Comparative study of the use of sarcosine, proline, and glycine as

advertisement

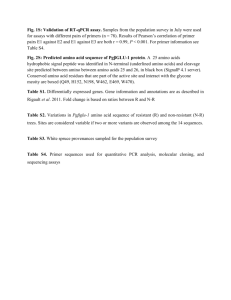

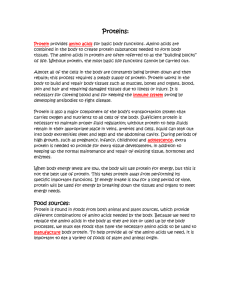

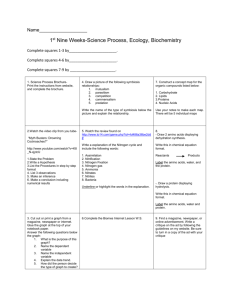

Comparative study of the use of sarcosine, proline, and glycine as acrylamide inhibitors in ripe olive processing Antonio Higinio Sánchez, Víctor Manuel Beato, Antonio López-López and Alfredo Montaño* Antonio Higinio Sánchez (ahiginio@cica.es), Food Biotechnology Department, Instituto de la Grasa (C.S.I.C.), Avenida Padre García Tejero 4, 41012 Seville, Spain Víctor Manuel Beato (vmbeagal@ig.csic.es), Food Biotechnology Department, Instituto de la Grasa (C.S.I.C.), Avenida Padre García Tejero 4, 41012 Seville, Spain Antonio López-López (all@cica.es), Food Biotechnology Department, Instituto de la Grasa (C.S.I.C.), Avenida Padre García Tejero 4, 41012 Seville, Spain * Corresponding autor. Alfredo Montaño (amontano@cica.es), Food Biotechnology Department, Instituto de la Grasa (C.S.I.C.), Avenida Padre García Tejero 4, 41012 Seville, Spain. Tel: +34 95 4691054, fax: +34 95 4691262 Acknowledgments This work was supported in part by the European Union (FEDER funds) and the Spanish government through Project AGL 2010-19178. Financial support from the Junta de Andalucía (group AGR-208) is also acknowledged. 1 Abstract 2 The main purpose of this study was to evaluate the inhibitory effect on acrylamide (AA) 3 formation and the impact on sensory characteristics in ripe olives of three selected 4 amino acids (sarcosine, proline, and glycine), which previously showed high AA 5 inhibition rates in an olive model system. Each amino acid was separately added to 6 packing solutions to give 100 or 200 mM at equilibrium, prior to a sterilization 7 treatment at 121 ºC. The results showed that sarcosine at 100 mM may be a good 8 candidate for reducing the AA content in ripe olives with a limited effect on sensory 9 characteristics. Studies with a model solution of AA and sarcosine heated at 121 ºC for 10 30 min suggested that the main mechanism for the inhibitory effect of sarcosine on AA 11 formation was the Michael reaction. 12 13 Keywords: Acrylamide; amino acids; glycine; proline; ripe olives; sarcosine 2 14 Introduction 15 Acrylamide (AA) aroused worldwide concern after 2002 when it was found that it could 16 be formed in foods during cooking (Tareke et al. 2002). This compound has been 17 classified by the International Agency for Research on Cancer (IARC) as a probable 18 human carcinogen (IARC 1994). Particular attention has been paid to potato products 19 and bakery products (Amrein et al. 2004; Taubert et al. 2004; Claus et al. 2008) because 20 of their high AA concentrations and their high rate of consumption as a staple food. The 21 formation of AA was believed to be generally associated with the application of harsh 22 heat treatments (e.g. roasting, baking, deep-frying) with temperatures exceeding 150 °C. 23 Astonishingly, although these heat conditions do not apply to ripe olive processing, this 24 product presents high levels of AA (200-2000 ng g-1) according to earlier exploratory 25 surveys (United States Food and Drug Administration 2006) and further studies (Casado 26 and Montaño 2008). 27 Ripe olives (also called “Californian-style table olives”) are one of the most 28 prominent classes of table olive commercialized in the world. In this type of processing 29 the olives, mostly in the green and cherry stages of ripening, are usually stored in brine 30 with 4-6% NaCl for 2-8 months, depending on production demand. The brine may be 31 acidified to pH 4 with acetic acid and kept under aerobic conditions to prevent spoilage. 32 Alternatively, the usage of acidified water (2.4% acetic acid) under anaerobic conditions 33 has been proposed (de Castro et al. 2007). Once the stored fruits are sorted and graded, 34 they are treated with a series of dilute NaOH solutions (lye) to remove their natural 35 bitterness, caused by oleuropein. Between lye treatments, the fruits are aerated. During 36 this operation, the fruits are progressively darkened by means of polyphenol oxidation. 37 After the lye treatments and oxidation, the olives are washed several times with water to 38 remove most of the residual lye, reaching a final pH of around 7, and placed in 3-5% 3 39 brine with ferrous gluconate or ferrous lactate to maintain the black colour. Finally, the 40 olives are canned in brine and heat sterilized, generally at 121-126 ºC (Sánchez et al. 41 2006). 42 The use of additives for the potential inhibition of AA formation is a strategy 43 that has been investigated in different foods, including ripe olives (Casado et al. 2010). 44 Sodium bisulfite was demonstrated to be the most effective compound to eliminate AA 45 in ripe olives, but this additive is not currently permitted in the EU (European 46 Commission 2011). Proline (Pro), sarcosine (N-methyl glycine; Sar), and glycine (Gly) 47 have also been demonstrated to be effective inhibitors of AA formation in a ripe olive 48 model system, although at concentrations 10 times higher compared to sulfite (López- 49 López et al. 2014). However, the effectiveness of these amino acids in real food and 50 their impact on the sensory characteristics of olives has not been provided. Although in 51 a previous publication (Casado and Montaño 2008) we demonstrated that AA in ripe 52 olives remained stable during storage for at least up to 6 months, the AA content could 53 change with storage time in the presence of AA-reducing additives. The mentioned 54 amino acids could form amino acid-AA adducts through the Michael addition type 55 reactions thereby reducing the AA content. This has been demonstrated for Pro and Gly 56 through the identification of the corresponding Michael adducts in aqueous model 57 systems (Koutsidis et al. 2009; Liu et al. 2011), but direct evidence for AA-Sar adduct 58 formation has not been provided. 59 Therefore, the aims of the present work were (1) to assess the impact of the 60 amino acids Sar, Pro and Gly on AA contents and on the sensory characteristics of ripe 61 olives, (2) to assess the stability of AA in the presence of added amino acids during 62 storage , and (3) to study the reaction between AA and Sar in an aqueous model system 4 63 heated at 121 ºC in order to confirm the type of reaction involved based on the 64 identification of the main reaction product by LC/MS. 65 66 Materials and methods 67 Chemicals 68 Individual amino acids (Gly, L-Pro, Sar) were supplied by Sigma-Aldrich (St. Louis, 69 MO, USA). Deionised water (Milli-Q; Millipore Corp.) was used throughout. All 70 reagents and chemicals used for the AA analysis were as described in Casado and 71 Montaño (2008). All other chemical and solvents were of analytical grade from various 72 suppliers. 73 74 Preparation of ripe olives 75 Hojiblanca cultivar olives (≈ 25 kg), which had been preserved in acidified water (2.4% 76 acetic acid) for more than six months, were subjected to darkening following the 77 habitual procedure for the elaboration of ripe olives. Briefly, olives were treated in a 78 cylindrical stainless steel container with a lye solution of 3% NaOH, which 79 progressively penetrated the flesh until the alkali reached the pit (treatment time ≈ 6 h). 80 Next, the lye was removed and the olives were washed with water until the pH reached 81 8.0. During the lye treatment and washing, air was injected through the bottom of the 82 container. Then, a 0.1% ferrous gluconate solution was added to fix the black colour. 83 After the darkening step, the olives were packed in “A314” glass bottles (145 g of pitted 84 olives plus 170 mL of brine capacity) and covered with brine containing 3% NaCl, 85 0.015% ferrous gluconate, and the corresponding amino acid (Pro, Sar, or Gly). Amino 86 acids were added to give equilibrium concentrations of 100 and 200 mM, which were 87 demonstrated to be effective concentrations to inhibit AA formation in a ripe olive 5 88 model system (López-López et al. 2014). For the corresponding calculations, the 89 moisture content of the olives was assumed to be 75% (w/w). A control product was 90 prepared using the same brine without any additive. If necessary, before the olives were 91 covered, the pH of the packing brine was adjusted to 6.5-7.0 by the addition of NaOH or 92 HCl. Fifteen bottles from each treatment were sterilized in a static retort (Steriflow, 93 SAS, Paris, France)similar to that used at olive industry. In case of ripe olives a 94 minimum value for accumulated lethality of 15F0 must be reached according to Trade 95 Standard Applying to Table Olives (IOOC, 2004) and this was the intended lethality in 96 the present work. The real conditions of retort were as follows: (1) before starting the 97 retort cycle, the bottles were pre-heated at 50 ºC for 10 min; (2) in the heating phase or 98 come-up time of the retort cycle (22 min), the water process was heated by steam in the 99 primary circuit of heat exchanger; (3) in the holding phase (15 min), temperature (121 100 ºC) and pressure (2.8 bar) were stabilized; and (4) in the cooling phase (18 min), cold 101 water was injected in the heat exchanger in order to cool down the process water. The 102 cycle period was 55 min. The experimental Fo value through measurement of 103 temperature from the coldest point of the bottle during sterilization treatment was 104 calculated as 15.5. The sterilised bottles were stored at room temperature for 8 months. 105 The initial sampling was performed after 20 days (and not immediately after heating 106 treatment) to ensure that the equilibrium inside the bottles had been reached. Samples 107 were also taken at the end of the storage period to assess the effect of storage time on 108 AA level and quality parameters. 109 110 AA determination 111 The AA content was determined following a gas chromatography-mass spectrometry 112 (GC-MS) method (with previous derivatisation of AA), as described previously (Casado 6 113 and Montaño 2008). After the addition of 13C3-AA as internal standard and further 114 clean-up of the sample, bromination of the AA double bond was performed. The 115 reaction product (2,3-dibromopropionamide) was extracted with ethyl acetate and dried 116 over sodium sulphate, and the solvent was evaporated to dryness under a stream of 117 nitrogen. The derivative was then converted to 2-bromopropenamide with triethylamine, 118 and analysed by GC-MS. Acrylamide in samples was quantified using the ion at m/z 119 151 for 2-bromopropenamide and the ion at m/z 154 for 2-bromo(13C3)propenamide. 120 The detection and quantification limits were calculated to be 6 and 20 μg/L, 121 respectively, from the values obtained after performance of the analysis using standard 122 solutions (Casado and Montaño 2008).. Taking into account the sample preparation 123 used, the above values would correspond to 60 and 200 ng g-1 of olives, respectively. 124 The analytical errorunder repeatability conditions ( n = 6) for 580 ng g-1 of AA in pulp 125 of ripe olives was 2.9% (Casado and Montaño 2008). 126 127 Amino acids determinations 128 Added amino acids were analysed by HPLC after derivatisation with 9- 129 fluorenylmethylchloroformate (FMOC-Cl). Olives, after pitting, were homogenised and 130 10 g of slurry were added to 500 mL of distilled water at 70 ºC in a beaker and the 131 mixture was stirred vigorously for 10 min using a magnetic bar. The content was then 132 transferred into a 1-L flask and made up to volume with water. After mixing, an aliquot 133 (1 mL) was centrifuged at 11600g for 5 min. The supernatant, after proper dilution with 134 water, was derivatised and then analysed following the method of Montaño et al. 135 (2000) with slight modifications. A Kinetex C18 (2.6 μm, 150 x 4.6 mm i.d.; 136 Phenomenex, Torrance, CA) column, held at 45 ºC, and gradient elution with two 137 eluents (A and B) was used. Eluent A: to 3 mL acetic acid and 7 mL 1M 7 138 triethylammonium acetate were added to 900 mL of water plus 100 mL of acetonitrile, 139 and the pH was adjusted to 6.8 with 20 M NaOH. Eluent B: acetonitrile-water (90:10). 140 The gradient was: 0 to 4 min from 12% to 18% B (liner gradient), 4 to 7 min with 18% 141 B, and 7 to 14 min from 18% to 27% B (linear gradient).The flow rate was constant at 142 1.1 mL/min. To purge the column, after the elution of FMOC-amino acid, eluent B 143 percentage was increased to 80% within 5 and maintained for 5 min. The HPLC system 144 consisted of a Waters 2695 separations module (Waters Assoc., Milford, MA, USA) 145 connected to a Waters 996 photodiode array detector (wavelength 265 nm). 146 147 Quality parameters 148 The firmness of the olives was measured using a Kramer shear compression cell 10 149 blades coupled to a Texture Analyser TA.XT.Plus, (Stable Microsystems, Godalming, 150 UK) with a 50 kg load cell. A force/displacement curve was logged using the system 151 software (Texture Expert). The test speed was set at 200 mm min−1 with an acquisition 152 rate of 250 data points per second. The firmness of the olives in each bottle was 153 expressed as the mean of 10 replicate measurements, each of which was performed on 4 154 olives. The shear compression force was expressed as N/g. 155 Colorimetric measurements on the olives were made using a Colour-View 156 Model 9000 spectrophotometer (BYK-Gardner, Inc., Silver Spring, MD). Interference 157 by stray light was minimised by covering the samples with a box with a matt black 158 interior. Colour was expressed as reflectance at 700 nm (García et al. 1999). Lower 159 reflectance values indicate darker colours. The data of each measurement are the 160 average of 20 olives. 161 Sensory evaluations were performed in order to determine whether samples with 162 selected additives were significantly different from a control sample (ripe olives without 8 163 additive). The panelists (3 women and 13 men between 32 and 64 years old from our 164 Department) had been previously trained so that they could recognise the normal 165 flavour of the product. For this, the control sample was used as the reference product. 166 Evaluations were done in individual sensory booths under controlled environmental 167 conditions (20-22 ºC, incandescent lighting). The panelists were presented 168 simultaneously with two samples and were asked whether they perceived the samples to 169 be the same or different according to the so-called difference paired comparison test 170 (Lawless and Heymann 2010). Samples, coded with 3-digit numbers, were randomly 171 provided to the judges in colourless, transparent cups covered with a watch glass. Tap 172 water was offered between samples for cleansing the palate. In addition to record the 173 answers, there was space on the score sheet to write down comments. In order to 174 increase the power of the difference test, the number of judgments was increased by 175 replicate (duplicate) evaluations. Each evaluation was carried out on two separate days. 176 The Smith´s test was used for detecting differences between replicates. 177 178 Preparation of AA/Sar model system 179 An aqueous model solution (1 mL) containing equimolar concentrations of AA and Sar 180 (12.5 mM) was added to a glass pressure tube (length 10.2 cm, outside diameter 0.8 cm; 181 Sigma-Aldrich). The tube was sealed and heated at 121 ºC for 30 min in a thermostated 182 silicon oil bath. After heating, the tube was immediately immersed in an ice bath to stop 183 further reaction. The model solution before and after heating was subjected to LC/MS, 184 according to the method described by Koutsidis et al. (2009) with modifications. The 185 LC/MS system consisted of a Waters 2695 separation module connected to a Waters 186 ZMD mass detector operated in positive electrospray ionisation mode (ESI+) and 187 controlled by MassLynx software (Micromass, Wythenshawe, U.K.). Aliquots of the 9 188 samples (10 μL) were injected into a Discovery HF F5 column (150 x 4.6 mm, 3 μm) 189 (Sigma-Aldrich/Supelco) maintained at 35 ºC. The mobile phase consisted of 20:80 190 methanol:water with 0.1% formic acid, at a flow rate of 0.3 mL/min. The mass 191 spectrometer was operated at the following settings: capillary voltage, 3 kV; cone 192 voltage, 20 V; source temperature, 100 ºC; desolvation temperature, 350 ºC; desolvation 193 gas flow, 400 L/h nitrogen; and cone gas flow, 90 L/h. 194 195 Statistical analysis 196 Statistical data (mean, SD, 95% confidence interval) were calculated using an Excel 197 spreadsheet (Microsoft Excel 2010). Sensory data from the difference paired 198 comparison tests were analysed by the binomial test using statistical tables that show the 199 minimum number of correct judgments to establish significance at probability levels of 200 5 and 1% (Lawless and Heymann 2010). 201 202 203 Results and discussion 204 Effect of amino acids on AA formation 205 The selected amino acids were added to give concentrations of 100 or 200 mM in olive 206 juice or brine, after equilibrium was reached inside the bottles. Actual concentrations of 207 these amino acids (in free form) measured in olive pulp were considerably lower than 208 the above-mentioned values (Table 1). This appears to indicate that part of the amino 209 acids reacted with olive components, which would be initially present in olives or 210 would be formed during the heating treatment of sterilisation (e.g. AA). For example, 211 Maillard reaction can easily occur during heat treatment favored by the alkaline pH of 212 product (the pH of olive juice prior heating was 8.4). This reaction involves the 10 213 interaction of amino acids with sugar-derived α-dicarbonyl compounds, which implies 214 an amino acid loss (Kwak and Lim 2004). In addition, Strecker degradation of amino 215 acids during heating would be highly likely. This reaction involves the reaction of 216 amino acids with o-quinones derived from polyphenol oxidation (Rizzi 2006). The 217 darkening process in ripe olives has been mainly related to chemical oxidation reactions 218 involving the oxidation of natural o-diphenols in olives to quinones, followed by the 219 transformation of quinones into different dark compounds (Marsilio et al. 2001). The 220 concentrations of each amino acid in olive pulp did not significantly change during 221 storage (Table 1) 222 The impact of the above compounds on AA formation in ripe olives was 223 evaluated after both 20 days and 8 months of storage at room temperature (Table 2). 224 After 20 days of storage, the control product contained 598 ng g-1 of AA in the pulp. Pro 225 and Sar showed a similar behavior, both showing ~60% and ~80% reductions at 226 concentrations of 100 and 200 mM, respectively. For Gly, the reduction rates were 34% 227 and 52% for 100 and 200 mM, respectively. These findings agree with our previous 228 results in ripe olive model system (López-López et al. 2014), although the reduction 229 rates in that case were slightly higher. The above-mentioned behavior of Pro and Sar 230 suggests that the nucleophilic reactivities of Pro and Sar were closely similar and 231 significantly higher than reactivity of Gly. Brotzel and Mayr (2007) reported 232 nucleophilicity parameters (N) for protein amino acids, with Pro showing a significantly 233 higher value than that of other protein amino acids except cysteine. 234 After 8 months of storage, additional AA reductions with respect to those 235 observed after 20 days were found in all cases, with the exception of the product 236 containing 100 mM Gly which maintained the same level of AA. Consequently, the 237 AA content was lower than the detection limit (i.e. 60 ng g-1 of olives) in the products 11 238 containing 200 mM Sar and 200 mM Pro, respectively. The AA level was also low (69 239 ng g-1 pulp) in the product containing 100 mM Sar. It must also be noted that AA in the 240 control decreased by approximately 25% compared to its content after 20 days of 241 storage (from 598±61 to 459±27 ng g-1 pulp, mean±95% CI, n=6). This result is in 242 disagreement with that previously reported by Casado and Montaño (2008) , who did 243 not found any significant change of AA during storage of ripe olives, but the time 244 period studied by these authors was shorter than ours (6 vs. 8 months). Decreases of AA 245 in the control can be attributed to the reaction of AA with special food components 246 and/or reaction products during storage (Hoenicke and Gatermann 2005). 247 248 Effect of amino acids on quality parameters 249 The influence of the amino acids studied on the surface colour of ripe olives is shown in 250 Table 3. The color values (%R700) were always <10, which can be rated as “good color” 251 in the ripe olive scale established by Fernández and Garrido (1971). After 20 days 252 storage, only Sar at 100 mM and Gly at 200 mM appeared to slightly affect the R700 253 parameter, but in an opposite way. Thus, the olives containing 100 mM Sar showed a 254 positive effect on colour with a significant decrease in R700 compared to control (i.e. 255 their colour was darker than that of the control) which resulted in a R700 <6.5 256 corresponding to a “very good color” in the above-mentioned color scale. On the other 257 hand, Gly at 200 mM provoked a significant increase in R700 compared to control (i.e. a 258 loss of black colour in comparison with the control, although the effect was not great 259 enough to produce a noticeable visual difference. The different behaviour of Sar and 260 Gly with respect to colour was confirmed in determinations performed after 8 months of 261 storage. An explanation for this result cannot be readily given due to the complex 262 mechanisms involved in the browning of ripe olives (Maillard reactions, oxidative 12 263 polymerization of phenols). The type of amino acid could affect the type of melanoidin 264 formed during the Maillard reaction, which would result in varying degrees of browning 265 (Kwak and Lim 2004). Experiments using model solutions instead of using the real 266 food might provide some clarification on this subject. 267 The impact of the selected amino acids on olive firmness is shown in Table 4. 268 As expected, in general the effect of amino acids on firmness was negligible. Only the 269 sample containing Sar at 200 mM showed a significant increase in firmness compared 270 to the control after 20 days of storage. This effect was confirmed after 8 months of 271 storage, not only for 200 mM but for 100 mM Sar as well. We have not found any 272 plausible explanation for this observation. However, it must be pointed out that the 273 firmness increase with respect to control (< 2 N/g) was not large enough to produce a 274 noticeable improvement in olive texture. 275 With regards to product flavour, after 20 days of storage, paired comparison 276 tests showed significant differences in all products compared to the control (Table 5), 277 with the exception of Sar at 100 mM. It must be pointed out that the results of the 278 difference paired comparison test only indicate whether the panelists could significantly 279 discriminate between the samples (Lawless and Heymann 2010). Since the number of 280 panelists was small for this type of test, replicate (duplicate) evaluations were carried 281 out in order to increase the power of the test. The Smith´s test showed that the two 282 replications were not significantly different (data not shown), so that data were pooled 283 and analyzed as if each judgment was made by a different panelist. From the panelists´ 284 comments recorded on the score sheets, it was possible to know that all amino acid- 285 containing samples had an attribute (sweetness) in common. It is known that all the 286 three studied amino acids are sweet amino acids and this taste was clearly noted by 287 panelists at the 200 mM level. Even for Sar at 100 mM level, a slightly sweet taste was 13 288 perceived by some of the panelists. However, the sample that is higher in sweetness, at 289 the same amino acid concentration, cannot be reliably identified from the difference 290 paired comparison test. A two-alternative forced choice (2-AFC) test would be more 291 appropriate for this purpose (Lawless and Heymann 2010), but unfortunately we did not 292 have enough sample bottles to perform it.. 293 All in all, the above-mentioned results suggest that Sar at 100 mM may be a good 294 candidate for reducing the AA content in ripe olives with a limited or slightly positive 295 impact on quality parameters. Sar is more recommendable than Pro because its effect 296 with regard to quality parameters is more favorable. In addition, a feature of the 297 structure of Sar is that it does not present a chiral carbon atom adjacent to the carboxyl 298 group. Therefore, the possibility of amino acid racemisation (i.e. the process of 299 conversion of L-amino acid into its mirror image, named D-amino acid) during 300 sterilisation treatment of ripe olives does not apply to Sar. On the contrary, racemisation 301 could occur in case of Pro, which may impair digestibility and nutrition quality 302 (Friedman 2010). Although the toxicity of the isomer D-Pro has not been evaluated in 303 humans, some toxic effects have been reported in experiments with rats (Kampel et al. 304 1990). 305 306 Sar and AA reaction 307 Previous investigations (Koutsidis et al. 2009; Liu et al. 2011) have demonstrated that 308 some amino acids (eg Gly) can react with AA at temperatures higher than 150 ºC 309 through the Michael reaction to form the adducts shown in Fig. 1. In the case of 310 secondary amine containing amino acids such as Sar or Pro only the adduct with one 311 molecule of AA would be formed. The present study appears to confirm this mechanism 312 in the Sar/AA model system heated at l21 ºC, as one main reaction product was detected 14 313 in the heated sample with a molecular weight corresponding to that of the AA-Sar 314 adduct (MW 160). As only a quite simple model system was analysed and no complex 315 foodstuffs, the use of tandem mass spectrometry was not required. In the total ion 316 chromatogram (TIC) of the heated mixture, this reaction product coeluted with Sar (7.2 317 min) and the MS spectrum of the peak showed the possible presence of the AA-Sar 318 adduct through its molecular ion at m/z 160.9 corresponding to [M+H]+ along with the 319 sodium adduct ion [M+Na]+ at m/z 182.9 (Fig. 2). No reaction product was detected in 320 the non-heated sample. 321 Although the exact mechanism of AA formation is still unknown, several studies 322 suggest that asparagine and reducing sugars, in contrast to other heated foods (e.g. fried 323 potatoes, bread, roasted coffee and almonds), are irrelevant for AA formation in ripe 324 olives (Amrein et al. 2007; Casado and Montaño 2008). Recent investigations support 325 the role of peptides/proteins as precursors of acrylamide formation in this product 326 (Casado et al. 2013). Thus, the inhibitory effect of Sar on AA formation, rather than 327 mediated through reacting with precursors or reaction intermediates, would be mainly 328 based on its capacity to eliminate AA through adduct formation in the Michael reaction. 329 Conclusions 330 Of the studied amino acids, Sar at 100 mM had the highest impact on the AA level in 331 ripe olives along with the lowest effect on olive flavour. This amino acid appeared to 332 slightly improve the colour and firmness of olives. The AA-reducing effect of any of the 333 studied amino acids was demonstrated to be extended even to the product storage phase. 334 In conclusion, we believe that Sar could be a good candidate as an additive to reduce 335 AA contents in ripe olives. This amino acid could significantly decrease toxic 336 acrylamide content with concomitant accumulation of the Michael adduct. However, the 15 337 toxicological properties of this adduct are not known. This subject would warrant 338 further investigation. Sar has not been previously tested in any heated food to reduce 339 AA content. Therefore, the present work is the first one in which Sar is applied in foods 340 to that end. 341 342 References 343 344 345 Amrein TM, Andres L, Escher F, Amadó R. 2007. Occurrence of acrylamide in selected foods and mitigation options. Food Addit Contam A. 24:13-25. 346 Amrein TM, Schiónbochler B, Rohner F, Lukac H, Schneider H, Keiser A, Escher F, 347 Amadó R. 2004. Potential for acrylamide formation in potatoes: data from the 348 2003 harvest. Eur Food Res Technol. 219:572-578. 349 350 351 352 353 354 355 Brotzel F, Mayr H. 2007. Nucleophilicities of amino acids and peptides. Org Biomol Chem. 5:3814-3820. Casado FJ, Montaño A. 2008. Influence of processing conditions on acrylamide content in black ripe olives. J Agric Food Chem. 56:2021-2027. Casado FJ, Sánchez AH, Montaño A. 2010. Reduction of acrylamide content of ripe olives by selected additives. Food Chem. 119:161-166. Casado FJ, Montaño A, Spitzner D, Carle R. 2013. Investigations into acrylamide 356 precursors in sterilized table olives: Evidence of a peptic fraction being 357 responsable for acrylamide formation. Food Chem. 141:1158-1165. 358 Claus A, Mongili M, Weisz G, Schieber A, Carle R. 2008. Impact of formulation and 359 technological factors on the acrylamide content of wheat bread and bread rolls. J 360 Cereal Sci. 47:546-554. 16 361 De Castro A, García P, Romero C, Brenes M, Garrido A. 2007. Industrial 362 implementation of black ripe olive storage under acid conditions. J Food Eng. 363 80:1206-1212. 364 European Commission. 2011. Commission regulation (EU) No 1129/2011 of 11 365 November 2011 amending Annex II to Regulation (EC) No 1333/2008 of the 366 European Parliament and of the Council by establishing a Union list of food 367 additives. Off J Eur Union L 295/1. Available from: http://eur- lex.europa.eu/ 368 LexUriServ/LexUriServ.do?uri=OJ:L:2011:295:0001:0177:En:PDF 369 Fernández MJ, Garrido A. 1971. Aceitunas negras por oxidación en medio alcalino I. El 370 color como criterio de madurez y de calidad en el producto elaborado. Grasas 371 Aceites 22:193-199. 372 373 374 375 376 García P, Brenes M, Romero C, Garrido A. 1999. Color and texture of acidified ripe olives in pouches. J Food Sci. 64:248-251. Hoenicke K, Gatermann R. 2005. Studies on the stability of acrylamide in food during storage. J AOAC Int. 88:268-273. IARC. 1994. Monographs on the evaluation of carcinogen risks to humans: Some 377 industrial chemicals. Acrylamide. Lyon: International Agency for Research on 378 Cancer. pp 389-433. 379 IOOC. 2004.Trade standard applying to table olives. Document COI/OT/NC no. 1. 380 Madrid: International Olive Council. Available from: 381 http://www.internationaloliveoil.org/ 382 Kampel D, Kupferschmidt R, Lubec G. 1990. Toxicity of D-proline. In: Lubec G, 383 Rosenthal GA, editors. Amino acid: chemistry, biology and medicine. Leiden, 384 Netherlands: Escom Science Publishers, p. 1164. 17 385 Koutsidis G, Simons SPJ, Thong YH, Haldoupis Y, Mojica-Lazaro J, Wedzicha BL, 386 Mottram DS. 2009. Investigations on the effect of amino acids on acrylamide, 387 pyrazines, and Michael addition products in model systems. J Agric Food Chem. 388 57:9011-9015. 389 Kwak E-J, Lim S-I. 2004. The effect of sugar, amino acid, metal ion, and NaCl on 390 model Maillard reaction under pH control. Amino Acids 27:85-90. 391 392 393 Lawless HT, Heymann H. 2010. Sensory evaluation of food. Principles and practices. 2nd. Ed. New York: Springer. Liu J, Chen F, Man Y, Dong J, Hu X. 2011. The pathways for the removal of 394 acrylamide in model systems using glycine based on the identification of 395 reaction products. Food Chem. 128:442-449. 396 López-López A, Beato VM, Sánchez AH, García-García P, Montaño A. 2014. Effects 397 of selected amino acids and water-soluble vitamins on acrylamide formation in a 398 ripe olive model system. J Food Eng. 120:9-16. 399 400 Marsilio V, Campestre C, Lanza B. 2001. Phenolic compounds change during California-style ripe olive processing. Food Chem. 74:55-60. 401 Martins SIFS, Jongen WMF, van Boekel MAJS. 2001. A review of Maillard reaction in 402 food and implications to kinetic modelling. Trends Food Sci Tech. 11:364–373. 403 Montaño A, Sánchez AH, de Castro A. 2000. Changes in the amino acid composition of 404 green olive brine due to fermentation by pure culture of bacteria. J Food Sci. 405 65:1022-1027. 406 Rizzi GP. 2006. Formation of Strecker aldehydes from polyphenol-derived quinones 407 and α-amino acids in a nonenzymic model system. J Agric Food Chem. 54:1893- 408 1897. 18 409 410 411 Sánchez AH, García P, Rejano L. 2006. Elaboration of table olives. Grasas Aceites 57:86-94. Tareke E, Rydberg P, Karlsson P, Eriksson S, Törnqvist M. 2002. Analysis of 412 acrylamide, a carcinogen formed in heated foodstuffs. J Agric Food Chem. 413 50:4998-5006. 414 Taubert D, Halfinger S, Henkes L, Berkels R, Schöming E. 2004. Influence of 415 processing parameters on acrylamide formation during frying of potatoes. J 416 Agric Food Chem. 52:2735-2739. 417 United States Food and Drug Administration. 2006. Survey data on acrylamide in food: 418 individual food products. Available from: http://www.fda.gov/Food/ 419 FoodborneIllnessContaminants/ChemicalContaminants/ucm053549.htm 420 19 421 Figure captions 422 423 Figure 1. Michael addition reactions of acrylamide with glycine, proline, and sarcosine. 424 425 Figure 2. Total ion chromatograms obtained by LC/MS (positive ion mode) of the 426 model solution of acrylamide (AA) with sarcosine (Sar) before and after heating at 121 427 ºC for 30 min. The inserts were the MS spectra of the peak at 7.2 min. 20 Table 1. Actual concentrations of added amino acids in olive pulp after 20 days and 8 months of storage Actual concentration (free form)a Sample 20 days 8 months 100 mM Pro 64.9 ± 2.3 57.8 ± 7.0 200 mM Pro 133.6 ± 13.8 120.5 ± 20.0 100 mM Sar 48.7 ± 4.7 61.1 ± 8.7 200 mM Sar 101.2 ± 16.0 128.7 ± 42.7 100 mM Gly 63.2 ± 7.0 63.8 ± 4.8 200 mM Gly 126.1 ± 28.5 121.1 ± 7.2 a Data values (in mM) are mean ± 95% confidence interval (n=3). 21 Table 2. Impact of the selected amino acids on the acrylamide content of ripe olives after 20 days and 8 months of storagea Storage time 8 months 459 ± 27† Sample Control 20 days 598 ± 61 100 mM Pro 200 mM Pro 100 mM Sar 227 ± 21* 115 ± 18* 216 ± 27* (62) (81) (58) 133 ± 29*† ND*† 69 ± 7*† (71) (94) (85) 200 mM Sar 100 mM Gly 200 mM Gly 104 ± 27* 337 ± 25* 248 ± 30* (80) (35) (52) ND*† 305 ± 31* 183 ±14*† (97) (34) (60) a Acrylamide contents in ng g-1 of pulp. Data values are mean ± 95% confidence interval (n=6). Reduction rates (%) compared to the corresponding control in parentheses. *Significant difference with respect to the corresponding control. † Significant difference with respect to the acrylamide content at 20 days storage. ND = not detected (< 60 ng g-1 of pulp) 22 Table 3. Impact of the selected amino acids on the surface color of ripe olives (R700) after 20 days and 8 months of storagea Storage time Sample 20 days 8 months Control 7.06 ± 0.35 6.99 ± 0.31 100 mM Pro 7.35 ± 1.36 6.91 ± 0.30 200 mM Pro 6.80 ± 0.32 7.19 ± 0.64 100 mM Sar 5.87 ± 0.20* 6.24 ± 0.07*† 200 mM Sar 6.85 ± 0.10 6.55 ± 0.18† 100 mM Gly 6.83 ± 0.23 7.59 ± 0.04*† 200 mM Gly 7.91 ± 0.49* 8.45 ± 0.36* a Values are mean ± 95% confidence interval (n=3). *Significant difference with respect to the corresponding control. † Significant difference with respect to R700 at 20 days storage. 23 Table 4. Impact of the selected amino acids on the firmness (N/g) after 20 days and 8 months of storagea Sample Storage time 20 days 8 months Control 9.81 ± 0.49 9.60 ± 0.76 100 mM Pro 9.39 ± 0.44 9.19 ± 0.64 200 mM Pro 9.19 ± 0.62 9.59 ± 0.68 100 mM Sar 10.54 ± 0.36 11.18 ± 0.69* 200 mM Sar 11.13 ± 0.49* 11.59 ± 0.68* 100 mM Gly 10.61 ± 0.62 10.28 ± 0.86 200 mM Gly 11.04 ± 0.79 10.51 ± 0.97 a Values are mean ± 95% confidence interval (n=3). *Significant difference with respect to the corresponding control. 24 Table 5. Difference paired comparison tests for additive-containing samples compared to control (without additive) Samples compareda No. of correct judgmentsb Significancec Flavour descriptors used by some panellists for the additive-containing sample 100 mM Pro vs control 24 ** Sweet, unpleasant, strange 200 mM Pro vs control 24 ** Sweet, atypical, unpleasant, strange 100 mM Sar vs control 20 ns Slightly sweet 200 mM Sar vs control 30 ** Sweet, atypical 100 mM Gly vs control 23 * Sweet Sweet, atypical, 200 mM Gly vs 24 ** unpleasant, butter odor control a Pro = proline, Sar = sarcosine, Gly = glycine. b Number of judgments = 32 (2x16). Smith´s test showed that the two replications were not significantly different, so that data were pooled. c **, significantly different at p=0.01; *, significantly different at p=0.05; ns, not significantly different. 25