Pre-audit/audit checklist and report NAME OF AUDITOR

advertisement

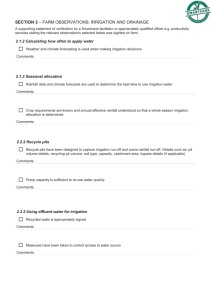

Pre-audit/audit checklist and report NAME OF AUDITOR/ FACILITATOR: DATE: NAME OF GROWER: PRE/AUDIT OBJECTIVE: SIGNATURE OF AUDITOR/FACILITATOR: FARM BEING AUDITED Signed as a true and accurate record of evidence sighted during the pre-audit/audit ADDRESS OF FARM ADDRESS 1: AUDIT SCOPE: ADDRESS 2: (LIST MODULES) SUBURB: STATE: PC INSTRUCTIONS FOR COMPLETING THE PRE/AUDIT CHECKLIST Evidence sighted must be documented in the “evidence sighted” column. Examples are to be included, as applicable, including dates and details. Based on the evidence sighted, a finding must be determined. Options are: Compliant with Smartcane BMP Industry standard (C – BMP). This finding indicates that the evidence provided is sufficient to address the industry standard. Compliant with Smartcane BMP and above industry standard (C – above). Criteria for above industry standard are shown in italics. Where there is no italic criteria specified, the industry standard should be demonstrated. Non-compliant with Smartcane BMP – below standard (NC – below). Evidence shows that the industry standards are not met or there is insufficient evidence to demonstrate compliance with the Smartcane BMP industry standard. Not applicable (NA) – the criteria does not apply for the enterprise. A reason for this finding must be documented in the evidence section. At the end of each module, complete the overall rating. In order to achieve a rating of Compliant with Smartcane BMP industry and above Industry standard (C – above), all relevant criteria must have been rated at this level, with no criteria rated at below industry standard or at Smartcane BMP Industry standard. If any items are rated at Smartcane BMP standard and there is a higher standard listed, then the overall finding shall be Smartcane Industry Standard. In order to achieve a rating of Compliant with Smartcane BMP Industry standard (C – BMP), all relevant criteria must have been rated at this level, with no criteria rated at below industry standard. If any of the relevant criteria are rated at Non-compliant with Smartcane BMP standard (NC-below), this rating should be recorded. SECTION 1 – SOIL HEALTH AND NUTRIENT MANAGEMENT KEY AREA QUESTION 1.1.1 Managing Compaction At Industry Standard - Is row spacing & most machinery wheel spacing matched? - Were rows initially established using GPS guidance? - Are machinery operations delayed to avoid operating in wet field conditions where possible EXAMPLES OF EVIDENCE REQUIRED Farm observation* Optional: Photographs Farm observation* and/or GPS records (sourced from the contractor or grower) Farm observation* and/or Farm diary and/or Statutory declaration Optional: Cultivation records Rainfall record ABOVE Industry Standard - Is row spacing and all machinery wheel spacing matched? - Is GPS guidance used for all field operations: bed forming, planting, spraying and harvesting? - Machinery is not operated in wet field conditions. Farm observation* Optional: Photographs Farm observation* and/or GPS records sourced from the contractor or grower Farm observation* and/or Farm diary and/or Statutory declaration Optional: Cultivation records Rainfall record EVIDENCE SIGHTED FINDING (C – BMP; C – above NC – below N/A) 1.2.1 Trash Management At Industry Standard - Is a green cane trash blanket retained on suitable soils? - In a cold environment: Is trash raked from the stool and maintained in the interspace or is cane burnt prior to harvest? - Where water logging risk exists, is cane burnt prior to harvest? 1.3.1 Fallow Management ABOVE Industry Standard Is a green cane trash blanket retained throughout the crop cycle and after the final ratoon as fallow cover? At Industry Standard - Is soil cover maintained throughout the wet season? If yes, is the cover a trash blanket and sprayed out cane or is a fallow crop (e.g. legumes) grown? - Living cane is sprayed out during the fallow period to break pest and disease cycles? ABOVE Industry Standard - Are rotational crops grown on all fallow land to break weed and pest cycles? - Are residues from rotational crops maintained on the soil surface and not incorporated between crop cycles (Cane is zero till planted into rotational crop stubble)? 1.4.1 Preparing Land for Planting At Industry Standard - Do tillage methods minimise soil structural damage & compaction Farm observation* Optional: Photographs (aerial or onsite) and/or Google earth Farm observation* and/or Burning records and/or Farm Diary Farm observation* and/or Burning records Farm observation* and/or Farm Diary Farm observation* and/or Block management records and/or Photo (verified) with reference point Farm observation* and/or Block management records and/or Photo (verified) with comments Farm observation* or Block management records and Photographs (verified) with comments Farm observation* or Block management records and Photographs (verified) with comments Block management records or Farm Diary or Cultivation record or Photographs (verified) with reference point of minimum/zonal tillage equipment in use - Is plant cane established after a fallow using zonal or minimal tillage? Examples include: Undertaking minimum number of cultivations necessary to achieve reliable germination of either the break crop or sugar cane crop. Restricting area of cultivation to the area growing the cane stools and leaving the inter-row area uncultivated. Replacement of operations such as full inversion ploughing and rotary hoeing with less invasive tillage systems such as zonal discing and ripping. Retention of plant residue like cane trash and/or break crop plant residue on the soil surface. ABOVE Industry Standard Is plant cane established after a fallow using zero tillage? 1.5.1 Tillage management in-crop At Industry Standard - Is tillage in plant cane kept to a minimum necessary to establish row profiles and irrigation furrows and to apply fertiliser and pesticide? - For GCTB is there tillage in ratoons other than during fertiliser and pesticide application? ABOVE Industry Standard Is cultivation in plant and ratoon crops limited to coulter applied fertilisers and pesticides? Are Performed beds used in plant cane? Block management records or Farm Diary or Cultivation record or Photographs (verified) with reference point of minimum/zonal tillage equipment in use Block management records or Farm Diary or Cultivation record or Photographs (verified) with reference point of minimum/zonal tillage equipment in use Farm Diary Cultivation record and Fertiliser record and Pesticide record Farm Diary Cultivation record and Fertiliser record and Pesticide record Farm Diary - cultivation records, fertiliser and pesticide application records PLUS pre-formed beds photograph Optional/Extra GPS coverage map for different implements 1.6.1 Managing salinity and sodicity 1.7.1 Soil Sampling 1.8.1 Calculating optimum nutrient rate At Industry Standard - Has the presence/risk of salinity and sodicity been determined? - Have soil tests been conducted? - Do on-farm management practices address sodic soils e.g. application of soil ameliorants? - Has the quality of irrigation water been determined? - Is the risk of salinity & sodicity been considered and managed in irrigation practices? ABOVE Industry Standard Where the presence / risk of salinity or sodicity has been identified, has regular monitoring of root zone soil and water conditions been conducted? Is current knowledge regarding local shallow groundwater conditions used to manage salinity? At Industry Standard - Is soil sampling conducted and sent for analysis? - Are soil test results kept? -Are soil test results used to refine future nutritional programs? ABOVE Industry Standard - Are soil types mapped and soil management zones developed? - Are soil samples collected for each management zone? - Are location sample sites recorded to identify trends in the fertility? At Industry Standard - Is the regulated method used to develop a nutrient program for N&P? - For N, is district yield potential used with Soil test results EM mapping Soil test results Diary record detailing farm practices Application records of ameliorants Implemented Land and Water Management plan Water test results Land and Water Management plan Irrigation plan Monitoring Records and an Implemented Land and Water Management plan or Irrigation Plan DNRM monitoring records Soil sampling results less than 12 months old Nutrition application records or Nutrient management plan Nutrition application records and Soil map and Farm map with GPS/mapping of sampling sites Nutrient application records or Fertiliser recommendations report 1.9.1 Placement 1.9.2 Timing adjustments made according to the N mineralisation index of soils, based on the OC %? Note other sources of N including from irrigation water, mill mud and legumes are voluntary deductions. ABOVE Industry Standard - Is the Six Easy Steps Nutrient Management Plan used - Is the Six Easy Steps Nutrient Management Plan with nutrient rates based on farm or sub-district yield potential and - Are Mechanisms to more closely match nutrient rates to crop requirements being explored? At Industry Standard - Is fertiliser applied banded on the surface of steep slopes? If so, is fertiliser applied when the crop root system has developed? or - Are fertilisers applied subsurface in the drill (stool split or side banded)? or - Are surface-banded fertiliser products incorporated by overhead irrigation as soon as possible or within 7 days? - Are mill by-products applied in the row and not in the inter-space? - If liquid fertiliser products are used, are these applied subsurface or on the surface only under pressure? At Industry Standard - Is fertiliser applied six to eight weeks after harvesting or when cane is approximately 600mm high on early to mid-season cut cane, where practical? - For late cut cane, is weather taken into consideration to determine when fertiliser is Nutrient Management Plan Nutrient Management Plan and Nutrient application records Optional: Leaf test results Placement records Nutrient application records Farm observation* Placement records Nutrient application records Mill mud application records Farm observation* Harvesting time records and Fertiliser application records Harvesting records for comparative block Farm observation* which includes notes on rainfall forecast sources applied? - Fertiliser is never applied when runoff from storms is expected before the nutrient can penetrate to the root zone? ABOVE Industry Standard Split application in ratoons conducted if practical? 1.10.1 Calibration At Industry Standard Is application equipment calibrated prior to the season and at each product and batch change? ABOVE Industry Standard Are correctly calibrated automatic controllers and variable rate application equipment used? 1.11.1 Record Keeping At Industry Standard Are records kept for the following: Soil tests Application rates Products Placement Calibration of equipment Details of person applying fertiliser Are records used to review and modify future nutrient management? used Fertiliser application records Records of rainfall forecast relative to fertiliser application Harvesting records for comparative block Farm observation* noting what rainfall forecasts sources are used. Rainfall records Fertiliser application records Rainfall records Fertiliser application records Calibration records and Fertiliser application records or Contractor – receipt/invoice which shows calibration method/equipment Calibration records and Photograph of calibrated automatic controllers and variable rate application equipment Soil testing records Records of application rates Product record Placement records Calibration records Application records – person details Plans ABOVE Industry Standard Are records kept in digital form linked to GPS to monitor and modify future nutrient management? Record and plan SUMMARY SOIL HEALTH AND NUTRIENT MANAGEMENT Does meet the requirements (practice and/or evidence) to be audited for Smartcane certification Does not meet the requirements (practice and evidence) to be audited for Smartcane certification (Tick appropriate box) COMMENTS: __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ ______________________________________________________________________________________________________________________________________ SECTION 2 – WEED, PEST AND DISEASE MANAGEMENT KEY AREA 3.1.1 Canegrub Management 3.1.2 Rat management 3.1.3 Other pests QUESTION EXAMPLES OF EVIDENCE REQUIRED At Industry Standard - Have grub species been identified? - Are canegrub control decisions based on monitoring plant damage and/or risk assessment based on soil texture, proximity to known adult feeding sites and topography? ABOVE Industry Standard - Has a grub management plan been developed based on monitoring grub levels and plant damage and applying an individual block assessment framework, including paddock history? Farm observation* or Inspection records Farm map with damage areas marked and Monitoring records of treated blocks (if applicable) At Industry Standard - Are in-crop and harbourage areas managed to avoid build-up of rats? ABOVE Industry Standard - Are rat populations monitored and managed through harbourage management and baiting as required? At Industry Standard - Is the presence of or potential presence of other pests known and are management practices carried out to address these? ABOVE Industry Standard - Has a management program been prepared based on risk for other pests? Farm observation* or Record of bait application Grub management plan Baiting records Farm observation* or Procedure, inspection records or Nematode survey Management plan EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA 3.1.4 Weed management 3.1.5 Disease management QUESTION At Industry Standard - Has a weed management plan been developed in line with the SRA weed plan template and key considerations? - Is the weed management Plan implemented? ABOVE Industry Standard - Has an integrated weed management plan been developed and implemented? - Are yield maps used to determine low production areas more susceptible to weed incursions? - Is herbicide selection influenced by soil texture data derived from ground truthing of deep EC mapping patterns in conjunction with yield mapping layers? At Industry Standard - Do farm planning and operations consider the mechanisms of disease spread and implement strategies to avoid introduction and/or spread of disease on farm? - Are known diseased blocks actively managed to reduce or eliminate disease? ABOVE Industry Standard - As per Industry Standard above plus Is a disease survey prepared for the farm and updated each season? - Are rotational crops selected on their susceptibility (or ability to host) known pathogens such as lesion and root knot nematodes? EXAMPLES OF EVIDENCE REQUIRED Weed management plan Records of weed management Integrated weed management plan Yield maps Mapping Farm observation* & Records of clean seed purchase or Fungicide use records or Planting records (including timing) or HWT record or Plant source inspection through CPS or Pachymetra survey Farm observation* or Plan (e.g. use of varieties) or Farm diary EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA 3.1.6 Product selection 3.1.7 Chemical storage and mixing and user accreditation 3.1.8 Chemical application and record keeping QUESTION At Industry Standard - Are all products used approved (registered or permitted) for intended purpose and timing of application? - Are products selected in accordance with integrated management plans?(weeds/pest/disease) At Industry Standard - Do all people who apply chemicals have the appropriate competencies and training? - Are chemicals stored in appropriate storage premises that meet the requirements of WHS? - Are chemicals mixed at locations on the farm that meet label requirements and address legislation? - Are chemical drums disposed of through drumMuster? At Industry Standard - Are products applied according to the label or permit directions and legislative requirements? - Are records of chemical application kept for each field? - Are nozzles selected based on label requirements for product and target? - Is application equipment calibrated at the start of each season and at change of product or change of water rate? - Are herbicides applied at the ideal weed and crop EXAMPLES OF EVIDENCE REQUIRED Chemical use records Weed Management Plan Optional evidence Integrated pest management plan Farm Observation * Certificates of competencies (AHCPMG301A/RTC3401, CHCCHM303A/RTC3704, AHCCHM304A/RTC3705) or Commercial operator’s licence Photograph of chemical storage Chemical Storage risk assessment Photograph chemical mixing location Drummuster/ChemClear receipts and Chemical use records (which show identity of person applying) Chemical use records EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA QUESTION growth stages? - Is a chemical management plan that identifies sensitive areas, buffer zone and problem pest areas developed as part of an IWM or IPM plan and reviewed annually? - Does the timing of chemical applications minimise loss of chemicals in runoff? - Are residual chemicals applied prior to the commencement of the wet season? ABOVE Industry Standard - Are residual herbicides reduced by banding residuals along the drill and using knockdowns in the inter-row? - Are automatic flow rate controllers and precision application equipment used and, is there continuous monitoring and calibration of these? EXAMPLES OF EVIDENCE REQUIRED EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) Farm observation* and Chemical use records Calibration/monitoring records Optional: Photographs of application equipment Photograph of application SUMMARY WEED, PEST AND DISEASE MANAGEMENT The overall rating for weed, pest and disease management is: Does meet the requirements (practice and/or evidence) to be audited for Smartcane certification Does not meet the requirements (practice and evidence) to be audited for Smartcane certification (Tick appropriate box) COMMENTS: __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________________________ SECTION 3 – IRRIGATION AND DRAINAGE KEY AREA QUESTION EXAMPLES OF EVIDENCE REQUIRED 2.1.1 Calculating the amount of water to apply Industry Standard - Has the water holding capacity of farm soils been determined from soil maps or published data? - Are irrigation application amounts matched to the water holding capacity? Soil map and water holding capacity or Publications outlining water holding capacity of soils on the farm Records of irrigation volume application and Irrigation records 2.1.2 Calculating how often to apply water Industry Standard Is weather and climate forecasting used when making irrigation decisions? Is water applied to match crop demand based on simple crop growth monitoring or district evaporation figures and crop factors? Farm observation* or Weather and climate records Evaporation records or Mini pan calibration and scheduling records ABOVE Industry Standard - Is weather and climate forecasting used when making irrigation decisions? - Is water applied to match crop demand based on infield measurements with soil moisture monitoring equipment? Farm observation* or Weather and climate records Soil moisture monitoring records EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA 2.1.3 Seasonal allocation 2.2.1 Run-off and deep drainage management QUESTION Industry Standard - Are rainfall data and climate forecasts used to determine the best time to use irrigation water? - Is the application time and allocation matched to cane growth stage? EXAMPLES OF EVIDENCE REQUIRED Farm Observations* Historical/rainfall records and forecasts Climate forecasting from webpage/newsletter Evaporation records and/or minipan calibration records at district level Farm observation* or Whole of season irrigation water budget and Allocation information Sunwater water usage records and - Evaporation records ABOVE Industry Standard - Are crop requirements known and annual effective rainfall understood so that a whole of season irrigation allocation is determined? - If extra water is required are leasing and temporary allocation transfers investigated, though they may not be feasible to implement? Farm observation* - Whole of season irrigation water budget and Industry Standard - Is irrigation managed to minimise run-off and deep drainage by matching application volumes to soil water deficit? Irrigation records volume application ABOVE Industry Standard - Is irrigation managed to minimise run-off and deep drainage? Allocation information Sunwater water usage records AND Evaporation records AND/OR minipan calibration records at district level Irrigation records volume application including water from recycling EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA 2.2.2 Recycle pits 2.3.1 Irrigation water quality testing QUESTION - Is run-off captured in tail water systems and recycled on farm? Industry Standard - Have pits been designed to capture irrigation run-off and some rainfall run-off? - Is pumping capacity sufficient to re-use water quickly? - Is the pit sited so that it does not leak or access the groundwater table? Industry Standard - Is irrigation water quality tested? - Are the water quality test results used to make decisions on management of water e.g. application of ameliorants, mixing water supplies EXAMPLES OF EVIDENCE REQUIRED Farm observation* Pit volume details - Recycling pit volume, soil type, capacity, catchment area, - Bypass details (if included) Farm observation* or Pumping capacity records Catchment area, depth to groundwater Water quality testing records or Local authority water quality report Sunwater records Grower records Irrigation plan or Recommendation from technical expert and Irrigation and water quality records EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA 2.3.2 Using effluent water for irrigation QUESTION Industry Standard - Is recycled water appropriately signed? - Have measures been taken to control access to water source? - Has the recycled water been tested for nutrient and salt levels? - Is there a management plan which takes into account nutrients supplied by the water and aims to minimise the risk of salinity occurring? - Is irrigation managed to ensure run-off does not occur? ABOVE Industry Standard As above plus (4 items) Is there an ongoing monitoring program in place? Has tail water recycling been implemented? EXAMPLES OF EVIDENCE REQUIRED Farm observation* Photograph of Signage (verified) Farm observation* or Photograph of Controlled access (verified) Water quality test report Local authority water quality report Management Plan Farm observation* and Management plan which shows soil water holding capacities and irrigation records which show application volumes Monitoring records Farm observation* and Management plan which shows soil water holding capacities and irrigation records which show application volumes Monitoring records EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA 2.4.1 & 2.4.2 & 2.4.3 & 2.4.4 System management 2.5.1 Surface drainage system design QUESTION Industry Standard Furrow - Is row length and profile matched to soil type? - Is inflow rate managed to ensure soakage while minimising drainage and run-off losses? Overhead high pressure - Is tow path spacing matched to the machine and operating conditions? - Is application rate matched to soil type? - Are irrigators only operated in low wind conditions? (low wind defined as wind that doesn’t affect distribution of droplets) - Are nozzles checked to ensure they are maintained and are operating correctly? Overhead low pressure - Is end of pivot instantaneous application rate managed to prevent exceedance of soil infiltration rate? - Are application rates matched to soil infiltration rate? - Are sprinklers regularly checked to ensure they are operating correctly? Drip - Is emitter spacing and output matched to soil type and crop requirement? - Is the filtration system adequate? DRAINAGE Industry Standard - Has a drainage plan been develop to ensure water is removed from the farm within 72 hours (or as quickly as possible given local conditions) EXAMPLES OF EVIDENCE REQUIRED Farm observation* and/or System design specifications Farm map showing row lengths and general soil types and Irrigation application records System design specifications or Farm map showing system design Farm observation* or Farm diary Irrigation records showing application rate (or amount and duration of run) Farm observation* or Inspection records System design specifications showing application rates and soil type as indication of infiltration rate or Farm map showing system design Farm observation* or Inspection records System design specifications or Farm map showing system design Drainage plan or Farm map showing drainage or Local area drainage plan or ERMP map EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) KEY AREA QUESTION while minimising erosion and downstream flooding? ABOVE Industry Standard As above plus has a sediment retention basin been installed to filter sediment and chemicals? 2.5.2 Subsurface drainage system design 2.6.1 Erosion Industry Standard - Has a drainage system that removes excess water from the root zone been implemented? - Are acid sulphate soils considered? - Is saline drainage water disposed of appropriately? Industry Standard - Is grass maintained on headlands and drains? - Is cover maintained on fallow ground? ABOVE Industry Standard As above (2 items) plus have sediment traps been constructed and are they in use? EXAMPLES OF EVIDENCE REQUIRED Drainage plan or Farm map showing drainage or Local area drainage plan or ERMP map and Photograph of Sediment basin (verified) Land & Water Management plan or Drainage plan Farm observation* or Soils map Drainage plan Farm observation* Farm observation* or Farm diary records showing fallow management or photograph of fallow cover (verified) Farm observation* Sediment traps SUMMARY IRRIGATION AND/OR DRAINAGE The overall rating for irrigation and /or drainage is: Does meet the requirements (practice and/or evidence) to be audited for Smartcane certification Does not meet the requirements (practice and evidence) to be audited for Smartcane certification EVIDENCE SIGHTED FINDING (C – BMP C – above NC – below N/A) (Tick appropriate box) COMMENTS: __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ OVERALL AUDIT REPORT Module FINDING (C – BMP, C – above, NC – below, N/A) Recommendation (certification, action required) 1 Soil health and nutrient management 2 Irrigation and/or drainage management 3 Weed, pest and disease management 4 Crop production and harvesting management 5 Natural systems management 6 Farm business management 7 Work health and safety Evidence to support finding and reason for N/A should be detailed in the checklist) Issue Identified Action required. Evidence required How is this evidence to be provided (e.g. visit, send document) RECOMMENDATION TO CANEGROWERS AUDIT OFFICE The pre/audit revealed that (select appropriate assessment): All sections of the relevant Smartcane BMP module requirements were demonstrated and met the Smartcane BMP industry standard / Smartcane BMP above Industry standard and therefore certification is recommended for the following modules: (circle appropriate module(s) and level of certification) o Soil health and nutrient management (Smartcane BMP at Industry Standard / Smartcane BMP Above Industry Standard) o Crop production and harvest management (Smartcane BMP at Industry Standard / Smartcane BMP Above Industry Standard) o Weed, pest and disease management (Smartcane BMP at Industry Standard / Smartcane BMP Above Industry Standard) o Irrigation and drainage (Smartcane BMP at Industry Standard / Smartcane BMP Above Industry Standard) o Natural systems management (Smartcane BMP at Industry Standard / Smartcane BMP Above Industry Standard) o Farm business management (Smartcane BMP at Industry Standard / Smartcane BMP Above Industry Standard) o Workplace health and safety (Smartcane BMP at Industry Standard / Smartcane BMP Above Industry Standard) Non-compliance(s) was identified and a further visit will be required to close out the issue Non-compliance(s) was identified and follow up evidence must be sent All sections of the Smartcane BMP module requirements were not able to be audited and a further visit / review of documents is required before a recommendation can be made (Tick appropriate box) COMMENTS