Chemical Management Guide - Charles Darwin University

advertisement

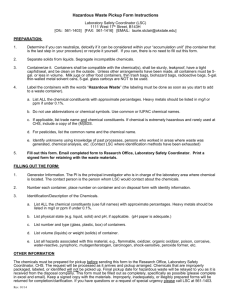

Chemical Management Guide All guides are intended to give further details to information contained in a particular piece of legislation, policy, code, agreement or procedure and must therefore be read in conjunction with them. INTRODUCTION This guide has been developed to provide guidance and information to support staff and students in risk management of chemicals. The guidance material is intended for use for chemicals only, such as hazardous substances, dangerous goods and scheduled poisons. The guide does not provide information or guidance on biological materials or biological substances. Throughout this guide the generic term “chemical” is generally used. The term “hazardous chemical” as defined by Northern Territory Work Health and Safety (NUL) Regulations 2011, is used when the guidance applies specifically to this classification of chemical. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 1 of 17 1. Abbreviations................................................................................................................................... 3 2. Relevant Definitions ........................................................................................................................ 3 3. Health and Safety Responsibilities ................................................................................................. 4 3.1 Legislation, Codes of Practice, Standards, Policy, Procedure and Guides .............................. 4 3.2 Duty of Care ............................................................................................................................ 4 3.3 General Workplace Management ........................................................................................... 4 3.4 How to manage work health and safety risks ......................................................................... 4 3.5 Chemical Risk Assessment ...................................................................................................... 5 3.6 Emergency Management Plan ................................................................................................ 5 4. Induction, Information, Training and Supervision ............................................................................ 5 5. First Aid ........................................................................................................................................... 6 6. Personal Protective Equipment (PPE) ............................................................................................ 6 7. Permits and Licencing ..................................................................................................................... 6 8. Safety Data Sheet (SDS) ................................................................................................................ 7 9. Records and Information Management ........................................................................................... 8 9.1 Inventory ................................................................................................................................. 8 9.2 CDU Manifest .......................................................................................................................... 8 9.3 ChemWatch GOLDFFX............................................................................................................. 8 10. Purchasing .................................................................................................................................. 8 10.1 General.................................................................................................................................... 8 10.2 Importation ............................................................................................................................. 9 11. Packaging and Labelling ............................................................................................................. 9 11.1 Packaging ................................................................................................................................ 9 11.2 Labelling .................................................................................................................................. 9 12. Storage and Handling ............................................................................................................... 10 12.1 General.................................................................................................................................. 10 12.2 Handling - Decanting ............................................................................................................. 11 12.3 Transport of chemicals.......................................................................................................... 11 13. Globally Harmonised System of Classification and Labelling of Chemicals (GHS) ................. 12 14. Waste management .................................................................................................................. 13 14.1 Segregation and Storage of Waste ....................................................................................... 13 14.2 Waste Management Records................................................................................................ 14 14.3 Packaging and Labelling of Waste......................................................................................... 14 14.4 Waste Treatment .................................................................................................................. 14 15. Monitoring and Health Surveillance .......................................................................................... 15 16. Essential Supporting Information .............................................................................................. 16 Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 2 of 17 1. Abbreviations AS/NZS CDU ECO NUL PCBU PPE SDS WHS Australian/New Zealand Standard Charles Darwin University Emergency Control Organisation National Uniform Legislation Persons Conducting a Business or Undertaking Personal Protective Equipment Safety Data Sheet Work Health and Safety 2. Relevant Definitions In the context of this document: Authorised Person means a person who has permission, is qualified or licensed and competent for the task at hand. Chemical is defined as any element, chemical compound or mixture of elements and/or compounds where chemical(s) are distributed. Chemicals may be in solid, liquid, gas or plasma form. Chemicals of Security Concern are chemicals that have been identified by the Australian Government as requiring attention due to their potential for misuse by terrorists. Dangerous goods are substances or articles that pose an immediate risk to safety of people, property or the environment. (e.g. flammable, toxic, oxidising, corrosive, radioactive). Dangerous goods are classified using criteria set out, or referred to in the Australian Dangerous Goods Code 7 th Edition. A dangerous good can also be a hazardous substance and/or a drug, poison or controlled substance. Drug Precursors are chemicals which can be used for illicit drug manufacture. Hazard means a situation or thing that has the potential to harm people, property or the environment. Hazardous chemicals are pure chemicals, or chemical mixtures that present an immediate or long term risk of injury or illness. The risk can be associated with health hazards or physiochemical hazards (e.g. flammable, corrosive, reactive, radioactive etc.). A hazardous substance can also be a dangerous good and/or a drug, poison or controlled substance. Person Conducting a Business or Undertaking (PCBU) is the legal entity operating a business or undertaking. A PCBU may be an individual person or an organisation conducting a business or undertaking. It is not an individual, unless they are conducting the business in their own name as a sole trader or partner. Persons engaged solely as a worker or officer of the business or undertaking are excluded from the definition of PCBU. Physicochemical hazard means a hazard relating to both the physical and chemical properties of a chemical Risk is the possibility that death, injury or illness might occur when exposed to a hazard. Safety Data Sheet (SDS) is a document prepared by the vendor (manufacturer/importer/supplier) of a chemical which describes uses, chemical and physical properties, health hazard information, precautions for use, safe handling and emergency information. It is a legislative requirement for the vendor to supply a copy of the SDS for each chemical to the end user. Scheduled Carcinogens are cancer-causing chemicals that require authorisation if used or stored in the workplace and means a carcinogenic substance listed in Schedule 1 or Schedule 2 of National Model Regulations for the Control of Scheduled Carcinogenic Substances. Scheduled Poisons are chemicals (pure substances and mixtures) listed in the Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) that have special controls applied to how they are packaged, labelled, dispensed and used to ensure the safety of the community. This includes Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 3 of 17 pure chemicals, agricultural and veterinary products, therapeutic goods, medicines and pharmaceuticals. A scheduled poison can also be a hazardous substance and/or a dangerous good. The Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) is the record of decisions regarding the classification of medicines and chemicals into Schedules and includes model provisions about containers and labels, and recommendations about other controls on medicines and chemicals. Worker means any person carries out work in any capacity for the University, including but not limited to, University’s staff member, contractor, subcontractor and their employee, apprentice or trainee, student gaining work experience, and volunteer; Workplace means a place where work is carried out for the University and includes any place where a worker goes, or is likely to be, while at work. This may include, but is not limited to, laboratories, workshops, training rooms, on-site recreational facilities, vehicles or vessels, on field trips, in teaching facilities, in offices, in rural environments and any area of industry operations. 3. Health and Safety Responsibilities 3.1 Legislation, Codes of Practice, Standards, Policy, Procedure and Guides The legislative governance and other information pertaining to chemical management is complex and extensive. A list of Acts and Regulations, Codes of Practice, Standards, Guides and CDU Policy and Procedure that are applicable to Charles Darwin University activities that involve chemicals is included at the end of this document. 3.2 Duty of Care Primary duty of care – Persons conducting a business or undertaking (PCBU) must ensure, so far as reasonably practicable the health and safety of all persons engaged or influenced by the persons activities, by eliminating or minimising the exposure to hazards and risks as far as reasonably practicable. Workers and others – while at work, a worker must take reasonable care for their own health and safety whilst also taking all reasonable measures to ensure that their acts or omissions do not adversely affect the health and safety of other persons. The worker must comply and cooperate with any reasonable policy or procedure relating to health or safety at the workplace. Work Health and Safety Policy http://www.cdu.edu.au/governance/policies/pol-044.pdf 3.3 General Workplace Management The following principles apply to all individuals working within University workplaces: Keep the area clean, organised and tidy at all times. Report all hazards, unsafe conditions and unsafe acts. The last person leaving the area at any time must ensure that the area is locked to prevent unauthorized entry. No staff member or other unauthorized persons are to enter the areas out of hours, unless access has been approved by the relevant Supervisor, and Security is advised of the out of hours work. 3.4 How to manage work health and safety risks It is the responsibility of all workers to identify any hazards and ensure they are reported to supervisors or management so that effective controls can be implemented. Employees are encouraged to attend WHS Risk Management Training and to read the CDU Risk Management Policy. http://www.cdu.edu.au/governance/policies/pol-036.pdf This document will provide information relating to: Duty to identify hazards Managing risks to health and safety Hierarchy of control measures Maintenance of control measures Review of control measures Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 4 of 17 3.5 Chemical Risk Assessment A chemical risk assessment determines whether there is a risk to staff or students’ health from using a chemical in the workplace (including any new chemicals or by-products that may be produced during an activity). Therefore all staff and students who engage in activities associated with chemicals must be aware of the hazards and risks associated with chemicals and the controls that have been put in place to reduce the risks. A risk assessment should be completed before a chemical is used for the first time in the workplace. For newly purchased chemicals a risk assessment should have been completed prior to purchase. The chemical risk assessment should be kept where users of the chemical can access the risk assessment easily and quickly and ensures that: • chemicals will be appropriately and safely managed from purchase through until disposal; • emergency plans have been developed and can be implemented in the event of an adverse incident. Risk assessment must be completed using the Charles Darwin University template(s): Risk Assessment Form Risk management is about exercising responsibility to ensure workers and the public are properly protected. The Risk Assessment Form allows you to identify the hazard, then identify and control the associated risk. Hazardous Substances Risk Assessment This form is to be completed to ensure that all possible safety precautions have been taken into consideration. It is in addition to the Risk Assessment form but only if the work entails the use of hazardous substances. Instructions on how to complete chemical risk assessments is contained in the Guide to Risk Management (under review) 3.6 Emergency Management Plan CDU has an Emergency Management Plan in place to ensure the safety of the University community http://www.cdu.edu.au/governance/Plans/emergencymanagementplan.pdf. The plan provides the framework for the effective response to emergencies and/or disasters, and management of the return to normality. As a result, Team Leaders, Building Wardens, Wardens should ensure: That an Evacuation Diagram/s for the building is displayed in a prominent position/s throughout the building. Ensure a level of preparedness within the building by having a sufficient number of Wardens (ECO members). Participate in Emergency Evacuation Exercise training & drills Develop an area specific “Action Plan” relevant to the risks, taking into account assistance to mobility impaired, students and visitors. Ensure clear access and egress to emergency exits at all times Ensure appropriate spill management equipment and kit(s) are available and accessible 4. Induction, Information, Training and Supervision For the application of safe practices involved in chemical management activities, supervisors, workers and others should be formally trained and have the required knowledge and authorisation to handle, store and dispose of chemicals. This is particularly important for new employees or inexperienced people. Information, training and instructions provided, must be suitable and relevant to the nature of the work carried out by the worker, and the nature of risks and control measures associated with the work. Information or instructions should be delivered in a way that is readily understandable by any person to whom it is provided. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 5 of 17 Induction, training and instruction should include: safety procedures emergency procedures and location of emergency equipment risk management location of, and access to, safety data sheets correct and safe use of chemicals the nature of the hazards the proper use and maintenance of personal protection equipment (PPE) good housekeeping other statutory requirements the use and maintenance of measures for the control of each risk Supervisors and Managers should ensure that the competency level of employees is appropriate and that any training programs and information provided to workers is regularly reviewed. Areas must keep records of which employees have been trained and the type of training they have completed. 5. First Aid All areas where chemicals are either in storage or use are to have appropriate first aid equipment available and accessible during the hours of operation. As per Code of Practice – First Aid in the Workplace, the number of first aid kits and their content is to be based on a risk assessment of the work activities, and will be maintained by the designated First Aid Officer. Further information can be obtained from: First Aid Procedures First Person on Scene (Accident /Incident) Procedure As part of a person’s induction to the workplace they should be advised of: The location of the First Aid equipment. The designated First Aid Officers 6. Personal Protective Equipment (PPE) The use of personal protective equipment should only be considered when there are no other practical control measures available (i.e. as a last resort). Normally PPE is used in combination with other control measures to provide the best solution. PPE may be used as an interim measure until a more effective way of controlling the risk can be established. When PPE is used, ensure the PPE is appropriate for the task and that it is clean and in good repair before and after use. Additional information can be sourced from the CDU Guide for Selection, Purchase and Use of PPE (under review) 7. Permits and Licencing The procurement and possession of some chemical classifications have permit and licensing requirements. Refer to the relevant links for specific information, legislation and permit/licensing requirements. Industrial Chemicals, including chemicals used domestically • • • Industrial chemicals and health Medicines and therapeutic goods Poisons Chemical Management Guide Contact Officer: WHS Consultant • • • Food additives Contaminants Natural toxicants Version 1 Page 6 of 17 Chemicals of Security Concern • Chemicals of national security concern Agricultural and Veterinary Chemicals • Chemicals used in primary production – agricultural and veterinary products Radiation Protection - NT • Ionizing and non-ionizing radiation Medicines & Poisons Control - NT • Scheduled substances and Therapeutic Goods Illicit drugs precursor chemicals 8. Safety Data Sheet (SDS) A Safety Data Sheet: Is a 16 section document that provides information on the properties of hazardous chemicals and how they affect health and safety in the workplace and should always be referred to when assessing risks in the workplace. It helps the user of a chemical to identify, assess and control risks associated with the use of the chemical in the workplace including information on the identity of the chemical, health and physicochemical hazards, safe handling and storage procedures, emergency procedures, and disposal considerations. Must legally be supplied by Vendors (manufacturers/importers/suppliers) Many vendors provide access to their SDS on their webpages. If you can only access the SDS in this way, print and/or save a copy and have it uploaded to ChemWatch GOLDFFX for future reference. Must be less than 5 years old. For chemicals/products that are in use or storage and no longer supplied by a vendor the last known version of the SDS must kept in lieu of an SDS that is less than 5 years old. Must be prepared in accordance with the Code of Practice for the Preparation of Safety Data Sheets for Hazardous Chemicals. Note: some overseas SDS may not meet Australian requirements. Chemicals should not be purchased or used until a complete SDS compliant with Australian requirements is provided by the vendor. Is not required for non-hazardous chemicals. Many non-hazardous chemicals and products do have a SDS available and the SDS provides a method for determining the chemical’s hazardous status. It is strongly advised that an SDS for a non-hazardous substance is retained and is referenced to determine safe use, handling storage and disposal. Must be readily accessible to all persons who may be using, handling or storing the chemicals. This includes, but is not limited to staff, students and emergency services. This access must be as close to the work as is reasonably practicable. Access arrangements will depend on the environment and the infrastructure that is already in place. Can be obtained through ChemWatch GOLDFFX CDU uses ChemWatch GOLDFFX as the primary source of SDS for staff and students who have ready access to a computer. Given that computers and/or power do not always work, it is highly recommended that hardcopies of the SDSs are available within the work area and located in close proximity to the chemicals and work area. Is not a Product Specification Sheet, Consumer Medicines Information sheet or similar. These types of documents only provide information on the performance characteristics of the chemical and directions for application – not all the information contained in a SDS. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 7 of 17 9. Records and Information Management 9.1 Inventory A chemical inventory identifies the name, location and quantity of all chemicals kept by an area. The University requires a chemical inventory for each area that uses, handles or stores chemicals. It is a record of all hazardous and non-hazardous chemicals and products. Please note: household products in household quantities can be exempted from this process (e.g. there is no need to inventory the can of insect spray or the bottle of dishwashing liquid if you have a small container of it as purchased from the local supermarket.) Note: the inventory is identified as ‘manifest’ in ChemWatch. 9.2 CDU Manifest All area inventories are loaded to GOLDFFX and combine to total the Chemical Manifest for CDU. This data allows for the maintenance of the Hazardous Chemical Register for the university. All areas that use, handle or store chemicals must maintain their chemical inventory within GOLDFFX CDU manifest. Areas are advised to regularly (at least annually) maintain and review all chemicals registered on their area manifest in ChemWatch to ensure accuracy, currency and availability. 9.3 ChemWatch GOLDFFX ChemWatch GOLDFFX is the chemical management system in use at Charles Darwin University. It allows access to Safety Data Sheets (SDS), labelling and management of chemical inventories/manifests. Access to GOLDFFX is available through the CDU Library ( http://www.cdu.edu.au/library/search/az_databases.html#C ). All staff and students of CDU can access GOLDFFX to view SDS and produce labels by using the General User access link on the Library page Work areas with manifests in GOLDFFX can access GOLDFFX to manage their manifest, view SDS and produce labels by using the Power User access link on the Library page. Contact your supervisor to find out the access details for your area. If you are unable to source your area's PowerUser access details or wish to setup a new PowerUser account contact Health, Safety and Environment Training for GOLDFFX is available via Learnline. Email Health, Safety and Environment to organise your enrolment. 10. 10.1 Purchasing General If you intend on purchasing new product(s), a risk assessment should be completed prior to purchase. This will include obtaining the SDS to determine the: chemical classification (hazardous substance, dangerous good, scheduled poison etc); subsequent regulatory requirements; controls for the safe use, storage and transport; waste management requirements; and first aid and emergency requirements. This information enables the proposed user to ensure that: 1. Facilities and resources are available to use, store and dispose of the chemical safely; 2. Regulatory requirements can be met; and 3. Appropriate controls are put in place prior to purchase. Where the purchaser has identified that a chemical is hazardous there may also be an opportunity at this stage to acquire a less hazardous chemical. When purchasing new chemicals a safe and sustainable disposal method should be identified. Any specialised clean up equipment should also be identified with the purchase of a new chemical. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 8 of 17 In summary, remember to: • (where reasonably practicable) purchase less hazardous chemicals; • purchase small quantities to reduce manual handling issues, storage space and waste; • ensure the chemical is added to the inventory/manifest; and • ensure the SDS is available and can be accessed by everyone 10.2 Importation Wherever possible procure your chemicals from a reputable Australian supplier. Importation of chemicals into Australia is complex and is covered by a number of jurisdictions and legislation. Staff and students who wish to import chemicals into Australia must contact the relevant Australian Government department for their legal requirements and obligations. 11. 11.1 Packaging and Labelling Packaging A hazardous chemical is correctly packed if the chemical is packed in a container that: • • • • 11.2 is in sound condition; and will safely contain the chemical for the time the chemical is likely to be in that container; and is made of material compatible with, and will not be adversely affected by, the chemical; and does not usually contain food or beverages and cannot be mistakenly identified as containing food or beverages. Labelling The purpose of labelling is to ensure that the contents of a container can be readily identified by product name, and to provide basic information about the contents of the container – its ingredient(s), hazards and precautions for safe use. Products purchased from reputable suppliers must have labelling compliant with Schedule 9 of the NT Work Health and Safety (NUL) Regulations 2011. General requirements for labels A hazardous chemical is correctly labelled if the chemical is packaged in a container that has a label written in English and includes the following: • the product identifier of the chemical; • the name, address and contact telephone number of the Australian manufacturer or importer of the substance; • the identity (or generic name if it is commercially confidential) and proportion of each ingredient • any hazard pictogram consistent with the correct classification of the chemical • any hazard statement, signal word and precautionary statement consistent with the correct classification of the chemical • any information about the hazards, first aid and emergency procedures relevant to the chemical, not otherwise included in the hazard statement or precautionary statement • Expiry date – if applicable Small container labels Applicable to containers where is it too small for a label to be attached to it to include all the requirements referred to above. A hazardous chemical is correctly labelled if the chemical is packaged in a small container that has a label written in English and includes the following: • • • • the product identifier of the chemical; the name, address and contact telephone number of the Australian manufacturer or importer of the substance; any hazard pictogram consistent with the correct classification of the chemical any other information referred to in general requirements that can be reasonably practicable to include Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 9 of 17 Decanted or transferred chemicals labels A container into which a chemical has been decanted or transferred must be labelled if the decanted substance is not used immediately; or is supplied to someone else. The container is correctly labelled if the label is written in English and includes the following: • • the product identifier of the chemical; any hazard pictogram consistent with the correct classification of the chemical Where labelling is required, but it is not practical to label the actual container with the product name (for example, because the container is too small or the chemical has a long name) some other means to identify the contents of the container should be used. For example, you could use a numbering system (i.e. number a series of small containers) and record the contents of each container in a table. It is then important to ensure the “identification table” is made available in the work area and that all staff and students likely to be exposed to the substance(s) are informed of the meaning of the identification method used. Unlabelled containers If an unlabelled container is found in the workplace, the contents should be identified and correctly labelled before the chemical is used. If the contents of a container are not known, treat it as dangerous or hazardous until conclusively proved otherwise. A label such as ‘CAUTION DO NOT USE: UNKNOWN SUBSTANCE’ should be attached to the container and the container should be removed from use until its contents are identified. If you are unable to identify the contents, the container (and contents) must be disposed of as an “unknown substance” using a waste management contractor with the appropriate certification to do so. In summary, remember to: • Package all chemicals in containers that are in sound condition and not going to be affected by the chemical; • Never use food and beverage containers to store chemicals; • Label the containers with as much information as possible to aid in identification, storage, risk management and emergency management 12. 12.1 Storage and Handling General Many chemicals have specific storage requirements because of their physical properties. Storage arrangements should be identified during the chemical risk assessment and appropriate provisions provided. Consideration must be given to the quantities that will be stored, particularly as bulk storage areas may require additional signage and controls. The way chemicals are stored is integral to minimising risks to health and safety. If goods are not compatible they must not be stored together in a way that allows them to come into contact. When storing chemicals, it may be necessary to employ a variety of segregation techniques, including isolation by distance; cut-off storage (separate rooms or enclosures); or detached storage (separate buildings). Certain incompatible goods will require different segregation techniques. When storing dangerous goods, the SDS should always be checked. The compatibility chart in Australian Standard AS 3833:2007 ‘The storage and handling of mixed classes of dangerous goods, in packages and intermediate bulk containers’ provides a more complete and detailed analysis of compatibility. Fundamental Principles of chemical storage: 1. Chemicals should be stored according to hazard class (ex. flammables, oxidizers, health hazards/toxicity, corrosives, etc.). Incompatible chemicals shall be kept segregated from one another; Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 10 of 17 2. Specific licensing conditions or constraints may need to be considered e.g. locked cabinets, secure rooms with access control 3. Separate solids from liquids 4. The quantities of hazardous chemicals should be kept to a minimum, commensurate with their usage and shelf life. 5. Ensure chemical containers and their lids, seals/stoppers are appropriate for the type and quantity of chemical stored. As far as is practicable, chemicals should be stored in the containers in which they are supplied. Packaging shall be inspected regularly to ensure their integrity. Leaking or damaged containers shall be removed to a safe area for repacking or disposal. 6. Use spill trays/spill absorbent material to contain spills 7. All packages in storage shall be labelled to allow unambiguous identification of the contents and labels should comply with the relevant regulations (refer to Labelling section of this guide) 8. Shelves should be covered with chemical-resistant paint or chemical-resistant coating and be secure and strong enough to hold chemicals being stored on them. Do not overload shelves. 9. Opening of packages, transferring contents, dispensing of chemicals or sampling should not be conducted within in or on top of a chemical storage cabinet or cupboard unless it is specifically designed for this purpose and appropriate procedures and equipment are used. 10. Procedures shall be established to deal with clean up and safe disposal of spillages. Supplies and materials needed to control and clean up the spillages shall be readily accessible. 11. Periodically review the chemicals held in storage and correctly dispose of those no longer required using the university chemical waste procedures 12. Do not store chemicals in, under or on top of mechanical air and fume extraction devices such fume cupboards, laminar flow cabinets, biological safety cabinets and dust/fume extractors. 12.2 Handling - Decanting Where reasonably practicable, chemicals should be kept in their original container with the original labelling from the vendor (manufacturer/supplier). Where chemicals are decanted to a separate container, the new containers must be appropriate for the chemical they will hold and be correctly labelled. Particular attention must be given to decanting chemicals that pose unique hazards such as: • solvents which can create explosive atmospheres; • chemicals that may give off fumes; or • asphyxiants Consideration to manual handling and spill management should be given and appropriate transfer devices (e.g. bottle top dispensers, drum pour decanting cradles, mechanical pumps etc.) should be used where identified through risk assessment. 12.3 Transport of chemicals Chemicals must be in the vendor’s (manufacturer/supplier) original packaging where possible and all legal requirements met, including paperwork, placarding and labelling. The packages shall contain packing material to reduce the chance of damage to the chemical containers. Where liquids in glass containers are to be shipped, vermiculite or other suitable packing materials shall be used if not in the supplier’s original packaging. 12.3.1 Transport within buildings by staff and students 1. 2. 3. 4. Move only the required amount of chemicals Never transport incompatible chemicals together Use spill trays/spill absorbent material to contain spills Never travel in an elevator with chemicals. If possible use the stairs. If you must use the elevator, place the chemicals on a trolley, affix a “do not enter” sign to the trolley, lock the trolley wheels, press the button and send the lift to the floor you need. Travel by stairs to the floor you need, open the elevator and remove the trolley. 5. Always use devices designed for, and approved for, transport of specific items e.g. gas trolleys for gas bottles, dewars for cryogens, Winchester carriers etc. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 11 of 17 12.3.2 Transport outside buildings (including off-campus) by staff and students Specific requirements will apply for transporting dangerous goods and chemicals in a vehicle between buildings on the same university campus or outside Charles Darwin University property. The requirements will vary depending on the chemicals being transported however the following should be observed in every case: 1. 2. 3. 4. Move only the required amount of chemicals Never transport incompatible chemicals together Use spill trays/spill absorbent material/spill kit to contain spills Always use devices designed for and approved for transport of specific items e.g. gas trolleys for gas bottles, Dewars for cryogens, Winchester carriers etc. 5. Observe Dangerous Goods transport rules – seek information from the carriage agent you wish to use (e.g. freight company) and/or Competent Authority – Road and Rail Competent Authority – Air Transport Competent Authority – Sea Transport Chemicals in this classification must adhere to legislative requirements when being transported and stored. Safety hazards such as flammability, explosiveness and dangerous reactions are of concern with dangerous goods. There are restrictions on the carriage of chemicals on airlines (international and domestic) so check with your carrier. Consult the airline you are travelling with. For international travel review the Guide for Travellers - Know before you go (Australian Government - Customs and Border Protection publication) 12.3.3 Restrictions on transport In some areas and communities, some chemicals have restrictions or are prohibited by law from being supplied, possessed or consumed in any way. You must check what restrictions may be in place in the area you are travelling to or through and severe penalties apply for contravening the restrictions. A couple of examples are the alcohol restrictions in place across Australia and the bans or restrictions placed on volatile and aromatic chemicals and inhalants such as certain fuel types, paints, aerosols, glues. 13. Globally Harmonised System of Classification and Labelling of Chemicals (GHS) The WHS (NUL) Regulations 2011 implement a system of chemical hazard classification, labelling and safety data sheet (SDS) requirements based on the GHS. Transition to the GHS will occur over a 5 year period from 1 January 2012 until 31 December 2016. The Code of Practice for Managing Risks of Workplace Hazardous Chemicals refers to hazard classes and categories under the GHS, however, it also applies to workplace hazardous substances and dangerous goods classified under the NOHSC Approved Criteria and the ADG Code, respectively. Most substances and mixtures that are dangerous goods under the ADG Code are also hazardous chemicals. The GHS poster shows GHS signal words, pictograms and hazard statements for each GHS hazard class and category under the WHS Regulations and can be used to assist in the preparation of labels or to help end-users of chemicals understand the link between each hazard class and the various pictograms, signal words and hazard statements. Dangerous Goods classifications still apply to the transport of chemicals by road or rail. The Australian Dangerous Goods Code (ADG7) sets out the requirements for transporting dangerous goods by road or rail. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 12 of 17 Some confusion regarding the GHS labelling of hazardous chemicals may occur for chemicals that are dangerous goods labelled to meet transport requirements. Class labels recommended for the transport of dangerous goods as specified in the ADG7 Code may be used instead of the relevant hazard pictograms specified in the GHS but both should never be used on the same label. Note that the WHS (NUL) Regulations 2011 refer to hazard classes and categories in accordance with the GHS, rather than dangerous goods classes, categories and divisions. A comparison of dangerous goods classifications under the ADG7 Code with those under the GHS is provided in Appendix G of the Code of Practice for Labelling of Workplace Hazardous Chemicals. Do the new GHS symbols mean the same thing as the DG symbols? No. The GHS system has redefined some of the hazards. This means that for some chemicals the labels may be vastly different. This does not mean that the substance has become more or less hazardous, but the way the hazard has been classified has changed. This makes it difficult to compare the GHS and ADG systems. 14. Waste management Areas should consider the following points when disposing of chemicals: • Identify materials for disposal • Refer to the SDS for advice on disposal and ensure a copy is provided with all items being disposed • Clearly mark containers for disposal and ensure disposal containers are correctly and clearly labelled to identify the contents (including ratios or concentrations of components) • If necessary, seek advice on disposal containers and methods—this may vary for small or large scale disposals • Ensure incompatible items pending disposal are stored correctly • Keep a record of what is being disposed, including how, when, where, and why • Update ChemWatch area manifest to reflect changes (e.g. quantity, delete stock no longer held) Chemical waste can include solvents, acids, alkalis, toxic materials, photographic chemicals, paints, contaminated glassware and consumables, and laboratory chemicals that are no longer required or have deteriorated with age. Waste products derived from hazardous substance often have similar hazard characteristics to the hazardous substance from which they were derived, so appropriate consideration must be given to the packaging, labelling, handling and storage of waste products, just as for other hazardous substances. All waste must be identified with full chemical name (IUPAC nomenclature preferred) and concentration. Avoid trade names, and do not use abbreviations or formulae. Where the waste is a mixture, each constituent must be identified and concentrations reported – do not forget to include the solvent. Safety Data Sheets (SDS) must be obtained for all components of the waste in order to make a judgement on the segregation, storage and ultimate disposal of the waste. 14.1 Segregation and Storage of Waste The requirements for the segregation and storage of chemical waste are similar to the requirements for the storage of chemicals in general – refer to Section 13 of this guide. Incompatible chemical waste must be segregated as far as possible to reduce the risk of a dangerous reaction. For further information about chemical compatibilities, consult the product label, safety data sheet (SDS). Compatible chemical waste may generally be collected in the same container. A system of bulking compatible chemical waste into approved dangerous goods containers for ultimate disposal by a registered chemical waste disposal contractor may be considered. Where possible it is desirable that the waste generator bulk their waste (taking into account possible incompatibilities or chemical reactions). The individual components and their concentrations must still be noted on the container label. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 13 of 17 14.2 Waste Management Records A record of chemical waste disposed should be kept by the area with the following details: 14.3 Date/Name: Date of generation/Name of person/area generating waste. Full chemical name: must list all components and concentrations Number of containers: Total volume or weight: Physical state of waste: eg liquid, solid or sludge Dangerous Goods/GHS information Any other information required by external waste contractor(s) Packaging and Labelling of Waste 15.3.1 Packaging of waste If waste can be stored safely in a plastic bottle as opposed to a glass bottle then it is preferred. However, if it is unsafe in a plastic bottle then the most suitable container should be used. Liquid and solid hazardous waste can be re-packaged in the original packaging as long as it is labelled as waste. Ensure sufficient head space when filling containers, that is, DO NOT fill past the neck of the container. Chemically contaminated consumables (e.g. bench covers, heavily contaminated PPE, agarose and acrylamide gels) must be collected in strong leak proof bags (double-bagged) and labelled as per the labelling section below. Chemically contaminated plastic pipette tips, glassware or sharp objects must be disposed of in rigid containers (e.g. a sturdy container with a plastic liner or a dangerous goods drum) and labelled as per section 15.2.3 “Labelling of Waste”. 15.3.2 Labelling of waste The waste generator is responsible for ensuring that the waste containers are labelled appropriately and labels are legible. Labels are to be completed and securely affixed to each container to indicate the following details: 1. Identification of waste: (IUPAC name preferred – avoid common or trade names). Do not use abbreviations or formulae. 2. Hazards classification: Non-hazardous/ Hazardous 3. DG/GHS information and pictograms: e.g. Non Dangerous/ Flammable/ Corrosive/ Toxic/ Oxidising 4. Source of waste: Name of waste generator i.e. individual/work area/research group/undergraduate unit code 5. Date: Waste generation date 6. Other: any other information required by the contractor(s) 14.4 Waste Treatment 14.4.1 On-site waste treatment and disposal In some instances chemical waste may be treated in-house, but only if the material(s) convert to a non-hazardous product. Never discard chemicals down any general sink - unless you have verified that this is an appropriate disposal method. Unless specified on the SDS, no waste should be allowed to enter drains or general waste collection. It may be possible to neutralise some chemical wastes where staff have the required experience and technical competence. It may also be possible to dilute a chemical or mix it to a concentration that effectively renders it possible to dispose of on-site. Note: Neutralisation and dilution may be possible treatment methods but are not an acceptable alternative to appropriate disposal. If there is any doubt about the treatment method, personnel should not proceed - seek advice from Health, Safety and Environment. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 14 of 17 14.4.2 Disposal via External Contractor Where on-site disposal is not possible areas must use a fully licensed waste contractor to ensure that waste is disposed of in a safe and environmentally responsible way. The contractor must be licensed to collect and transport the waste. Containers must be properly labeled, stored in a suitable container, and stored appropriately until collection. Arrangements must be in place for waste to be collected regularly by the licensed waste contractor for appropriate off-site treatment. 14.4.3 Empty chemical containers and packaging Empty chemical containers can contain residual amounts of chemicals. In an effort to ensure that this residue is handled properly and to be able to recycle or properly dispose of these containers, the following procedure should be followed: 1. Consult the SDS for disposal information for the chemical 2. Remove the residual chemical by either - Following the SDS information - Triple rinsing container (and lid) as per rinse procedure below OR - Evaporation (e.g. ethanol is highly volatile and will evaporate) and then triple-rinse OR - Neutralisation followed by triple-rinse or evaporation/rinsing 3. Collect or dispose rinse waste as per rinse procedure below 14.4.3.1 Rinse procedure: All chemical containers, liquid or solid, must be rinsed 3 times before being discarded. A rinse should consist of minimal solvent (depending on the chemical, this may be water or another solution) being swirled carefully around the full surface of the container. The first rinse should always be collected as chemical waste. Depending on the nature of the chemical (as outlined in the SDS) the second and third rinses may need to be collected as chemical waste or can go down the drain. Always ensure that plenty of water is used to flush the material down the drain. After the containers are rinsed they can be discarded appropriately as described below. All caps should be left off of the discarded containers, containers should be labelled with “empty” and the label removed, blacked out or made illegible prior to being discarded. Caps should be triple-rinsed as per containers and may need to be sent as chemical waste (depending on the chemical) or be discarded as general waste. 14.4.3.2 Reuse/ Recycle/ Disposal of Cleaned Containers: All chemical containers must follow the above rinse procedure before being reused or discarded in any form. The use of empty (rinsed as above) chemical containers as chemical waste containers is an effective form of recycling. Empty chemical packaging may only be discarded into the general rubbish if: there are no hazardous residues (attained via triple rinsing or, in some cases, evaporation); any labels have been removed or defaced; and the lids have been removed. 15. Monitoring and Health Surveillance Advice is to be sought from CDU WHS unit should any monitoring of the work environment or health of workers be required to assess the degree of risk employees are exposed to. Some chemicals and products require mandatory routine monitoring and health surveillance (e.g. radiation). Other monitoring may be evident to a work area either through the risk assessment process or through notification of an issue or hazard report. Monitoring of the work environment and health may also form part of a follow up to Accident, Injury and Incident reporting. Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 15 of 17 If a worker requests both health surveillance and environmental monitoring, the matter must be discussed with the worker’s immediate manager/supervisor. If doubt exists about the level of exposure an assessment of the workplace should be undertaken. All reports and results of any monitoring or health surveillance undertaken by an external consultant should be recorded by managers/supervisors and communicated with the university WHS unit. The procedures followed, substances measured, results obtained, conclusions drawn and control measures implemented should be documented. Health monitoring records for all workers must be kept for at least 30 years after the record is made, even if the worker no longer works at the workplace. For asbestos health monitoring, these records must be kept for at least 40 years, due to the long period of time it can take for asbestos-related disorders to develop. Results of environmental monitoring are to be made readily accessible to employees who are, or are likely to be, exposed in the area that was monitored. Results of all health surveillance shall be treated and released in accordance with confidentiality and the NT Work Health and Safety (NUL) Act and Regulations 2011 and Charles Darwin University Privacy Policy 16. Essential Supporting Information CDU Policies, Guides or Procedures Work Health and Safety Policy Emergency Management Plan First Aid Procedures First Person on Scene (Accident /Incident) Procedure Induction, information, training and supervision Personal Protective Equipment (PPE) Risk Management Policy Safe Work Procedures Privacy Policy Acts & Regulations Work Health and Safety (National Uniform Legislation) Act 2011 Work Health and Safety (National Uniform Legislation) Regulations Dangerous Goods Act Dangerous Goods Regulations Transport of Dangerous Goods by Road and Rail (National Uniform Legislation) Act Transport of Dangerous Goods by Road and Rail (National Uniform Legislation) Regulations Incorporating the: Australian Dangerous Goods Code 7th Edition National Model Regulation - Control of Scheduled Carcinogenic Substances Codes of Practice How to Manage Work Health and Safety Risks Hazardous manual tasks First aid in the workplace National Code of Practice for Chemicals of Security Concern Managing the Work Environment and Facilities Labelling of Workplace Hazardous Chemicals Preparation of Safety Data Sheets for Hazardous Chemicals Managing Risks of Hazardous Chemicals in the Workplace Guides and Fact Sheets Guidance of the Classification of Hazardous Chemicals under the WHS Regulations Globally Harmonized System of Classification and Labelling of Chemicals (GHS) - 3rd Edition Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 16 of 17 Health Monitoring for Exposure to Hazardous Chemicals - Guide for persons conducting a business or undertaking Health Monitoring for Exposure to Hazardous Chemicals - Guide for workers Health Monitoring for Exposure to Hazardous Chemicals - Guide for medical practitioners Hazardous Chemicals Requiring Health Monitoring Emergency plans - fact sheet Australian and New Zealand Standards AS/NZS 31000.2009 AS/NZS 2243.1-1997 AS/NZS 2243.2-1997 AS/NZS 2243.1-1993 AS/NZS 3833:2007 Risk Management – Principals and guidelines Safety in Laboratories Part 1: General Safety in Laboratories Part 2: Chemical Aspects Safety in Laboratories Part 10: Storage of Chemicals The storage and handling of mixed classes of dangerous goods, in packages and intermediate bulk containers Document History and Version Control Version Date Approved Approved by Brief Description 1 22/07/2014 WHS Manager Created document Chemical Management Guide Contact Officer: WHS Consultant Version 1 Page 17 of 17