Project - Worcester Polytechnic Institute

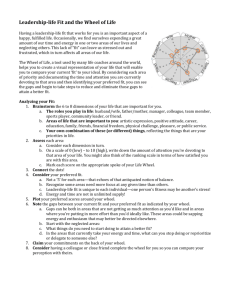

advertisement