View/Open - Sacramento

advertisement

STRUCTURAL HEALTH MONITORING WITH THE MODAL STRAIN ENERGY

METHOD DURING SEISMIC LOADING

A Project

Presented to the faculty of the Department of Civil Engineering

California State University, Sacramento

Submitted in partial satisfaction of

the requirements for the degree of

MASTER OF SCIENCE

in

Civil Engineering

(Structural Engineering)

by

Kurt Keiichi Plenert Horiuchi

SPRING

2014

STRUCTURAL HEALTH MONITORING WITH THE MODAL STRAIN ENERGY

METHOD DURING SEISMIC LOADING

A Project

by

Kurt Keiichi Plenert Horiuchi

Approved by:

__________________________________, Committee Chair

Dr. Benjamin Fell, P.E.

____________________________

Date

ii

Student: Kurt Keiichi Plenert Horiuchi

I certify that this student has met the requirements for format contained in the University format

manual, and that this thesis is suitable for shelving in the Library and credit is to be awarded for

the thesis.

__________________________, Graduate Coordinator ___________________

Dr. Matthew Salveson, P.E.

Date

Department of Civil Engineering

iii

Abstract

of

STRUCTURAL HEALTH MONITORING WITH THE MODAL STRAIN ENERGY

METHOD DURING SEISMIC LOADING

by

Kurt Keiichi Plenert Horiuchi

The purpose of this project is to provide a review of existing literature and research in the field of

Structural Health Monitoring, and exercise the concepts obtained from the review in theoretical

example 4-story steel building. The structural health monitoring system will be designed to

monitor the performance and detect damage in a special steel moment resisting frame and special

steel concentrically braced frame under lateral seismic loading. To aid in the design and

implementation of the structural health monitoring system, pushover analyses were conducted to

assess likely locations of damage. From the pushover analyses, a set of damage cases were

created for each frame that were used in a theoretically confirm the Modal Strain Energy damage

detection algorithm. The modal strain energy method is a vibration-based method of structural

health monitoring that utilizes operational modal analysis and the time domain decomposition

technique. For each damage case, computer modal analysis was used to obtain theoretical mode

shape data of the structure. In each damage case, the modal strain energy method algorithm was

appeared to correctly identify in the story level of the lateral force resisting frame that contained

the damage.

_______________________, Committee Chair

Dr. Benjamin Fell, P.E.

_______________________

Date

iv

TABLE OF CONTENTS

Page

List of Tables…………………………………………………………………………………….viii

List of Figures…………………………………………………………………………………..…ix

Chapter

1. INTRODUCTION ....................................................................................................................... 1

1.1

Motivation .......................................................................................................... 1

1.2

Objectives and Scope.......................................................................................... 3

1.3

Organization and Outline.................................................................................... 4

2. LITERATURE REVIEW AND MODAL STRAIN ENERGY METHODOLOGY................... 6

2.1

Goals and Limitations of Structural Health Monitoring ..................................... 6

2.1.1 The Process of Structural Health Monitoring ......................................... 6

2.1.2 Facts and Limitations of Structural Health Monitoring ........................ 12

2.2

Past and Present Issues in Structural Health Monitoring.................................. 17

2.2.1 Structural Health Monitoring Economy ............................................... 17

2.2.2 Structural Health Monitoring Instrumentation ..................................... 18

2.2.3 Data Processing and Communications ................................................. 19

2.2.4 Research and Development .................................................................. 20

2.3

The Modal Strain Energy Method of Structural Health Monitoring ................ 20

3. ARCHETYPE BUILDING DESCRIPTION AND PUSHOVER ANALYSIS ........................ 27

v

3.1

Project Introduction .......................................................................................... 27

3.1.1 East –West: Special Steel Moment Resisting Frame ............................ 28

3.1.2 North-South: Special Steel Concentrically Braced Frame ................... 29

3.2

Structural Health Monitoring Assumptions ...................................................... 31

3.2.1 Gravity Loads and Lateral Loads ......................................................... 31

3.2.2 Material and Member Assumptions...................................................... 32

3.3

Analysis Layout ................................................................................................ 34

3.4

East-West Frames: Pushover Analysis and Results.......................................... 35

3.4.1 Pushover Analysis ................................................................................ 35

3.4.2 Pushover Analysis Results.................................................................... 35

3.5

North-South Frames: Pushover Analysis and Results ...................................... 37

3.5.1 Pushover Analysis ................................................................................ 37

3.5.2 Pushover Analysis Results.................................................................... 38

4. PROPOSED ARCHETYPE BUILDING INSTRUMENTATION SYSTEM DURING

DYNAMIC LOADING ............................................................................................................ 40

4.1

General Structural Health Monitoring Layout .................................................. 40

4.1.1 Data Collection and Pre-processing...................................................... 40

4.1.2 General Sensor Layout ......................................................................... 41

4.2

E-W: Special Steel Moment Resisting Frame Instrumentation and Analysis .. 41

vi

4.3

N-S: Special Steel Concentrically Braced Frame Instrumentation

and Analysis ..................................................................................................... 46

5. SUMMARY…………… ........................................................................................................... 52

5.1

Summary........................................................................................................... 52

5.2

Conclusions and Recommendations ................................................................. 54

APPENDIX A. AISC SHAPES ..................................................................................................... 56

APPENDIX B. PUSHOVER ANALYSIS RESULTS .................................................................. 58

APPENDIX C. TIME DOMAIN DECOMPOSITION TECHNIQUE .......................................... 63

APPENDIX D. ERRORS ASSOCIATED WITH THE CALCULATION OF

MODAL CURVATURE THROUGH NUMERICAL DIFFERENTIATION .... 68

APPENDIX E. SAP2000 MODAL ANALYSIS RESULTS ........................................................ 71

REFERENCES………………. ..................................................................................................... 97

vii

LIST OF TABLES

Tables

Page

3.1 Reduced Beam Section (RBS) Geometry Values .................................................................... 29

3.2 Dead and Live Loads on the Structure ..................................................................................... 31

3.3 Seismic Design Criteria as per ASCE 7-10 ............................................................................. 32

3.4 Vertical Distribution Ratios ..................................................................................................... 32

4.1 SSMRF Mode Shape Data ....................................................................................................... 43

4.2 SSMRF Mode Period ............................................................................................................... 44

4.3 SSMRF Damage Indicators ..................................................................................................... 45

4.4 SSCBF Mode Shape Data ........................................................................................................ 48

4.5 SSMRF Mode Period ............................................................................................................... 49

4.6 SSCBF Damage Indicators ...................................................................................................... 50

viii

LIST OF FIGURES

Figures

Page

3.1 Plan view of 4-story steel structure for SHM application ........................................................ 27

3.2 Elevation view of E-W Special Steel Moment Resisting......................................................... 28

3.3 Reduced Beam Sections ........................................................................................................... 29

3.4 N-S Special Steel Concentrically Braced Frame Elevation ..................................................... 30

3.5 N-S Concentrically Braced Frame Elevation and Bracing Members ...................................... 30

3.6 A992 Steel Stress vs. Strain ..................................................................................................... 33

3.7: (a) E-W Pushover Collapse Mechanism and (b) Damage States 1-3 considered as

part of the SHM investigation in Chapter 4............................................................................. 36

3.8 E-W Pushover Curve: Base Shear vs. Displacement ............................................................... 36

3.9 (a) N-S Pushover Collapse Mechanism and (b) Damage States 1-3 considered as

part of the SHM investigation in Chapter 4............................................................................. 38

3.10 N-S Pushover Curve: Base Shear vs. Displacement .............................................................. 38

4.1 Instrumentation of the Special Steel Moment Resisting Frame ............................................... 42

4.2 First Three Modes of the Special Steel Moment Resisting Frame ........................................... 43

4.3 Moment Frame Yield Event Diagram...................................................................................... 44

4.4 Instrumentation of the Special Steel Concentrically Braced Frame ........................................ 47

4.5 First Three Modes of the Special Steel Concentrically Braced Frame .................................... 48

4.6 SSCBF Yield Event Diagram .................................................................................................. 49

ix

1

CHAPTER 1. INTRODUCTION

1.1

Motivation

To address the many complexities in structural design of buildings and other structures, and to

simplify the design process of ordinary structures, engineers often rely on provisions from

established organizations such as the American Society of Civil Engineering 7 (2010) for

minimum loads to apply to buildings, and the American Institute of Steel Construction (AISC,

2011) and the American Concrete Institute (ACI, 2012) for nominal strength equations. These

provisions are widely accepted methods for design, providing the designer with loading

information, suitable analysis approaches, and material and member strength capacities. During

design, mean values of material properties are routinely used, as are simplified analysis

techniques to save costly design time. Examples of the latter include soil structure interaction, and

connection behavior – the effects of which are usually ignored. Modern design methodologies,

such as Load Resistance and Factor Design (LRFD) (ASCE, 2010) are useful in resolving the

statistical distribution of building materials and structural loadings, leading to load combination

equations with amplification factors based on the variability of each load. For example, live load

surveys have demonstrated much more scatter about the mean load as compared to dead loads,

and thus, after a structural reliability analysis, are assigned higher load factors (1.6 as compared

to 1.2 for dead loads). In the same reliability analysis, capacity reduction factors are applied to

nominal connection and member strengths according to a target safety index for the component.

The goal of LRFD is to provide an economical design in service load situations, while guarding

against catastrophic failure in overload situations.

While reliable and safe, typical design and the inherent assumptions made therein, leads to a

product, which lacks the level of precision of those in other engineering fields. Additionally, as

2

the building or bridge structure ages, visual inspections are often the only method used to ensure

that society is safe to utilize the structure for its intended purpose. It is not common to precisely

verify, through instrumentation, the actual performance of the structure. Beyond the design

calculations and analysis models, which may be very accurate in some instances, it is difficult to

know the actual load paths and their magnitudes of the built structure. In addition, assessing any

damage or ageing of a structure is left up to annual building inspection. During inspections, when

serious issues are found, the structure may be taken out of service until a solution can be designed

and constructed. At this point, the opportunity may have passed to implement a cheaper and

easier solution to the initially smaller problem.

Structural Health Monitoring (SHM) is a technique that can provide information as to the load

demands on existing structures, while also assessing the overall integrity of the structural system.

There are various methods that are currently used to accomplish this goal, but they all rely on

instruments such as strain gauges and accelerometers, combined with data acquisition systems

and, in some cases, wireless communication technology. With all of these components, a SHM

system creates a neural system of sensors and central data processing to monitor the real-time

performance of the structure and assess potential damage. Damageability can be detected through

a number of post-processing routines using ambient vibration measurements from recorded

accelerations, displacements, or material strains. By applying basic engineering principles all the

way through to sophisticated structural verification, one can find the structural stiffness of a story,

member, connection, or even a critical zone of a member. A permanent reduction in stiffness

implies that the monitored element has undergone damage.

While the SHM system allows engineers to monitor load demands on critical members, as well as

damageability states, the system also provides a feedback loop to help improve future modeling

3

capabilities. The purpose of this project is to describe the basic principles of SHM and provide a

sample instrumentation plan for a 4-story building that uses a moment resisting frame and

concentrically braced frame to resist lateral loads. A seismic loading case is considered for this

sample building, in which the SHM system is designed for using a method of vibration-based

SHM that evaluates structural health through operational and ambient vibrations.

1.2

Objectives and Scope

The first objective of this document is to provide a thorough review of available SHM literature.

This review is to include information from the initial development of SHM through to

contemporary research being conducted. The purpose of the literature review is to compile a set

of information that the reader can use to develop a clear understanding of the background and

requirements of the discipline. The intent is to leave the reader with stronger grasp of how to

design and implement a SHM system, by referencing common methods, challenges, and potential

solutions.

The second objective of this document is to derive the theory behind a specific SHM method

referred to as the Modal Strain Energy Method as it was first stated by Stubbs and Kim in their

research document titled “Field Verification of Non-destructive Damage Localization and

Severity Estimation Algorithm” (Stubbs 1996). This method was developed for dynamic bridge

monitoring, and is now widely implemented for many other structures. Since the initial

development of this theory, others have since expanded it for use in more specific cases such as

bending plates and detailed damage severity estimations.

The final objective of this document is to provide the reader with a detailed example of a partial

design of a SHM system for a 4-story steel building using special moment resisting and special

4

concentrically braced lateral force resisting systems. The design will be based on modal analyses

and pushover analyses to determine important locations to monitor on the building. The layout of

the story specific SHM sensor system will then be created from this information. The pushover

analysis will also provide a collapse event timetable to create realistic damage cases to use the

MSEM to theoretically detect damage after each event. Recommendations will be made as to

further SHM system design, as well as revisit key design concepts mentioned in the literature

review.

1.3

Organization and Outline

Chapter 2 shall be composed of the SHM literature review. The review is to be guided by the

requirements of the SHM system, theoretical implications, and instrumentation obstacles

presented during the general design of the SHM system. Basic guidelines to SHM system design

will follow from this. These guidelines are intended to be extensions of decisions that the

designer will need to make before, and during design process to arrive at the ideal SHM system

for the structure. Lastly, this chapter will lay out the theory behind the Modal Strain Energy

method of SHM. This theoretical development will involve equation derivation for stiffness

calculation and statistical layout of data processing based on the theory originally developed by

N. Stubbs and J.-T. Kim, and using numerical approximations mentioned in Appendix C and D.

Chapter 3 will begin with a description of the design of a SHM system for a four-story steel

building. Details for the lateral force resisting system will be described for both lateral axis of the

building. A list of SHM system assumptions and their reasoning will be defined. The SHM

system will be designed to monitor for seismic loadings as well as system stiffness reduction,

therefore these criteria will guide the reasoning behind the assumptions and the design analysis.

Finally, pushover analyses will be performed and their results summarized for the structure. A

5

brief narrative will be provided to guide the reader through the analysis and how the results will

aid in the SHM system design.

In chapter 4, the information from chapter 3 will be used to instrument the four-story steel

building. Sensor type, and placement will be shown, along with the reasoning behind the layout.

For each lateral force resisting system, the results of the pushover analysis will be used to create

three damage cases that the MSEM algorithm will be used to detect damage in. Damage detection

results will be summarized in a table for each lateral force resisting system.

Chapter 5 will provide a summary of the report as well as recommendations for future

investigation of the SHM system. This chapter will also aim to complete the document with key

observations and conclusions drawn from the four-story steel building example with respect to

the information provided in the literature review.

6

CHAPTER 2. LITERATURE REVIEW AND MODAL STRAIN ENERGY

METHODOLOGY

The purpose of this literature review is to familiarize the reader with past research and

advancements in the field of SHM, and to develop a procedure for the design of the health

monitoring system of a 4-story steel building presented in subsequent chapters of this report. The

review includes literature from the earliest uses of SHM in civil structures, to contemporary

research currently being used in the field. This will provide a basis for the design and

implementation of a SHM system, and the framework of the modal strain-energy method for

SHM.

2.1

Goals and Limitations of Structural Health Monitoring

To monitor the health of a structure, the SHM system gathers data from the structure to infer

loading conditions. The measured data from the SHM system is used, along with engineering,

physics, and mathematics principles to evaluate the status of the structure in terms of damage and

its location. Because SHM infers structural behavior from actual in-field conditions, it becomes

an invaluable asset for, not only damage detection, but design confirmation.

2.1.1

The Process of Structural Health Monitoring

A general process for SHM and system design was described in a book titled “Fibre Optic

Methods for Structural Health Monitoring” (Glisic 2007). The process outlined key phases of

SHM system design and related tasks, and is as follows.

i.

Establishment of the goal(s) of health monitoring

ii.

Identifying and selecting representative parameters to be monitored

iii.

Selecting appropriate monitoring systems

7

iv.

Designing the sensor network

v.

Establishing the monitoring schedule

vi.

Developing the data exploitation system

vii.

Developing the cost of the monitoring system

For the purposes of this document, these concepts will be used and frequently revisited. The

following subsections outline the requirements and deliberation of each of the above mentioned

phases.

2.1.1.1 Establishment of the Goal(s) of Health Monitoring

Clearly defining the goals of the SHM system is important because there are several types of

monitoring systems that each accomplishes a separate set of goals. Defining the goals involve

careful outlining of objectives for the SHM system. A few helpful questions that can help target

the goals are as follows.

a. What is the level of monitoring required (simple low level monitoring or high level

detailed monitoring)?

b. How extensive does the monitoring need to be (comprehensive monitoring or partial

monitoring)?

The intent of defining SHM goals is to outline a scope and avoid designing a system that falls

short of its expectations or includes unnecessary and expensive appurtenances. As mentioned

previously, the goal of SHM for the context of this report will be to detect seismic damage to a

steel moment resisting frame and braced frame.

8

2.1.1.2 Identifying and Selecting Representative Parameters to be Monitored

Some examples of parameters that can be monitored are material strain at a key location on the

structure, or acceleration or deflections at a location in the building. The choice of parameters to

be monitored by the SHM system is related to the list of SHM goals and scope defined in the first

phase of SHM system design. It can be a complicated and tedious process to develop the list of

parameters, so the list of goals and scope can help abate the task. In general, a detailed structural

analysis is important in defining parameters to monitor. Analyses, such as a pushover analysis,

help identify areas of the structure that are at risk of damage. For example, if it is determined that

excessive building drift is a potential problem for the structure, instrumentation at each floor level

to monitor story drift in the building is appropriate; story drift being the parameter being

monitored. This process of choosing parameters gives the engineer a more clear direction to move

in as they begin to develop the finer details of the SHM system.

The parameters that will be monitored as part of this report are the accelerations at each level of a

steel moment frame and braced frame lateral resisting components of a building. In Chapter 3, the

report qualitatively discusses a method to use strain gauges to more precisely determine the

damaged area of specific members. Chapter 4 will then show how the acceleration data at each

level can be used to detect damage in a specific story level. This will be shown performed for

both frame systems.

2.1.1.3 Selecting Appropriate Monitoring Systems

The selection of the appropriate monitoring system type can be a challenging decision if a scope

is not clearly defined. In general, this decision is guided by the expected loadings and behavior of

the structure. For example, structures that are more predisposed to dynamic lateral loadings, such

9

as earthquakes and wind loads, require a different type of monitoring system then a structure that

is expected to experience larger amounts of creep, (material deformation caused from long term

stress) due to large gravity loads. Listed below, are the three types of SHM systems that currently

exist, and what they entail.

a. Static Monitoring: Monitoring of static parameters such as strains, deflections, and

curvature. These systems are economical and good for long term monitoring damage

from static loadings, such as creep.

b. Dynamic Monitoring: Monitoring dynamic parameters such as acceleration and

dynamic strains. These systems are good for monitoring dynamic loads caused by

earthquakes, wind loads, traffic, heavy machinery, etc.

c. System Identification and Modal Analysis: Monitoring parameters such as system

modal frequencies. These systems integrate elements of dynamic monitoring and

modal response to identify damage. This type of system often uses vibration in the

system to measure the structure’s response.

2.1.1.4 Designing the Sensor Network

In modern SHM systems, computers are used to collect, process, and summarize data given by

the sensors on the structure. The sensor network in the SHM system refers to the interconnected

neural network of sensors and their location on the structure. These sensors report their

measurement data to a central computer for data processing.

Minimizing the complexity of the sensor network is important for efficiency and economy. Aside

from complicated instrumentation requirements, complex systems can sometimes lead to data

10

processing problems and difficulties during instrumentation. This is discussed in further detail

later in this chapter, but is a factor in the design of the sensor network.

A few questions that can help guide the design of the sensor network are as follows.

a. What are the optimum locations for data readings on the structural system (such as areas

on the structure that are more prone to damage)?

b. Is there symmetry or other geometrical advantage in the structure that can allow the SHM

system to function with fewer sensors or by some other less complicated method?

c. Is there enough redundancy in the system to provide supportive data for calculations of

damage location?

2.1.1.5 Establishing the Monitoring Schedule

SHM systems also differ in how they collect data. Some systems collect data on a continuous

basis. Other systems collect data at certain time intervals, such as on a daily basis. It is even

possible to program the system to stay dormant until the structure experiences activity in its

sensors above a certain range, effectively reading data during a particular event.

Continuous systems are ideal for monitoring structures that are expected to change loading often,

such as a bridge with traffic loads, or a tall building that experiences large wind loads. Time

interval systems are optimal for monitoring the structural performance during the life of the

structure. This is good for evaluating structural creep as well as serviceability damage. Time

interval systems are not, however, well equipped for monitoring disastrous events such as

earthquakes. These systems would likely only record data at a single time instance during the

event, rather than at many time instances in the case of a continuous monitoring system. Dormant

systems are particularly useful for monitoring unpredictable events while still being efficient with

11

its data processing and storage. These systems do not require as much backup storage space for

data records since comprehensive data records for the entire structure are not created as often.

However, because data records are not as extensive for this monitoring schedule type, it may not

be an ideal system for special cases where structure loadings are constantly changing.

Regardless of the monitoring schedule type, the SHM system goals, defined earlier, need to

support this decision. Several helpful questions to consider during the decision-making process

are as follows. What are the goals of the SHM system and how do they relate to the monitoring

schedule? What are the chances of an earthquake, heavy wind storm, or other unpredictable

event, in which continuous monitoring would be necessary? Are there any hazards that the system

would not be prepared for if the structure was not continuously monitored? If unpredictable

events and other hazards are not an issue, is there another reason that the structure requires

continuous monitoring? What is the SHM financial budget, and how will it be affected by the

choice of monitoring schedule?

2.1.1.6 Developing the Data Exploitation System

Data exploitation involves extraction and processing of sensor data. The first step in this process

requires the sensors in the sensor network to obtain data by measuring a quality of the structure.

Once the sensors have obtained data from the structure, they must send the data to the central

computer through a communication network. The central computer then processes the data to a

useable state and reports the findings. During the data processing step extensive data

manipulation, using material properties, geometry, and time history data is necessary. The type of

data manipulation depends on the type of SHM system as defined by the previous phases. In the

case of the seismic force resisting 4-story steel building example that will be discussed in chapter

3 and 4, data manipulation involves calculations as per the modal strain-energy method, as

12

described in section 2.3. It is also important to note that data processing can be strenuous in

regards to computer processing, and can thus present a few issues that are discussed later in

section 2.2.

2.1.1.7 Developing the Cost of the Monitoring System

The last phase of SHM system development is evaluating the system in terms of its financial cost.

Costs of design, instrumentation, operation, and maintenance are all factors in this evaluation. In

the cases where the SHM system is deemed too expensive by the owner, it is important to prepare

evidence to support the current system design, as well as prepare a list of elements of the SHM

system that can be reduced or removed and the consequences of doing so. To help identify

elements of the SHM system that can be reduced or removed, the engineer should reconsider the

scope and goals of the SHM system in terms of its sensor network, monitoring schedule, etc.

2.1.2

Facts and Limitations of Structural Health Monitoring

Like other disciplines, SHM has physical restrictions that limit it. In a paper titled “The

Fundamental Axioms of Structural Health Monitoring” (Worden 2007), the authors attempt to

describe the foundation of SHM in terms of its limitations and fundamental scientific truths.

The following is a list of the most important fundamental truths of SHM followed by a brief

description of each item.

i.

All materials have flaws

ii.

Two system states must be compared to assess damage

iii.

There are various depths of damage detection

iv.

Sensors cannot measure damage

v.

SHM sensing systems are defined by how damage is initiated and evolved

13

vi.

There is a tradeoff between damage sensitivity and noise

2.1.2.1 All Materials Have Flaws

Regardless of how a material is formed, flaws are always present because of a variety of

contributing factors. For example, some flaws result from the arrangement of material particles at

the molecular level, in which the presence of electrical signals, heat, or large/small dissimilar

molecules alter the arrangement of molecules in a material lattice, and thus change the behavior

of the material. In the field of material science and engineering, engineers and scientists use

material flaws to gain specific properties in the material. In the case of carbon steel, a small

amount of carbon is alloyed with iron to change the lattice arrangement of the iron atoms to give

carbon steel the properties that it is known for.

Unfortunately, there are no practical methods that allow a material to be formed without any

flaws. This results in uniquely flawed materials, in which determining its actual material

properties, such as elastic strength and yield strength, are difficult to do without extensive

material testing. Consequently, engineers must rely on material classifications that regulate the

formation of a material in order to assume material properties that have been empirically

approximated through extensive material testing.

2.1.2.2 Two System States Must Be Compared To Assess Damage

As described earlier, SHM systems determine the health of a structure from a system of sensors

that measure qualities in the structure. The SHM system does not measure damage directly, but

rather, it compares the structure’s current state to its undamaged state in order to assess damage in

the structure. There are a variety of different methods that take advantage of sensor readings on

the newly built structure to use for its undamaged state, however, in the case of the modal strain

14

energy method of SHM, which shall be the focus of the later chapters of this document, the

undamaged state can either be determined from sensor readings of the structure before damage

has occurred, or a theoretical state determined from elastic properties of the structure’s materials.

2.1.2.3 There are Various Depths of Damage Detection

In general, there are four levels of damage detection in a structure; each requiring a different level

of human supervision. The first level is the detection of damage in the structure. This can be done

solely by means of computer calculation; i.e. minimal human supervision is necessary for this

level of detection. The second level is pinpointing the location of damage. Again, this can usually

be done solely by means of computer calculation, requiring minimal human supervision. The

third level is detecting the type of damage (cracks, yield, breaks). At this level, it becomes

difficult for the SHM system to correctly identify damage types. With special instrumentation, it

is possible for the SHM system to classify the type of damage, however, the only way to confirm

this classification is through physical human inspection. Finally, the last level of damage

detection is ranking the severity of damage. With special instrumentation, a SHM system can give

a preliminary severity ranking to damage, however this must be confirmed with physical human

inspection as many factors can contribute to error in this preliminary severity ranking, such as

noise or uncommon damage types.

In the case of the MSEM, discussed later in this chapter, the level of damage detection will be

focused on existence and location of damage.

2.1.2.4 Sensors Cannot Measure Damage

As previous discussions in this document have alluded to, sensors cannot measure damage

directly. Sensors, instead, measure a quality such as strain or displacement, and through data

15

processing are able to infer the existence or non-existence of damage in the structure. For

instance, standard displacement transducers measure a one-dimensional relative displacement

between two points. However, they are commonly used to estimate the propagation of cracks

(increased damage) by measuring the displacement between opposite sides of the crack, i.e. how

much the crack has opened up. A change of displacement between opposite sides of the crack

results in a change in the propagation of the crack and, thus, the possibility of new damage in the

structure. The sensor only aids in the detection and/or evaluation of damage by providing data to

the SHM system to process.

2.1.2.5 SHM Sensing Systems are Defined by how Damage is Initiated and Evolved

Just as there are different avenues in which damage can occur in a structure, there are different

types of SHM sensing systems that are appropriate for various situations. For instance, damage

from seismic loadings tend to be better evaluated using VBSHM, where as damage from creep is

usually better evaluated using a static monitoring system. Furthermore, impact type loads to a

structure usually cause localized damage requiring more localized monitoring, while cyclic wind

loads can cause system fatigue, which require system wide monitoring. Each SHM system

operates uniquely, thus, it is important for the engineer to understand the type of damage and the

time scales on which the system will operate. The following is a list of properties that should be

considered for the SHM sensing system.

(i.)

Types of data to be acquired.

(ii.)

Sensor types, number, and locations.

(iii.)

Bandwidth, sensitivity, and dynamic range.

(iv.)

Data acquisition/telemetry/storage system.

(v.)

Power requirements.

16

(vi.)

Sampling intervals (continuous monitoring versus monitoring only after extreme

events or at periodic intervals).

(vii.)

Processor/memory requirements.

(viii.)

Excitation source (active sensing).

(Worden 2007)

The following, is a list of factors that should be considered during the selection of SHM

hardware:

(i.)

The length-scales on which damage is to be detected.

(ii.)

The time-scale on which damage evolves.

(iii.)

How will varying and/or adverse operational and environmental conditions affect the

sensing system.

(iv.)

Cost

(Worden 2007)

This list pinpoints key functions of the hardware to consider during selection, and, ultimately,

aids in the selection of ideal hardware in the SHM system.

2.1.2.6 There is a Tradeoff between Damage Sensitivity and Noise

Sensitive equipment is more receptive to small deviations in measurement. However, with this

gain in sensitivity, a susceptibility to data noise is also gained. Since hyper-sensitive equipment

can detect slight measurement changes, it is also more prone to detecting slight measurement

changes due to foreign environmental conditions. Thus, there is a fundamental tradeoff between

monitoring system sensitivity and noise in the data readings. For example, an exposed

17

hypersensitive accelerometer is prone to measuring vibrations of the instrument from wind

blowing past it rather than only measuring vibrations from the structure. This creates small

fluctuations in data readings that, if not handled correctly can lead to compounding error during

data processing.

2.2

Past and Present Issues in Structural Health Monitoring

SHM in civil structures is still a relatively young discipline compared to other engineering fields.

Although SHM systems are currently being implemented for a wide variety of purposes, it still

has much foreseeable growth in the future. Despite this, the field of SHM has overcome many

obstacles in the past, which is one of the reasons it has become such a promising field. While

some of the obstacles have grown obsolete due to technological advancements, others have been

overcome due to refinement in common SHM practices. Unfortunately, some obstacles still exist

and are contemporary research topics in SHM. This chapter seeks to present some of the major

challenges that SHM is faced with and how it has or has not overcome them.

2.2.1

Structural Health Monitoring Economy

SHM systems are expensive due to the large amount of design work, instrumentation, operation,

and maintenance necessary to implement a SHM system. Despite the many benefits of SHM,

owners are often reluctant to agree to the additional costs to implement a SHM system when,

from their perspective, the structure is fully stable without it. Cost-benefit studies are conducted

to provide evidence to the owner that the benefits of a SHM system outweigh the cost of SHM

system.

Generally, in today’s market, sensors and other instrumentation are more widely available at a

relatively inexpensive price compared to the past. The growth of the SHM field has created a

18

higher demand in this market, and has allowed suppliers to respond with lower prices. As the

field continues to develop, it is likely that more standardized SHM practices will be developed,

which will allow SHM systems to be more economically feasible.

However, other than relying on economic supply and demand to solely guide a cost-benefit

assessment, to further alleviate the financial objections of an owner to the implementation of a

SHM system, the cost-benefit assessment should consider how the following benefits relate to the

system.

a. Structural safety protection.

b. Decreased response time for inspection and repair after a traumatic event.

c. Data guided building inspections to improve the efficiency of them.

d. Possibility for cheaper repairs (if caught before failure).

e. Historical data for future research and retrofit design.

2.2.2

Structural Health Monitoring Instrumentation

Instrumentation for SHM can be challenging because it requires that every sensor be accessible

by personnel (for inspection, repair, or replacement) and computer (for data processing) via wires

or radio signal. This can create complications during instrumentation because the locations of

sensors and wires are restricted by the placement of necessary structural elements and other

furnishings. To avoid this, it is important to coordinate with the architect and other engineers

(MEP, etc.) to carefully instrument the structure and minimize these types of conflicts. Wireless

sensors have become popular recently because they avoid complicated wiring and allow their data

transmittal to be centralized in small communication hubs that report to the central computer. The

communication hubs can be placed in easily accessible areas which helps reduce the problem of

19

instrument access and wiring concerns. Currently, wireless sensors have become ideal because

wireless communication networks, capable of transmitting large amounts of data, can be installed

at a relatively low cost.

Historically, over instrumentation has been known to cause problems during data processing.

Computer processors have a finite amount of data that can be processed at one time. Exceeding

the amount of data that the processor is capable of handling can slow the system down and

potentially freeze it due to overload. Since each additional sensor provides more data for the

system to process, over instrumentation is a common cause of processor overload. In today’s

market, however, processing power is more advanced than it was in the past. Data overload is less

of a concern because the processor capacity is higher, and therefore the overload threshold is

more distant.

2.2.3

Data Processing and Communications

SHM actively relies on a system that communicates between sensor and central computer for data

processing and management. In systems that utilize radio signals to send data to the central

computer, an appropriately sized network connection is necessary. Twenty years ago, dial-up

connections were popular, but would not be sufficient for the size of data transfer required by a

SHM system, according to Brownjohn (2006). Although dial-up connections are obsolete in

America, some of the more advanced communications networks can also be considered too slow

for SHM. In a paper entitled “Structural Health Monitoring on Civil Infrastructure” (Brownjohn

2006), the author estimates an average SHM system requiring at least 700 kbps/3G data

connectivity for data compression and pre-processing in the SHM system. However, this

connectivity rate demand is not uncommon and can easily be met by communication networks in

today’s market.

20

2.2.4

Research and Development

In a paper entitled “Structural Health Monitoring on Civil Infrastructure” (Brownjohn 2006), the

author stresses the necessity of continued research. Although researchers in the field have

scientifically tested all concepts referenced by this document, many unverified theories exist.

Additionally, many tested theories still require more verification to be fully recognized as an

acceptable method of SHM. Brownjohn (2006) notes that SHM often loses grant funding

opportunities to fields that have more immediate results and conclusions. In fact, he explains that

much of the early research and testing in SHM was financed by owners rather than grant money

from the scientific community. Currently, grant funded research is more common, but still a

contributing factor to the growth speed of the field.

SHM also requires the contribution of many disciplines: structural engineers, mechanical

engineers, electrical engineers, computer engineers, and communications engineers. Brownjohn

(2006) explains that, in the past, a lack of collaboration has existed within the research realm of

SHM. Unfortunately, this issue is still apparent and the only way to relieve it is to create

awareness of it.

2.3

The Modal Strain Energy Method of Structural Health Monitoring

The Modal Strain Energy Method (MSEM), also known as the Modal Stiffness technique, was

first proposed in the paper entitled “Field Verification of Nondestructive Damage Localization

Severity” (Stubbs 1996). This report presented the theory behind the MSEM and then attempted

to prove its effectiveness with a full scale example.

The MSEM is a SHM method that falls under the umbrella of Vibration-Based SHM (VBSHM).

These methods are rooted in detecting structural damage by using vibrations to extract

21

information from the entire damaged structure to compare it to previous structural data from

when the structure was still undamaged.

The behavior of a structure is dependent on the behavior of its individual elements; therefore

changes in those elements, such as damage, create a global change. This allows the possibility to

sense local damage from a global perspective. In the case of the MSEM the mode shapes of the

structure provide the global perspective and means to sense member stiffness loss, caused by

damage, at a local level.

For VBSHM, vibrations in the structure are necessary for damage detection. In the past, many

methods of evoking vibrations have been used. Some older techniques involved sending constant

vibrations into the structure by the use of special vibration inducing equipment. This method has

since phased out and been replaced with Operational Modal Analysis (OMA). OMA takes

advantage of the ambient and operational vibrations, such as traffic loads, for the damage

detection algorithm. OMA is ideal because it does not require expensive vibration inducing

equipment, and only requires that noise in the system be minimal. The minimization of noise has

been a popular research topic in OMA SHM in the past; however it is not part of the discussion of

this document. Through previous research, OMA has been confirmed to work conjunctively with

the MSEM, and thus is optimal for its implementation.

As mentioned earlier in this chapter, SHM depends on a comparison of two different states. The

basic process of the MSEM is to calculate the modal stiffness of each finite element member

(member) of an undamaged structure and compare it to the modal stiffness of the same member

on the potentially damaged structure (referred to from here on as the damaged structure). These

ratios are then used for damage detection by statistically pinpointing member ratios that indicate a

22

large decrease in stiffness. The result of this analysis allows the SHM system to locate where

damage has occurred in the structure.

The following is a theoretical development of the MSEM described above, as it was first

proposed by Stubbs and Kim (1996). For a more generalized description of the theory in matrix

form, see the “Vibration-Based Structural Health Monitoring of Highway Bridges” (CalTrans

2008).

For the undamaged structure, Equation 2.1 can be used to calculate the ith modal stiffness of the

structure.

𝐿

𝐾𝑖 = ∫0 𝑘(𝑥)[𝜙𝑖′′ (𝑥)]2 𝑑𝑥

Eqn. 2.1

Where L represents the length of the beam, x represents the location along the length of the beam,

𝑘(𝑥) represents the bending stiffness of the beam, and 𝜙𝑖′′ (𝑥) represents the second derivative of

the ith mode shape of the beam, 𝜙𝑖 (𝑥).

The jth member contributes the following member stiffness, 𝐶𝑖𝑗 , for the ith mode.

𝐶𝑖𝑗 = 𝑘𝑗 ∫𝑗 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥

Eqn. 2.2

In this equation, 𝑘𝑗 is the stiffness of the jth member.

The fractional modal stiffness of the jth member, Fij, can be calculated with the following equation

𝐹𝑖𝑗 =

𝐶𝑖𝑗

𝐾𝑖

Eqn. 2.3

23

The parameters in Equations 2.1, 2.2, and 2.3 can also be calculated for the damaged structure

where asterisks are used to denote variables pertaining to the undamaged structure.

𝐿

∗

𝐾𝑖 ∗ = ∫0 𝑘 ∗ (𝑥)[𝜙𝑖′′ (𝑥)]2 𝑑𝑥

∗

𝐶𝑖𝑗 ∗ = 𝑘𝑗 ∗ ∫𝑗 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥

𝐹𝑖𝑗 ∗ =

𝐶𝑖𝑗 ∗

𝐾𝑖 ∗

Eqn. 2.4

Eqn. 2.5

Eqn. 2.6

By definition, the sum of all of the ith modal stiffnesses for the structure is equal to unity –

∗

𝑁𝐸

∑𝑁𝐸

𝑗=1 𝐹𝑖𝑗 = ∑𝑗=1 𝐹𝑖𝑗 = 1

Eqn. 2.8

Assuming that the structure is made up of multiple members –

𝐹𝑖𝑗 ≪ 1

Eqn. 2.9

𝐹𝑖𝑗 ∗ ≪ 1

Eqn. 2.10

Thus, Stubbs and Kim proposed the following relationship to compare the undamaged and

damaged states –

1 + 𝐹𝑖𝑗 ≈ 1 + 𝐹𝑖𝑗 ∗

Eqn. 2.11

Stubbs and Kim (1996) were able to show that this was a good assumption for a bridge with 50

elements. In general, they pointed out that with their example, each element contributed roughly

2% of the entire structure’s stiffness. However, based on previous research, it is not apparent

what the exact limit is for Equation 2.11 to be an acceptable assumption.

24

This relationship can be used to find the ratio between the stiffness of the undamaged to the

damaged structure by substituting Equations 2.3 and 2.6 into Equation 2.11 and normalizing –

𝐶𝑖𝑗∗

𝐾𝑖 ∗

𝐶𝑖𝑗

1+

𝐾𝑖

1+

1=

=

(𝐶𝑖𝑗 ∗ +𝐾𝑖 ∗ )𝐾𝑖

Eqn. 2.12

(𝐶𝑖𝑗 +𝐾𝑖 )𝐾𝑖 ∗

Substituting Equations 2.1, 2.2, 2.4, and 2.5 into Equation 2.12 yields the following –

∗

1=

∗

𝐿

𝐿

(𝑘𝑗 ∗ ∫𝑗 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥 +∫0 𝑘 ∗ (𝑥)[𝜙𝑖′′ (𝑥)]2 𝑑𝑥) ∫0 𝑘(𝑥)[𝜙𝑖′′ (𝑥)]2 𝑑𝑥

𝐿

∗

𝐿

(𝑘𝑗 ∫𝑗 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥 +∫0 𝑘(𝑥)[𝜙𝑖′′ (𝑥)]2 𝑑𝑥) ∫0 𝑘 ∗ (𝑥)[𝜙𝑖′′ (𝑥)]2 𝑑𝑥

Eqn. 2.13

Stubbs and Kim then make an assumption that the total stiffness of the structure remains

relatively unchanged, namely that 𝑘 ∗ (𝑥) ≈ 𝑘(𝑥), so that these terms may be canceled. Stubbs and

Kim were able to show that this assumption is valid for damages of at least 30%, while Li et. al

(2006) were able to show that this assumption was valid for locating damage in a building story

level even after completely removing all brace components of one story’s frame, effectively

reducing the story’s stiffness by a large percent. Based on previous research, however, there is not

a clear limit that exists for this assumption to stay valid.

The term 𝑘𝑗 ∗ can be factored from the top equation, and the term 𝑘𝑗 from the bottom equation.

These terms can then be divided out onto the other side of the equation to reveal an important

ratio. This ratio is the ratio of the stiffness of the undamaged structure to the damaged structure.

The following is the resulting equation.

∗

𝐿

∗

𝐿

𝑘𝑗

(∫𝑗 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥+∫0 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥) ∫0 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥

𝑗

∗

𝐿

𝐿

(∫𝑗 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥+∫0 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥) ∫0 [𝜙𝑖′′ (𝑥)]2 𝑑𝑥

𝛽𝑗𝑖 = 𝑘 ∗ =

=

𝑁𝑈𝑀𝑗𝑖

𝐷𝐸𝑁𝑗𝑖

Eqn. 2.14

25

If undamaged, ij should be equal to one, whereas a positive result would indicate a relative

decrease in modal stiffness of the jth member with respect to mode i. A negative result would

indicate that a relative increase in member modal stiffness has occurred, which can be interpreted

as a shift in structural system stiffness, from a damaged member to the jth member.

By summing these ratios for all modes, a single indicator for the jth member can be found –

𝛽𝑗 =

∑𝑖 𝑁𝑈𝑀𝑗𝑖

∑𝑖 𝐷𝐸𝑁𝑗𝑖

Eqn. 2.15

Using a standard score normalization the normalized classification value can be obtained –

𝑍𝑗 =

(𝛽𝑗 −𝜇𝛽𝑗 )

𝜎𝛽𝑗

Eqn. 2.16

In this equation, 𝜇𝛽𝑗 is the mean value of 𝛽𝑗 ’s measured, and 𝜎𝛽𝑗 is the standard deviation of this.

𝑍𝑗 is called the damage indicator, where a large positive value is a higher indication that damage

has occurred, where negative values, and values closer to zero tend to represent a global shift in

relative stiffness.

As shown in equation 2.14, the MSEM relies solely on the second derivative of the mode shapes.

To obtain these, the SHM sensor system must first obtain the mode shapes from the sensor data.

The process known as Time Domain Decomposition Technique, which is summarized in

Appendix C, is used to extract mode shape data from time variant modal data such as

instantaneous modal acceleration or dynamic modal strain data. To obtain modal data from

measured data, band-pass filters can be used to separate data into their modal contributions using

a frequency range for each mode. Once the modal data has been decomposed using the band-pass

filters, and the mode shapes are extracted using the Time Domain Decomposition Technique, the

26

second derivative of the mode shape/modal curvature, can be obtained through numerical

approximation. See Appendix D for information on numerical methods for estimating modal

curvature.

This method and theoretical framework will form the basis of the design of the SHM system and

the placement of sensors described in Chapters 3 and 4.

27

CHAPTER 3. ARCHETYPE BUILDING DESCRIPTION AND PUSHOVER

ANALYSIS

3.1

Project Introduction

To gain a better understanding of SHM, this chapter and the subsequent chapters will provide an

in depth look at the partial design of a SHM system that monitors seismic activity for a four story

steel building comprised of special steel moment frames and special steel concentrically braced

frames designed to resist lateral loads. The SHM system will be designed to monitor lateral

seismic loading on the building.

The layout of the building is from example 4.3 and 5.3 in the 2nd edition of the AISC Seismic

Design Manual (AISC 2012). Below is a plan view of the building. All floors and roof have the

same geometric layout. The floor and roof levels are also assumed to function as a rigid

diaphragm. This allows the dynamics of the building during a cyclic load to be modeled using a

kinematic condensation approach to decrease the amount of degrees of freedom that are

dynamically contributing to the system.

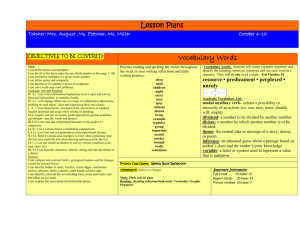

Figure 3.1 Plan view of 4-story steel structure for SHM application

28

This building is ideal for this example because it integrates two different lateral force-resisting

systems that contrast how different frames can be instrumented with the SHM sensor system.

The SHM sensing system will be largely made up of dynamic strain gauges and accelerometers.

Dynamic strain gauges are sensors that measure the strain, change in length, and its change over

time on the surface of a member at a particular location. Accelerometers measure the

instantaneous acceleration at a particular location. This allows the SHM system to locate damage

as per the MSEM. Details for strain gauge, accelerometer types, and sensor layout for each frame

type can be found in chapter 4.

3.1.1

East –West: Special Steel Moment Resisting Frame

The lateral force resisting system in the east-west direction of the building is comprised of two

identical, symmetric, Special Steel Moment Resisting Frames. The geometry of these frames is

summarized in the following elevation drawing.

Figure 3.2 Elevation view of E-W Special Steel Moment Resisting

29

The following figure and table summarize the reduced beam sections in the frame.

Figure 3.3 Reduced Beam Sections

Table 3.1 Reduced Beam Section (RBS) Geometry Values

D (in.)

bbf (in.)

a (in.)

b (in.)

c (in.)

R (in.)

bbf-RBS (in.)

I0 (in4)

IRBS (in4)

3.1.2

W21x44

20.7

6.5

4

16

1

32.2

5.4

843

833

W24x76

23.9

8.99

5.5

18

2

21.3

6.75

2100

2065

North-South: Special Steel Concentrically Braced Frame

The lateral force resisting system in the north-south direction of the building is comprised of two

identical, symmetric, Special Steel Concentrically Braced Frames. These frames are summarized

in the following elevation drawing.

30

Figure 3.4 N-S Special Steel Concentrically Braced Frame Elevation

The following figure summarizes the tube steel bracing pattern and sections in the frame.

Brace shapes

Story

Designation

4

HSS6.00x0.312

3

HSS6.875x0.500

2

HSS7.500x0.500

1

HSS8.625x0.500

Figure 3.5 N-S Concentrically Braced Frame Elevation and Bracing Members

31

3.2

Structural Health Monitoring Assumptions

Since the MSEM relies on comparison of the potentially damaged structure state to an idealized

undamaged elastic structure state, a few assumptions are necessary to make for the idealized

model.

3.2.1

Gravity Loads and Lateral Loads

Gravity loads include the weight of the building and all of its expected loads. Since in reality,

gravity loads will always be acting on the structure whether it is experiencing seismic activity or

not, a nonlinear representation of the structure (model) will be created to account for geometric

nonlinearity in the structure caused by the gravity loads before any lateral seismic forces are

applied. This representation will ideally give results that more accurately reflect what is

happening in the field. Below is a table that summarizes the assumed loads on the structure for

the ideal gravity load case.

Table 3.2 Dead and Live Loads on the Structure

LOAD

Dfloor

Droof

L0,floor

Lfloor

S

Curtain Wall

VALUE

85 psf

68 psf

80 psf

50 psf (reduced)

20 psf

175 lb/ft

Below is a table that summarizes the Seismic Design Criteria as per ASCE 7-10.

32

Table 3.3 Seismic Design Criteria as per ASCE 7-10

SEISMIC DESIGN

CRITERIA

Risk Category

Seismic Design Category

R

Ω0

Cd

Ie

SDS

ρ

VALUE

FOR

SSMRF

I

D

8

3

5.5

1.0

1.0

1.0

VALUE

FOR

SSCBF

I

D

6

2

5

1.0

1.0

1.0

This criterion is used to find the vertical distribution of seismic force ratios as per the ASCE 7-10.

These ratios will be used to examine the behavior of the structure after member yield has

occurred. The member yield events will be determined through a pushover analysis, which will be

discussed in further detail later in this chapter. Below is a table depicting the vertical distribution

ratios.

Table 3.4 Vertical Distribution Ratios

Level

2

3

4

Roof

3.2.2

C vx

0.115

0.217

0.321

0.347

Material and Member Assumptions

All of the wide flange members are assumed to be made of ASTM A992 Carbon Steel and the

hollow structural section (HSS) braces are assumed to be ASTM A500 Grade B.

33

The members of the building will assume elasto-plastic material yield. For more information on

elasto-plastic material relationships, please refer to the text “Mechanics of Materials” (Gere

2009), or other mechanics of materials text. See below for a representative elasto-plastic stress

versus strain diagram.

Figure 3.6 A992 Steel Stress vs. Strain

All structural steel shapes are assumed to be of ideal dimension matching that in Table 1-1 of the

AISC Steel Construction Manual (AISC 2011). See Appendix A for a full list of structural steel

shape dimensions and properties referenced in this document.

The member connections are assumed to be designed as per the AISC Seismic Design Manual

(AISC 2012) and the AISC Steel Construction Manual (AISC 2011), and therefore stronger than

the structural members. With this assumption, the monitoring scope can be reduced to focus on

instrumentation of the structural members and not locally in the connections. However, with the

MSEM, a damaged connection will provide a loss of calculated stiffness in the structure, and can

thus be detected without physically assigning a sensor to monitor the connection, but physical

verification of damage by a human will be necessary.

34

3.3

Analysis Layout

In the E-W direction, two identical Special Steel Moment Resisting Frames resist the later

seismic forces. Since both identical frames ideally contribute the same rigidity, the assumption

that system torsion effects can be neglected in this direction. In the N-S direction, two identical

Special Steel Concentrically Braced Frames resist the lateral seismic forces. By the same

reasoning as was used the E-W direction, the assumption that system torsion effects can be

neglected in this direction as well.

Since torsion is assumed to not play a role in the behavior of the frames, the frames can be

analyzed as simple 2-dimensional frames rather than a more complicated 3-dimensional frame

representing the entire building. This also allows the identical frames to be instrumented

identically.

For each frame, north-south and east-west, a pushover analysis will be performed to assess

member yield events (damage cases) of the frame. A pushover analysis is a nonlinear analysis

that uses material nonlinearity combined with an increasing lateral load at which structural

members yield. With a pushover analysis, the ultimate capacity of a structure can be tracked as

members yield in sequence until the overall collapse of the structure. The pushover analysis will

be completed using an acceleration based increasing load. The absolute displacement at the roof

level will govern the analysis to structural collapse. The results from this analysis will be used as

a basis for the detail story specific monitoring system, to instrument story levels that are more

susceptible to damage. The results for the pushover analysis will also be used to determine the

most important yield events, to look at further in Chapter 4. Chapter 4 will focus on three yield

events as damage cases to determine the expected system stiffness loss and the expected damage

indication calculation.

35

3.4

East-West Frames: Pushover Analysis and Results

The east-west lateral force resisting system is composed of identical Special Steel Moment

Resisting Frames. The following is a narrative discussing the implementation of the pushover

analysis.

3.4.1

Pushover Analysis

As discussed earlier in this chapter, the pushover analysis in the east-west direction can be

conducted on a 2-dimensional frame. See Figure 3.2 and Figure 3.3 for specifics on the frame’s

geometry. For the analysis, the supports will be assumed as pins (no moment resistance), and the

elements will be frame members (resisting axial, shear, and moment loads).

The pushover analysis was completed for this lateral force resisting system using SAP2000. The

analysis was based on the SAP2000 acceleration-based increasing lateral load. The analysis was

monitored by roof level displacement until structural collapse.

3.4.2

Pushover Analysis Results

Below is a figure of the pushover collapse mechanism, where the circles represent plastic hinge

locations, and the pushover curve depicting base shear versus the monitored displacement at the

roof level.

36

(a)

(b)

Figure 3.7: (a) E-W Pushover Collapse Mechanism and (b) Damage States 1-3 considered as

part of the SHM investigation in Chapter 4.

Figure 3.8 E-W Pushover Curve: Base Shear vs. Displacement

The change of slope in the above graph is the result of member yielding. The resulting maximum

displacement before collapse during the pushover analysis is about 35 inches and maximum

recorded base shear was 461 kips occurring right before collapse.

The pushover analysis showed that most of the initial member yielding occurred in the second

floor level beam members, and later in the first story column members. The upper levels did not

experience member yielding until a collapse mechanism had already formed as shown in Figure

37

3.7. This suggests that the story specific SHM system should be focused more heavily on the first

story members compared to the upper levels since they are likely to be the first members to

experience loss of stiffness due to yielding.

A modal analysis showed that the mode 1, 2, and 3 periods were 1.0, 0.3, and 0.2 seconds

respectively. For more details on the push over analysis please see Appendix B.

3.5

North-South Frames: Pushover Analysis and Results

The north-south lateral force resisting system is composed of identical Special Steel

Concentrically Braced Frames. The following is a narrative describing the implementation of the

pushover analysis.

3.5.1

Pushover Analysis

As discussed earlier in this chapter, the pushover analysis in the north-south direction can be

conducted on a 2-dimensional frame due to the neglect of torsional effects. See Figure 3.4 and

Figure 3.5 N-S Concentrically Braced Frame Elevation and Bracing Members

for specifics on the frame’s geometry. For the analysis, the columns will be modeled as

continuous members that resist axial, shear, and moment loads. The beams will be modeled as

simply supported beams with pin supports. The braces will be modeled as truss members,

supporting only axial loads.

The pushover analysis was completed for this lateral force resisting system using SAP2000. The

analysis was based on the SAP2000 acceleration based increasing lateral load, and was

displacement controlled and monitored through until structural collapse.

38

3.5.2

Pushover Analysis Results

Below is a figure of the pushover collapse mechanism, where circles on braces represent brace

buckling and circles on columns represent plastic hinging, and the pushover curve depicting base

shear versus the monitored displacement at the roof level.

(a)

(b)

Figure 3.9 (a) N-S Pushover Collapse Mechanism and (b) Damage States 1-3 considered as

part of the SHM investigation in Chapter 4.

Figure 3.10 N-S Pushover Curve: Base Shear vs. Displacement

39

The change of slope in the above graph is the result of member yielding. The maximum base

shear recorded was about 690 kips at a displacement of about 20 inches.

The pushover analysis showed that most of the initial member yielding was in the first and second

story brace members. The levels above the second story did not experience member yielding

before a collapse mechanism was formed as per Figure 3.9. This shows that the story specific

SHM system should be focused more heavily on the first and second story braces compared to the

upper levels.

A modal analysis showed that the mode 1, 2, and 3 periods were 1.0, 0.3, and 0.2 seconds

respectively. For more details on the push over analysis please see Appendix B.

40

CHAPTER 4. PROPOSED ARCHETYPE BUILDING INSTRUMENTATION

SYSTEM DURING DYNAMIC LOADING

4.1

General Structural Health Monitoring Layout

4.1.1

Data Collection and Pre-processing

As chapter 2 discussed, the MSEM of SHM will be implemented for the example steel building

described in chapter 3. The MSEM requires modal shapes of the structure determined from

instrument measurement for its damage detection algorithm. For more information on the MSEM

please consult chapter 2.

OMA, as described in chapter 2, is used as the data gathering source for MSEM. From the data

collected (acceleration or dynamic strain data), for use in the MSEM algorithm, mode shapes of

the structure need to be estimated. In the past, this was a challenge because single data points are

difficult to decay into their modal contributions. Presently, with the development of band-pass

filters, a device used to accept data contributions during a certain frequency range and reject data

outside the range, it is possible to focus data collection on multiple frequency ranges to extract

the data’s modal contributions corresponding to the modal frequencies. For the band-pass filter

data extraction to correctly work, a range of frequencies need to be established for each mode

shape that will be used in the MSEM algorithm.

After the modal contribution data is gathered from the sensors using band-pass filter data

extraction, a numerical analysis is necessary to approximate the mode shapes. This analysis is

called Time Domain Decomposition Technique (TDDT) formally described in (Cal Trans 2008).

See Appendix C for more information on the TDDT.

41

The result of the TDDT numerical analysis is an approximation for the mode shapes of a

structure, or element of the structure, calculated over a time range. Modal curvature can be

estimated from the mode shapes as second derivatives of the mode shape curve and then used in

the MSEM algorithm.

4.1.2

General Sensor Layout

For the SHM of the example building, uniaxial accelerometers placed at each floor level, to

measure the motion of the floor slabs as the building experiences lateral excitation, and will be

used to gather mode shape data of the entire frame structure. These sensors will allow damage

detection to be located per story level, and will be the focus of further discussions in this

document. For story level detail monitoring, uniaxial dynamic strain gauges will be installed to

detect damage at the member level.

4.2

E-W: Special Steel Moment Resisting Frame Instrumentation and Analysis

Since Special Steel Moment Resisting Frames are designed for ductility in its beams and use

reduced beam sections to control beam yielding, it is important to monitor the reduced beam

sections. For this case, strain gauges shall be placed at the top flange of each reduced beam

section. Each beam will also have a strain gauge located at the center of the beam on the top

flange. This sensor will allow for monitoring of beam dynamics. This will be sufficient for beams

on the upper floors that are not expected to experience yielding until late in the frame collapse

mechanism. For the lower level beams, a more detailed strain gauge layout is necessary. This is

shown in Figure 4.1.

Strain gauges will also be installed above and below all column connections, as that is where

yielding is expected to occur in the columns. These gauges will be designed to monitor absolute

42

strain levels that exceed the columns elastic capacity and also work as a redundancy in the SHM

system.

For this example, however, the focus is on story level damage detection. As described earlier, this

damage detection is performed using accelerometers at each level to obtain the first three mode

shapes of the structure. Below is a diagram of the instrumentation of the Special Steel Moment

Resisting Frame that resists the lateral loads in the east-west direction.

Figure 4.1 Instrumentation of the Special Steel Moment Resisting Frame

Below is a diagram, generated by SAP2000, depicting the first three modes of the structure

respectively.

43

Figure 4.2 First Three Modes of the Special Steel Moment Resisting Frame

Below is a table with the mode shapes according to accelerometer locations at each floor,

generated by SAP2000’s modal analysis for each of the damage cases (yield events).

Sensor Location/

Story Level

Table 4.1 SSMRF Mode Shape Data

Damage States

Undamaged Case

Damage Case 1

Damage Case 2

Damage Case 3

{q}1

{q}2

{q}3

{q}1

{q}2

{q}3

{q}1

{q}2

{q}3

{q}1

{q}2

{q}3

1

2

3

-0.58

-0.82

-1.02

0.97

0.88

0.00

-1.03

0.16

1.27

-0.59

-0.84

-1.02

0.95

0.88

-0.02

1.04

-0.16

-1.26

0.59

0.86

1.02

0.94

0.87

-0.03

-1.05

0.16

1.25

-0.71

-0.90

-0.99

-1.03

-0.71

0.21

1.05

-0.48

-1.12

4

-1.17

-1.30

-0.77

-1.15

-1.32

0.77

1.13

-1.33

-0.77

-1.04

1.35

0.84

Below is a table summarizing the period of the respective modes for each damage case as per the

SAP2000 modal analysis.

44

Table 4.2 SSMRF Mode Period

Period (s)

Mode

1

2

3

Undamaged

Case

Damage

Case 1

Damage

Case 2

Damage

Case 3

1.0

0.3

0.2

1.1

0.3

0.2

1.2

0.3

0.2

1.8

0.4

0.2

For the following sections, please refer to the following diagram that depicts the order of yield

events from the pushover analysis. These events will be referred to as Damage Case 1, 2, and 3,

respectively.

Figure 4.3 Moment Frame Yield Event Diagram

Using the mode shape data, the second derivative of the mode shape was numerically

approximated and used in equation 2.15 to obtain the 𝛽𝑗 values that represent stiffness loss of

each column and beam member in the system. Using a standard score normalization, shown in

equation 2.16, 𝑍𝑗 values can be obtained which represent the damage indication. Because the

MSEM algorithm does not allow for an accurate member specific damage location within a

45

specific story, the stiffness loss ratios and damage indicators of each member in a story level was