Waste Heat Recovery for Diesel Trains

advertisement

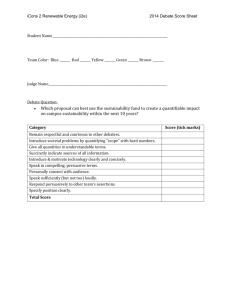

Waste Heat Replacement for Diesel Trains Tico Bergman The purpose of this report is to explain the importance and technique of increasing the efficiency of diesel trains by replacing waste heat with electricity. Diesel trains stop by use of dynamic braking. This is a process that uses an electric traction motor of the trains to generate electricity. The electricity that is harnessed is generated by the process of slowing down of the train. In the traditional process of dynamic braking, this energy is sent to a resistor that dissipates the heat into the atmosphere. In this process, the only form of heat involved is waste heat. Dynamic brakes convert kinetic energy into electricity Energy is sent to a dissipation process Energy is sent into the atmosphere in the form of waste heat http://www.engineeringexpert.net/Engineering-Expert-Witness-Blog/?p=2026 The above image is a diagram of a current, simplified, dynamic braking system. This system utilizes gravity as the source of energy and an electric motor to slow the weight and harness the energy. As you can see, the resistor heats up and this heat is dissipated into the atmosphere. This system is very similar to that of the dynamic braking system of trains but trains harness energy from the kinetic energy of the train, not gravity. The rest of the system in the train is very similar, but what we need to do is harness this electricity. Through my research, I have found a process that bypasses the current process of converting electricity into waste heat and instead converts it into hydrogen through a reversible fuel cell process. In my process the electricity is harnessed through the existing electric traction motor during the slowing down of the train. This electricity would then be sent through the reversible fuel cell and converted into hydrogen gas, which is easily stored in compressed gas canisters. The canisters will charge while the train is slowing down and can use the energy at any time by simply reversing the fuel cell process and converting the compressed hydrogen gas into a useful form of electricity, which is fed directly into the trains electrical system. Dynamic brakes convert kinetic energy into electricity Reversible fuel cell converts electricity into hydrogen Hydrogen gets stored in compressed gas storage canisters on a separate car Fuel cell process can be reversed to convert hydrogen into electricity There are five main assumptions used during my calculations. The first is that the average weight of a freight train is 6,000 tons. The second is that the disks will increase in temperature from 300 degree Kelvin to 500 degree Kelvin. The third is that the trains are in use for 24 hours a day. The fourth is that the trains average the equivalent of 10 full stops per 24-hour period. The fifth assumption is that diesel freight trains use 30 kilowatt-hours/mile. There is approximately 2.773 trillion tons of freight transported per year, which, with the 6,000 ton estimate per train, tells us that we can estimate there to be 462 million trips made per year, made at an average of 62 meters per second. Using the energy balance equation, we find that the waste heat of the system is equal to the change in kinetic energy, or roughly 10.7 kilojoules of waste heat per stop per train. The Carnot efficiency equation was then used to calculate the potential efficiency of this braking system. Assuming the brakes increase temperature 200 degrees Kelvin, an accurate estimate from my research, and the ambient temperature is around 300 degrees Kelvin, then the efficiency is 40 percent. Taking the waste heat, multiplying be 24 hours, dividing by .4 times 7225200 (number of seconds per 140,490 mile trip, which is average length), yields the kilowatt*hour/stop amount of 88.5. Combining this with the assumption that the train will stop 10 times per day, we get 885 kilowatts produced per train per day. In 2001 the Commission for Integrated Transport conducted research on the German ICE train lines and found that they use 31-53 kilowatt*hours/mile. Using this fact in conjunction with the estimation of 885 kilowatt*hours/day statistic found above reveals that if we harnessed all 10658872 Kilojoules of waste heat then the diesel train would gain enough energy to travel 30 miles every day. Now diesel train have a gas efficiency of 436 mile*ton/gal, which divided by 1 trail/6,000 tons gives us an efficiency of 0.073 train*miles/gallon. Dividing our 30 miles of travel by 0.073 miles / gallon gives us a gain of 413 gallons of fuel per train. Up until now, I have ignored the 40 percent efficiency rating. So, we must multiply this number of 413 gallons by 0.4, to get an actual gain of 165 miles, or $620 with a diesel price of $3.75 per gallon. This information is displayed in the below chart. Train braking Qwaste (kJ) Carnot Efficiency 10,658,872 40% Watts (kw) Hours used/day 26,647,180 24 kwh/day $/day 885 620 The functional structure of my design would be a large reversible fuel cell and storage canisters held on the train. The most logical place for such a structure would involve adding another car to the train that has the purpose of housing this structure. This would, however, add weight to the train and, if current technology were implemented, would need to be cooled because of high operating temperatures. Current reversible fuel cells have lower efficiencies than nonreversible fuel cells due to the higher temperatures of operation. http://www.knowledgepublications.com/solar_hydrogen.htm The above picture is a small-scale reversible fuel cell. The train car would be full of stacks of these units all linked together in conjunction, which would allow for maximum hydrogen production and storage and electrical conversion when the process is reversed. There are very few reversible fuel cells that are commercially available and those that are available are quite expensive. The remaining space in the train cart would be filled with high-pressure gas tanks, such as the ones in the below picture. http://www.pentairaqua.com/pro/en-US/resource/other-pentair-resources/ These tanks would store the hydrogen once generated by the brakes and allow for it to be used when the electricity is needed. These tanks are relatively cheap, costing around $700 for 120 gallons of compressed gas. The total expenses for a cart that has fuel cells and compressed gas tanks would be quite high. I estimate that the fuel cells, compressed tanks, and cooling unit on the train would cost around $500,000. With my calculated value of savings of $620 per day, the train would take 2.2 years to pay off the system. This system would be beneficial because there is no slowing the use of diesel trains in our country. Because the train system is privatized, there is no pressure to move to electric trains because none of the train companies want to pay the money to switch over. This technology would be valuable because it works in conjunction with existing diesel train technology and would have a pay-back period of only 2.2 years.