and AlN(0001)

advertisement

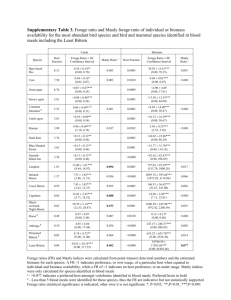

AtMol deliverable reporting 1D1.41 GaN(0001) and AIN (0001) Growth and Characterization by NC-AFM 1-T1.4: Large gap epitaxial surface preparation WP1.1 Surface preparation Lead participant: P1-Toulouse Other participants: Person Months: P1 : 12.3 Start date:0 Planned End date:24 Real end date:36 Introduction This deliverable is presenting the successful growth of an AlN(0001) thin layer and its surface characterization by UHV Non Contact Atomic Force Microscope (NC- AFM). The main goal is here to develop a growth recipe in order to get nitride surfaces with the lowest density of dislocations and defects and the largest step terraces with the final objective to deliver a large electronic gap surface material to avoid surface leakage current for the planar conductance measurement of a single molecular wire. The growth of the nitride layers was performed in the Molecular Beam Epitaxy (MBE) chamber with an NH3 gaz precursor. The sample characterization was performed on the interconnected to the MBE chamber UHV-STM/AFM microscope. Both chambers belong to the UHV factory of P1-Toulouse specially designed for this purpose and installed in the new P1-Toulouse Pico-Lab clean room since May 2012. The starting recipe for an AlN(0001) growth was the one used in the CNRS laboratory CHREA which is a well-known specialist in nitride epitaxial growth. The initial substrate used in CRHEA is Si(111) starting from its (7x7) reconstruction. It is known that the roughness of the Si(111)-(7x7) surface facilitates the emergence of dislocations during AlN(0001) epitaxy. So the first P1-Toulouse studies concentrate on the test methods to prepare the Si(111)-(7x7) surface in order to obtain a smooth enough top surface. This study consists in chemical preparation of the silicon sample, heating at high temperature under the MBE chamber with insitu RHEED surface monitoring and then UHV transfer to the RT AFM/STM for NC-AFM and Kelvin probe force microscopy (KPFM) characterizations of the obtained surface. The chemical preparation consists in covering the surface with a protective oxide layer before the welding. Then, this oxide layer was removed with the solution of HF 1% just before its entrance in the MBE chamber. The quality of the Si(111)-7x7 surface depends on the amount of oxide that is removed before its entrance in the MBE chamber. After more than 12 attempts, it was found that the completely deoxidized surface is rougher than the surface for which the oxide has been partly removed as shown the NC-AFM images presented in Fig. 1. Figure 1 : (a,c) 500x500nm² NC-AFM images of Si(111)-7x7 surface (a) ∆f=-20Hz, A=2nm, bias=1V f0=269kHz, Q=38105 (c) ∆f= - 5Hz, A=8nm, bias=350mV, f0=264kHz, Q=35258 ; (b) : enlargement of an area on (a), 11x11nm², ∆f=- 25Hz, A=2nm, bias=891mV From this clean Si(111)-(7x7) surface, a first step of nitridation under NH3 flux was performed before starting the AlN(0001) growth. The growth was followed by an in-situ RHEED characterization to obtain the information on the growth conditions as a function of the growth parameters such as the Al flux, the NH3 pressure and the substrate temperature. The surface roughness was directly obtained recording NC-AFM and KPFM images at scale below 1 µm and by SEM imaging for larger scale images. Figure 2 shows NC-AFM images of AlN(0001) surface grown with a growth rate of 90 nm/h (a) and 125 nm/h (b) and the other growth parameters identical. Figure 2 : 300x300nm² NC-AFM image of AlN(0001) surface made at 90 nm/h (a) and 125 nm/h (b) growth rate, 60 sccm NH3, P=1e-4 Torrs and Tsubstrate=900°C. (a) ∆f=-25Hz, A=2nm, f0=278.4kHz, Q=34400 (b) ∆f=-25Hz, A=5nm, f0=278.4kHz, Q=35255 The NC-AFM images obtained on the nitride surface allows to clearly observed two kinds of defects: (1) the dislocations arising from the 23% mismatch between Si(111) and AlN(0001) and also the 14% difference of the thermal expansion coefficient and (2) the holes or islands related to the growth conditions. P1-Toulouse have also studied the effect of the Al/NH3 flux and the NH3 gaz flow on these defects density, as presented on figure 3. The values of dislocations and defects were counted on 3 images of (500 nm x 500 nm) for each set of parameters growth. Due to this low number of samples process, it was very difficult to determine an error bar for this growth process. A full year of processes with a systematic change of each parameters would have been required which is clearly out of the scope of the P1Toulouse contribution to AtMol. Such statistic will be established like for any wafer fab process especially because of the compulsory use of the UHV-NC-AFM delicate technique of characterization, not yet in use on line in any semi-conductor fab around the world. Nevertheless, the first experimental curves below provide a qualitative information on the surface quality as a function of the growth conditions. They were immediately used by the P5Barcelona to provide the first ever determination of the surface atomic scale structure awaited for AlN(001) and to guide P1-Toulouse in the experimental determination of this unique surface structure. Figure 3 : The density of defects (dislocations and holes) as a function of the III/V ratio and of the NH3 gaz flow measured by UHV-NC-AFM in-situ in the P1-Toulouse DUF where the UHV-NCAFM is on line with the RHEED and the MBE. It is not yet possible to give the error bar. This analysis shows that there is a plateau of defects density close to 600 by µm2 for III/V ratio between 2 and 6, and that the NH3 gaz flow has a light effect for a flow higher tha, 20 sccm. The best growth parameters are a NH3 gaz flow between 20 and 120 sccm and an III-V ratio between 2 and 6. But even with these optimized growth parameters, the total number of defects is very high, close to 600 by µm2. The growth of GaN(0001) on these best AlN(0001) surfaces does not change the defects density. The dislocations density due to the crystal parameters mismatch between Si(111) and AlN(0001) could be decreased by replacing the Si(111) substrate with SiC(0001) which has the same cell parameters and thermal dilatation coefficient than AlN(0001). Thus, P1-Toulouse have started the study of the AlN(0001) growth on hexagonal SiC(0001) substrate. The preparation of the SiC(0001) surface is that simple as compared to Si(111). But P1-Toulouse have acquired the corresponding know-how from a previous work realized in 2010 and 2011 in the framework of the MolSiC ANR French research project. The process starts using 6H-SiC(0001) substrates. Before these substrates, they were annealed under H2 at 10-3 Torrs and 1100°C to remove the roughness and defects of the surface. Then, the SiC(0001) substrate was prepared on the MBE chamber by annealing at a temperature between 900°C and 950°C under a light Si beam flux in order to get the initial (√3x√3)R30° reconstruction. The growth of AlN(0001) is started with the same procedure than on Si(111) substrate. The first surfaces obtained with the 6H-SiC(0001) where not observable by NC-AFM. Indeed the SEM images presented in fig 4(a) shows clearly an important roughness at the µm scale, incompatible with our goal. This roughness can be linked to the periodicity of the cell along the c-axis and the growth of AlN with stacking faults. Indeed the 6H-SiC(0001) substrate has a periodicity of 6 monolayers along the c-axis while AlN(0001) is only 2. The presence on the initial 6HSiC(0001) surface of steps with one ML height allows the nucleation of AlN domains, which are not in phase on the (0001) plane leading to a huge density of stacking faults. To increase the surface quality, it is thus important to have step edges with height equal to the c parameter of the initial SiC substrate. This means for 6H-SiC(0001) step height of 6 ML, which is quite difficult to realize. Figure 4 : SEM images of AlN(0001) grown on 6H-SiC(0001) with no step bunching (left) and on 4HSiC(0001) with step bunching of 4 ML (right). Size : (left) 1,94x1,46 µm and (right) 16 x 12 µm. Fortunately, Dr. Okumura team in Japan has shown in 2008 that the growth of AlN(0001) on 6H-SiC(0001) prepared in specific conditions revealed a very low density of stacking faults. P1-Toulouse had decided to use their surface preparation recipe but starting with 4H-SiC(0001) substrates, which are now the only commercially available SIC substrate. Figure 4(b) shows a SEM image of an AlN(0001) 200 nm thick layer grown on 4H-SiC(0001) prepared to have step bunching of 4 ML. The effect of the step bunching is clearly seen with a very flat surface observed by SEM. Furthermore the NC-AFM images obtained on such AlN layers shows a better organization of the surfaces: the total density of defects is decreased by at less a factor 4 with less than 150 defects / µm2. On the (500nmx500nm) NC-AFM image presented in figure 5, the number of dislocations is 22 and there is still a twelve holes. But the main difference compared to AlN layers grown on Si(111) is that the terraces can be flat on wider area : it is possible to see (100 nm x 100 nm) flat terraces, while on Si(111) only (20 nm x 20 nm) were observable. As on Si(111), the growth of GaN(0001) thin layers on AlN(0001) does not change drastically the quality of the surface as shown on figure 5(b). Figure 5 : 500x500nm² NC-AFM image of (left) AlN(0001) and (right) GaN(0001) surface grown on 4H-SiC(0001) substrate. Thickness 200 nm, growth rate = 100nm/h, 120 sccm NH3, P=1e-4 Torrs and Tsubstrate=950°C. NC-AFM images parameters : (left) ∆f=-20Hz, A=2nm, f0=260.0kHz, Q=34000 (right) ∆f=-10Hz, A=5nm, f0=260.0kHz, Q=34000 Conclusion: The studies of the MBE-growth of AlN(0001) by in-situ RHEED, NC-AFM and SEM has allowed us to determine the preparation of the initial substrate and to optimize the growth parameters in order to get flat terraces at the atomic scale with the lowest density of defects. This work as started only in September 2012 due to MBE chamber problems after the moving in the Pico-Lab cleanroom. All the results were obtained only in 15 months. The knowhow on the AlN(0001) growth can be now used to start Task 4.2 in Unit 4 with the growth of nano and micro-electrodes for the measurement of the surface electronic gap of AlN(0001). Publication: AlN(0001) growth on Si(111) and 4H-SiC(0001) studied by NC-AFM, F. Chaumeton, D. Martrou, R. Laloo and S. Gauthier, in preparation (2014).