Membrane Separation Lab 6 Group 5

advertisement

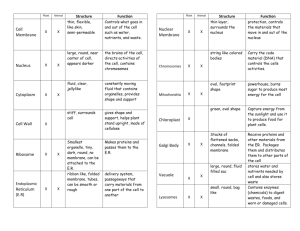

Air Membrane Separation University of Illinois Membrane Air Separation In this lab two membranes are used to separate oxygen from nitrogen in air. The two separators are used in series and in parallel to see which set-up will result in the best separation. 1 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Final Lab Report Unit Operations II Lab 6 February 9, 2016 Group 5 Andrew Duffy Daniyal Qamar Jeff Tyska Bernard Hsu Ryan Kosak Tomi Damo Alex Guerrero 2 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Contents 1. Summary ............................................................................................................................................... 4 2. Results ................................................................................................................................................... 5 3. Discussion............................................................................................................................................ 11 4. Conclusion ........................................................................................................................................... 14 5. References .......................................................................................................................................... 14 6. Appendix I: Data Tabulation/Graphs .................................................................................................. 15 7. Appendix II: Error Analysis .................................................................................................................. 21 8. Appendix III: Sample Calculations ....................................................................................................... 24 9. Appendix IV: Individual Team Contributions ...................................................................................... 27 3 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 1. Summary In this lab the goal was to find the effect of pressure and different configurations of membranes on the separation of air into its constituent components. For the configurations, two membranes were set up in parallel and in series. The air was approximated as a mixture of only nitrogen and oxygen. From the data in this lab, it can be concluded that increasing the pressure increases the amount of separation in the cylinders, and that a series configuration works better than a parallel one. For both the parallel and series trials, the concentration of oxygen in the air through the membrane increased in each trial (as can be seen in table 1). This makes sense since there shouldn’t be a high enough of an oxygen concentration to create a boundary layer on the membrane. Since there is no boundary layer, the diffusion of oxygen through the layer increases when pressure is increases. This trend occurs in both configurations because the exact configuration of the membrane does not matter; only the concentration of oxygen at the surface does (concentration at the boundary layer). The series configuration was found to separate the oxygen from the nitrogen better than the parallel configuration, which also makes sense. In the parallel configuration, all of the air only sees one membrane, and thus is only separated once. With the series configuration, the air is separated twice, and thus there is a better separation. This can be seen in table 1, where the concentration of oxygen in the concentrated stream is, on average 0.5% higher. Similarly, the concentration of oxygen in the retentate stream is about 1.4% higher (on average) in the parallel configuration. These conclusions are also backed by our other data and calculated values. The density of oxygen and nitrogen different (oxygen is heavier), and the trends in concentration with configuration and pressure can also be seen in the pressure data. Similarly, the flow rates of oxygen in the permeate were 4 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois also calculated. As expected, the flow rates of oxygen in the permeate increased when pressure was increased, and they were higher in the series configuration than the parallel configuration. Overall this lab went very well, and the data consistently supported the conclusion that the series configuration separated the oxygen from the nitrogen better than the parallel configuration, and the higher pressures resulted in higher oxygen concentrations in the permeate. 2. Results The solubility of the particular gas being separated from air depends on its solubility in the separating membrane. Calculations were made to determine the flux of the air through the membranes, the diffusivity of Oxygen through the membrane, the solubility of Oxygen in the membrane, the permeability of the membrane, the separation factors, the recoveries, and the stage cuts. Most of these properties increase as the pressure of the incoming air increases. An increase in pressure also dictates to an increase in the amount of oxygen and nitrogen coming through the membranes. As pressure increases, the flux, diffusivity, permeability, and separation factors all increase as well. The following graphs and data help visualize these properties better: 5 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Flux vs Pressure 1.000 0.950 Flux (g/m2-min) 0.900 0.850 0.800 Parallel 0.750 Series 0.700 0.650 0.600 90 95 100 105 110 115 120 125 Pressure (psi) Figure 1: Flux vs. Pressure Figure 1 makes it clear that as the inlet pressure of the gas increases the flux increases as well. As pressure was increased from 100 to 122 psi the flux increased from 0.718 to 0.955 g/m2min for parallel configuration and from 0.741 to 0.965 g/m2min for series configuration. The errors were relatively low for the flux ranging in ±0.01 g/m2min to 0.001. These errors were relatively low for the flux ranging in ±0.01 g/m2min. The flux for the parallel configuration is lower since the force is divided into two separators instead of a single pass. The flux was obtained from the inlet flow of the air and the area of the membrane, the appendix I and III have detailed calculations on flux. 6 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Diffusivity vs Pressure 0.00290 Diffusivity (m2/min) 0.00270 0.00250 0.00230 Parallel 0.00210 Series 0.00190 0.00170 0.00150 90 100 110 120 130 Pressure (psi) Figure 2: Diffusivity vs. pressure Diffusivity is the area per time the component (oxygen in this case) covers, as pressure increases there is a bigger driving force and more area is covered in less time. Figure 2 shows the graph of diffusivity of oxygen vs pressure. As the pressure increases the driving force of oxygen through the membrane also increases and thus there is a higher diffusivity. Since the concentration of oxygen is lower in the series configuration (more membrane area to go through) the diffusivity in the series configuration is lower. The error was in the ±10-4 m2/min range which is low for the given diffusivities. The diffusivity was obtained from the oxygen flux and concentrations from the inlet and outlet flows. 7 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Solubility Constant vs Pressure 5.40E-05 Solubility (mol/Pa-m3) 5.20E-05 5.00E-05 4.80E-05 Parallel 4.60E-05 Series 4.40E-05 4.20E-05 4.00E-05 70 80 90 100 110 120 130 Pressure (psi) Figure 3: Solubility vs. Pressure At first glance figure 3 seems unusual since solubility of gasses increase as pressure increases according to Henry’s law. But if the units are looked at more closely the solubility is expressed in mol/m3Pa. As the pressure increases it has a decreasing affect on the solubility. If the same data is expressed in mol/m3 units, then solubility decreases as the pressure increases. The parallel and series configuration have the similar solubilities of oxygen since pressure and concentration have very little affect on solubility. The material has a certain affinity towards oxygen and that stays constant for each configuration. The errors were in the ranges of ±10-6 mol/Pa m3, this number seems pretty high but it is acceptable. 8 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Permeability per thickness vs Pressure Permeability (mol/Pa-min-m4) 1.180E-07 1.160E-07 1.140E-07 1.120E-07 1.100E-07 Parallel 1.080E-07 Series 1.060E-07 1.040E-07 1.020E-07 95 100 105 110 115 120 125 Pressure (psi) Figure 4: Permeability vs. Pressure The permeability also increases with increasing pressure as figure 4 shows. Permeability is the amount of gas that passes through the membrane. As the driving force (pressure) increases the permeability increases as well since more oxygen goes through the membrane. Since Permeability = Diffusivity X Solubility, and the solubility is inversely proportional with pressure. Since the pressure in the parallel configuration is lower, a higher permeability is observed. The values increase from 1.101E07 to 1.169E-07 for the parallel configuration and from 1.049E-07 to 1.111E-07 for the series configuration as the pressure is increased from 100 to 122 psi. The permeability was obtained from the solubility and the diffusivity both of which were obtained using the concentrations and the flow rates of oxygen and air. Appendices I and III provide details over these calculations 9 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Separation Factor vs Pressure 9.000 8.000 7.000 6.000 Parellel alpha prime 5.000 Parallel alpha double prime 4.000 Series alpha prime Series alpha double prime 3.000 2.000 1.000 95 100 105 110 115 120 125 Pressure (psi) Figure 5: Separation Factors vs. Pressure Figure 5 shows the separation factors vs. pressure, this is the ratio of the amounts of oxygen in the permeate and the retentates. Since the final concentration of oxygen is lower in the series configuration (double pass) the separation factors are higher (higher separations). The series prime data is the ration of the oxygen concentrations in the permeate and feed streams. Most of the errors were in the ±0.1 range for alpha prime and ±0.01 for alpha double prime. 10 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Recovery and Stage Cut vs Pressure 1.000 0.900 O2 Rec. Parallel 0.800 N2 Rec. Parallel 0.700 Stage Cut Parallel O2 Rec. Series 0.600 N2 Rec. Series 0.500 Stage Cut Series 0.400 70 80 90 100 110 120 130 Pressure (psi) Figure 6: Recovery/Stage Cuts vs. Pressure Figure 6 shows the recoveries and stage cuts of oxygen in both the configurations of membrane separators. As the pressure is increased the recovery increases as well, more of the oxygen is driven through the membrane. The stage cuts are also shown in the graph and they increase as pressure increases as well. The recovery is the amount of oxygen separated from the feed stream and the cut is the amount of permeate per the amount of air fed. The errors for recovery were in the ±0.01 range while the error for cuts were in the ±1 range which is relatively high. 3. Discussion As can be seen in Figure 1 the flux vs. pressure is linear for both configurations, yet the fluxes for the series configuration are larger than those in the parallel configuration. As stated before in the anticipated results, this outcome was expected. It was a reliable assumption, because in the series configuration the air will be passing through two different membranes, one after the other resulting in a lower pressure drop (higher separation). This differs in the parallel configuration, where the air stream 11 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois will be split into two and each stream will pass through the membranes only once, thus leading to a higher pressure drop (less separation). So the flux for the parallel configuration is lower since the pressure is divided into two separators instead of a single two pass. The solubilities were also calculated for each component. With the units of solubility expressed in mol/m3Pa it can be seen that as the pressure increases, there is a decreasing affect on the solubility. Given the fact that the solubility constants are inversely related to the pressure drop, it was reasonably assumed that the solubility constants for both components would be higher in the parallel configuration compared to the series configuration. This is because as stated before, the pressure drop is higher for the parallel configuration as opposed to the series. The parallel and series configuration have the similar solubilities of oxygen since pressure and concentration have very little affect on solubility. *Note that since the change in pressure was kept the same for both configurations in which Figure 3 depicts the solubilities being the same for both configurations. Although, if the change in pressures were varied the new figure would depict the solubility being lower for the parallel configuration than in series, for the reasons stated above. With this information it was reasonably assumed that the diffusivity for each component would be higher in the parallel configuration as opposed to the series since it was confirmed the solubility is lower for the parallel configuration. In addition, as the pressure increases the driving force of oxygen through the membrane also increases and thus there is a higher diffusivity. Since the concentration of oxygen is lower in the series configuration – due to more membrane area – the diffusivity in the series configuration is lower. As can be seen in Figure 2 these reasonable assumptions were confirmed. Lastly, the permeability of each component was calculated. Permeability is the product of diffusivity and solubility, with the solubility being inversely proportional with pressure. As stated previously, since the pressure in the parallel configuration is lower, a higher permeability was observed. 12 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois The compiled results show that permeability also increases with increasing pressure as seen in Figure 4. Since permeability is a measurement of the amount of gas that is passed through the membrane it was a reasonable assumption that as the pressure (driving force) increases, the permeability will increase as well since more oxygen will permeate through the membrane. Given the fact that the measuring devices in this lab were extremely accurate the errors in the measured values were very minimal. The most probable source of experimental error involved the oxygen analyzers. After calibrating the two sensors, they still differed by around 0.3 from each other despite them measuring the same air. With this error propagating throughout the rest of the lab there were a few areas where this experimental error affected the ability to draw conclusions. This was notable with the solubility constant for oxygen, which had a big error (57.5%) associated with it. This can be attributed to the fact that the solubility constant for oxygen is directly proportional to the concentration of oxygen inside the membrane wall, which was measured with the oxygen analyzers that were not reading the same values. Due to the differing oxygen readings, the pressure of oxygen per thickness, α'O2, N2, and α''O2, N2 yielded high average errors. This is again because these values were defined in terms of mole fractions – which were calculated from the oxygen analyzers that measured concentrations in mole percent. These errors would have significantly been reduced if both oxygen analyzers were calibrated to both read the same exact volume percent of oxygen and not starting the lab until this occurred. This way the values measured with the oxygen analyzers would have fewer experimental error associated it. Definitive conclusions that could be made are that the values for flux, diffusivity, and permeability will increase as pressure increases, and solubility constants will decrease as pressure increases. For all these values the permeability and diffusivity for the parallel configuration should be higher than the series configuration. This is due to the fact the solubility constant will be lower as 13 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois pressure increases, and also because in the series configuration the air will be passing through two different membranes, one after the other resulting in a lower pressure drop, rather than in the parallel configuration, where the air stream will be split into two and each stream will pass through the membranes only once, thus leading to a higher pressure drop. 4. Conclusion In this lab the goal was to find the effect of pressure and different configurations of membranes on the separation of air into its constituent components. For the configurations, two membranes were set up in parallel and in series. The air was approximated as a mixture of only nitrogen and oxygen. From the data in this lab, it can be concluded that increasing the pressure increases the amount of separation in the cylinders, and that a series configuration works better than a parallel one. For both the parallel and series trials, the concentration of oxygen in the air through the membrane increased in each trial (as can be seen in table 1). This makes sense since there shouldn’t be a high enough of an oxygen concentration to create a boundary layer on the membrane. Since there is no boundary layer, the diffusion of oxygen through the layer increases when pressure is increases. This trend occurs in both configurations because the exact configuration of the membrane does not matter; only the concentration of oxygen at the surface does (concentration at the boundary layer). The series configuration was found to separate the oxygen from the nitrogen better than the parallel configuration, which also makes sense. In the parallel configuration, all of the air only sees one membrane, and thus is only separated once. With the series configuration, the air is separated twice, and thus there is a better separation. This can be seen in table 1, where the concentration of oxygen in 14 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois the concentrated stream is, on average 0.5% higher. Similarly, the concentration of oxygen in the retentate stream is about 1.4% higher (on average) in the parallel configuration. These conclusions are also backed by our other data and calculated values. The density of oxygen and nitrogen different (oxygen is heavier), and the trends in concentration with configuration and pressure can also be seen in the pressure data. Similarly, the flow rates of oxygen in the permeate were also calculated. As expected, the flow rates of oxygen in the permeate increased when pressure was increased, and they were higher in the series configuration than the parallel configuration. Overall this lab went very well, and the data consistently supported the conclusion that the series configuration separated the oxygen from the nitrogen better than the parallel configuration, and the higher pressures resulted in higher oxygen concentrations in the permeate. 5. References W.E. McCabe, J.C. Smith, and P. Harriott 2001. Unit Operations of Chemical Engineering, McGraw Hill, New York. 15 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 6. Appendix I: Data Tabulation/Graphs Membrane Separation Tank Outlet (psig) 140 140 140 Run Run 1 || Run 2 || Run 3 || Run 4 -Run 5 -Run 6 -- Gauge Outlet (psig) 122 110 100 FM1 (SLPM) 6.13 5.47 5 140 140 140 tube side 122 6.06 110 5.46 100 4.95 1 = Nonpermeate shell side 2= Permeate || = parallel -- = series FM2 (SLPM) 11.4 9.95 8.98 O2 Sensor 1 7.4 7.2 7.2 O2 Sensor 2 34.5 33.7 33 11.41 10.05 9 6 5.7 6 34.8 34.1 33.9 slpm=standard liters per minute Table 1 Run Run 1 || Run 2 || Run 3 || ΔP (psi) 122 110 100 Jo2 (g/m2min) 0.955 0.814 0.718 DO2/L (m2/min) 0.00265 0.00231 0.00209 ΔP (psi) 122 110 100 SO2 (mol/Pam3) 4.41E-05 4.84E-05 5.26E-05 PO2/L (mol/Pa-min-m4) 1.169E-07 1.116E-07 1.101E-07 Run 4 -Run 5 -Run 6 -- 122 110 100 0.965 0.832 0.741 0.00252 0.00220 0.00199 122 110 100 4.41E-05 4.84E-05 5.26E-05 1.111E-07 1.065E-07 1.049E-07 Table 2 16 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Run Run 1 || Run 2 || Run 3 || α'O2,N2 6.591 6.551 6.348 α''O2,N2 1.981 1.912 1.853 ΔP (psi) 122 110 100 Run 4 -Run 5 -Run 6 -- 8.362 8.561 8.035 2.008 1.947 1.929 122 110 100 O2 Recovery 1.068 1.035 1.009 N2 Recovery 0.410 0.417 0.420 Stage cut 0.650 0.645 0.642 0.413 0.420 0.422 0.653 0.648 0.645 1.082 1.052 1.041 Table 3 Flux vs Pressure Drop 1.000 0.950 0.900 Flux (g/m2-min) 0.850 0.800 Parallel Series 0.750 0.700 0.650 0.600 70 80 90 100 110 120 130 Pressure Drop (psi) Figure 7 17 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Diffusivity per thickness vs Pressure Drop 0.00290 0.00270 Diffusivity (m2/min) 0.00250 0.00230 Parallel 0.00210 Series 0.00190 0.00170 0.00150 70 80 90 100 110 120 130 Pressure Drop (psi) Figure 8 Solubility Constant vs Pressure Drop 5.40E-05 5.20E-05 Solubility (mol/Pa-m3) 5.00E-05 4.80E-05 Parallel 4.60E-05 Series 4.40E-05 4.20E-05 4.00E-05 70 80 90 100 110 120 130 Pressure Drop (psi) Figure 9 18 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Permeability per thickness vs Pressure Drop 1.180E-07 1.160E-07 Permeability (mol/Pa-min-m4) 1.140E-07 1.120E-07 1.100E-07 Parallel Series 1.080E-07 1.060E-07 1.040E-07 1.020E-07 70 80 90 100 110 120 130 Pressure Drop (psi) Figure 10 Separation Factor vs Pressure Drop 9.000 8.000 7.000 6.000 Parellel alpha prime 5.000 Parallel alpha double prime Series alpha prime Series alpha double prime 4.000 3.000 2.000 1.000 70 80 90 100 110 120 130 Pressure Drop (psi) Figure 11 19 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Recovery and Stage Cut vs Pressure Drop 1.000 0.900 0.800 O2 Rec. Parallel N2 Rec. Parallel 0.700 Stage Cut Parallel O2 Rec. Series N2 Rec. Series Stage Cut Series 0.600 0.500 0.400 70 80 90 100 110 120 130 Pressure Drop (psi) Figure 12 20 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 7. Appendix II: Error Analysis Measuring Device Pressure Sensor Digital Oxygen Sensor Flow meter Uncertainty in Measurement ± 1 PSIG ± 0.1 Percent ± 0.1 SLPM Three main sources of instrumental error were present for this experiment. The pressure sensors, digital oxygen sensor, and flowmeters were used to measure the values needed in determining calculations. These instruments are both accurate and easy to read. The Digital Oxygen Sensor was calibrated before use however; there was some error present in the calibration. After exposing the sensors to the ambient air they both read about 21% oxygen but the two sensors differed by around 0.3 from each other despite them measuring the same air. The pressure sensors and flow meters did not need calibration. As always there was also the possibility of human error present caused my misreading the indicators or by calculation error. Other than those sources of error this lab was done relatively accurately. This was mostly due to the fact that there were few measurements needed and the instruments used were accurate and easy to operate. Run Run 1 || Run 2 || Run 3 || Run 4 -Run 5 -Run 6 Jo2 (g/m2min) 0.012516 Error Analysis Table I QO2 QO2 (SLPM) (NLPM) 0.005085 0.010170 QO2 ([N]-m3)/min ρP (kg/m3) 0.000086 0.012430 0.008210 0.003342 0.006685 0.000048 0.008161 0.102772 0.041909 0.083818 0.000533 0.102239 0.011820 0.004800 0.009599 0.000082 0.011738 0.008814 0.003586 0.007172 0.000053 0.008762 0.105955 0.043148 0.086295 0.000565 0.105390 21 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois -- Analysis of error from Table I: The diffusive flux calculated using Fick’s Law produced an average error of 4.98%. The volumetric flow rate of oxygen exiting the oxygen rich stream produced an average error of 4.9%. The density of the permeate produced an average error of 3.39% Overall the error present in this experiment is very low. There are relatively few numbers of measurements taken during this lab and the equipment used is accurate. The density of the permeate stream depends only on the measurement obtained from O2 sensor 2. This sensor was calibrated before the lab was conducted and has an error of ± 0.1% associated with it. The volumetric flow rate of oxygen depends on O2 Sensor 2 and Flow Rate 2. Flow Meter 2 had an error of ± 0.1 SLPM .The diffusive flux depends on the previous two calculations and the thickness of the membrane (provided by the manufacture) therefore the only measurable point of error would be O2 Sensor 2. Run Run 1 || Run 2 || Run 3 || Run 4 -Run 5 -Run 6 -- Error Analysis Table II Cin,2 FM2 (mol/m3) (NLPM) N/A N/A Cin,1 (mol/m3) N/A FM1 (NLPM) N/A DO2/L (m2/min) 5.35579E-05 N/A N/A N/A N/A N/A N/A N/A N/A pO2 (Pa) 0.888004207 SO2 (mol/Pam3) 5.1047E-06 N/A 4.0375E-05 0.72 3.8809E-06 N/A N/A 0.001759024 7.200473405 7.4394E-05 N/A N/A N/A N/A N/A N/A N/A N/A N/A 4.82228E-05 0.720011675 6.2882E-06 N/A N/A N/A N/A 2.1328E-05 0.570012272 2.9753E-06 N/A N/A N/A N/A 0.001721844 6.000394505 7.4394E-05 22 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Analysis of error for Table II: The pressure of oxygen in the nitrogen rich stream produced an average error of only 0.005%. The Solubility Constant for oxygen had an average error 57.5% associated with it. The Diffusivity of oxygen per thickness of the membrane yielded an error of 26.5%. Both the pressure of oxygen in the nitrogen rich stream and the Solubility Constants of oxygen were dependent of the measurements taken from O2 Sensor 1 and the outlet pressure gauge. These two pieces of equipment have errors of ± 0.1% and ± 1 PSIG respectively. The Diffusivity of oxygen per thickness of the membrane depends on O2 Sensor 1, O2 Sensor 2, and Flow Meter 2. The error in these instruments is stated above. Run Run 1 || Run 2 || Run 3 || Run 4 -Run 5 -Run 6 -- PO2/L (mol/Pa-minm4) 1.8824E-08 Error Analysis Table III α'O2,N2 α''O2,N2 O2 Recovery 0.24854628 0.05193083 0.21596665 CN2,r (mol/m3) N/A N2 Recovery 0.07749319 Stage Cut 0.13059018 1.42401E-08 0.15265225 0.04455491 0.13290789 N/A 0.04916656 0.08172921 1.5564E-07 9.5194518 2.06543431 8.30990503 N/A 3.45872448 5.24896362 1.75806E-08 0.46029265 0.04578146 0.19672683 N/A 0.06936061 0.1179853 1.36579E-08 0.45490829 0.01285494 0.14820561 N/A 0.05578717 0.09119116 1.48361E-07 12.0979024 2.16826296 8.58095947 N/A 3.47871539 5.27634161 Analysis of error for Table III: The error calculated from the values in Table III was much higher than that of the previous two tables. Pressure of Oxygen per thickness, α'O2, N2, and α''O2, N2 produced average errors of 55.7%, 51.6%, and 37.7% respectively. The other three values in the table yielded errors of over 100%. 23 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 8. Appendix III: Sample Calculations All sample calculation values are sampled from trial 1 of the parallel separation, the rest are identical. Known Values: A 2.7 m2 ρO2 1.331 kg/m3 ρN2 MW-O2 MW-N2 1.165 32 28 kg/m3 g/mol g/mol Total Flux: 𝐽𝑜2 = 𝑄𝑜2 𝜌 𝑛𝐴 Where: Qip = Volumetric flow rate of species i in the permeate in m3/min ρ =Density of permeate in kg/m3 A = Area of membrane, (in this case 2.7m2 per module) n = Number of modules used, (in this case 2) 0.955 ( g/m2 min) = 0.00422 ( m3/min) * 1.22 (kg/m3) * 1000 (g/kg) / 2 * 2.7 (m2) Diffusivity Flux: 𝐷𝑖 𝐿 = 𝐽𝑖 (𝐶𝑖𝑛1 −𝐶𝑖𝑛2 ) Where: Ji = Flux of component i in grams/m2 min Di = Diffusivity of component i in m2/min L = Thickness of membrane in meters Cin1 = Concentration of component i inside membrane wall on feed side in mol/m3 Cin2 = Concentration of component i outside the membrane wall on permeate side in mol/m3 0.00264 ( m2/min) = 0.955 ( g/m2 min) / 32 ( g/mol) * ( 14.34 – 3.07 ) (mol/m3) Henry’s Law: 𝐶𝑖𝑚 = 𝑆𝑖 𝑝𝑖 Where: Cim = Concentration of component i inside the membrane wall in mol/m3 Si = Solubility constant for component i in the membrane in mol/m3Pa pi = Partial pressure of component i in the gas phase in Pa 3.07 ( mol/m3) = 4.41X10^-5 ( mol/Pa m3) * 69736.19 ( Pa) 24 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Permeation: 𝑃𝑖 = 𝐷𝑖 𝑆𝑖 Where: Pi = Component i membrane permeability in mol/m3sPa Di = Diffusivity of component i in m2/s Si = Solubility constant for component i in the membrane in mol/m3Pa 1.11X10^-7 (mol/Pa min m4) = 0.00264 ( m2/min) * 4.41X10^-5 ( mol/Pa m3) Separation Efficiency: 𝑃 𝛼𝑖𝑗 = 𝑃 𝑖 𝑗 Where: αij = Separation factor Pi = Component i membrane permeability in mol/m3sPa Based on feed composition 1.98 = ( 34.5 / 65.5 ) * ( 0.79/0.21 ) Recovery: 𝑂2 𝑅𝑒𝑐𝑜𝑣𝑒𝑟𝑦 = 𝑄𝑝 𝐶𝑂2𝑝 𝑄𝑓 𝐶𝑂2𝑓 Qp = Volumetric flow rate of permeate in m3/s Qf = Volumetric flow rate of feed in m3/s CO2f = Molar concentration of oxygen in feed in mol/m3 CO2p = Molar concentration of oxygen in permeate in mol/m3 CN2f = Molar concentration of nitrogen in feed in mol/m3 CN2r = Molar concentration of oxygen in permeate in mol/m3 1.06 = ( 12.23 / 6.57 + 12.23) * ( 14.35 * 32 / 0.21 * 1.33 * 1000) Stage Cut: 𝑆𝑇𝐴𝐺𝐸𝐶𝑈𝑇 = 𝑄 𝑄𝑝 𝑝 +𝑄𝑓 Where: Qp = Volumetric flow rate of permeate in m3/s Qf = Volumetric flow rate of feed in m3/s 0.65 = 12.23 / ( 6.57 + 12.23) Error Sample: 25 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois Relationship between Z and (A,B) Z=A+B Z = A-B Z=A*B Z= A/B Relationship between errors ΔZ and (ΔA,ΔB) (ΔZ)2 = (ΔA)2 + (ΔB)2 Z=An ΔZ/Z = n * ΔA/A Z= Ln(A) ΔZ = ΔA/A Z= exp(A) ΔZ/Z = ΔA ΔZ ∆𝑍 = √(ΔA)2 + (ΔB)2 (ΔZ/Z)2 = (ΔA/A)2 + (ΔB/B)2 ∆𝑍 = (√( ΔA 2 ΔB 2 ) +( ) )×𝑍 A B 𝑛 × ∆𝐴 𝑍 ×𝐴 ∆𝐴 ∆𝑍 = 𝐴 ∆𝑍 = 𝑍 × ∆𝐴 ∆𝑍 = An example of error is given using trial 1 parallel for finding the error in the oxygen flux , J O2. E JO2 = E QO2 + E ρO2 0.012 = 0.000086 + 0.0124 26 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 9. Appendix IV: Individual Team Contributions Name: Andrew Duffy Operator (Both Lab Days) Pre-Lab Editing Final Lab Editing Summary Introduction Literature Review / Theory Apparatus Materials and Supplies Procedure Anticipated Results Results Discussion Conclusion References Data Tabulation / Graphs Error Analysis Sample Calculations Job Safety Analysis Power Point Presentation Total Time (Hours) 7 0 0 0 1 0 0 0 0 0 0 0 0 0 0 2 0 0.5 0 10.5 Description Operated lab with group Time (Hours) 7 0 0 0 0 0 0 0 0 1 0 0 0 0 2.5 0 Description Operated lab with group Wrote Section Wrote Section Wrote Section Name: Bernard Hsu Operator (Both Lab Days) Pre-Lab Editing Final Lab Editing Summary Introduction Literature Review / Theory Apparatus Materials and Supplies Procedure Anticipated Results Results Discussion Conclusion References Data Tabulation / Graphs Error Analysis Wrote Section Compiled Data 27 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 0 0 0 10.5 Sample Calculations Job Safety Analysis Power Point Presentation Total Name: Ryan Kosak Operator (Both Lab Days) Pre-Lab Editing Final Lab Editing Summary Introduction Literature Review / Theory Apparatus Materials and Supplies Procedure Anticipated Results Results Discussion Conclusion References Data Tabulation / Graphs Error Analysis Sample Calculations Job Safety Analysis Power Point Presentation Total Time (Hours) 7 0.5 1.5 0 0 1.5 0 0 0 0 0 0 0 0 0 0 0 0 0 10.5 Description Operated lab with group Time (Hours) 7 0 0 0 0 0 0.5 1.5 0 0 2 0 0 Description Operated lab with group Compiled Wrote Section Name: Daniyal Qamar Operator (Both Lab Days) Pre-Lab Editing Final Lab Editing Summary Introduction Literature Review / Theory Apparatus Materials and Supplies Procedure Anticipated Results Results Discussion Conclusion Wrote Section Wrote Section 28 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 0 0 0 0 0 0 11 References Data Tabulation / Graphs Error Analysis Sample Calculations Job Safety Analysis Power Point Presentation Total Name: Tomi Damo Operator (Both Lab Days) Pre-Lab Editing Final Lab Editing Summary Introduction Literature Review / Theory Apparatus Materials and Supplies Procedure Anticipated Results Results Discussion Conclusion References Data Tabulation / Graphs Error Analysis Sample Calculations Job Safety Analysis Power Point Presentation Total Time (Hours) 7 0 0 0 0 1.5 0 0 0 0 0 0 0 0 0 0 2 0 0 10.5 Description Operated lab with group Time (Hours) 7 0 0 0 0 0 0 0 1.5 0 Description Operated lab with group Wrote Section Wrote Section Name: Alex Guerrero Operator (Both Lab Days) Pre-Lab Editing Final Lab Editing Summary Introduction Literature Review / Theory Apparatus Materials and Supplies Procedure Anticipated Results Wrote Section 29 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016 Air Membrane Separation University of Illinois 0 2 0 0 0 0 0 0 0 10.5 Results Discussion Conclusion References Data Tabulation / Graphs Error Analysis Sample Calculations Job Safety Analysis Power Point Presentation Total Wrote Section Name: Jeff Tyska Operator (Both Lab Days) Pre-Lab Editing Final Lab Editing Summary Introduction Literature Review / Theory Apparatus Materials and Supplies Procedure Anticipated Results Results Discussion Conclusion References Data Tabulation / Graphs Error Analysis Sample Calculations Job Safety Analysis Power Point Presentation Total Time (Hours) 7 1.5 0 2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 10.5 Description Operated lab with group Compiled Wrote Section 30 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Spring 2011 2/9/2016