Environmental Profile of Algal Hydrothermal Liquefaction

advertisement

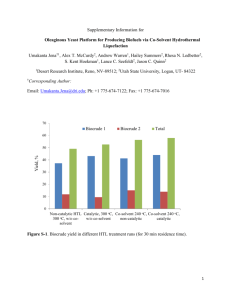

1 Environmental Profile of Algal Hydrothermal Liquefaction – A Country 2 Specific Case Study 3 Bhavish Patel, Miao Guo, Nilay Shah and Klaus Hellgardt* 4 Imperial College London, Department of Chemical Engineering, South Kensington, London, SW7 2AZ, U.K. 5 *Corresponding Author, Tel: +44 (0)20 7594 5577, E-mail: k.hellgardt@imperial.ac.uk 6 Abstract 7 Microalgae are known to be an important feedstock not just for biofuel but also biochemical 8 production. In this investigation we utilise a cradle-to-biorefinery-gate attributional LCA (aLCA) 9 methodology to evaluate the environmental impacts of Nannochloropsis sp. derived algal biocrude 10 production. A database of primary experimental data for continuous fast Hydrothermal Liquefaction 11 (HTL) and Hydrotreating (HDT) is combined with secondary data from literature to investigate the 12 overall environmental profiles of cultivation, dewatering, HTL and HDT for various scenarios based 13 on the energy generation mix of 5 countries (Brazil, UK, Spain, China and Australia) as well as a 14 comparison with fossil crude. The investigation found that Brazil delivers best environmental profiles 15 for all scenarios, primarily due to its significant contribution from hydropower. Furthermore, the 16 cultivation and HTL processes account for nearly 90% of environmental burdens whereas dewatering 17 and HDT only contribute less than 8%. The research findings highlight the importance of the several 18 factors on the resulting 3G biofuel profiling e.g. energy resource, processing technology choice and 19 the co-product(s) and emissions profiling methodology. Algal biocrude is still undergoing research 20 and development compared to the well-developed fossil crude industry. Via integration and 21 optimisation at process and value chain levels, algae-derived biocrude has the potential to deliver an 22 environmentally sustainable alternative to the fossil crude, provided the energy input for processing is 23 from a renewable source. 24 Keywords: Environmental emission profile, HTL, algal biorefinery, LCA 25 Highlights: 26 Cradle to biorefinery-gate LCA using experimental HTL and HDT data 27 Country specific environmental emissions profile for algal biofuel 1 28 Environmental emission comparison of fossil and algal biocrude 29 1.0 Introduction 30 The use of fossil fuels to sustain global energy demand has resulted in detrimental environmental 31 effects. As a major energy consumer, transportation sector alone accounts for 32% of total EU energy 32 demand and in 2012 was responsible for 25% of greenhouse gasses (GHGs) emissions in the EU-28 33 (EU Commission 2013 and EEA 2014). The increasing GHG levels (elevation in CO2 concentration 34 to 400 ppm) along with fossil resources depletion have triggered ambitious policies mandating 35 renewable energy sources within regional/national energy portfolio (Ewald 2013). The role of biofuels 36 in the UK is acknowledged under the EU Renewable Energy Directive (RED), mandating a policy 37 target of a 10% share of renewable energy within the EU transport framework by 2030 (EU Directive 38 2009/28/C). Currently, 1st and 2nd generation biomass feedstock are commercially used for fuel 39 production but due to their intrinsic environmental and social disadvantages (Demirbas 2009), 40 emphasis on 3rd generation (3G) feedstock such as microalgae has resulted in substantial research and 41 development. 42 Compared to other biomass feedstock, microalgae have a faster growth rate, ability to grow in fresh, 43 saline or waste water and more importantly, it is not a primary food crop and thus does not compete 44 for arable land or increase food prices (Patel et al. 2012). Although algae compete with food for 45 fertiliser, the nutrient requirements can be potentially offset by algal cultivation using waste water as 46 well as nutrient recycling from aqueous phase. The lipid, carbohydrate and protein present in 47 microalgae can be converted to fuel precursors or chemicals using several processing technologies 48 (Patel et al. 2015). 49 For conversion of algal biomass without prior fractionation, Hydrothermal Liquefaction (HTL) is 50 understood to be a promising treatment option, particularly since it negates drying thus reducing costs 51 and energy consumption (Lardon et al. 2009). Water under hydrothermal conditions undergoes an 52 enhancement in its properties (density, Cp, ionic product and dielectric constant) causing it to behave 53 like an organic solvent with acidic/basic catalytic properties which is ideal for the conversion of 54 biomass macromolecules to simpler components without addition of harmful solvents (Savage 1999). 2 55 Several studies (Garcia Alba et al. 2011, Jena et al. 2011, Biller and Ross 2013 and Reddy et al. 2011) 56 have successfully demonstrated utilization of HTL to convert algae paste and the research outcome 57 has pointed towards reducing the Residence Time (RT) from hours to minutes (Patel and Hellgardt 58 2013, Jazrawi et al. 2013 and Faeth et al. 2013). Typically, HTL alone is not sufficient and post 59 processing of HTL derived biocrude is necessary to reduce the Oxygen/Nitrogen content through 60 Hydrotreatment (HDT). 61 The implication of combining these processes on environmental performance is expected to be 62 significant especially since there have been major improvements in cultivation and dewatering. It is 63 necessary to examine whether advances in algal biofuel production process is cascaded to result in 64 improvement for its environmental profiling. A widely accepted method used to quantify the 65 environmental metrics of a product/process is Life Cycle Assessment (LCA). There have been 66 several investigations which attempt to quantify LCA impacts of algal biofuels production via 67 different processing routes with most focusing on cultivation or biodiesel production using lipid 68 extraction pathway (Patel et al. 2015). The outcome from these studies elucidated that algae drying 69 process is a main contributor to GHG emission and thus, there has been increasing research attention 70 on wet processing route where algal biomass with high moisture content can be directly utilised as 71 feedstock thus there is no need to dry feedstocks (Chen et al. 2014). 72 To date, a limited number of LCAs have been conducted on HTL (or thermochemical) processing (K. 73 de Boer et al. 2012, Grierson et al. 2013, Fortier et al. 2014, Bennion et al. 2014, Ponnusamy et al. 74 2014, Liu et al. 2013, Frank et al 2013,). Most studies are based on literature data and therefore the 75 general consensus on LCA profiling has not yet been attained. For instance, Frank et al. (2011) 76 concluded that even though HTL uses wet algae, there is an increase of GHGs emission of 1.5 times 77 compared to the traditional route (drying and extraction). But conversely Fortier et al. 2014 suggested 78 that with proper heat integration it is possible to reduce GHGs by 76%. Additionally, by using 79 reaction conditions which maximise biocrude yield (low RT and high temperature) coupled with the 80 high energy recovery in the biocrude of up to 88% (Higher Heating Value (HHV) on a dry weight 81 basis), a further reduction in GHGs and costs can be obtained, resulting in environmental and 82 financial benefits (Zhou et al. 2013). Literature review indicates that no publically available study has 3 83 used data from a continuous HTL flow reactor system which would most probably be implemented at 84 commercial scale. 85 Ultimately, scale-up of an algal biorefinery with multiple product vectors would be the way forward 86 to support (economically) algal biofuel production, but nonetheless, the biofuel produced should instil 87 environmental benefit. Depending on the geographic location or strain used, various products could be 88 extracted and produced using benchmarked processing techniques, for instance HTL biocrude 89 production (Moody et al. 2014, Golberg et al. 2014 and Zinoviev et al. 2015) The algal biorefinery 90 system with energy inputs met by national/regional grid energy mix might not lead to environmentally 91 superior algae biofuel compared with fossil fuels which depends on the region under investigation. A 92 thorough literature review suggests a knowledge gap in LCA of continuous HTL processing (and 93 subsequent HDT) of algal biomass with varying system configuration (e.g. low RT) and different 94 locations (Patel et al. 2015). Particularly there is a lack of country specific comparison analysis of 95 HTL-based algal processing based on empirical data derived from experimental work. This study 96 presents LCA modelling of potential algal biofuel refinery systems to advance the understanding of 97 environmental profiles of algal HTL and HDT processing with varying HTL/HDT reaction 98 configurations and (energy) supply chain at different locations. This study aims to not only fill up the 99 knowledge gap, but more importantly provide scientific insights into the process design and 100 optimisation to enable ongoing empirical work to be more efficiently focused on key environmentally 101 damaging steps to contribute to future sustainable development of algal biorefinery. As such the 102 biorefinery systems are modelled in 5 countries (Brazil, UK, Spain, China and Australia) with 103 differing energy mixture and varying HTL/HDT reaction conditions. 104 2.0 Method 105 2.1 Product system and functional unit 106 A cradle-to-biorefinery-gate attributional LCA (aLCA) approach was applied to evaluate the 107 environmental impacts of the algae-derived liquid fuels (3G biofuel). As illustrated in Figure 1, the 108 subsystems modelled within the system boundary include algae cultivation, algae dewatering, HTL 4 109 and HDT. The aqueous phase fraction produced at the HTL stage is sent to waste water treatment 110 anaerobic digestion (AD) unit. The biogases produced from AD were further sent to combine heat 111 and power (CHP) system for energy recovery. 112 obtained from laboratory experiments (for downstream processing HTL and HDT stages), 113 supplemented by secondary data from literature. However, lab-scale data may not represent the 114 system performance at pilot-scale or commercial-scale fully, given the substantial number of 115 parameters still undetermined. Thus further research would be needed on system scaling-up by 116 process simulation, data production and validation against larger-scale operational data, if available. 117 The LCA study was performed using SimaPro® 7.3 (PhD version) and the biofuel produced from 118 algae, called biocrude, was modelled as potential replacement or blending fuel with crude oil at a 119 refinery and was thus compared directly with fossil crude. The functional unit was defined as ‘per MJ 120 crude oil produced at refinery gate’. A problem oriented (midpoint) approach - CML 2 baseline 2000 121 (v2.05) was applied in the current study as the ‘default’ Life Cycle Impact Assessment (LCIA) 122 method. The impact categories to be investigated include biotic depletion, global warming potential, 123 acidification, eutrophication, ozone depletion, photochemical oxidation and human and eco-toxicities. 124 Other environmental impact categories including land occupation/ land use, Energy Return on 125 Energy Investment (EROEI), are excluded from current LCA system boundary but could be explored 126 in future research. Especially EROEI, as an indicator to assess the energetic profitability of a system, 127 has been applied in algal biocrude research to explore issues like maximizing the energy recoveries 128 of alternatives processes e.g. study carried out by Tercero et al. (2013).EROEI could be incorporated 129 into future LCAs as an energy payback efficiency indicator for algal biocrude production via HTL 130 routes. 131 The acidification characterisation model incorporated in CML 2 baseline 2000 is derived from RAINS 132 model (Regional Air Pollution Information and Simulation) where main acidifying gases accounted 133 for include SOx, NOx, NH3. However, another concern is the ocean acidification effects caused by 134 CO2, which is still in its infancy. Thus further studies are required to explore biological and LCA inventory was developed using primary data 5 135 biogeochemical consequences of ocean acidification process as well as potential incorporation of 136 ocean acidification evaluation into LCA framework. Algae Cultivation & Harvesting Electricity Algae Dewatering Electricity External heat Solvent Transportation CO2 N/P nutrients Media water Electricity Atmospheric Emissions Water-internal recycle Algae paste Atmospheric emissions Hydrothermal Liquefaction Waste water WWT Biocrude Bioenergy Electricity External heat H2 Catalyst Hydrotreating Atmospheric emissions Upgraded Biocrude 137 138 Figure 1 - System boundary for algae-derived biocrude 139 2.2 Allocation approach 140 A ‘system expansion’ allocation approach was applied for the biocrude production processes to 141 account for the multiple product mixture present in the system. These were 1) HTL stage where 142 multiple-products include the biocrude oil plus electrical power generated from the on-site AD/CHP 143 system in addition to the nutrient contained in recovered biochar; 2) HDT stage where the upgraded 144 biocrude and biochar recovery as a potential fuel source are produced. It was assumed that the 145 electricity co-product would directly displace an equivalent amount of electrical power generated 146 from the average national grid mixture of the corresponding country in each scenario. The biochar 147 recovery from HTL and HDT were assumed to substitute a ‘functional equivalent’ quantity (dry basis) 6 148 of national average N fertilizer production and an equivalent amount of charcoal, respectively. Thus, 149 this allocation approach awards the biocrude production system with ‘avoided burdens’ credits for the 150 fossil fuel consumption and subsequent emissions avoided for an equivalent amount of avoided 151 product generation. 152 An alternative allocation approach - energy allocation - recommended by the EU RED was examined 153 in sensitivity analysis (Section 3.5) where the environmental burdens were allocated among the co- 154 products (e.g. biocrude and energy recovery) based on their energy contents. 155 A stoichiometric carbon-counting approach was used to ‘track’ the biogenic carbon flows from algae 156 biomass into biocrude oil over the life cycle (Guo et al. 2014). This C-counting approach with regard 157 to the biocrude was applied to firstly determine the carbon ‘sequestered’ into the biocrude (from the 158 algae cultivation phase of the life cycle) and downstream release of this carbon during the subsequent 159 processing of the biocrude. The sequestration of carbon into biocrude thus represents a ‘negative’ 160 GHG emission at this stage of the life cycle but this carbon is then returned to the environment in 161 various ways depending upon the consequent fate of the biocrude products. 162 2.3 Process description – Life Cycle Inventory Analysis (LCA) 163 LCA inventory for each process was developed using primary experimental data (for downstream 164 processing HTL and HDT stages), supplemented by literature data. The inventories for chemical 165 production or fuel-specific energy production were derived from the Ecoinvent database (v2.2). The 166 dataset for global fossil crude oil derived from Ecoinvent database (v2.2) was used to represent the 167 average refinery industry for fossil crude oil production including extraction, production and 168 transportation. The detailed LCI analysis is presented below. 169 2.3.1 Cultivation 170 The cultivation data used in this study is derived from literature, whereby it is assumed that the 171 Nannochloropsis sp. was inoculated in a laboratory (tubular reactor) and then cultivated in raceway 172 ponds. Jorquera et al. 2010 investigated the case for algal growth in open raceway ponds with an 173 output of 100000 kg/year of biomass (dry wt. basis) for Nannochloropsis sp. Although algae biomass 7 174 productivity and efficiency could vary with geographical variation in climate condition and resource 175 availability, such special variations has been excluded from LCA scope due to the research focus 176 being placed on algal processing technology evaluation under currently study. A thorough literature 177 review we conducted suggests that limited analyses have been performed at spatially explicit levels 178 (Patel et al. 2015) thus spatial variation in LCA profiles due to the impact of cultivation site location 179 on dominant species and algae growth can be explored in future research. The main energy input 180 associated with the cultivation process is the power for pumping the fluid and paddlewheel for open 181 raceways to give a total energy consumption of 3.785 MJ/kg of dry algal biomass. 182 2.3.2 Dewatering 183 The dewatering of cultivated algal broth is assumed to be conducted through a commercially available 184 spiral plate centrifuge manufactured by Evodus B. V. The use of a centrifuge designed specifically for 185 algae dewatering has the advantage of not damaging the cells in the process and also eliminate the 186 requirement for flocculants, sedimentation or other biomass concentrating procedure. The energy 187 consumption for the equipment is 0.95 kWh per m3 of mixture processed (Evodus 2015). The 188 centrifuge is capable of achieving final concentration of 31.5 wt.-% of Nannochloropsis sp. (Milledge 189 and Heaven 2013) which is within the range of HTL reactor for biomass processing (Knorr et al. 190 2013). 191 2.3.3 HTL 192 The algae paste obtained from the centrifuge was pumped in a HTL reactor at the required pressure 193 and temperature. The HTL reaction data is obtained from experimental investigation using a 194 laboratory scale continuous flow reactor with a volume of 2 ml. Reactions were carried out at 300, 195 325, 350 and 380°C and RT of 0.5, 1, 2 and 4 min using a biomass slurry of 1.5wt.-%. Further 196 detailed information on the experimental investigation and its outcomes can be found in Patel and 197 Hellgardt (2015). The yields for various fractions (biocrude, aqueous soluble fraction and char), 198 energy content (HHV) as well as the elemental (Carbon, Hydrogen, Nitrogen and Oxygen) 199 composition have been summarized in SI 1. It should be noted that although cyclohexane was used in 8 200 the laboratory scale reactor to prevent blockage, solvents are not necessarily required at pilot scale 201 (Jazrawi et al. 2013 and Elliot et al. 2014). Therefore, cyclohexane is not accounted as an input in 202 LCA model. Additionally, the main product after HTL is defined as biocrude, whereas the product 203 from HDT is defined as upgraded biocrude. 204 Based on experimental data, multiple regression analyses were performed using built-in Microsoft 205 Excel regression analysis toolbox to generate regression models for LCA inputs in Simapro. 206 Continuous variables (e.g. yields of biocrude, aqueous fraction and char, elemental compositions) 207 were expressed as regression functions of HTL residence time and reaction temperature – this 208 approach would allow for development of a dynamic LCA model with projection power. 209 Experimental data and sample multivariable regression model can be found in SI 1. It is assumed that 210 the aqueous soluble fraction produced at the HTL stage is fed into AD and CHP system for energy 211 recovery. The aqueous soluble fraction is defined as the matter partitioned into the aqueous phase 212 after HTL. In this study, all biodegradable compounds were assumed to be digested under AD thus 213 theoretical biogas production was used to estimate the maximum energy recovery. The biogas 214 production (assumed as 65% CH4 (v/v); 35% CO2 (v/v)) from AD system was estimated based on the 215 theoretical chemical oxygen demand (COD), which can be derived from Equation 1, and the 216 theoretical CH4 potential (COD equivalence of CH4), which was calculated based on Equation 2 217 (Speece 1996). The energy generation from CHP system is calculated based on a study carried out on 218 an AD commercial plant in the UK, where electricity conversion efficiency is approximately 1.2 219 kWh/m3 biogas (net calorific value of biogas is 21.48 kJ/L), and 50% of energy contained in biogas is 220 assumed to be recovered as thermal energy (Guo et al. 2013) . For the formula CnHaObNc (1mol) 221 COD = 222 Where, the formula of the aqueous soluble fraction was derived from elemental analysis results and n, 223 a, c and b refer to the moles of C, H, O and N, respectively. 2 n (a 3 c) / 2 b 32 g O2 2 (1) 224 225 9 226 CH4 + 2O2 CO2 + 2H2O 227 Where - each mole of CH4 consumes two moles of oxygen. Therefore, 1g COD destruction is 228 equivalent to 0.35L CH4 at 0°C and 760mm Hg pressure (STP) or 0.395L CH4 at 35°C and one 229 atmosphere (Speece 1996). 230 Although the algal concentration in the reaction solution for the experimental investigation was low, it 231 is possible for a HTL reactor system to handle 36.6 wt.-% solids (Knorr et al. 2013) without any 232 adverse effect from increased algal concentration to HTL (Barreiro et al. 2013 and Toor et al. 2011). 233 For the energy input required for HTL we used the Q=mCpT relationship for algal paste with biomass 234 concentration of 31.5 wt.-% to give a temperature dependent value ranging from 1.87 to 2.42 MJ/kg 235 biomass processed. The ambient temperature was taken as 25°C and the Cp of algae as 1.371 kJ/kg/K 236 (Ponnusamy et al. 2014). 237 2.3.4 HDT 238 Catalytic HDT is the last biorefinery process under investigation. The biocrude product from HTL is 239 subjected to catalytic upgrading under 110 bar of hydrogen at 400°C and RT of 1hr to yield upgraded 240 biocrude which could potentially be blended with fossil crude at a refinery. The aim of the HDT 241 process was to increase the HHV of the oil by deoxygenation. Further information on the 242 experimental procedure can be found in Patel et al. 2014 and the data used is included in SI 1. The 243 results of 5wt.-% loaded Pt/Al2O3 (surface area 101.36 m2/g and pore volume 0.2194 cm3/g ) Pt/C 244 (surface area 1204.39 m2/g and pore volume 0.8742 cm3/g) and control (uncatalysed) were used as 245 model experiments since these gave the highest deoxygenation, HHV and upgraded biocrude yield, 246 respectively [SI 1] based on our laboratory experiments. The energy requirement for HDT was 247 estimated assuming crude oil equivalent heat capacity of biocrude as 1.81 kJ/kg/K (Burger et al. 1985) 248 and a ΔT of 340°C based on HTL outlet temperature (after potential heat recovery and fraction 249 separation) of 60°C. In addition to this, the H2 requirement was assumed as 0.0375 wt.-% of biocrude 250 (Schmidt et al. 2014). 251 2.4 LCA Case Description (2) 10 252 Several cases accounting for different experimental conditions, processing options and allocation 253 approach were explored for the five countries. In Case 1, cumulative LCIA profiles of HTL processes 254 under all reaction conditions were explored followed by contributional analyses of three reaction 255 conditions (300°C/0.5 min, 380°C/0.5 min and 380°C/4 min), which were selected to represent HTL 256 reaction severity (upper and lower bound) and best-performance process with highest biocrude yield. 257 The energy content, defined as the Higher Heating Value (HHV) was not of particular interest during 258 the selection since most HTL reaction conditions yield similar HHV values. Hence, according to our 259 previous work (Patel and Hellgardt 2015) HTL at 380°C and 0.5 min RT is considered as favourable 260 reaction condition thus selected as illustrative example in cases 3-5 due to its high biocrude yield and 261 good aqueous soluble fraction recovery. In Case 2, the biocrude derived from selected HTL reaction 262 conditions was compared to fossil crude on an equivalent function unit basis. Case 3 was 263 implemented to portray the process contributional analysis for upgraded biocrude oil produced from 264 HTL reacted at 380°C and 0.5 min RT as well as selected HDT reaction conditions. In Case 4, a 265 comparison between upgraded biocrude produced at three HDT conditions and fossil crude is 266 presented. Finally in Case 5 a scenario sensitivity analysis method was applied which involves 267 calculating different scenarios in order to analyse the influences of input parameters on either LCIA 268 output results or rankings (Guo et al. 2014). A reversal of the rank order of counterparts for LCA 269 comparisons and an arbitrary level of a 10% change in the characterized LCIA profiles for a single 270 product system were chosen as the sensitivity threshold, above which the influence of allocation 271 approach or AD scenario was considered to be significant. 272 3.0 Results and Discussion 273 The following sections present and discuss the results of the various scenarios modelled in this 274 investigation along with the impact categories and normalised comparisons (%) presented in Figures 275 2-9. The LCIA scores for each individual impact category and scenarios are given in SI 2 (Tables S1- 276 S52). 277 3.1 Case 1- Contributional analysis for biocrude oil at HTL stage 11 278 Cumulative environmental profiles for the biocrude is presented in Figure 2 where the overall 279 contribution of electrical energy inputs at algae cultivation and HTL stages vary within the range of 280 55-65% and 32-40%, respectively. Energy demand for dewatering is responsible for up to 7% of 281 environmental impact across all impact categories whereas less than 3% of environmental burden is 282 attributed to N/P nutrient required for algae cultivation. These can be explained by the fossil fuel 283 consumptions as well as the emissions evolved from fossil resource extraction and transportation, 284 electricity generation and transmission. On abiotic depletion, natural gas, hard coal and crude oil 285 inputs dominate the environmental profiles. Scores on GWP100, acidification and POCP are driven 286 by the emissions from combustion of coal, natural gas and heavy fuel oil including SOx, NOx, CO, 287 CO2, and CH4. Organic compounds like PAH and heavy metals such as Arsenic, Nickel, Selenium 288 released from fuel combustion or production of power plant construction materials account for over 289 85% of the impact on human toxicity. Over 90% of aquatic toxic impact can be attributed to the heavy 290 metallic elements/ions released to water body from ash/spoil disposal during coal mining and 291 combustion (e.g. nickel ion, vanadium ion, copper ion, cobalt, and beryllium). Not only electricity 292 generation but also its transmission brings environmental damage on terrestrial toxicity impact 293 category due to the chromium emitted at transmission network and also the atmospheric emission of 294 mercury evolved from coal combustion. Fossil resource production and transport share more than 295 95% of the ODP load, which is mainly caused by CClBrF2 emission from natural gas transportation, 296 CClF3 released from crude oil production and CCl4 as a result of Chlorine inputs for coal production. 297 The environmental benefits arising from biogenic carbon sequestration at algae cultivation stage is 298 sufficient to offset the positive impacts induced by biocrude production (HTL with a residence time of 299 0.5 min, except in Australia) leading to biocrude products with negative GHG scores (Figure 2). 300 Exported electricity from the HTL process and nutrient recovery from biochar also add towards 301 ‘avoided burden’ credits across all impact categories by substitution for the equivalent amounts of 302 electricity generated from the respective national grids and ‘functional equivalent’ quantity (dry basis) 303 of national average N fertilizer production. As shown in Figure 2, HTL at a residence time of 0.5 min 304 (300/380 °C) had higher nutrient recovery (biochar yield) and greater export of surplus electricity due 12 305 to higher amount of matter in the aqueous phase resulting in higher COD content in liquid being sent 306 to WWT compared to HTL at 380°C, 4 min. However, these benefits were overridden by 307 environmental burdens in most cases, except in the case of biocrude production in Brazil, UK, Spain 308 and China in GWP100 terms (Figure 2 and 3). 309 The comparisons between five countries are determined by the fossil resources for electricity 310 production mix. Grid electricity in Brazil is predominantly generated by hydropower which accounts 311 for 80%, whereas Spain and UK have a relatively balanced fuel mix, but conversely Australia and 312 China are coal intensive energy generators. Therefore, Brazil followed by Spain and UK are 313 suggested as better locations for producing HTL biocrude based on the environmentally advantageous 314 figures compared to China and Australia on almost all impact categories (Figure 2) except for ODP, 315 where the comparison results are driven by profile of natural gas and fuel oil. 316 As expected, the reaction temperature and RT play an important role in LCA outcomes. For short 317 residence time (0.5 min or 2 min) an improvement in environmental performance with increased HTL 318 temperature is observed on almost all impact categories except for GWP100 where no clear trend is 319 shown, but the optimal reaction temperature identified for GHG balance is 300°C. With longer 320 residence time (4 min), different trends are suggested in Figure 3 which elucidates a decline in 321 environmental scores with increased HTL temperature. For HTL with reaction temperature above 322 300°C, a RT of 0.5 min is indicated as an environmentally superior option compared with longer RT. 323 Similarly, for HTL at lower temperature (300°C), 4 min shows several environmental advantages over 324 shorter RTs. An exception is Brazil where a RT of 0.5 min demonstrates clear advantage for any 325 reaction temperature group. HTL at 300°C for 0.5 min deliver the best GWP100 profiles, whereas on 326 other impact categories HTL at 380°C for 0.5 min represents the optimum option offering the best 327 environmental performance (Figure 3), which can be explained by its high biomass conversion 328 efficiency (biocrude yield ) . 329 330 13 331 332 14 333 Figure 2 - LCIA profiles of biocrude at HTL stage at 300°C, 4 min (a), 380°C, 0.5 min (b) and 334 380°C, 4 min (c). [Unit: 1kg biocrude; Method: CML 2 baseline 2000] 335 336 Figure 3 - LCIA profiles of biocrude at HTL stage in Brazil (a), Australia (b), China (c), Spain 337 (d) and UK (e). [Unit: 1kg biocrude at HDT stage; Method: CML 2 baseline 2000] 338 3.2 Case 2 - Cumulative life cycle impacts for HTL biocrude vs. fossil crude 339 The LCA comparison between biocrude produced via HTL and fossil crude is performed on an 340 equivalent function unit basis (Figure 4). Under most HTL reaction conditions (except for 380 °C, 4 341 min), and countries (except for Australia) investigated, HTL processed biocrude is observed to be 15 342 overall environmentally superior to fossil crude on GWP100 and ODP impact category basis. 343 However, higher impact scores than fossil crude oil are found in the other impact categories (except 344 for Brazil, which benefits from its hydropower, delivers better scores on abiotic depletion, and 345 eutrophication). In this study, the dataset derived from Ecoinvent (V2.2) representing global average 346 refinery industry for fossil crude production (including extraction, production and transportation) has 347 been adopted in the LCA comparisons. However, country-specific environmental profiles for fossil 348 crud accounting for spatial variation in transportation distance is not accounted for and could be 349 explored in future LCA research as it is beyond the scope of this investigation. 350 16 351 Figure 4 - LCIA comparison of HTL biocrude vs. fossil crude at 300°C, 4 min (a), 380°C, 0.5 352 min (b) and 380°C, 4 min (c). [Unit: 1 MJ crude oil produced; Method: CML 2 baseline 2000] 353 3.3 Case 3 - Contributional analysis for upgraded biocrude oil at HDT stage 354 The ‘cradle-to-biorefinery gate’ LCIA profiles of upgraded biocrude using different catalyst for HDT 355 is presented in Figure 5, where biocrude derived from HTL with a RT of 0.5 min and a reaction 356 temperature of 380°C is used as an illustrative example. Regardless of different countries and reaction 357 conditions, LCIA profiles of upgraded biocrude is dominated by energy-intensive cultivation and 358 HTL processes. These are responsible for over 90% of environmental burdens across all impact 359 categories mainly due to the fossil fuel consumed for electricity generation and the emissions released 360 during fossil fuel production, transportation and combustion. These environmental burdens include 361 the fossil resource depletion caused by coal, natural gas and crude oil inputs for grid electricity 362 generation, impacts on GWP100, acidification and POCP due to atmospheric emission of CH4, CO2 363 SOx NOx released from fossil fuel combustion. Additionally, the eutrophication precursors such as 364 PO43- , NOx from coal extraction and combustion, ODP impacts brought by CClBrF2 and CClF3 365 emissions from natural gas transportation and crude oil extraction, toxic compounds and heavy metals 366 released from electricity generation and transmission (e.g. Beryllium, Vanadium, Nickel, PAH 367 evolved from coal mining and burning and heavy fuel oil combustion as well as the Chromium 368 emissions at electricity transmission stage) all contribute towards substantiating the environmental 369 burden. Less than 8% of overall environmental burden is attributable to energy demand at dewatering 370 and HDT process. Generally, the contribution of H2 inputs at HDT stage and nutrient demand for 371 algae cultivation (diammonium phosphate and urea) are negligible, except for abiotic depletion where 372 H2 component is responsible for up to 20% of environmental burden (positive value above line) due to 373 the gas and oil consumed for H2 production i.e. cracking process. The burden from H2 production 374 could potentially be reduced by using renewable H2 from solar/wind water splitting or biomass 375 gasification with a lower environmental emission profile (Koroneos et al. 2004). Biogenic carbon 376 sequestered into upgraded biocrude at the algae cultivation stage brings significant ‘negative’ impacts 377 on GWP100, acting to ‘offset’ the impact of burden incurred from the biocrude production and 17 378 leading to Brazilian case with a net negative GHG balance at biorefinery factory gate. Environmental 379 ‘savings’ (Figure 5) across all impact categories are also derived from the ‘avoided burden’ credits 380 from electricity exported from AD/CHP system during the HTL process and biochar recovery at HTL 381 and HDT stages (substitutions for the functional equivalent amount of fertilizer nutrients and charcoal 382 respectively). 383 Amongst the five countries, Brazil and Spain represent good locations for producing upgraded 384 biocrude, delivering lowest environmental impact on almost all impact fronts (Figure 5) except for 385 ODP, where China leads. These outcomes are driven by the different fossil resources for electricity 386 production mix. Brazil and Spain benefit from hydropower driven electricity supply and a balanced 387 fuel resource, respectively. Conversely, Australia and China where grid electricity supplies are 388 dominated by coal represent the worst scenarios in most impact categories except for low ODP 389 impacts of China, which can be explained by minor proportion of natural gas and fuel oil in electricity 390 production mix. 391 The reaction conditions as well as conversion efficiency/yield is another key factor affecting 392 environmental profiles for biocrude production system. Benefiting from high upgraded biocrude yield, 393 non-catalytic HDT (control) delivers a better environmental profile than catalytic HDT (with Pt/Al2O3 394 or Pt/C) (Figure 6). The production process with HTL reaction condition of 380°C and 0.5 min, 395 combined with a non-catalytic HDT deliver the best environmental performances compared with 396 other systems for producing upgraded biocrude (Figure 6). The lack of environmentally advantageous 397 outcome for catalytic HDT process suggests the need of better catalyst capable of producing upgraded 398 biocrude with better HHV at higher yields and greater denitrogenation as well as optimising the 399 reaction conditions. 400 401 402 18 403 19 404 Figure 5 - ‘Cradle-to-biorefinery-gate’ LCIA profiles of biocrude at HDT stage for control (a), 405 Pt/Al2O3 (b), and Pt/C (c) catalysed reactions. [Unit: 1kg upgraded biocrude; Method: CML 2 406 baseline 2000] 407 408 Figure 6 - ‘Cradle-to-biorefinery-gate’ LCIA profiles of upgraded biocrude in Spain (a), UK (b), 409 China (c), Brazil (d) and Australia (e). [Unit: 1kg biocrude at HDT stage; Method: CML 2 410 baseline 2000) 411 3.4 Case 4 - Cumulative life cycle impacts for upgraded biocrude oil at use phase 20 412 As illustrated in Figure 7, comparison of results (based on energy functional units) between upgraded 413 biocrude and fossil crude vary with countries, reaction conditions, and impact categories. Upgraded 414 biocrude produced in Brazil is shown as environmentally competitive to fossil crude in terms of 415 GWP100, abiotic depletion, ODP and POCP, especially for HTL condition of 380°C/0.5 min and 416 HDT (non-catalytic) which shows environment advantage or equivalent over fossil crude for nearly 417 all impact categories. With the reduction in conversion efficiency (biomass to biocrude) during HTL 418 (defined as either increased RT to 4 min or decreased temperature to 300°C), upgraded biocrude 419 derived via catalytic HDT in Spain and UK shift to a disadvantageous ODP position with regard to 420 fossil crude whereas GWP100 profiles of biocrude produced in Spain move from being negative (net 421 GHG removal from atmosphere) to positive values (net addition of GHG to atmosphere). In general, 422 to deliver the same energy functional unit, biocrude struggles and is hardly competitive with fossil 423 fuel on acidification, eutrophication and toxicity impact categories. 21 424 425 Figure 7 - LCIA comparison of upgraded biocrude vs. fossil crude at 300°C, 0.5 min (a), 380°C, 426 0.5 min (b) and 380°C, 4 min (c). [Unit: 1 MJ crude oil produced; Method: CML 2 baseline 427 2000) 428 22 429 3.5 Case 5 - Sensitivity analysis on allocation approach and AD scenarios 430 Sensitivity analysis using the allocation approach (Figure 8) indicated that the influence of allocation 431 choice on LCIA profiles of biocrude produced from HTL varies with reaction conditions modelled for 432 the impact categories investigated. GWP100 was the most sensitive impact category for the allocation 433 approach but it is not the case for remaining impact categories. Switching from system expansion to 434 the energy allocation approach leads to significantly increased GWP100 score (range from 20% to 435 over 100%) for biocrude modelled for most HTL reaction conditions whereas GWP100 profiles 436 remain stable in the case of severe HTL reaction at 380°C/4 min. With energy allocation approach, 437 China moves from being negative (net GHG removal from atmosphere) to positive value (net addition 438 of GHG to atmosphere), which is above the chosen 10% sensitivity threshold. The allocation 439 approach was not a sensitive factor in terms of the LCIA comparison between HTL biocrude and 440 fossil crude in almost all impact categories but in GWP100 where China shifts from environmentally 441 advantageous to disadvantageous over fossil crude. 442 Furthermore, sensitivity analysis was conducted to test the influences of AD scenario at HTL stage on 443 the LCIA comparisons of HTL biocrude vs. fossil crude. As demonstrated in Figure 9 (and Tables 444 S50-S52 in SI2 (in comparison with results in Figure 4 and Table S21-23 in SI2), the LCIA profiles of 445 HTL biocrude in general is sensitive to AD scenarios. Shifting from HTL with AD energy recovery to 446 exclusion of AD unit, the increase in the environmental impacts for HTL biocurde vary with HTL 447 reaction conditions, country and impact categories (generally ranging between 5-55%). With 448 increasing reaction severity of HTL, the effects of AD energy recovery on the LCIA profiles of 449 biocrude decreases significantly. AD scenario does not produce any effect on the environmental 450 footprint of HTL for the reaction at 380°C and RT 4 min. GWP100 represents the most sensitive 451 impact category, where the case of China moves from negative to positive for the GWP100 scores 452 when the AD energy recovery unit is excluded. AD case study is only a sensitive parameter for the 453 comparisons between fossil crude and the biocrude supply chain modelled for China (China case 454 study shifted from superior to inferior system to fossil crude) but not for other LCIA comparisons. 23 455 456 Figure 8 - Sensitivity analysis of characterized LCIA profiles of fossil crude vs. HTL biocrude at 457 HTL 300°C, 0.5 min (a), 380°C, 0.5 min (b) and 380°C, 4 min (c) (unit: 1 MJ crude oil 458 produced; method: CML 2 baseline 2000). 24 459 460 25 461 Figure 9 - Sensitivity analysis on AD scenarios – fossil crude vs. HTL biocrude at 300°C, 0.5 min 462 (a), 380°C, 0.5 min (b) and 380°C, 4 min (c) (unit: 1 MJ crude oil produced; method: CML 2 463 baseline 2000). 464 4.0 Conclusion 465 The utilisation of algae as biomass for biofuel production can only be realised at an industrial 466 biorefinery scale if it is economically and environmentally sound. Economic feasibility can be 467 achieved by value chemical production but environmental improvement measured using assessment 468 tools such as LCA can only be achieved by improvement in process integration and technological 469 development. As determined from this investigation, even with significant reduction in HTL 470 processing time, HTL still accounts for over 40% environmental burdens in almost all impact 471 categories. From our investigation it can be seen that if the energy mix used to power an algal 472 biorefinery is environmentally beneficial, substantial improvement can be made in reducing GWP100 473 emissions, as seen for the case of Brazil where up to 80% electricity is generated using hydropower. 474 Furthermore, the results indicate the need to transition towards cleaner electricity production systems 475 to ensure the benefit is cascaded down to emerging liquid fuel production technologies such as algae. 476 If implemented, whether the higher costs (and environmental benefits) associated with fuel produced 477 from algae mask the lower costs (and environmental detriments) associated with fossil crude remains 478 to be seen. Specifically, the key aspect of the comparative analyses presented here for algae derived 479 biocrude oil production across various potential supply chains has been to highlight the importance of 480 the following main factors on the resulting biofuel profiles-. 481 The specific energy resource being used (e.g. hydropower dominated electricity in Brazil) 482 HTL processing technology (e.g. residence time, reaction temperature) 483 Level of biocrude upgrading (e.g. severity of upgrading at HDT stage) 484 Importance of co-product(s) and emissions profiling methodology applied in the LCA 485 methodology (e.g. system expansion vs. energy allocation approach) 26 486 Under most reaction conditions biocrude produced (except for Australia) via HTL delivers 487 environmental saving compared with fossil crude on GWP100 and ODP; whereas at HDT stage, only 488 upgraded biocrude produced in Brazil remained environmentally competitive to fossil resource in 489 terms of GWP100 and ODP profiles. Algae feedstock processed at the optimal configurations 490 (e.g.380°C, 0.5 min) with environmentally favourable energy supply (e.g. Brazil scenarios) is shown 491 in our modelling to offer life cycle GWP100 savings over fossil crude of 80% or more, placing them 492 well within the most desirable categories being targeted by policymakers internationally (e.g. the EU 493 Renewable Energy Directive, the USA Renewable Fuel Standard). However, looking at the overall 494 GWP100 (Table 1), it becomes apparent that although a substantial contributor, the negative impact of 495 HTL can be marginalized by energy recovery of by-products, which was AD in this case. Whether 496 this can be realised effectively at an industrial scale remains to be seen and can only be explored 497 through further practical investigation. 498 Table 1 – GWP100 for HTL, AD and Total overall impact [Total is based on process defined in 499 Fig. 1. Only HTL and AD shown for comparison purpose] 500 501 502 503 Country Brazil UK Spain China Australia HTL AD Total GWP 100 (kg CO2 eq per kg biocrude) 0.1020 -0.3690 -4.8800 1.4 -0.7320 -1.59 0.993 -0.6080 -2.6 1.98 -1.0800 -0.132 2.12 -0.9110 0.349 504 505 Algal biocrude is still under development and research compared to the well-developed fossil crude 506 industry. Modelling research as demonstrated in current study could provide analytical tools and 507 insightful information for process or value chain configuration and enables ongoing empirical work to 508 be more efficiently focused on key performance-limiting and environmentally damaging steps to 509 accelerate algal biorefinery research. The LCA of HDT/HTL reaction matrix with varying conditions 510 investigated under this study highlight optimal configuration for HTL/HDT process. By combining 27 511 statistical method (e.g. multivariate regression analysis) with LCA model, this study also 512 demonstrates the development of a dynamic model with projection power. More research effort is 513 required to explore various optimisation options for algal biorefinery, including feedstock 514 optimisation (e.g. strain screening), process integration and optimisation (e.g. energy integration, 515 energy and resource recovery), as well as supply chain integration and optimisation (e.g. 516 incorporation of algal biocrude system into other production supply chains, selection of optimal 517 location for biorefinery). In the long term, such integration and optimisation at process and value 518 chain level, combined with the utility of renewable energy source for processing, it is likely that 519 algae-derived biocrude has the potential to exhibit environmentally sustainable biorefinery. 520 521 522 523 524 525 526 527 528 529 530 531 532 28 533 Abbreviations 3G - Third Generation ABD - Abiotic Depletion ACD - Acidification EUT - Eutrophification FAE - Freshwater Aquatic Ecotoxicity GWP - Global Warming Potential HDT - Hydrotreatment HTL - Hydrothermal Liquefaction HUT - Human Toxicity LCA - Life Cycle Assessment MAE - Marine Aquatic Ecotoxicity ODP - Ozone Layer Depletion POCP - Photochemical Oxidation Potential RT - Residence Time TEE - Terrestial Ecotoxicity 534 535 536 537 538 539 540 541 542 543 544 545 29 546 547 548 References 1. Azadi, P., Brownbridge, G., Mosbach, S., Smallbone, A., Bhave, A., Inderwildi, O., & Kraft, 549 M. (2014). The carbon footprint and non-renewable energy demand of algae-derived 550 biodiesel. Applied Energy, 113, 1632-1644. 551 552 2. Barreiro, DL., Prins,W., Ronsse, F., & Brilman, W., (2013). Hydrothermal liquefaction 553 (HTL) of microalgae for biofuel production: State of the art review and future prospects, 554 Biomass and Bioenergy. 53, Pages 113-127 555 556 3. Batan, L., Quinn, J., Willson, B., & Bradley, T. (2010). Net energy and greenhouse gas 557 emission evaluation of biodiesel derived from microalgae. Environmental science & 558 technology, 44(20), 7975-7980. 559 560 4. Bennion, E. P., Ginosar, D. M., Moses, J., Agblevor, F., & Quinn, J. C. (2015). Lifecycle 561 assessment of microalgae to biofuel: Comparison of thermochemical processing pathways. 562 Applied Energy. 563 564 565 5. Biller, P., & Ross, A. B., (2012). Hydrothermal processing of algal biomass for the production of biofuels and chemicals. Biofuels. 3, 603-623. 566 567 568 6. Bradley, T., Maga, D., & Antón, S. (2015). Unified approach to Life Cycle Assessment between three unique algae biofuel facilities. Applied Energy. 569 570 571 7. Burger, J., Sourieau, P.,& Combarnous, M., 1985. Thermal methods of oil recovery, Technip , Paris, 1985 572 30 573 574 8. Campbell, P. K., Beer, T., & Batten, D. (2011). Life cycle assessment of biodiesel production from microalgae in ponds. Bioresource technology, 102(1), 50-56. 575 576 577 9. Chen, W. H., Lin, B. J., Huang, M. Y., & Chang, J. S. (2014). Thermochemical conversion of microalgal biomass into biofuels: A review. Bioresource technology, 184, 314-327. 578 579 10. Davis, R. E., Fishman, D. B., Frank, E. D., Johnson, M. C., Jones, S. B., Kinchin, C. M., 580 Skaggs, R. L., Venteris, E. R., & Wigmosta, M. S. (2014). Integrated evaluation of cost, 581 emissions, and resource potential for algal biofuels at the national scale. Environmental 582 science & technology, 48(10), 6035-6042. 583 584 11. de Boer, K., Moheimani, N. R., Borowitzka, M. A., & Bahri, P. A. (2012). Extraction and 585 conversion pathways for microalgae to biodiesel: a review focused on energy consumption. 586 Journal of Applied Phycology, 24(6), 1681-1698. 587 588 589 12. Demirbas, A., 2009. Pyrolysis of biomass for fuels and chemicals. Energy Sources Part A. 31, 1028-1037. 590 591 13. EEA, EEA greenhouse gas - data viewer. 2014, The European Environment Agency. URL: 592 http://www.eea.europa.eu/data-and-maps/data/data-viewers/greenhouse-gases-viewer 593 [Accessed Aug 2014] 594 595 14. European commission Consumption of energy. URL: 596 http://epp.eurostat.ec.europa.eu/statistics_explained/index.php/Consumption_of_energy 597 [Accessed Aug 2014] 598 31 599 600 601 602 15. European Union, Directive 2009/28/EC of the European Parliament and of the Council 2009, The European Parliament and the Council of the European Union 16. Evodus Website , http://www.evodos.eu/index.php/spiral-plate-technology.html [Accessed 02/02/2015] 603 604 605 17. Ewald, J., 2013. Carbon Dioxide at NOAA’s Mauna Loa Observatory reaches new milestone: Tops 400 ppm’. NOAA Research, 10 May 2013. 606 607 608 18. Faeth, J. L., Valdez, P. J., Savage, P. E., 2013. Fast hydrothermal liquefaction of Nannochloropsis sp. to produce biocrude. Energy Fuels. 27, 1391-1398. 609 610 19. Fortier, M. O. P., Roberts, G. W., Stagg-Williams, S. M., & Sturm, B. S. (2014). Life cycle 611 assessment of bio-jet fuel from hydrothermal liquefaction of microalgae. Applied Energy, 612 122, 73-82. 613 614 20. Frank, E. D., Elgowainy, A., Han, J., & Wang, Z. (2013). Life cycle comparison of 615 hydrothermal liquefaction and lipid extraction pathways to renewable diesel from algae. 616 Mitigation and Adaptation Strategies for Global Change, 18(1), 137-158. 617 618 21. Garcia Alba, L., Torri, C., Samorì, C., van der Spek, J., Fabbri, D., Kersten, S. R., Brilman, 619 D. W., 2011. Hydrothermal treatment (HTT) of microalgae: evaluation of the process as 620 conversion method in an algae biorefinery concept. Energy 458 Fuels. 26, 642-657. 621 622 22. Grierson, S., Strezov, V., & Bengtsson, J. (2013). Life cycle assessment of a microalgae 623 biomass cultivation, bio-oil extraction and pyrolysis processing regime. Algal Research, 2(3), 624 299-311. 625 32 626 23. Guo, M., Littlewood, J., Joyce, J., Murphy, R., 2014. The environmental profile of bioethanol 627 produced from current and potential future poplar feedstocks in the EU. Green Chemistry. 16, 628 4680-4695. 629 630 24. Guo, M., Stuckey, DC., Murphy, RJ., 2013. Is it possible to develop biopolymer production 631 systems independent of fossil fuels? Case study in energy profiling of polyhydroxybutyrate- 632 valerate (PHBV). Green Chem. 15, 706-717. 633 634 635 25. Jazrawi, C., Biller, P., Ross, A. B., Montoya, A., Maschmeyer, T., Haynes, B. S., 2013. Pilot plant testing of continuous hydrothermal liquefaction of microalgae. Algal Res. 2, 268-277. 636 637 26. Jena, U., Das, K. C., Kastner, J. R., 2011. Effect of operating conditions of thermochemical 638 liquefaction on biocrude production from Spirulina platensis. Bioresour. Technol. 102, 6221- 639 6229 640 641 642 27. Jonker, J. G. G., & Faaij, A. P. C. (2013). Techno-economic assessment of micro-algae as feedstock for renewable bio-energy production. Applied Energy, 102, 461-475. 643 644 28. Jorquera, O., Kiperstock, A., Sales, E. A., Embiruçu, M., Ghirardi, M. L., 2010. Comparative 645 energy life-cycle analyses of microalgal biomass production in open ponds and 646 photobioreactors. Bioresour. Technol. 101, 1406-1413 647 648 29. Knorr, D., Lukas, J., Schoen, P. 2013. Production of Advanced Biofuels via Liquefaction – 649 Hydrothermal Liquefaction Reactor Design: April 5, 2013. NREL/SR-5100-60462, National 650 Renewable Energy Laboratory, Golden, Colorado, USA. 651 33 652 30. Koroneos, C., Dompros, A., Roumbas, G., & Moussiopoulos, N. (2004). Life cycle 653 assessment of hydrogen fuel production processes. International Journal of Hydrogen Energy, 654 29(14), 1443-1450 655 656 657 31. Lardon, L., Hélias, A., Sialve, B., Steyer, J. P., Bernard, O., 2009. Life-cycle assessment of biodiesel production from microalgae. Environ. Sci. Technol., 43, 6475-6481. 658 659 32. Liu, X., Saydah, B., Eranki, P., Colosi, L. M., Mitchell, B. G., Rhodes, J., & Clarens, A. F. 660 (2013). Pilot-scale data provide enhanced estimates of the life cycle energy and emissions 661 profile of algae biofuels produced via hydrothermal liquefaction. Bioresource technology, 662 148, 163-171. 663 664 665 33. Malik, A., Lenzen, M., Ralph, P. J., & Tamburic, B. (2014). Hybrid life-cycle assessment of algal biofuel production. Bioresource Technology, 184, 436-443. 666 667 668 34. Milledge, JJ., Heaven, S., 2013. A review of the harvesting of micro-algae for biofuel production. Reviews in Environ.Sci. Biotech. 12, 165-78. 669 670 35. Mu, D., Min, M., Krohn, B., Mullins, K. A., Ruan, R., & Hill, J. (2014). Life Cycle 671 Environmental Impacts of Wastewater-Based Algal Biofuels. Environmental science & 672 technology, 48(19), 11696-11704. 673 674 36. Orfield, N. D., Fang, A. J., Valdez, P. J., Nelson, M. C., Savage, P. E., Lin, X. N., & 675 Keoleian, G. A. (2014). Life cycle design of an algal biorefinery featuring hydrothermal 676 liquefaction: effect of reaction conditions and an alternative pathway including microbial 677 regrowth. ACS Sustainable Chemistry & Engineering, 2(4), 867-874. 678 34 679 37. Passell, H., Dhaliwal, H., Reno, M., Wu, B., Amotz, A. B., Ivry, E., Gay, M., Czartoski, T., 680 Laurin, L., & Ayer, N. (2013). Algae biodiesel life cycle assessment using current 681 commercial data. Journal of environmental management, 129, 103-111. 682 683 684 685 38. Pate, R., Klise, G., & Wu, B. (2011). Resource demand implications for US algae biofuels production scale-up. Applied Energy, 88(10), 3377-3388. 686 687 39. Patel, B., Arrillaga, P. A., Izadpanah, A., Millan-Agorio, M., & Hellgardt, K., (2015) 688 Catalytic Hydrotreatment of fast liquefaction algal biocrude. Energy & Fuels (awaiting 689 submission) 690 691 692 40. Patel, B., Hellgardt, K., 2013. Hydrothermal upgrading of algae paste: Application of 31 P‐NMR. Environ. Prog.Sustain.Energy. 32, 1002-1012. 693 694 695 41. Patel, B., Tamburic, B., Zemichael, F. W., Dechatiwongse, P., Hellgardt, K., 2012. Algal biofuels: a credible prospective?. ISRN Renew. Energy 2012 696 697 698 42. Patel. B., Hellgardt, K., 2015. Hydrothermal Upgrading of Algae Paste in a Continuous Flow Reactor. Bioresour. Technol. 19, 460-468 699 700 43. Patel. B., Guo. M., Izadpanah. A., Shah. N., Hellgardt. K., 2015. A Review on Hydrothermal 701 Pre-treatment Technologies and Environmental Profiles of Algal Biomass Processing. 702 Bioresour. Technol. (In Print) 703 35 704 44. Ponnusamy, H., Reddy, H, K., Muppaneni, T., Downes, C, M., Deng, S., 2014. Life cycle 705 assessment of biodiesel production from algal bio-crude oils extracted under subcritical water 706 conditions. Bioresour. Technol.170, 450-461. 707 708 45. Quinn, J. C., & Davis, R. (2014). The potentials and challenges of algae based biofuels: A 709 review of the techno-economic, life cycle, and resource assessment modeling. Bioresource 710 technology. 711 712 46. Razon, L. F., & Tan, R. R. (2011). Net energy analysis of the production of biodiesel and 713 biogas from the microalgae: Haematococcus pluvialis and Nannochloropsis. Applied Energy, 714 88(10), 3507-3514. 715 716 47. Reddy, H. K., Muppaneni, T., Rastegary, J., Shirazi, S. A., Ghassemi, A., & Deng, S., 2013. 717 Hydrothermal extraction and characterization of bio‐crude oils from wet chlorella 718 sorokiniana and dunaliella tertiolecta. Environ. Prog.Sustain.Energy, 32, 910-915. 719 720 721 48. Sander, K., & Murthy, G. S. (2010). Life cycle analysis of algae biodiesel. The International Journal of Life Cycle Assessment, 15(7), 704-714. 722 723 724 49. Savage, P. E., 1999. Organic chemical reactions in supercritical water. Chme. Rev. 99, 603622. 725 726 50. Schmidt, A. J., Albrecht, K. O., Hart, T. R., Butcher, M. G., Drennan, C., Snowden-Swan, L. 727 J., Kinchin, C. (2014). Process design and economics for the conversion of algal biomass to 728 hydrocarbons: whole algae hydrothermal liquefaction and upgrading. Pacific Northwest 729 National Laboratory. 730 36 731 732 51. Singh, A., & Olsen, S. I. (2011). A critical review of biochemical conversion, sustainability and life cycle assessment of algal biofuels. Applied Energy, 88(10), 3548-3555. 733 734 735 52. Speece, R, E., 1996. Anaerobic Biotechnology for Industrial Wastewaters, Archae Press, Nashville, Tennessee, USA. 736 737 53. Stephenson, A. L., Kazamia, E., Dennis, J. S., Howe, C. J., Scott, S. A., & Smith, A. G. 738 (2010). Life-cycle assessment of potential algal biodiesel production in the United Kingdom: 739 a comparison of raceways and air-lift tubular bioreactors. Energy & Fuels, 24(7), 4062-4077. 740 741 54. Toor, SS., Reddy, H., Deng, S., Hoffmann, J., Spangsmark, D., Madsen, LB., Holm- 742 Nielsen, JB., Rosendahl, LA., 2013. Hydrothermal liquefaction of Spirulina and 743 Nannochloropsis salina under subcritical and supercritical water conditions, Bioresour. 744 Techno. 131, 413-419 745 746 55. Tredici, M. R., Bassi, N., Prussi, M., Biondi, N., Rodolfi, L., Zittelli, G. C., & Sampietro, G. 747 (2015). Energy balance of algal biomass production in a 1-ha “Green Wall Panel” plant: How 748 to produce algal biomass in a closed reactor achieving a high Net Energy Ratio. Applied 749 Energy. 750 751 56. Zhou, Y., Schideman, L., Yu, G., & Zhang, Y. (2013). A synergistic combination of algal 752 wastewater treatment and hydrothermal biofuel production maximized by nutrient and carbon 753 recycling. Energy & Environmental Science, 6(12), 3765-3779. 754 37