View

advertisement

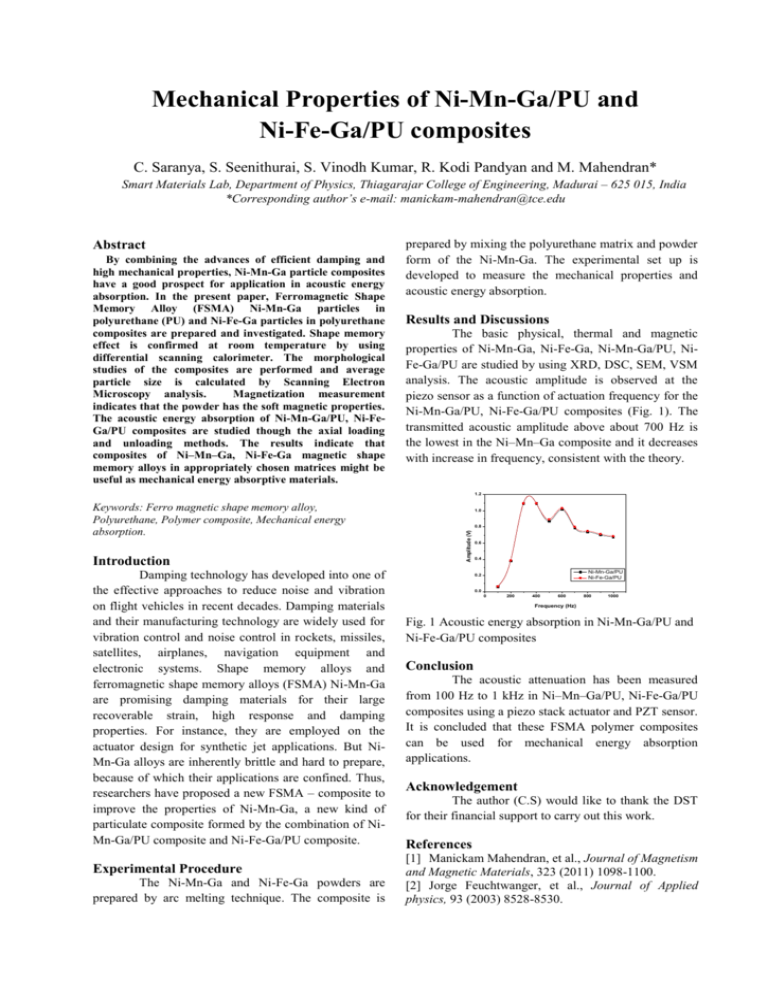

Mechanical Properties of Ni-Mn-Ga/PU and Ni-Fe-Ga/PU composites C. Saranya, S. Seenithurai, S. Vinodh Kumar, R. Kodi Pandyan and M. Mahendran* Smart Materials Lab, Department of Physics, Thiagarajar College of Engineering, Madurai – 625 015, India *Corresponding author’s e-mail: manickam-mahendran@tce.edu Abstract By combining the advances of efficient damping and high mechanical properties, Ni-Mn-Ga particle composites have a good prospect for application in acoustic energy absorption. In the present paper, Ferromagnetic Shape Memory Alloy (FSMA) Ni-Mn-Ga particles in polyurethane (PU) and Ni-Fe-Ga particles in polyurethane composites are prepared and investigated. Shape memory effect is confirmed at room temperature by using differential scanning calorimeter. The morphological studies of the composites are performed and average particle size is calculated by Scanning Electron Microscopy analysis. Magnetization measurement indicates that the powder has the soft magnetic properties. The acoustic energy absorption of Ni-Mn-Ga/PU, Ni-FeGa/PU composites are studied though the axial loading and unloading methods. The results indicate that composites of Ni–Mn–Ga, Ni-Fe-Ga magnetic shape memory alloys in appropriately chosen matrices might be useful as mechanical energy absorptive materials. prepared by mixing the polyurethane matrix and powder form of the Ni-Mn-Ga. The experimental set up is developed to measure the mechanical properties and acoustic energy absorption. Results and Discussions The basic physical, thermal and magnetic properties of Ni-Mn-Ga, Ni-Fe-Ga, Ni-Mn-Ga/PU, NiFe-Ga/PU are studied by using XRD, DSC, SEM, VSM analysis. The acoustic amplitude is observed at the piezo sensor as a function of actuation frequency for the Ni-Mn-Ga/PU, Ni-Fe-Ga/PU composites (Fig. 1). The transmitted acoustic amplitude above about 700 Hz is the lowest in the Ni–Mn–Ga composite and it decreases with increase in frequency, consistent with the theory. 1.2 Introduction Damping technology has developed into one of the effective approaches to reduce noise and vibration on flight vehicles in recent decades. Damping materials and their manufacturing technology are widely used for vibration control and noise control in rockets, missiles, satellites, airplanes, navigation equipment and electronic systems. Shape memory alloys and ferromagnetic shape memory alloys (FSMA) Ni-Mn-Ga are promising damping materials for their large recoverable strain, high response and damping properties. For instance, they are employed on the actuator design for synthetic jet applications. But NiMn-Ga alloys are inherently brittle and hard to prepare, because of which their applications are confined. Thus, researchers have proposed a new FSMA – composite to improve the properties of Ni-Mn-Ga, a new kind of particulate composite formed by the combination of NiMn-Ga/PU composite and Ni-Fe-Ga/PU composite. Experimental Procedure The Ni-Mn-Ga and Ni-Fe-Ga powders are prepared by arc melting technique. The composite is 1.0 0.8 Amplitude (V) Keywords: Ferro magnetic shape memory alloy, Polyurethane, Polymer composite, Mechanical energy absorption. 0.6 0.4 Ni-Mn-Ga/PU Ni-Fe-Ga/PU 0.2 0.0 0 200 400 600 800 1000 Frequency (Hz) Fig. 1 Acoustic energy absorption in Ni-Mn-Ga/PU and Ni-Fe-Ga/PU composites Conclusion The acoustic attenuation has been measured from 100 Hz to 1 kHz in Ni–Mn–Ga/PU, Ni-Fe-Ga/PU composites using a piezo stack actuator and PZT sensor. It is concluded that these FSMA polymer composites can be used for mechanical energy absorption applications. Acknowledgement The author (C.S) would like to thank the DST for their financial support to carry out this work. References [1] Manickam Mahendran, et al., Journal of Magnetism and Magnetic Materials, 323 (2011) 1098-1100. [2] Jorge Feuchtwanger, et al., Journal of Applied physics, 93 (2003) 8528-8530.

![paper_ed25_4[^]](http://s3.studylib.net/store/data/007713488_2-cf325043bd2e211b44b68a5d00fecac8-300x300.png)