soppom-mgmt_sum_2013 (link is external)

advertisement

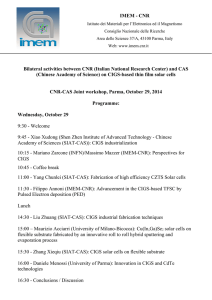

(C-) SIM' Call 2009 Stage 2 Proposal for SIBO program SoPPOM Solution based Processing of Photovoltaic Modules SIBO Program 2009-5 SB01: "abCIGS" SB02"weTCOat" SB03"phyCIGS" SBO4 “APSYNC” ICON1: "OPvTECH" ICON2: "ClGstack" ICON3: “SOLCAP” Sections AIF 1 / 1 37 SIM' IfflOVdij • iwT SIBO-Program SoPPOM Management Summary The PV market "The solar electricity market is booming. By the end of 2007, the cumulative installed capacity of solar photovoltaic (PV) systems around the world had reached more than 9 GW. This compares with a figure of 1.2 GW at the end of 2000. lnstallations of PV cells and modules around the world have been growing at an average annual rate of more than 35% since 1998. Such has been the growth in the solar electricity industry that it is now worth more than an annual 13 billion." (Solar Generation V — 2008, EPIA/Greenpeace report). "PV cells are generally made either from crystalline silicon, sliced from ingots or castings or from grown ribbons, or thin film (TF), deposited in thin layers on a low-cost backing. Most cell production (90% in 2007) has so far involved the former, whilst future plans have a strong focus on the latter. Thin film technology based on silicon and other materials is expected to gain a much larger share of the PV market. This technology offers several advantages, such as low material consumption, low weight and a smooth appearance" (Solar Generation V — 2008, EPIA/Greenpeace report). Attractiveness of thin film PV market is driven by the potential of higher automation, lower production costs (thinner active layers, less labor-intensive process) and, eventually, lower operating costs (Euros/kWh). These new technologies need however further development to allow mass production of high efficient modules at low costs and be able to compete with cSi whose cost is strongly decreasing. The opportunities Today, the thin layers are typically sputtered or evaporated onto a substrate in vacuum conditions. The disadvantages of this technology are high investment costs for production and low yields in materials use. If the vacuum processes could be replaced by solution based processes (such as printing, electrochemical deposition, ..) one could reduce the investment cost dramatically, and increase the material yield significantly. Two material systems allow the development of efficient processes in particular, TF PV based on Cupper Indium Gallium Diselenide/sulfide (CIGS) and organic photovoltaics (OPV). Both allow solution based production technology and have the cost and / or efficiency potential needed for a successful future market development. The goal of this proposal is therefore to set up a spearhead knowledge base in thin film PV module production on the basis of breakthrough production technology by means of solution based processes based on CIGS chemistry and OPV. Besides the systems mentioned above, also alternative chemistries and routes will be monitored to guarantee sustainable development of the technology. In the long run alternatives for components such as scarce in and the Cads-buffer layer will be essential. 2/137 The challenges Replacement of the vacuum based processes is however not so evident, one needs to have full control over the layers, compositions, contaminants, interfaces, grain boundaries, defect chemistry, substrate interactions, homogeneity of the layer, ... Control over these parameters is already a challenge in established vacuum technologies, certainly over large areas. For solution based processes the issues are of even greater concern, since these are not well studied yet. The principles of solution based processing have been demonstrated on ceil level with nice efficiencies, the translation of this technology to large areas and to modules is today still at question. In our opinion this translation is still not achieved, mainly because of a lack of fundamental understanding of the issues mentioned above. PV situation in Flanders In Flanders, academia and industry have built a strong S&T-platform in the silicon-based systems. Complementary to this, the major part of the industrial value chain from material supply to production of PV-modules is covered in Flanders. Flanders also has world leading research groups in the OPV-domain. In the field of thin film technologies, however, there has until now never been a major effort to set up a comprehensive research and industrial activity, although these technologies intrinsically have a low cost potential because of the small I amounts of active materials used and the potential for in line high volume production. Furthermore, almost all competences needed to become a major player in this domain are present in Flanders. The consortium and project organization A complementary team of industrials has joined efforts to submit this proposal. They are all active in different aspects of today's PV industry, Umicore (Ge, Si, TF PV, concentrator PV), Agfa (conductive polymers), Solvay (OPV), AGC (PV glass substrates), NOVOPOLYMERS (encapsulants) and A.Schulman (masterbatches). All industrial partners in this consortium are interested to further grow their PV related business in the future and to adopt new technologies. The industrial consortium is complemented with the most relevant research groups in Flanders, all working in their specific fields of expertise and focused to address the mentioned issues in solution based TF PV processing. UGent (semiconductor nanoparticle (NP) and film processing, dispersion, PV cell characterization and design), KULeuven (rapid sintering, rnodelling, suspension technology, PV cell understanding), UA (advanced NP and TF characterization), UHasselt (transparent conducting oxide (TCO) NP and film processing, characterization, OPV polymer chemistry), IMEC/Imomec (cell characterization, cell integration, layer characterization, grain boundary characterization), KaHo St Lieven (optical modeling), FLAMAC (high throughput chemistry). The consortium has organized the SIBO proposal into two different lines, a science oriented and a science & technology oriented axis. In the science axis, 4 SBO's are defined. SBO 1 focuses on the active layer for OPV and CIGS in all its aspects, starting from the precursors, stabilization, deposition, sintering to the recrystallisation into the right layers. For OPV mainly the introduction of colloids in the active layer will be studied to enhance the spectral range of OPV active layers. SBO 2 is similar to SBO1, but with a focus on TCO layers applicable for the CIGS technology as well as for OPV technology. A strong common 4 / 137 theme in both SBO 1 and 2 is the characterization of the precursors, the layers, interlayers, and performance measurement (both of line as in situ during film formation). Another common theme for SBO 1 and 2 is the development of a profound theoretical understanding about the sintering and re-crystallization aspect of the thin layers. In SBO 3 the cell physics and characterization are studied specifically for CIGS cells, complemented by developing cell integration capacity and cell performance measurement. SBO4 deals with the development of high throughput methods for production of bigger amounts of NPs for formulation into inks. The science & technology axis is a mirror of the science axis, and is oriented at the more technological aspects of this program in which the different companies of the consortium will participate. Main topics to be addressed are the development of an in-depth understanding of the synthesis technologies of NP's (precursors) needed for the active layers, deposition technologies taking into account the formulation aspects of the precursors, an understanding about annealing and fast annealing processes to allow in line processing, and the basic knowledge for PV cell integration on the basis of CIGS technology, which today is not available in Flanders. This is developed in 3 proposed ICON projects, one from an OPV perspective and the other from a CIGS perspective as well as one focusing on encapsulants to increase durability and maintain / improve photovoltaic device performance. Valorization Valorization of the proposed SIBO program can be seen in several ways. From a scientific and technological point of view, the program will result in an in-depth understanding of the thin film technology, thus contributing to the progress of knowledge and the global positioning of Flemish research groups in this field. Industrially speaking, an even stronger supply base to the PV industry will be created in Flanders, focused on new, promising technologies and in case of successful development of this program (plus extensions) could create access to a TFPV market which will be worth several billions euro in 2020. From an environmental point of view, the program will create more efficient, low cost processes that will contribute to a wider spread of PV technology. Last but not least, it will result in the creation new academics as well as industrial jobs. The goals of the program Overall, the program will lead to an even broader science and technology base for the PV field in Flanders, and will ensure Flanders to be active in nearly all aspects of the PV technology. It will enlarge Flanders activities to all available technologies, and create PV cell integration and evaluation capacity in all the different niches of PV technology. This would place Flanders at the forefront on PV science and technology in the world and make Flanders a PV technological hotspot. Based on solution based processing and CIGS as a model chemistry, the consortium bas the ambition to reach the following targets in 2018: 14% cell efficiency, 10-12% module efficiency (30x30 cm) For OPV the 2018 targets are: 12% cell efficiency 9% module efficiency This would for sure be a first step and would not be sufficient in terms of efficiency to bring these processes to the market – More focussed R&D work would then be needed.