 131, 2792-2802. P. K. Bae, K. N. Kim, S. J. Lee, H. J. Chang, C. K. Lee and J. K. Park, Biomaterials, 2009, 30, 836-842. I. Mekis, D. V. Talapin, A. Kornowski, M. Haase and H. Weller, J. Phys. Chem. B, 2003, 107, 7454-7462. S. Huang, Q. Xiao, R. Li, H.-L. Guan, J. Liu, X.-R. Liu, Z.-K. He and Y. Liu, Anal. Chim. Acta, 2009, 645, 73-78. D. V. Talapin, J. S. Lee, M. V. Kovalenko and E. V. Shevchenko, Chem. Rev., 2010, 110, 389-458. 37 Journal of Materials Chemistry – Review 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. 55. 56. 57. 58. A. Merkoci, ed., Biosensing using nanomaterials, Wiley, New Jersey, 2009. O. I. Mićić and A. J. Nozik, in Nanostructured Materials and Nanotechnology, Academic Press, San Diego, 2002, pp. 183-205. T. Jamieson, R. Bakhshi, D. Petrova, R. Pocock, M. Imani and A. M. Seifalian, Biomaterials, 2007, 28, 4717-4732. J. Tian, R. Liu, Y. B. Zhao, Q. Xu and S. Zhao, J. Colloid Interface Sci., 2009, 336, 504509. T. Jin, F. Fujii, Y. Komai, J. Seki, A. Seiyama and Y. Yoshioka, Int. J. Mol. Sci., 2008, 9, 2044-2061. H. D. Duong, C. V. G. Reddy, J. I. Rhee and T. Vo-Dinh, Sens. Actuator B-Chem., 2011, 157, 139-145. X. Michalet, F. F. Pinaud, L. A. Bentolila, J. M. Tsay, S. Doose, J. J. Li, G. Sundaresan, A. M. Wu, S. S. Gambhir and S. Weiss, Science, 2005, 307, 538-544. Y. Xing, Z. Y. Xia and J. H. Rao, IEEE Trans. Nanobiosci., 2009, 8, 4-12. C. Tortiglione, A. Quarta, A. Tino, L. Manna, R. Cingolani and T. Pellegrino, Bioconjugate Chem., 2007, 18, 829-835. P. Das, W. H. Zhong and J. P. Claverie, Colloid Polym. Sci., 2011, 289, 1519-1533. Y. Cui, X. Q. Gong, S. J. Zhu, Y. H. Li, W. Y. Su, Q. H. Yang and J. Chang, J. Mater. Chem., 2012, 22, 462-469. Y. G. Zheng, S. J. Gao and J. Y. Ying, Adv. Mater., 2007, 19, 376-380. Y. He, H. T. Lu, L. M. Sai, W. Y. Lai, Q. L. Fan, L. H. Wang and W. Huang, J. Phys. Chem. B, 2006, 110, 13370-13374. H. Zhang, Z. Zhou, B. Yang and M. Y. Gao, J. Phys. Chem. B, 2003, 107, 8-13. Y.-F. Liu and J.-S. Yu, J. Colloid Interface Sci., 2009, 333, 690-698. W. B. Xu, Y. X. Wang, S. Liang, R. H. Xu, G. X. Zhang, F. H. Xu and D. Z. Yin, J. Dispersion Sci. Technol., 2008, 29, 953-957. M. S. Abd El-sadek, A. Y. Nooralden, S. M. Babu and P. K. Palanisamy, Opt. Commun., 2011, 284, 2900-2904. R. Cui, H. C. Pan, J. J. Zhu and H. Y. Chen, Anal. Chem., 2007, 79, 8494-8501. W. R. Algar and U. J. Krull, J. Colloid Interface Sci., 2011, 359, 148-154. F. Aldeek, L. Balan, J. Lambert and R. Schneider, Nanotechnology, 2008, 19. C. P. Huang, Y. K. Li and T. M. Chen, Biosens. Bioelectron., 2007, 22, 1835-1838. A. D. Saran, M. M. Sadawana, R. Srivastava and J. R. Bellare, Colloid Surf. APhysicochem. Eng. Asp., 2011, 384, 393-400. J. P. Yuan, W. W. Guo, J. Y. Yin and E. K. Wang, Talanta, 2009, 77, 1858-1863. E. M. Ali, Y. G. Zheng, H. H. Yu and J. Y. Ying, Anal. Chem., 2007, 79, 9452-9458. J. J. Zhu, H. Wang, J. M. Zhu and J. Wang, Mater. Sci. Eng. B-Solid State Mater. Adv. Technol., 2002, 94, 136-140. L. Huang and H. Y. Han, Mater. Lett., 2010, 64, 1099-1101. J. L. Duan, L. X. Song and J. H. Zhan, Nano Res., 2009, 2, 61-68. S. Kanwal, Z. Traore, C. Zhao and X. Su, J. Lumines., 2010, 130, 1901-1906. M. Majumder, S. Karan, A. K. Chakraborty and B. Mallik, Spectroc. Acta Pt. A-Molec. Biomolec. Spectr., 2010, 76, 115-121. H. F. Qian, C. Q. Dong, J. F. Weng and J. C. Ren, Small, 2006, 2, 747-751. H. Qian, L. Li and J. Ren, Mater. Res. Bull., 2005, 40, 1726-1736. 38 Journal of Materials Chemistry – Review 59. 60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. 78. 79. 80. 81. 82. 83. 84. 85. A. D. Saran and J. R. Bellare, Colloid Surf. A-Physicochem. Eng. Asp., 2010, 369, 165175. M. A. Gondal, A. A. Bagabas and M. A. Dastageer, J. Nanopart. Res., 2011, 13, 38353842. Y. G. Zheng, Z. C. Yang, Y. Q. Li and J. Y. Ying, Adv. Mater., 2008, 20, 3410-3415. J. Chomoucka, J. Drbohlavova, V. Adam, R. Kizek, J. Hubalek and Ieee, Synthesis of Glutathione-coated Quantum Dots, Ieee, New York, 2009. L. Milne, P. Nicotera, S. Orrenius and M. J. Burkitt, Arch. Biochem. Biophys., 1993, 304, 102-109. M. Xue, X. Wang, H. Wang and B. Tang, Talanta, 2011, 83, 1680-1686. H. Goncalves, C. Mendonca and J. da Silva, J. Fluoresc., 2009, 19, 141-149. M. Cao, C. Cao, M. G. Liu, P. Wang and C. Q. Zhu, Microchim. Acta, 2009, 165, 341346. W. Dong, X. Ge, M. Wang and S. K. Xu, Luminescence, 2010, 25, 55-60. X. X. Wang, Y. Lv and X. D. Hou, Talanta, 2011, 84, 382-386. Z. Li, Y. X. Wang, G. X. Zhang and Y. J. Han, J. Inorg. Mater., 2010, 25, 495-499. J. J. Ma, J. G. Liang and H. Y. Han, Spectrosc. Spectr. Anal., 2010, 30, 1039-1043. C. Jiang, S. K. Xu, D. Z. Yang, F. H. Zhang and W. X. Wang, Luminescence, 2007, 22, 430-437. W. Dong, X. Ge, X. Y. Wang and S. K. Xu, Spectrosc. Spectr. Anal., 2010, 30, 118-122. C. B. Huang, C. L. Wu, J. P. Lai, S. Y. Li, J. S. Zhen and Y. B. Zhao, Anal. Lett., 2008, 41, 2117-2132. A. N. Liang, L. Wang, H. Q. Chen, B. B. Qian, B. Ling and J. Fu, Talanta, 2010, 81, 438443. A. Merkoci, L. H. Marcolino-Junior, S. Marin, O. Fatibello-Filho and S. Alegret, Nanotechnology, 2007, 18, 1-5. P. Thangadurai, S. Balaji and P. T. Manoharan, Nanotechnology, 2008, 19, 1-6. Y. G. Zheng, Z. C. Yang and J. Y. Ying, Adv. Mater., 2007, 19, 1475-1479. J. Cao, B. Xue, H. Li, D. W. Deng and Y. Q. Gu, J. Colloid Interface Sci., 2010, 348, 369-376. F. C. Liu, Y. M. Chen, J. H. Lin and W. L. Tseng, J. Colloid Interface Sci., 2009, 337, 414-419. J. Y. Ying, Y. G. Zheng and S. T. Selvan, in Colloidal Quantum Dots for Biomedical Applications, eds. M. Osinski, T. M. Jovin and K. Yamamoto, Spie-Int Soc Optical Engineering, Bellingham, 2008, pp. 86602-86602. V. Lesnyak, A. Dubavik, A. Plotnikov, N. Gaponik and A. Eychmuller, Chem. Commun., 2010, 46, 886-888. Z. T. Deng, F. L. Lie, S. Y. Shen, I. Ghosh, M. Mansuripur and A. J. Muscat, Langmuir, 2009, 25, 434-442. Z. Fang, Y. Li, H. Zhang, X. H. Zhong and L. Y. Zhu, J. Phys. Chem. C, 2009, 113, 14145-14150. K. S. Kumar, A. Divya and P. S. Reddy, Appl. Surf. Sci., 2011, 257, 9515-9518. Y. Gu, I. L. Kuskovsky, J. Fung, R. Robinson, I. P. Herman, G. F. Neumark, X. Zhou, S. P. Guo and M. C. Tamargo, Appl. Phys. Lett., 2003, 83, 3779-3781. 39 Journal of Materials Chemistry – Review 86. 87. 88. 89. 90. 91. 92. 93. 94. 95. 96. 97. 98. 99. 100. 101. 102. 103. 104. 105. 106. 107. 108. 109. 110. 111. 112. 113. T. Rameshwar, S. Samal, S. Lee, S. Kim, J. Cho and I. S. Kim, J. Nanosci. Nanotechnol., 2006, 6, 2461-2467. Z. H. Lin, M. Q. Wang, L. Z. Wei, X. H. Song, Y. H. Xue and X. Yao, J. Alloy. Compd., 2011, 509, 8356-8359. F. H. Huang, Y. L. Lan and P. F. Chen, J. Mater. Sci., 2011, 46, 5732-5736. S. Khene, S. Moeno and T. Nyokong, Polyhedron, 2011, 30, 2162-2170. Y. F. Li, M. Han, H. Y. Bai, Y. Wu, Z. H. Dai and J. C. Bao, Electrochim. Acta, 2011, 56, 7058-7063. Q. S. Wang, L. Yang, T. T. Fang, S. Wu, P. Liu, X. M. Min and X. Li, Appl. Surf. Sci., 2011, 257, 9747-9751. L. J. Zhang, C. L. Xu and B. X. Li, Microchim. Acta, 2009, 166, 61-68. T. Li, Y. Y. Zhou, J. Y. Sun, D. B. Tang, S. X. Guo and X. P. Ding, Microchim. Acta, 2011, 175, 113-119. Y. L. Li, J. Zhou, C. L. Liu and H. B. Li, J. Mater. Chem., 2012, 22, 2507-2511. W. R. Algar, A. J. Tavares and U. J. Krull, Anal. Chim. Acta, 2010, 673, 1-25. J. A. Chen, Y. Pei, Z. W. Chen and J. Y. Cai, Micron, 2010, 41, 198-202. U. Resch-Genger, M. Grabolle, S. Cavaliere-Jaricot, R. Nitschke and T. Nann, Nat. Methods, 2008, 5, 763-775. S. Ghaderi, B. Ramesh and A. M. Seifalian, J. Drug Target., 2011, 19, 475-486. A. Hoshino, S. Hanada and K. Yamamoto, Arch. Toxicol., 2011, 85, 707-720. J. L. Pelley, A. S. Daar and M. A. Saner, Toxicol. Sci., 2009, 112, 276-296. R. Hardman, Environ. Health Perspect., 2006, 114, 165-172. M. Bottini, F. Cerignoli, M. I. Dawson, A. Magrini, N. Rosato and T. Mustelin, Biomacromolecules, 2006, 7, 2259-2263. J. Shao, X. G. You, F. Gao, R. He and D. X. Cui, Chin. J. Anal. Chem., 2006, 34, 16251628. Y. Wu, G. P. Lopez, L. A. Sklar and T. Buranda, Anal. Biochem., 2007, 364, 193-203. T. Pellegrino, L. Manna, S. Kudera, T. Liedl, D. Koktysh, A. L. Rogach, S. Keller, J. Radler, G. Natile and W. J. Parak, Nano Lett., 2004, 4, 703-707. M. T. Fernandez-Arguelles, A. Yakovlev, R. A. Sperling, C. Luccardini, S. Gaillard, A. S. Medel, J. M. Mallet, J. C. Brochon, A. Feltz, M. Oheim and W. J. Parak, Nano Lett., 2007, 7, 2613-2617. C. A. J. Lin, R. A. Sperling, J. K. Li, T. Y. Yang, P. Y. Li, M. Zanella, W. H. Chang and W. G. J. Parak, Small, 2008, 4, 334-341. A. P. Alivisatos, ACS Nano, 2008, 2, 1514-1516. M. Bruchez, M. Moronne, P. Gin, S. Weiss and A. P. Alivisatos, Science, 1998, 281, 2013-2016. W. C. W. Chan and S. M. Nie, Science, 1998, 281, 2016-2018. X. H. Gao, L. L. Yang, J. A. Petros, F. F. Marshal, J. W. Simons and S. M. Nie, Curr. Opin. Biotechnol., 2005, 16, 63-72. A. M. Smith, H. W. Duan, A. M. Mohs and S. M. Nie, Adv. Drug Deliv. Rev., 2008, 60, 1226-1240. R. Hu, X. B. Zhang, R. M. Kong, X. H. Zhao, J. H. Jiang and W. H. Tan, J. Mater. Chem., 2011, 21, 16323-16334. 40 Journal of Materials Chemistry – Review 114. 115. 116. 117. 118. 119. 120. 121. 122. 123. 124. 125. 126. 127. 128. 129. S. Taniguchi, M. Green, S. B. Rizvi and A. Seifalian, J. Mater. Chem., 2011, 21, 28772882. M. Ciarlo, P. Russo, A. Cesario, S. Ramella, G. Baio, C. E. Neumaier and L. Paleari, Recent Patents Anti-Canc. Drug Discov., 2009, 4, 207-215. A. J. Tavares, L. R. Chong, E. Petryayeva, W. R. Algar and U. J. Krull, Anal. Bioanal. Chem., 2011, 399, 2331-2342. H. S. Mansur, Wiley Interdiscip. Rev.-Nanomed. Nanobiotechnol., 2010, 2, 113-129. A. Papagiannaros, T. Levchenko, W. Hartner, D. Mongayt and V. Torchilin, Nanomed.Nanotechnol. Biol. Med., 2009, 5, 216-224. E. B. Voura, J. K. Jaiswal, H. Mattoussi and S. M. Simon, Nat. Med., 2004, 10, 993-998. S. Kim, Y. T. Lim, E. G. Soltesz, A. M. De Grand, J. Lee, A. Nakayama, J. A. Parker, T. Mihaljevic, R. G. Laurence, D. M. Dor, L. H. Cohn, M. G. Bawendi and J. V. Frangioni, Nat. Biotechnol., 2004, 22, 93-97. F. Pinaud, D. King, H. P. Moore and S. Weiss, J. Am. Chem. Soc., 2004, 126, 6115-6123. L. A. Bentolila, Y. Ebenstein and S. Weiss, J. Nucl. Med., 2009, 50, 493-496. Z. Kaul, T. Yaguchi, S. C. Kaul, T. Hirano, R. Wadhwa and K. Taira, Cell Res., 2003, 13, 503-507. H. Z. Wang, H. Y. Wang, R. Q. Liang and K. C. Ruan, Acta Biochim. Biophys. Sin., 2004, 36, 681-686. J. Drbohlavova, V. Adam, R. Kizek and J. Hubalek, Int. J. Mol. Sci., 2009, 10, 656-673. H. Zhang, D. Yee and C. Wang, Nanomedicine, 2008, 3, 83-91. M. V. Yezhelyev, X. Gao, Y. Xing, A. Al-Hajj, S. M. Nie and R. M. O'Regan, Lancet Oncol., 2006, 7, 657-667. X. Y. Wu, H. J. Liu, J. Q. Liu, K. N. Haley, J. A. Treadway, J. P. Larson, N. F. Ge, F. Peale and M. P. Bruchez, Nat. Biotechnol., 2003, 21, 41-46. M. Yezhelyev, C. Morris, X. Gao, A. Marcus and R. M. O'Regan, Breast Cancer Res. Treat., 2005, 94, S48-S48. 41