Technology Test order and confirmation Scania

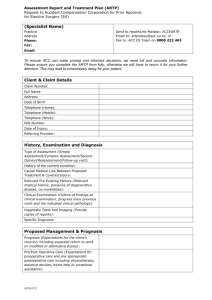

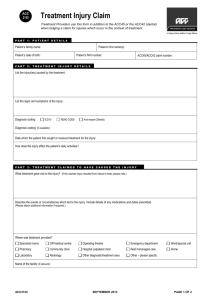

advertisement

Test order / Order Confirmation Scania Supplier ID (number) Orderer incl. e-mail & phone no Company (incl. address etc.) VAT number Invoice address (if other than above) Test samples Article name, no. and test series no. No of samples Specific article: __3__ pcs. Plane test panels, maximum size 100x200x3 mm: ____ pcs. Surface treatment Test Corrosion test and coating thickness measurement ACT acc. to STD4319 v1 Accredited method according to ISO/IEN 17025 Coating thickness measurement by X-ray spectrometric acc. to ISO 3497:2000 (Inorganic coatings) Coating thickness measurement by Gauge Meter acc. to SS-EN ISO 2808:2007, method 6 (Organic coatings) Test method Scribe Complementary tests will be included in the same report Temperature resistance before corrosion test at: 80°C 200°C 300°C during 24 hrs. acc. to STD4165 v13 (maximum sample size L35×H35×D20 cm, for other sample sizes please contact the laboratory before sending the test objects to Proton Technology) Adhesion test, Cross-cut, acc. to ISO 2409:2013 (Organic coatings) Adhesion test, Knife test acc. to STD2239 v.5 (Inorganic coatings and Organic coatings) Yes acc. to STD4271 v4, 0,5 mm wide scribe Where?____(optional) Requirements & Evaluation Supplied by test orderer (requirement levels A-D, 1-3) STD4113 v13 Organic coatings (propagation from scribe acc. to STD4271 v4, general corrosion acc. to ISO 4628-3:2003 and edge corrosion acc. to STD4455 v1) Test and evaluation whole sample acc. to requirement level______ Standard requirements STD4113 v13 Organic coatings (propagation from scribe acc. to STD4271 v4, general corrosion acc. to ISO 4628-3:2003 and edge corrosion acc. to STD4455 v1) Separate requirements on sample shall be applied. Test and evaluation area 1 acc. to requirement level______ Test and evaluation area 2 acc. to requirement level______ Test and evaluation area 3 acc. to requirement level______ Note! Areas shall be marked by supplier on samples STD4165 v13 Inorganic coatings (white corrosion and base metal corrosion) Test and evaluation acc. to requirement level______ Significant surface Side of the article that shall be exposed and part that shall be facing upwards in the chamber:____Supplied by test orderer Additional requirements Customers requirements outside standard Intermediate evaluations also at 2 and 4 weeks (organic coatings) or at 1 and 2 weeks (inorganic coatings) Note where the corrosion is found (on sharp edges/plane surfaces) No pictures in the Report Test only (no evaluation, no pictures, no report) Return to orderer *Address supplied by test orderer Discarded Tested material Other information - Note! The samples shall be conditioned by orderer (client) according to Scania requirements, if any, before samples are sent to Proton Technology. The samples shall not be exposed to moisture or large temperature changes before arriving to Proton Technology. The details shall be well-packaged when sent to Proton Technology so that no damages can come up during transportation. Proton Technology may clean the test objects before testing. Proton Technology is not responsible for reference details. Client can choose to save samples from the same batch for example for further testing. The testing may be destroyable. If the client has not made any comments before calculated start date, the test will be started and followed through. The samples are archived minimum one year from arrival date to Proton Technology. The samples can be sent back to the client before the archive time expires if requested by the client. Proton Technology will charge the customer for administration fee and cost for freight of the samples in return. If requirement for positioning objects according to a specific angle during test is required and can not be fulfilled due to the geometry the objects the objects will be positioned at an angle as close as possible to the requirements. Proton Technology will make sure the tests are performed according to this agreement. Deviations from the standards and/or requirements will be reported. Any deviations including ten per cent of the total test time or less and/or issues Technology assess as minor are not considered as significant for the test. The report will be written in English and sent by e-mail (pdf) or as a file by post depending on size. Delivery conditions according to YLK-10 (1994). Notes from the corrosion laboratory/ Confirmation of order: Test number Contact person Version Sample arrived Is a subcontractor used for the test (Yes/No) Name of Subcontractor Samples numbered by Proton Technology Calculated start date Important dates during the test period Latest day of Report Cost of testing (according to agreement) Address if samples returned Other Notes 1 N 1-3 EUR