Selecting reliable and robust freshwater macroalgae for

advertisement

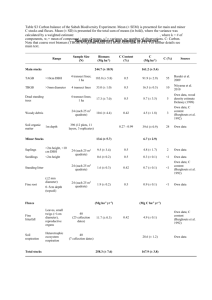

SUPPORTING INFORMATION LEGENDS Table S1. Alternative biorefinery options with sequential extraction of proteins, lipids or fatty acids (FA) and conversion of residual biomass to biocrude. Data show macroalgae projected productivities (P, in metric t ha-1 yr-1) and values (V, in US$ ha-1 yr-1) of commodities generated by marine (M) and freshwater (FW) macroalgae through different scenarios. Products prices are derived from equivalent commodities prices (see Methods). Note that theoretical values (V) are rounded to the nearest $100 for each scenario. Table S2. Sensitivity analyses of marine Derbesia and Ulva and freshwater Oedogonium for parameters influencing the value of feedstock (US$ ha-1 yr-1) for sequential extraction of protein from biomass and hydrothermal liquefaction of the residual biomass to biocrude. Values (A); Parameters (B); References (C); “Best Case” scenarios (D). Table S3. Biocrude yield from several studies on hydrothermal liquefaction of macroalgae and microalgae. M = marine origin, FW = freshwater origin, dw = dry weight, afdw = ash-free dry weight. Table S4. References cited in supporting information. 1 Table S1. 1. Scenario Commodity Biodiesel Biocrude Price (US$ t-1) Species Derbesia Ulva Chaetomorpha Cladophora Oedogonium Cladophora 2. 3. 4. 5. 6. 7. 8. 9. 10. Protein Biocrude - Protein 3+4 Lipid Biocrude - Lipid 6+7 Biocrude - FA 1+9 941 682 432 682 1170 682 682 P V 1.8 $1,700 7.1 $4,800 9.4 $4,100 5.4 $3,700 $7,800 4.5 $5,300 3.5 $2,400 $7,600 5.6 $3,800 $5,500 P V 0.6 $600 4.6 $3,100 6.8 $2,900 3.4 $2,300 $5,200 0.8 $900 4.0 $2,700 $3,600 4.1 $2,800 $3,400 P V 0.7 $700 4.0 $2,700 4.0 $1,700 3.3 $2,300 $4,000 1.2 $1,400 3.1 $2,100 $3,500 3.4 $2,300 $3,000 P V 0.8 $700 4.3 $2,900 5.5 $2,400 3.3 $2,200 $4,600 1.4 $1,700 3.1 $2,100 $3,800 3.6 $2,500 $3,200 P V 0.8 $800 3.3 $2,300 4.2 $1,800 2.5 $1,700 $3,500 1.8 $2,000 1.9 $1,300 $3,300 2.6 $1,800 $2,600 P V 0.6 $600 2.0 $1,300 3.4 $1,400 1.4 $900 $2,300 0.7 $800 1.4 $1,000 $1,800 1.5 $1,000 $1,600 Source M M M M FW FW 2 Table S2. A) Sensitivity Analysis Values Species Derbesia Ulva Oedogonium Parameter Biomass productivity Protein content Biocrude yield WTI crude oil price Soybean meal price Unit US$ ha-1 yr-1 US$ ha-1 yr-1 US$ ha-1 yr-1 US$ ha-1 yr-1 US$ ha-1 yr-1 15,526 7,705 7,245 11,973 5,230 4,954 11,135 3,549 3,341 7,780 7,705 7,630 5,283 5,230 5,176 3,590 3,549 3,509 9,544 7,705 6,221 6,394 5,230 3,980 4,426 3,549 2,774 8,137 7,705 7,199 5,502 5,230 4,911 3,755 3,549 3,308 9,149 7,705 6,660 6,273 5,230 4,475 4,194 3,549 3,084 (P) Biomass productivity (P1) Protein content (P2) Biocrude yield (P3) WTI crude oil price (P4) Soybean meal price (P5) Unit g m-2 d-1 wt% wt% US$ t-1 US$ t-1 24.0 11.9 11.2 26.1 11.4 10.8 16.0 5.1 4.8 22.0 21.6 21.2 16.6 16.3 16.0 23.0 22.5 22.0 18.5 12.3 7.3 12.2 8.1 3.7 20.6 13.7 7.6 763.3 682.5 587.9 763.3 682.5 587.9 763.3 682.5 587.9 585.8 431.9 320.7 585.8 431.9 320.7 585.8 431.9 320.7 Case Favourable Standard Unfavourable Favourable Standard Unfavourable Favourable Standard Unfavourable B) Sensitivity Analysis Parameters Parameter Species Derbesia Ulva Oedogonium Case Favourable Standard Unfavourable Favourable Standard Unfavourable Favourable Standard Unfavourable 3 C) Sensitivity Analysis References Case Parameter Biomass productivity Protein content Biocrude yielda WTI crude oil priceb Soybean meal priceb (P) (P1) (P2) (P3) (P4) (P5) This Study, +1 SD (P3) = standard + (standard * 0.5) Maximum price within the last 2 years Maximum price within the last 2 years Species Derbesia Favourable Magnussonc d Ulva Bolton Oedogonium Colee All species This Study, average This Study, average (P3) = 0.80*WLIP + 0.15*WCARB Average price within the last 2 years Average price within the last 2 years Unfavourable All species This Study, -1 SD This Study, -1 SD (P3) = 0.55*WLIP + 0.06*WCARB Minimum price within the last 2 years Minimum price within the last 2 years Standard a WLIP and WCARB are lipid and carbohydrate contents (wt%) of macroalgae respectively; conversion factors from Biller & Ross, 2011 b commodity prices from Indexmundi, http://www.indexmundi.com/australia/ c Magnusson et al., submitted d Bolton et al., 2009 e Cole, unpublished data D) Sensitivity Analysis "Best Case" All parameters are considered favourable Value of feedstock (US$ ha-1 yr-1) = 3.65c * (P1) * [((P2) * (P5)) + ((P3) * (P4))] / 100% Derbesia US$23,660 ha-1 yr-1 = 3.65 * 24.0 * [(22.0 * 585.8) + (18.5 * 763.3)] / 100 Ulva US$18,135 ha-1 yr-1 = 3.65 * 26.1 * [(16.6 * 585.8) + (12.2 * 763.3)] / 100 Oedogonium US$17,051 ha-1 yr-1 = 3.65 * 16.0 * [(23.0 * 585.8) + (20.6 * 763.3)] / 100 c multiplier derived from the conversion of productivity in g m-2 d-1 to productivity in t ha-1 y-1 4 Table S3. Reference Macroalgae Zhou et al. Anastasakis and Ross Microalgaeb Dote et al. Minowa et al. Yang et al. Biller and Ross Garcia Alba et al. Vardon et al. Ross et al. Biller et al. Zou et al. (a) Zou et al. (b) Brown et al. Duan and Savage Jena et al. Valdez et al. Yu et al. Species Enteromorpha prolifera Laminaria saccharina Botryococcus braunii Dunaliella terciolecta Microcystis viridis Chlorella vulgaris Nannochloropsis occulata Porphyridium cruentum Spirulina Desmodesmus sp. Spirulina Chlorella vulgaris Spirulina Nannochloropsis occulata Chlorella vulgaris Dunaliella terciolecta Dunaliella terciolecta Nannochloropsis sp. Nannochloropsis sp. Spirulina platensis Nannochloropsis sp. Chlorella pyrenoidosa Origin T (oC) Time (min) Equationa Mass of feed Biocrude yield (wt%) Algae basis M M 300 350 30 15 23.0 19.3 algae + catalyst algae + catalyst dw afdw FW M FW FW M M FW FW FW FW FW M FW M M M M FW M FW 300 300 340 350 350 350 350 375 300 350 350 350 350 360 360 350 350 350 350 280 60 5 30 60 60 60 60 5 30 60 60 60 60 50 30 60 60 60 60 120 64 43.8 33 36 35 27.1 29 49 32.6 27.3 20 34.3 38.9 25.8 36.9 43 57 39.9 39 39.4 algae algae cyanobacteria algae algae algae + catalyst cyanobacteria algae cyanobacteria algae + catalyst cyanobacteria + catalyst algae + catalyst algae + catalyst algae algae algae algae cyanobacteria algae algae afdw afdw afdw afdw afdw afdw afdw afdw afdw afdw afdw afdw afdw dw dw dw dw dw dw dw These biocrudes are composed of 68-75% carbon, 8-10% hydrogen, 9-19% oxygen and 4-8% nitrogen (dry weight)c a Biocrude yield (wt%) = Mass of biocrude (g) / Mass of feed (g) *100% b reproduced and modified from Lopez Barreiro et al., 2013 c Frank et al., 2013 5 Table S4. Anastasakis K, Ross AB (2011) Hydrothermal liquefaction of the brown macro-alga Laminaria saccharina: effect of reaction conditions on product distribution and composition. Bioresource Technology, 102, 4876-4883. Biller P, Ross AB (2011) Potential yields and properties of oil from the hydrothermal liquefaction of microalgae with different biochemical content. Bioresource Technology, 102, 215-225. Biller P, Riley R, Ross AB (2011) Catalytic hydrothermal processing of microalgae: decomposition and upgrading of lipids. Bioresource Technology, 102, 4841-4848. Bolton J, Robertson-Andersson D, Shuuluka D, Kandjengo L (2009) Growing Ulva (Chlorophyta) in integrated systems as a commercial crop for abalone feed in South Africa: a SWOT analysis. Journal of Applied Phycology, 21, 575-583. Brown TM, Duan P, Savage PE (2010) Hydrothermal liquefaction and gasification of Nannochloropsis sp. Energy & Fuels, 24, 3639-3646. Dote Y, Sawayama S, Inoue S, Minowa T, Yokoyama S (1994) Recovery of liquid fuel from hydrocarbon-rich microalgae by thermochemical liquefaction. Fuel, 73, 1855-1857. Duan P, Savage PE (2011) Hydrothermal liquefaction of a microalgae with heterogeneous catalysts. Industrial & Engineering Chemistry Research, 50, 52-61. Frank ED, Elgowainy A, Han J, Wang Z (2013) Life cycle comparison of hydrothermal liquefaction and lipid extraction pathways to renewable diesel from algae. Mitigation and Adaptation Strategies for Global Change, 18, 137-158. Garcia Alba L, Torri C, Samorì C, Van Der Spek J, Fabbri D, Kersten SR, Brilman DW (2011) Hydrothermal treatment (HTT) of microalgae: evaluation of the process as conversion method in an algae biorefinery concept. Energy & Fuels, 26, 642-657. Jena U, Das K, Kastner J (2011) Effect of operating conditions of thermochemical liquefaction on biocrude production from Spirulina platensis. Bioresource Technology, 102, 6221-6229. Lopez Barreiro D, Prins W, Ronsse F, Brilman W (2013) Hydrothermal liquefaction (HTL) of microalgae for biofuel production: state of the art review and future prospects. Biomass and Bioenergy, 53, 113-127. Magnusson M, Mata L, de Nys R, Paul NA (in press) Biomass, lipid and fatty acid production in large-scale cultures of the marine macroalga Derbesia tenuissima (Chlorophyta). Marine Biotechnology. Minowa T, Yokohama S, Kishimoto M, Okakura T (1995) Oil production from algal cells of Dunaliella tertiolecta by direct thermochemical liquefaction. Fuel, 74, 1735-1738. 6 Ross A, Biller P, Kubacki M, Li H, Lea-Langton A, Jones J (2010) Hydrothermal processing of microalgae using alkali and organic acids. Fuel, 89, 2234-2243. Valdez PJ, Dickinson JG, Savage PE (2011) Characterization of product fractions from hydrothermal liquefaction of Nannochloropsis sp. and the influence of solvents. Energy & Fuels, 25, 3235-3243. Vardon DR, Sharma BK, Scott J, et al.(2011) Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae, swine manure, and digested anaerobic sludge. Bioresource Technology, 102, 8295-8303. Yang YF, Feng CP, Inamori Y, Maekawa T (2004) Analysis of energy conversion characteristics in liquefaction of algae. Resources Conservation & Recycling, 43, 21-33. Yu G, Zhang Y, Schideman L, Funk TL, Wang W (2011) Hydrothermal liquefaction of low lipid content microalgae into bio-crude oil. Transactions of the ASABE, 54, 239-246. Zhou D, Zhang L, Zhang S, Fu H, Chen J (2010) Hydrothermal liquefaction of macroalgae Enteromorpha prolifera to bio-oil. Energy & Fuels, 24, 4054-4061. Zou S, Wu Y, Yang M, Imdad K, Li C, Junmao T (2010) Production and characterization of bio-oil from hydrothermal liquefaction of microalgae Dunaliella tertiolecta cake. Energy, 35, 5406-5411. (a). Zou S, Wu Y, Yang M, Li C, Tong J (2010) Bio-oil production from sub- and supercritical water liquefaction of microalgae Dunaliella tertiolecta and related properties. Energy & Environmental Science, 3, 1073-1078. (b). 7