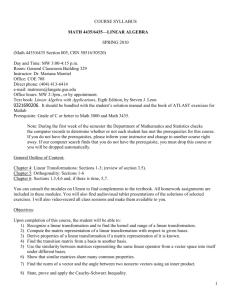

Use of Orthogonal Defect Classification and Acceptance Sampling

advertisement

Use of Orthogonal Defect Classification and Acceptance Sampling Models in the Design of

Experiments

Abstract:

There are several techniques for testing Application Software for Quality Assurance. The most

reliable technique is to perform a complete exhaustive testing of all the features of a particular

software. However, this is usually very expensive - both in terms of time and money. In other

instances, the testing is destructive, and therefore is counterproductive to perform 100% testing.

Full exhaustive testing is usually mandatory for the initial release of any software. However, for

subsequent releases, regression testing is the way to go. Under regression testing, the complete

suite of test cases need not be executed. Only a subset of the test cases is required. The

technique of selecting such a subset is the focus of this paper. One possible approach is to

identify the most critical features of software, and place more emphasis on those, while putting

less emphasis on the not-so-critical features. Another approach is to develop a statistical

procedure for identifying which test cases to perform, without necessarily identifying which

ones are critical, and which are not. Such random selection leads to a more representative

sample of the overall features of particular software, and defects identified are presumed to be

proportionate with the proportion of defects that would have been identified based on complete

exhaustive testing. A third approach is to use the technique of Orthogonal Defect Classification

(ODC). This is a mathematical technique that is used to develop a model that breaks down all

the features of the AUT into categories, then with the aid of standard orthogonal arrays, selects

which test cases to run. This paper focuses on the use of some of these statistical techniques in

the design and execution of the test Test Plans.

1

Introduction

Traditional Quality Assurance techniques involve the use of Acceptance Sampling. Acceptance

Sampling is a technique whereby a sample is randomly selected from a population of Test

Cases. The results of testing the sample can then be used to infer as to the quality of the

Application under Test. The analyst could adopt either the Simple Sampling Technique, or the

Double Sampling technique. The philosophy of the two approaches is essentially the same. The

difference is that in the case of double sampling, the testing is performed twice. Whenever new

software is developed, the proper approach is to execute all possible test scenarios. This is

because there is no baseline to compare the results with; therefore complete exhaustive testing is

to be expected. However, in subsequent releases of the Application, it is no longer necessary to

perform complete exhaustive testing. In this case, Regression Testing can be done using one or

the other of the available techniques.

Literature Survey

Construction of orthogonal arrays dates back to the early 1960s. Addelman (1960) was one of

the earliest proponents of orthogonal arrays. He developed the procedure for the determination

of the Main Effects for a Factorial Experiment. Box et. al. (1978) published their work on the

Design and Development of Mathematical Models for Experiment. Kempthorne (1979)

published his book on the Design and Analysis of Experiments. Other researchers in this field

include: John, P. W. M., (1971), Phadke, M. S. (1982, 1986, 1983, & 1987). This article is

based mostly on the work of Phadke (1989), in the book Quality Engineering using Robust

Design. Taguchi (1987) invented the Linear Graph technique for estimating interactions in an

orthogonal array experiment.

Acceptance Sampling on the other hand, has been used extensively in the field of Operations

Management. Bakir (1960) applied it to an appraisal of work performance using Control Charts.

Lin and Sheen (2005) applied it to the development of Capability Index based on Quality

Control charts. Mathes (2007) applied this technique to Statistical Process Control for Hospitals.

This paper is an attempt to integrate the inherent concepts of Acceptance Sampling into the

development and execution of test plans in an Interactive Voice Response environment.

Model I: Design of the Experiment using Orthogonal Defect Classification

The process of designing an orthogonal array experiment is based mostly on the theory of linear

graphs developed by Taguchi. Before constructing an orthogonal array, the following

requirements must be met:

1.

2.

3.

4.

The number of factors to be studied

The number of levels of each factor

An estimate of any possible interactions

Technical limitations of the study.

2

Consider the Application-Under-Test (AUT) to have a call flow that can be broken down

into five basic categories (factors)

1. Finding a Store

2. Get Zip Code

3. Obtain information

4. Request Promotional Code

5. Request Order Status

In order to simplify the selection of an appropriate orthogonal array matrix, it is necessary that

all the factors have the same number of levels. This will be accomplished by segmenting the

factors and adding dummy levels, where necessary. The result is the following:

1. Finding a Store

a) Play Store Information

b) Find More Stores

c) Give me an agent

2. Get Zip Code

a) Obtain Zip Code

b) Obtain Telephone number of Main Store

c) Give me an agent

3. Obtain information

a) Get name of Supervisor

b) Speak to a live Agent

4. Request Promotional Code

a) Request Promotional Code

b) Retrieve Promotional Code

c) Give me an agent

5. Request Order Status

a) Request status of an order

b) Request account number

c) Give me an agent

6. Request a live Agent

a) I want an agent

b) I don’t want to speak to a machine

Here we have 6 factors, Four with 3 levels, and 2 with 2 levels.

Orthogonal Array Selection

It should be recalled that Orthogonal Array Technique is only good for Regression Testing.

Therefore it does not necessarily cover every the leg of the Call Flow. However, it covers all the

functionalities of the Call Flow. In order to select the appropriate orthogonal array, the

following steps are required:

3

a) Determination of the degrees of freedom associated with the experiment.

b) Selection of an appropriate orthogonal array for the number of levels of each

factor/category.

c) Determination of the existence of possible interactions between factors

d) Make contingency plans for any deviations from ideal conditions.

a)

Determination of the Degrees of Freedom.

Consider a situation with six factors: A, B, C, D, E, and F. Assume factor A has 2 levels, and

factors (B, C, D, E, and F ) have 3 levels each. For any Orthogonal Array design, the overall

mean is always assigned on degree of freedom. Usually, the number of degrees of freedom

associated with any factor is equal to one less than the number of levels of the factor. The

degrees of freedom associated with interaction between any two factors are given by the product

of the degrees of freedom for each of the two factors. So if Factor A has (nA-1) degrees of

freedom, and Factor B has (nB-1) degrees of freedom, then the degrees of freedom for

interaction A X B = (nA-1)* (nB-1) = (nA-1)* (nB-1). The degrees of freedom for the experiment

would be as shown in the table below:

Factor/Interaction Degrees of Freedom

1

Overall mean

2–1=1

A

B, C, D, E, and F 5* (3 – 1) = 10

(2 – 1) x (3 – 1) = 2

AXB

14

Total

This means that at least 14 experiments need to be performed to cover the effects of all six

factors and their interactions.

b)

Selecting a Standard Orthogonal Array

There are several array-naming conventions. One convention is derived from the number of

rows and columns in the array, as well as the number of levels of each column of the array.

Thus the array L18(2137) indicates that the array has 18 rows; one 2-level column, and seven 3level columns. So the total number of columns in the array is 8, and the total number of test

cases executed is 18. It should be noted that the number of test cases must be at least equal to

the degrees of freedom required for the experiment. The number of columns on the other hand,

indicates the maximum number of factors that can be tested using that array. In addition, the

number of levels of the factors must match the numbers of levels of the columns in the array.

The idea is to utilize the minimum array that satisfies all the requirements of the experiment. If,

for instance, it is required to select an appropriate orthogonal array for an experiment that has

one 2-level factor and six 3-level factors, then the most appropriate array to select would be L18.

L16 would not have been appropriate because it does not have any 3-level columns. In situations

where the orthogonal array matrix has more columns than the number of factors, the extra

4

columns can be filed b creating an extra (dummy) level; and the matrix will still be

proportionally balanced.

Table of Standard Orthogonal Arrays

c) Determination of possible interactions.

In most situations, interactions the existence of interactions is miniscule. For this experiment,

there were no perceived interactions. The existence of interactions is dependent on the nature of

the factors, and can by designed using linear graphing techniques invented by Taguchi (1987).

Result

This Application Under Test (AUT) is a software application that is used for handling customer

requests in an Interactive Voice Response (IVR) environment. Each of the categories is

considered a factor of the experiment. There are four 3-level factors, and two 2-level factors. If

the testing were to be done using 100% testing, we would end up with or 324 (3422) test cases .

Therefore we need to construct an orthogonal array with at least four 3-level factors and at least

two 2-level factors. From the table of Standard Orthogonal Arrays, the most appropriate

5

orthogonal array to select is L36(2137). It is the minimum orthogonal array that satisfies the

requirement of the number of columns (6) for this experiment. The conclusion here is that we

have reduced the size of our test plan from 324 to 36 without losing the integrity of the test plan.

The corresponding percent defects detected under the two methods, yielded a percent defective

of 0.025, This shows that there is no loss in rigor by adopting the orthogonal array approach.

The advantage therefore is that we are able to arrive at the same conclusion with much less

resources.

L36(211312) Orthogonal Array

6

Columns

Expt. #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

3

1

1

1

1

1

1

1

1

1

1

1

3

3

3

3

3

3

3

3

3

3

3

3

4

1

1

1

1

1

2

2

2

2

2

2

1

1

1

1

2

2

2

2

3

3

3

3

5

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

1

1

1

1

6

1

1

1

1

1

2

2

2

2

2

2

3

3

3

3

1

1

1

1

2

2

2

2

7

1

1

2

2

2

1

1

1

2

2

2

1

1

2

3

1

2

3

3

1

2

2

3

8

1

1

2

2

2

1

1

1

2

2

2

2

2

3

1

2

3

1

1

2

3

3

1

23

11

11

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

10

10

10

10

10

10

9

9

9

9

9

9

8

8

8

8

8

8

0

12

0

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

9

9

9

9

9

9

10

10

10

10

10

10

11

11

11

11

11

11

0

0

12

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

9

1

1

2

2

2

1

1

1

2

2

2

3

3

1

2

3

1

2

2

3

1

1

2

10

1

2

1

2

2

1

2

2

1

1

2

1

1

3

2

1

3

2

3

2

1

3

2

11

1

2

1

2

2

1

2

2

1

1

2

2

2

1

3

2

1

3

1

3

2

1

3

12

1

2

1

2

2

1

2

2

1

1

2

3

3

2

1

3

2

1

2

1

3

2

1

13

1

2

2

1

2

2

1

2

1

2

1

1

2

3

1

3

2

1

3

3

2

1

2

14

1

2

2

1

2

2

1

2

1

2

1

2

3

1

2

1

3

2

1

1

3

2

3

15

1

2

2

1

2

2

1

2

1

2

1

3

1

2

3

2

1

3

2

2

1

3

1

16

1

2

2

2

1

2

2

1

2

1

1

1

2

3

2

1

1

3

2

3

3

2

1

17

1

2

2

2

1

2

2

1

2

1

1

2

3

1

3

2

2

1

3

1

1

3

2

18

1

2

2

2

1

2

2

1

2

1

1

3

1

2

1

3

3

2

1

2

2

1

3

19

2

1

1

2

1

1

2

2

1

2

1

1

2

1

3

3

3

1

2

2

1

2

3

20

2

1

1

2

1

1

2

2

1

2

1

2

3

2

1

1

1

2

3

3

2

3

1

21

2

1

1

2

1

1

2

2

1

2

1

3

1

3

2

2

2

3

1

1

3

1

2

22

2

1

1

1

2

2

2

1

1

1

2

1

2

2

3

3

1

2

1

1

3

3

2

23

2

1

1

1

2

2

2

1

1

1

2

2

3

3

1

1

2

3

2

2

1

1

3

24

2

1

1

1

2

2

2

1

1

1

2

3

1

1

2

2

3

1

3

3

2

2

1

25

2

1

1

2

2

2

1

2

2

1

1

1

3

2

1

2

3

3

1

3

1

2

2

26

2

1

1

2

2

2

1

2

2

1

1

2

1

3

2

3

1

1

2

1

2

3

3

27

2

1

1

2

2

2

1

2

2

1

1

3

2

1

3

1

2

2

3

2

3

1

1

28

2

2

2

1

1

1

1

2

2

1

2

1

3

2

2

2

1

1

3

2

3

1

3

29

2

2

2

1

1

1

1

2

2

1

2

2

1

3

3

3

2

2

1

3

1

2

1

30

2

2

2

1

1

1

1

2

2

1

2

3

2

1

1

1

3

3

2

1

2

3

2

31

2

2

2

2

1

2

1

1

1

2

2

1

3

3

3

2

3

2

2

1

2

1

1

32

2

2

2

2

1

2

1

1

1

2

2

2

1

1

1

3

1

3

3

2

3

2

2

33

2

2

2

2

1

2

1

1

1

2

2

3

2

2

2

1

2

1

1

3

1

3

3

34

2

2

2

1

2

1

2

1

2

2

1

1

3

1

2

3

2

3

1

2

2

3

1

35

2

2

2

1

2

1

2

1

2

2

1

2

1

2

3

1

3

1

2

3

3

1

2

2

2

2

1

2

1

2

1

2

2

1

3

2

3

1

2

1

2

3

1

1

2

3

36

1

2

3

18 18 18 18 18 18 18 18 18 18 18 0 12 12 12 12 12 12 12 12 12 12 12 12

18 18 18 18 18 18 18 18 18 18 18 0 12 12 12 12 12 12 12 12 12 12 12 12

0 0 0 0 0 0 0 0 0 0 0 0 12 12 12 12 12 12 12 12 12 12 12 12

A sample of the result of replacing the code number for each level of four of the 23 factors with

the actual caller utterance is shown in the matrix below.

Subset of L36(211312) Orthogonal Array after substitution

7

Columns

Expt. #

1

2

12

1

Play Store Info

Get Zip Code

Play Store info

2

Play Store Info

Get Zip Code Find More Stores

3

Play Store Info

Get Zip Code

Get an Agent

4

Play Store Info

Get Zip Code

Play Store info

5

Play Store Info

Get Zip Code Find More Stores

6

Play Store Info

Get Zip Code

Get an Agent

7

Play Store Info

Get Zip Code

Play Store info

8

Play Store Info

Get Zip Code Find More Stores

9

Play Store Info

Get Zip Code

Get an Agent

10

Play Store Info

Get Tel #

Play Store info

11

Play Store Info

Get Tel #

Find More Stores

12

Play Store Info

Get Tel #

Get an Agent

13

Play Store Info

Get Tel #

Play Store info

14

Play Store Info

Get Tel #

Find More Stores

15

Play Store Info

Get Tel #

Get an Agent

16

Play Store Info

Get Tel #

Play Store info

17

Play Store Info

Get Tel #

Find More Stores

Play Store Info

Get Tel #

18

Get an Agent

19

Find More Stores Get Zip Code

Play Store info

20

Find More Stores Get Zip Code Find More Stores

21

Find More Stores Get Zip Code

Get an Agent

22

Find More Stores Get Zip Code

Play Store info

23

Find More Stores Get Zip Code Find More Stores

24

Find More Stores Get Zip Code

Get an Agent

25

Find More Stores Get Zip Code

Play Store info

26

Find More Stores Get Zip Code Find More Stores

27

Find More Stores Get Zip Code

28

Find More Stores

Get Tel #

Play Store info

29

Find More Stores

Get Tel #

Find More Stores

30

Find More Stores

Get Tel #

Get an Agent

31

Find More Stores

Get Tel #

Play Store info

32

Find More Stores

Get Tel #

Find More Stores

33

Find More Stores

Get Tel #

Get an Agent

34

Find More Stores

Get Tel #

Play Store info

35

Find More Stores

Get Tel #

Find More Stores

36

Find More Stores

Get Tel #

Get an Agent

Get an Agent

Model II: Design of Experiment using Acceptance Sampling

The purpose of acceptance sampling is to specify criteria for accepting or rejecting a lot based

on certain operational characteristics. In a Quality Assurance environment, the results of any

8

testing can be described as dichotomous. The Test Case either passes or fails. These are the two

attributes to be considered when testing software. Attribute inspection is used when

measurements take on only two values; e.g. {defective, non-defective} or {on, off}; {pass, fail}.

Therefore in developing a sampling plan, we only need to specify two things:

i.

ii.

sample size, n

acceptance number, c

For a given n and c: If the number of defectives, x is less than c, accept the lot. If the number of

defectives, x is more than c, reject the lot. If on the other hand, the analyst is interested in

ensuring higher quality, they can design a Double Sampling Plan. In that case, the

considerations will be:

First take a sample of size n1. If the number of defectives x1, is less than c1, accept the lot; If the

number of defectives x1, is greater than c2, reject the lot; However, if c1 < x1 < c2; then:

Take a second sample of size n2. If now (x1 + x2) > c2, reject the lot; otherwise, if (x1 + x2) < c2,

accept the lot.

The Single Acceptance Sampling Model:

We will restrict our testing to single Acceptance Sampling since Double Sampling is basically a

replication of Single Sampling.

Let N be the total number of Test Cases in the Test Plan of a version of software that is already

in the field.

Let n be the total number of Test Cases to be selected for testing.

Let p be the proportion of Test Cases that result in a defect being identified. (This is presently

an unknown quantity).

Let p be the proportion of Test Cases that are identified from testing a sample of size n.

The idea is to obtain p as an estimate of the proportion of the overall test cases that will result

in identifying a defect in the Application. In order to implement this test plan, two parameters

need to be established - The maximum number of defects that the client can live with – the

Acceptance Number (c); and the maximum risk that the client is willing to take ()

The fairest way to accomplish this is for both the software developer and the client, to generate

an Operating Characteristic Curve, and use the result as a basis for determining the most

equitable values of customer acceptance and developer risk.

Development of the Operating Characteristic (O-C) curves

O-C curves are generated for the purpose of reducing the amount of computation that goes into

9

determining whether or not to accept a particular sample. It is obtained from calculating the

probability of acceptance for various values of percent defective.

Mathematically, we have:

n

p

q

k

p(k)

c

=

=

=

=

=

=

sample size

percent defective

(1 - p); percent non-defective

number of defective items

probability of k defectives

acceptance number (the limit of number of defective

items considered acceptable by the client)

P(x);

c

P(A)

x 0

n

where P(x) px (1 p) n x

x

then

Suppose we have a lot of size N, and take a sample of size n. What is the probability of

accepting the lot given that the percentage of defective items in the lot is p, and the acceptance

number C, is 0? This scenario follows a Binomial Distribution.

The probability function for a Binomial Distribution is given by:

n!

n

x

n-x

P(x) = p x (1 - p )n - x =

p (1 - p)

x! (n - x)!

x

Then Probability of acceptance, P(A) is given by:

n

P(A) P(x) p x (1 p)n x

x

These probabilities can be obtained from the Binomial Tables. A sample result of the

calculations is shown below.

10

Construction of the Operating Characteristic (OC) Curve

In order to construct the OC-curve 4 parameters have to be calculated:

1. AQL (Acceptance Quality Level): This is the minimum level of quality that is

assignable to a lot that is considered GOOD.

2. LTPD (Lot Tolerance Percent Defective) This is the minimum level of quality that is

assignable to a lot that is considered BAD.

3. Producer’s Risk ( is the probability that a producer’s GOOD lot is rejected. In other

words, the probability of committing a Type I error.

4. Consumer’s Risk ( is the probability that a BAD lot is accepted by the consumer. In

other words, the probability of committing a Type II error.

O-C CURVES FOR ATTRIBUTES

(Sample size, n = 10)

1.20

1.00

Probability of Acceptance - P(A)

c=5

c=4

0.80

c=3

0.60

c=2

c=1

0.40

c=0

0.20

0.00

percent defective - p

11

Figure 2: The Larson Nomogram for OC Curves

12

Producer's and Consumer's Risk Values

Producer's risk

Consumer's risk

n = 10, c = 0

.18

.10

n = 10, c = 1

.04

.37

n = 10, c = 2

.01

.67

Result.

Applying Acceptance Sampling technique to the same Application Under Test (AUT) in an

Interactive Voice Response (IVR) environment. We proceed by identifying the 6 basic

categories to be tested:

Finding a store

Get Zip Code

Obtain Payment Information

Ask about Promotions

Confirming an order

Asking for the status of an order

A caller’s utterance may or may not be correctly categorized; in which case, the application will

request that the caller repeat their utterance. If, on the other hand, the caller intent is properly

identified, the application will proceed to provide the required information. Thus each of these

utterances can be broken down into 3 categories:

IVR correctly recognizes the caller intent and proceeds to provide the requested

information

IVR barely recognizes caller intent and requests the caller to repeat their intent

IVR does not recognize caller intent and transfers caller to a live agent.

Using the Call Flow diagram, a Test Plan is developed to handle all possible combinations of

the caller intent. The total number of test cases was 324. Assuming that the client would like to

have 99.99% reliability, this implies that the customer is not ready to assume any risk more than

0.01. In other words, the consumer’s risk, = 0.01. The producer (software developer) on the

other hand should be able to assume a greater risk than the consumer; so the producer decides to

assume a risk of 0.05. Locating these two values on an Operating Characteristic Curve, we

come up with a sampling plan of n = 50 and c = 1.

13

1.00

= 0.05

0.95

Producer's risk

for AQL

P(A)

0.10

0.00

Percent

Defective

= .10

Consumer's

risk for

LTPD

Good

Lot

Indifference

Zone

Bad Lot

AQL

LTPD

Using a random number generator, a random sample of 50 test cases was extracted. Out of the

50 test cases, two test cases failed; but one was due to network issues; so that test case was

discarded. Essentially, 1 test case failed out of 49 test cases. This means that the proportion

defective based on a sample size of 49 is 1/49 (0.02). This corresponds very strongly with the

results previously obtained using orthogonal Defect Classification.

Conclusions and Recommendation.

Orthogonal Defect Classification belongs in the field of Robust Design developed in the 1950s

and early 1960s by Taguchi. It has been developed to improve productivity during research and

development so as to be able to develop high quality products at the cheapest cost. It applies the

ideas from statistical experimental design to reduce the variation of a product’s functionality. It

also ensures the conclusions arrived at in the laboratory are optimal. The three main categories

to consider in the design of an orthogonal array are: Operating cost, manufacturing cost, and

cost of Research and Development. Orthogonal Array experiments are utilized mainly in

bringing the cost of Research and Development to a minimum. The two major tools of Robust

Design are: Signal-to-Noise Ratio, and orthogonality. This is the same principle behind

Acceptance Sampling – using sampling statistics to make inferences about population

parameters. Because of the ease of setting up the Test Plan based on Acceptance Sampling

techniques, it is recommended that Acceptance Sampling be used in preference to the

orthogonal defect classification technique.

14

References

Addelman, S. “Orthogonal Main Effect Plans for Asymmetrical Factorial Experiments”

Technometrics (1962) vol. 3: pp. 21- 46.

Bakir, S. T. “A Quality Control Chart for Work Performance Appraisal.” Quality Engineering

17, no. 3 (2005): 429

Besterfield, Dale H. Quality Control, 18th ed. Upper Saddle River, JN: Prentice Hall, 2009

Box, G. E. P., Hunter, W. G., and Hunter, J. S. Statistics for Experimenters – An Introduction to

Design, Data Analysis and Model Building. New York: John Wiley and Sons, 1978.

Cochran, W. G. and Cox, G. M. Experimental Design. New York: John Wiley and Sons, 1957

Elg, M., J. Olsson, and J. J. Dahlgaard. “Implementing Statistical Process Control.: The

International Journal of Quality and Reliability Management 25, no. 6 (2008): 545.

Goetsch, Dagid L., and Stanley B. Davis. Quality Management. 5th ed. Upper Saddle Rover, NJ:

Prentice Hall, 2006

Lin, H., and G. Sheen. “Practical Implementation of the Capability Index Cpk Based on Control

Chart Data.” Quality Engineering 17, no. 3 (2003) 371.

Matthes, N., et al. “Statistical Process Control for Hospitals.” Quality Management in Health

Care 16, no. 3. (July – September 2007): 205

Montgomery, D. C. Introduction to Statistical Quality Control, 6th ed. New York: Wiley, 2008

Summers, Donna. Quality Management, 2nd ed. Upper Saddle River, NJ: Prentice Hall, 2009

Taguchi, G. Orthogonal Arrays and Linear Graphs. Dearborn, MI: ASI Press, 1987

Taguchi, G. and Phadke, M. S. “Quality Engineering through Design Optimization.”

Conference Record, GLOBECOM 84 Meeting, IEEE Communications Society. Atlanta, GA

(November 1984) pp. 1106-1113,

15