The building is occupied by an operational police

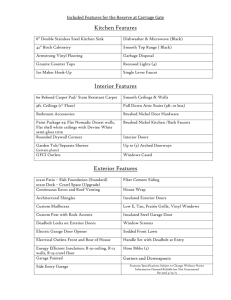

advertisement

SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 1 2 GENERAL CONDITIONS 1.1 The General Conditions, Labour Conditions and the Bidding Requirements are hereby made part of this section. 1.2. Security Requirements ; Only RCMP Standards for Security Clearance will be accepted. SCOPE OF WORK 2.1 The work shall consist of the removal of doors, windows, siding supply and installation of new exterior doors, windows and siding complete with new facia around window overhang, soffit as required, new vapour wrap. Close in two(2) windows in provost area reconstruct openings and finish to match new exterior and interior finish. Patch, repair paint all interior and exterior finishes associated with the installation of new doors and windows and siding are to match existing. Note: Door and window sizes at end of specifications. All measurements are approximate. Successful contractor must confirm measurements of all door and windows on site as existing windows and doors are to be replaced with new. 3 TEMPORARY FACILITIES 3.1 4 The General Contractors and all subcontractors shall be allowed to use space close to the work area as temporary storage for products and supplies used in the project. WORKMANSHIP 4.1 Workmanship to be of the best quality throughout and be executed in accordance with the best standard practice and all applicable codes. 4.2 Work of all trades shall be completed by qualified tradesmen. Page 1 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 5 6 7 INTERPRETATION OF SPECIFICATIONS 5.1 The Contractor shall, before close of tender, bring to the attention of the RCMP Asset Management Section the omission of an item which is obviously intended to be required for a complete job. Failure to cooperate in this respect will not relieve the contractor of the responsibility of completing the work in accordance with the standard of the contract as though it has been properly incorporated in the documents. 4.2 In any case of doubt as to the intention of the specifications, request clarification before proceeding. Should the specifications call for any items which are either impractical or impossible, the contractor is required to obtain instructions from the RCMP Asset Management Section before proceeding, otherwise the RCMP will assume that all work can be carried out in an acceptable manner. GENERAL REQUIREMENTS 6.1 The General Contractor and subcontractors shall comply with all applicable bylaws, rules and regulations of local and provincial authorities and pay for all licenses and fees associated with the work. 6.2 Where not otherwise stated or specified, the work shall conform to at least the minimum standards of the National Fire Code, National Building Code and Municipal and local building, electrical and plumbing codes. MATERIALS 7.1 8 All materials used in this contract shall be new unless otherwise specified and in accordance with the specifications. METHOD OF WORK 8.1 Schedule the work with Detachment Member in Charge so as to ensure continuity of the police operation. 8.2 Time of Completion - Commence the work immediately following official notification of contract award. Complete the work no later than January 31, 2014. Page 2 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 9 CUTTING, PATCHING AND EXISTING SERVICES 9.1 Do all cutting and patching necessary in order that first class results are obtained. All work carried out shall match existing surface, unless noted otherwise. It is the responsibility of the contractor to ensure that all patching is correct and complete. The contractor is responsible for all areas of construction: the contractor is not permitted to change or cause a change to the structural or physical integrity of the existing building whether by cutting, coring or other means without prior approval from the RCMP Asset Management Section. The building is occupied by an operational police force. All work that involves breaking into existing building services shall be coordinated with the Site Authority and is to cause as little disruption to existing operating systems. 10 11 CLEAN UP 10.1 During the performance of the work, keep the area tidy. 10.2 Upon completion of the work, leave the area in a neat and tidy condition. 10.3 All glazing, framing, flooring, fixtures, etc., must be left clean, ready for occupancy. GUARANTEE 11.1 12 Guarantee the quality of workmanship and material for a period of one year from the date of acceptance of the work. Make good at no extra cost to, and to the satisfaction of the RCMP, any defects that may develop within the guarantee period. CEILING & WALL FINISHES 12.1 Paint with environmentally friendly paint High Performance Acrylic Finish, MPI 9.2B 12.1.1 One coat latex primer-sealer tinted to color MPI 50 12.1.2 Two coats satin acrylic coating MPI 110 12.1.3 Apply with roller Page 3 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 13 PAINTING - low odor products are recommended 14 CONSTRUCTION- Exterior Siding 14.1 Product: 14.1.1 James Hardie Siding Products (inclusive of trim). Vertical siding to be replaced with Hardi Panel Select Sierra 8 Shake siding to be replaced with Hardie Shingle Staggered Notched Panel Product colour to be “Timber Bark” 14.1.2 Application of siding to be in accordance with the manufacturer’s recommendations. 14.1.3 Supply and install air barrier to be Dupont “Tyvek” OR EQUAL House wrap, installed as per manufacturer’s recommendation. 14.1.4 Clean up and dispose of all debris, nails and other unused materials. Note: Construction waste must be removed from the site and National Park, Prince Albert is the closest landfill location. 15 ELECTRICAL, FIRE ALARM, BUILDING SERVICES 15.1 Reconnect all existing electrical, water, or other exterior apparatus associated with the project. Includes, but is not limited to, door bell and lighting, water connections. Page 4 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ WINDOWS - 085050 PART 1 General 1.1 REFERENCES .1 Aluminum Association (AA), Designation System for Aluminum Finishes (2000) .2 Canadian General Standards Board (CGSB) .1 CAN/CGSB-1.40-[97], Anticorrosive Structural Steel Alkyd Primer. .2 CAN/CGSB-79.1-[M91], Insect Screens. .3 Canadian Standards Association (CSA) International .1 CSA-A440-[00]/A440.1-[00], A440-[00], Windows / Special Publication A440.1-[00], User Selection Guide to CSA Standard A440-[00], Windows. .2 CAN/CSA-G164-[M92 (R1998)], Hot Dip Galvanizing of Irregularly Shaped Articles. .3 CAN/CSA-Z91-[M90 (R2000)], Safety Code for Window Cleaning Operations. 1.2 SHOP DRAWINGS .1 Submit shop drawings in accordance with Section 013300 - Submittal Procedures. .2 Indicate materials and details in scale full size for head, jamb and sill, profiles of components, interior and exterior trim junction between combination unit’s elevations of unit, anchorage details, location of isolation coating, description of related components and exposed finishes fasteners, and caulking. Indicate location of manufacturer's nameplates. 1.3 MAINTENANCE DATA .1 Provide operation and maintenance data for windows for incorporation into manual 1.6 WASTE MANAGEMENT AND DISPOSAL .1 Separate and recycle waste materials in accordance with Construction Waste Management And Disposal. Page 18 – 1.5 Page 5 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ PART 2 Products 2.1 . MATERIALS 1 Materials: to CAN/CSA-A440 supplemented as follows: .2 All Aluminum windows and ventilation by same manufacturer. .3 Frames: Minimum 127 mm deep thermally insulated sections, with nailing flanges and without nailing flanges as detailed. .4 Extrusions shall be 6053 T54 alloy and temper. .5 Formed aluminum components shall be sheet of alloy and temper suitable for their purpose and finish. .6 Fasteners shall be 300 series stainless steel or 400 series stainless steel cadmium plated and of sufficient size and quantity to perform their intended function. .7 Weathering and glazing gaskets shall be extruded, black, closed cell or dense elastomer or durometer appropriate to the function. Exterior weathering shall be Tremco VISION strip. .8 Glazing tapes shall be macro-polyisobutylene, highly adhesive and elastic with built in shim. .9 Glass: to Section 088050 - Glazing. .10 Aluminum partition cap: Fabricated from minimum 1 mm thick aluminum, 10 mm exposed face, thickness to suit partitions. .11 Neoprene Seal: Compressed semi-rigid black neoprene air / acoustic seal. 2.2 WINDOW TYPE AND CLASSIFICATION .1 Types: .1 Fixed: with removable sealed double glazing. .2 Ventilation Unit: Factory fabricated, thermally broken, insulated, insert ventilator. Unit shall be complete with rain screen element and ventilator seal. Operation shall be by finger tip control of opening and closing without operating hardware. Unit shall appear visually the same in open or closed position. Page 6 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .2 Classification rating: to CAN/CSA-A440: .1 Fixed Windows .1 Air tightness: A3. .2 Water tightness: B7. .3 Wind load resistance: C5. .4 Condensation resistance: Temperature Index, I 69.9 .5 Glazing: To Section 088050 Glazing .6 Acceptable Products: .1 Kawneer Trifab VG 451 T .2 Ventilation Unit .1 To integrate with Fixed window, complete with restricted opening of 100mm maximum. .2 Options: .1 Pull Handle: Camlock with Pole Ring .2 Insect Screens .3 Acceptable Products: .1 Alumicor TotoVent SV2000 .3 Secure Ventilation Unit .1 Air tightness: A3. .2 Water tightness: B7. .3 Wind load resistance: C5. .4 Condensation resistance: Temperature Index, I 56 2.3 FABRICATION .1 Fabricate in accordance with CAN/CSA-A440 supplemented as follows: .2 Fabricate units square and true with maximum tolerance of plus or minus 1.5 mm for Page 7 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ units with a diagonal measurement of 1800 mm or less and plus or minus 3 mm for units with a diagonal measurement over 1800 mm. .3 Interior and exterior extruded aluminum framing sections shall be integrated with a glass reinforced nylon thermal break to form a rigid composite assembly without the use of fasteners or other thermal bridging elements. Composite frame assembly shall have a minimum of 7224N/100mm resistance to shear between the aluminum and the thermal break materials. Dry shrinkage of the thermal break shall not exceed 0.10% of the framing member length. .4 Framing shall be designed for screw spline corner construction. .5 Face dimensions detailed are maximum permissible sizes. .6 Fabricate windows of sizes and configurations indicated on drawings. Allow for adequate clearances and shim spacing around full perimeter of assemblies to enable proper installation. .7 Accurately and rigidly fit together all joints and corners. Match components carefully ensuring continuity of line and design. Ensure all joints and connections are flush, hairline and weatherproof. .8 Coupling mullions shall be designed to provide a functional split to permit modular construction and allow for thermal expansion. .9 Brace frames to maintain squareness and rigidity during shipment and installation. .10 All glazing pockets shall be vented, pressure equalized and drained to the exterior. Glass stops shall be lock-in screw less type. 2.4 OBSERVATION WINDOWS NA 2.5 ALUMINUM FINISHES .1 Finish exposed surfaces of aluminum components in accordance with Aluminum Association Designation System for Aluminum Finishes - 1980. .1 Clear anodic finish: designation AA- M12C22A31 Page 8 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 2.6 ISOLATION COATING .1 Isolate aluminum from following components, by means of isolation coating: .1 Dissimilar metals except stainless steel, zinc, or white bronze of small area. .2 Concrete, mortar and masonry. .3 Wood. 2.7 GLAZING .1 Glaze windows in accordance with CAN/CSA-A440. PART 3 3.1 Execution WINDOW INSTALLATION .1 Install in accordance with CAN/CSA-A440. .2 Install Aluminum windows as indicated on drawings and in accordance with Manufacturer’s recommendations, to achieve weather tight installations. Windows shall be plumb, level and free of warp or twist. .3 Arrange components to prevent abrupt variation in colour. .4 Use sufficient corrosion resistant anchorage devices to securely and rigidly fasten windows to building, without causing detrimental effects to shape or performance. .5 Maintain continuity of thermal barrier. 3.2 CAULKING .1 Seal joints between windows and window sills with sealant. Bed sill expansion joint cover plates and drip deflectors in bedding compound. Caulk between sill upstand and window-frame. Caulk butt joints in continuous sills. .2 Apply sealant in accordance with Section 079210 - Joint Sealing. Conceal sealant within window units except where exposed use is permitted by Engineer. END OF SECTION Page 9 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ GLAZING - 088050 PART 1 General 1.1 REFERENCES .1 American Society for Testing and Materials (ASTM) .1 ASTM D 2240-[97e1], Test Method for Rubber Property - Durometer Hardness. .2 ASTM F 1233-[98], Test Method for Security Glazing Materials and Systems. .2 Canadian Door and Window Manufacturers, Certification Program. .3 Canadian General Standards Board (CGSB) .1 CAN/CGSB-12.1-[M90], Tempered or Laminated Safety Glass. .2 CAN/CGSB-12.3-[M91], Flat, Clear Float Glass. .3 CAN/CGSB-12.4-[M91], Heat Absorbing Glass. .4 CAN/CGSB-12.5-[M86], Mirrors, Silvered. .5 CAN/CGSB-12.8-[97], Insulating Glass Units. .6 CAN/CGSB-12.10-[M76], Glass, Light and Heat Reflecting. .7 CAN/CGSB-12.11-[M90], Wired Safety Glass. .4 Flat Glass Manufacturers Association (FGMA), Glazing Manual .5 Laminators Safety Glass Association, Standards Manual. 1.2 PERFORMANCE REQUIREMENTS .1 Provide continuity of building enclosure vapour and air barrier using glass and glazing materials as follow: .1 Utilize inner light of multiple light sealed units for continuity of air and vapour seal. .2 Size glass to withstand wind loads, dead loads and positive and negative live loads acting normal to plane of glass to a minimum design pressure of 0.5 kPa. .3 Limit glass deflection to 1/200 with full recovery of glazing materials. 1.3 SHOP DRAWINGS .1 Submit shop drawings in accordance with standard - Submittal Procedures. Page 10 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 1.4 SAMPLES NA 1.5 MOCK-UPS NA 1.6 CLOSEOUT SUBMITTALS .1 Provide maintenance data including cleaning instructions for incorporation into manual 1.7 QUALITY ASSURANCE .1 Perform work in accordance with FGMA Glazing Manual. 1.8 ENVIRONMENTAL REQUIREMENTS .1 Install glazing when ambient temperature is 10 degrees C minimum. Maintain ventilated environment for 24 hours after application. .2 Maintain minimum ambient temperature before, during and 24 hours after installation of glazing compounds. 1.9 WASTE MANAGEMENT AND DISPOSAL .1 Separate and recycle waste materials in accordance Construction Waste Management and Disposal. 1.10 PACKAGING MATERIALS .1 Remove form site and dispose of all packaging materials at appropriate recycling facilities. .2 Dispose of all packaging material in appropriate on-site bin for recycling in accordance with site waste management program. PART 2 Products 2.1 MATERIALS: FLAT GLASS .1 Safety glass: to CAN/CGSB-12.1, transparent, minimum 6mm thick. .1 Type: tempered. .2 Class: float. .3 Category: 1. .2 Silvered mirror glass: to CAN/CGSB-12.5, minimum 6 mm thick. Page 11 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 1 Type: Tempered. .3 Wired glass: to CAN/CGSB-12.11, minimum 6mm thick. .1 Polished both sides (transparent). .2 Wire mesh styles: Square. .4 Polycarbonate security glazing: .1 Single 6 mm thick polycarbonate sheet, clear colour. .2 Ballistic performance: to ASTM F 1233. .3 Flexural strength: to ASTM D 790. .4 Light transmittance: minimum 88% to ASTM D 1003. .5 Surface burning characteristics for flame and smoke spread: to ASTM E 84. .6 Self ignition characteristics: to ASTM D 1929. .7 Acceptable manufacturer: .1 Lexan .5 Laminated Safety Glass .1 2 layers of 6mm laminated safety glass with a 0.030mm PVB interlayer. 2.2 MATERIALS: SEALED INSULATING GLASS .1 Glazing to exterior doors to be 6 mm tempered, 6 mm polycarbonate, 6 mm polycarbonate, 6 mm tempered. Total thickness 24 mm to exterior doors .2 25 mm sealed thermal units conforming to CAN2-12, 11-M76. Sealed unit to consist of 6 mm tempered PPG Solarban 60(2), 12 mm air space , Technoform spacer, argon gas fill, 6 mm tempered clear light .1 Glass: to CAN/CGSB-12.1. .2 Glass thickness: minimum 6mm each light. .3 Inter-cavity space thickness: minimum 12mm with low conductivity spacers (Edgetech TriSeal Super Spacer). .4 Glass coating: surface number 2, low "E" (sputtered low-emissivity coating), clear colour. .5 Inert gas fill: argon. .6 Visible Light Transmittance: 52%. .7 Visible Light Reflectance: 11% .8 Solar Energy Transmittance: 22%. .9 Solar Energy Reflectance: 31% .10 UV Light Transmittance: 25% .11 Metric U Value: 0..13 .12 Shading Coefficient: 0.38 .13 Solar Heat Gain Coefficient: 0.33 .14 Acceptable Products: .1 Comfort Ti-AC 40 as manufactured by AFGD Glass Page 12 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 2.3 ACCESSORIES .1 Setting blocks: Neoprene, 80-90 Shore A durometer hardness to ASTM D 2240, length of 25 mm for each square meter of glazing to suit glazing method, glass light weight and area. .2 Spacer shims: Neoprene, 50-60 Shore A durometer hardness to ASTM D 2240, 75 mm long x one half height of glazing stop x thickness to suit application. Self adhesive on one face. .3 Glazing tape: .1 Preformed butyl compound with integral resilient tube spacing device, 10-15 Shore A durometer hardness to ASTM D 2240; coiled on release paper; black colour. .2 Closed cell polyvinyl chloride foam, coiled on release paper over adhesive on two sides, maximum water absorption by volume 2%, designed for compression of 25%, to effect an air and vapour seal. .4 Glazing splines: resilient polyvinyl chloride, extruded shape to suit glazing channel retaining slot, colour as selected. .5 Lock-strip gaskets: to ASTM C 542. .6 Mirror attachment accessories: .1 Stainless steel clips. PART 3 Execution 3.1 EXAMINATION .1 Verify that openings for glazing are correctly sized and within tolerance. .2 Verify that surfaces of glazing channels or recesses are clean, free of obstructions, and ready to receive glazing. 3.2 PREPARATION .1 Clean contact surfaces with solvent and wipe dry. .2 Seal porous glazing channels or recesses with substrate compatible primer or sealer. .3 Prime surfaces scheduled to receive sealant. 3.3 INSTALLATION: EXTERIOR WET/DRY METHOD (PREFORMED TAPE AND SEALANT) .1 Cut glazing tape to length and set against permanent stops, 6 mm below sight line. Seal corners by butting tape and dabbing with sealant. .2 Apply heel bead of sealant along intersection of permanent stop with frame ensuring full perimeter seal between glass and frame to complete continuity of air and vapour seal. .3 Place setting blocks at 1/4 points, with edge block maximum 150 mm from corners. .4 Rest glazing on setting blocks and push against tape and heel head of sealant with Page 13 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ sufficient pressure to attain full contact at perimeter of light or glass unit. .5 Install removable stops with spacer strips inserted between glazing and applied stops 6 mm below sight line. Place glazing tape on glazing light or unit with tape flush with sight line. .6 Fill gap between glazing and stop with sealant to depth equal to bite of frame on glazing, maximum 9 mm below sight line. .7 Apply cap head of sealant along void between stop and glazing, to uniform line, flush with sight line. Tool or wipe sealant surface smooth. 3.4 INSTALLATION: INTERIOR - DRY METHOD (TAPE AND TAPE) .1 Cut glazing tape to length and set against permanent stops, projecting 1.6 mm above sight line. .2 Place setting blocks at 1/4 points, with edge block maximum 150 mm from corners. .3 Rest glazing on setting blocks and push against tape for full contact at perimeter of light or unit. .4 Place glazing tape on free perimeter of glazing in same manner described. .5 Install removable stop without displacement of tape. Exert pressure on tape for full continuous contact. .6 Knife trim protruding tape. 3.5 INSTALLATION: MIRRORS NA 3.6 CLEANING .1 Remove glazing materials from finish surfaces. .2 Remove labels after work is complete. .3 Clean glass and mirrors. 3.7 PROTECTION OF FINISHED WORK .1 After installation, mark light with an "X" by using removable plastic tape or paste. 3.8 SCHEDULE .1 Safety glass .1 Steel doors and wood doors which are not fire rated, ULC labelled. .2 Polycarbonate security glazing: .1 All glazing located within secure area. .2 Cell door glazing. .3 Sealed Triple Glazed Units: Page 14 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .1 Install sealed triple glazed units at exterior windows .2 Provide outboard lite of tempered laminated safety glass in exterior window unit above main entrance door. .4 Wired Glass: .1 Install wired glass at all interior steel doors and frames and wood doors which are fire rated, ULC labelled and where shown on the drawings. .5 Laminated Safety Glass .1 Reception counter. METAL DOORS AND FRAMES - 081114 PART 1 General 1.1 REFERENCES .1 American Society for Testing and Materials (ASTM International) .1 ASTM A653/A653M-[01a], Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. .2 ASTM E90-90 - Standard test for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements .3 ASTM E413-87 - Classification for Rating Sound Insulation .2 Canadian General Standards Board (CGSB) .1 CAN/CGSB-1.181-[99], Ready-Mixed Organic Zinc-Rich Coating. .2 CGSB 41-GP-19Ma-[84], Rigid Vinyl Extrusions for Windows and Doors. .3 Canadian Standards Association (CSA International) .1 G40.20/G40.21-[98], General Requirements for Rolled or Welded Structural Quality Steel/Structural Quality Steel. .2 CSA W59-[M1989(R2001)], Welded Steel Construction (Metal Arc Welding) (Metric Version). .4 Canadian Steel Door Manufacturers' Association, (CSDMA). .1 CSDMA, Specifications for Commercial Steel Doors and Frames, [1990]. .2 CSDMA, Recommended Selection and Usage Guide for Commercial Steel Doors, [1990]. .5 Underwriters' Laboratories of Canada (ULC) .1 CAN4-S104-[80(R1985)], Fire Tests of Door Assemblies. .2 CAN4-S105-[85(R1992)], Fire Door Frames Meeting the Performance Required by CAN4-S104. .6 CAN/ULC-S701-[01], Thermal Insulation, Polystyrene, Boards and Pipe Covering. Page 15 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .7 CAN/ULC-S702-[97], Thermal Insulation, Mineral Fibre, for Buildings. .8 CAN/ULC-S704-[01], Thermal Insulation, Polyurethane and Polyisocyanurate Boards, Faced. 1.2 SHOP DRAWINGS .1 Submit shop drawings in accordance with Submittal Procedures. .2 Indicate each type of door, material, steel core thicknesses, mortises, reinforcements, location of exposed fasteners, openings, glazed, arrangement of hardware, fire rating, finishes, and STC rating. .3 Indicate each type frame material, core thickness, reinforcements, glazing stops, location of anchors and exposed fastenings and reinforcing, fire rating, finishes and STC rating. .4 Include schedule identifying each unit, with door marks and numbers relating to numbering on drawings and door schedule. 1.3 SAMPLES NA 1.4 REQUIREMENTS .1 Steel fire rated doors and frames: labelled and listed by an organization accredited by Standards Council of Canada in conformance with CAN4-S104M [NFPA 252] for ratings specified or indicated. 1.5 WASTE MANAGEMENT AND DISPOSAL .1 Separate and recycle waste materials in accordance with Parks Canada & Construction Waste Management and Disposal . Disposal locations are: Prince Albert PART 2 2.1 Products MATERIALS .1 Hot dipped galvanized steel sheet: to ASTM A653M, [ZF75], 1.2 mm minimum base steel thickness in accordance with CSDMA Table 1 - Thickness for Component Parts. .2 Reinforcement: to CSA G40.20/G40.21, Type 44W, coating designation to ASTM A653M, [ZF75]. Page 16 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 2.2 DOOR CORE MATERIALS .1 Honeycomb construction: .1 Structural small cell, 24.5 mm maximum kraft paper 'honeycomb', weight: 36.3 kg per ream minimum, density: 16.5 kg/m3 minimum sanded to required thickness. .2 Stiffened: face sheets welded, insulated core. .1 Polyurethane: to CAN/ULC-S704 rigid, modified poly/isocyanurate, closed cell board. Density 32 kg/m3. .3 Temperature rise rated (TRR): core composition to limit temperature rise on unexposed side of door to 250 degrees Celsius at 30 minutes. Core to be tested as part of a complete door assembly, in accordance with CAN4-S104, ASTM E152 or NFPA 252, covering Standard Method of Tests of Door Assemblies and listed by nationally recognized testing agency having factory inspection service. 2.3 ADHESIVES .1 Honeycomb cores and steel components: heat resistant, spray grade, resin reinforced neoprene/rubber (polychloroprene) based, low viscosity, contact cement. .2 Polystyrene and polyurethane cores: heat resistant, epoxy resin based, low viscosity, contact cement. .3 Lock-seam doors: fire resistant, resin reinforced polychloroprene, high viscosity, sealant/adhesive. 2.4 PRIMER .1 Touch-up prime CAN/CGSB-1.181. 2.5 PAINT .1 Field paint steel doors and frames in accordance with Section 099120 – Interior Painting. Protect weatherstrips from paint. Provide final finish shall be free of scratches or other blemishes. 2.6 ACCESSORIES .1 Door silencers: single stud rubber/neoprene type. .2 Exterior and interior top and bottom caps: steel. .3 Fabricate glazing stops as formed channel, minimum 16 mm height, accurately fitted, butted at corners and fastened to frame sections with counter-sunk oval head sheet metal Page 17 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ screws. .4 Metallic paste filler: to manufacturer's standard. .5 Fire labels: metal riveted. .6 Sealant: Section 079210 - Joint Sealing. .7 Glazing: Section 088050 - Glazing .8 Make provisions for glazing as indicated and provide necessary glazing stops. .1 Provide removable stainless steel glazing beads for use with glazing tapes and compounds and secured with countersunk stainless steel screws. .2 Design exterior glazing stops to be tamper proof 2.7 FRAMES FABRICATION GENERAL .1 Fabricate frames in accordance with CSDMA specifications. .2 Fabricate frames to profiles and maximum face sizes as indicated. .3 Exterior frames: 1.6 mm welded type construction. .4 Interior frames: 1.6 mm welded type construction. .5 Blank, reinforce, drill and tap frames for mortised, templated hardware, and electronic hardware using templates provided by finish hardware supplier. Reinforce frames for surface mounted hardware. .6 Frame strike bucket to be able to accept 25 mm throw dead bolt. .7 Protect mortised cutouts with steel guard boxes. .8 Prepare frame for door silencers, 3 for single door, 2 at head for double door. .9 Manufacturer's nameplates on frames and screens are not permitted. .10 Conceal fastenings except where exposed fastenings are indicated. .11 Provide factory-applied touch up primer at areas where zinc coating has been removed during fabrication. Page 18 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .12 Insulate exterior frame components with polyurethane insulation. 2.8 FRAME ANCHORAGE .1 Provide appropriate anchorage to floor and wall construction. .2 Locate each wall anchor immediately above or below each hinge reinforcement on hinge jamb and directly opposite on strike jamb. .3 Provide 2 anchors for rebate opening heights up to 1520 mm and 1 additional anchor for each additional 760 mm of height or fraction thereof. 2.9 FRAMES: WELDED TYPE .1 Welding in accordance with CSA W59. .2 Accurately mitre or mechanically joint frame product and securely weld on inside of profile. .3 Cope accurately and securely weld butt joints of mullions, transom bars, centre rails and sills. .4 Grind welded joints and corners to a flat plane, fill with metallic paste and sand to uniform smooth finish. .5 Securely attach floor anchors to inside of each jamb profile. .6 Weld in 2 temporary jamb spreaders per frame to maintain proper alignment during shipment. 2.10 DOOR FABRICATION GENERAL .1 Doors: swing type, flush, with provision for glass and/or louver openings as indicated. .2 Exterior doors: hollow steel construction. Interior doors: honeycomb construction. .3 Doors to be 45 mm thick. .4 Fabricate doors with longitudinal edges locked seam and welded. Seams: grind welded joints to a flat plane, fill with metallic paste filler and sand to a uniform smooth finish. .5 Doors: manufacturers' proprietary construction, tested and/or engineered as part of a fully operable assembly, including door, frame, gasketing and hardware. Page 19 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .6 Blank, reinforce, drill doors and tap for mortised, templated hardware and electronic hardware. .7 Factory prepare holes 12.7 mm diameter and larger except mounting and through-bolt holes, on site, at time of hardware installation. .8 Reinforce doors where required, for surface mounted hardware. Provide flush steel top caps to exterior doors. Provide inverted, recessed, spot welded channels to top and bottom of interior doors. .9 Provide factory-applied touch-up primer at areas where zinc coating has been removed during fabrication. .10 Provide fire labeled doors for those openings requiring fire protection ratings, as scheduled. Test such products in strict conformance with CAN4-S104 and list by nationally recognized agency having factory inspection service and construct as detailed in Follow-Up Service Procedures/Factory Inspection Manuals issued by listing agency to individual manufacturers. .11 Manufacturer's nameplates on doors are not permitted. 2.13 THERMALLY BROKEN DOORS AND FRAMES .1 All exterior doors and frames to be thermally broken. .2 Fabricate thermally broken doors by using insulated core and separating exterior parts from interior parts with continuous interlocking thermal break. .3 Thermal break: rigid polyvinylchloride extrusion conforming to CGSB 41-GP-19Ma. .4 Fabricate thermally broken frames separating exterior parts form interior parts with continuous interlocking thermal break. .5 Apply insulation. Page 20 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ PART 3 Execution 3.1 INSTALLATION GENERAL .1 Install labeled steel fire rated doors and frames to NFPA 80 except where specified otherwise. .2 Install doors and frames to CSDMA Installation Guide. 3.2 FRAME INSTALLATION – (existing openings are to be verified by contractor on site.) .1 Set frames plumb, square, level and at correct elevation. .2 Secure anchorages and connections to adjacent construction. .3 Brace frames rigidly in position while building-in. Install temporary horizontal wood spreader at third points of door opening to maintain frame width. Provide vertical support at centre of head for openings over 1200 mm wide. Remove temporary spreaders after frames are built-in. .4 Make allowances for deflection of structure to ensure structural loads are not transmitted to frames. .5 Caulk perimeter of frames between frame and adjacent material. .6 Maintain continuity of air barrier and/or vapour retarder. 3.3 DOOR INSTALLATION .1 Install doors and hardware in accordance with hardware templates and manufacturer's Instructions. .2 Provide even margins between doors and jambs and doors and finished floor and thresholds as follows. .1 Hinge side: 1.0 mm. .2 Latch side and head: 1.5 mm. .3 Finished floor, top of carpet and thresholds: 13 mm. .3 Adjust operable parts for correct function. .4 Install louvres. 3.4 FINISH REPAIRS .1 Touch up with primer finishes damaged during installation. Page 21 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .2 Fill exposed frame anchors and surfaces with imperfections with metallic paste filler and sand to a uniform smooth finish. PART 1 General 1.1 REFERENCES .1 Canadian Steel Door and Frame Manufacturers' Association (CSDFMA). .1 CSDFMA Canadian Metric Guide for Steel Doors and Frames (Modular Construction): standard hardware location dimensions. .2 Canadian General Standards Board (CGSB). .1 CAN/CGSB-69.17-[M86(R1993)], Bored and Preassembled Locks and Latches. .2 CAN/CGSB-69.18-[M90]/ANSI/BHMA A156.1-[1981], Butts and Hinges. .3 CAN/CGSB-69.19-[93]/ANSI/BHMA A156.3-[1984], Exit Devices. .4 CAN/CGSB-69.20-[M90]/ANSI/BHMA A156.4-[1986], Door Controls (Closers). .5 CAN/CGSB-69.21-[M90]/ANSI/BHMA A156.5-[1984], Auxiliary Locks and Associated Products. .6 CAN/CGSB-69.22-[M90]/ANSI/BHMA A156.6-[1986], Architectural Door Trim. .7 CAN/CGSB-69.24-[M90]/ANSI/BHMA A156.8-[1982], Door Controls Overhead Holders. .8 CAN/CGSB-69.26-[96]/ANSI/BHMA A156.10-[1991], Power-operated Pedestrian Doors. .9 CAN/CGSB-69.28-[M90]/ANSI/BHMA A156.12-[1986], Interconnected Locks and Latches. .10 CAN/CGSB-69.29-[93]/ANSI/BHMA A156.13-[1987], Mortise Locks and Latches. .11 CAN/CGSB-69.30-[93]/ANSI/BHMA A156.14-[1991], Sliding and Folding Door Hardware. .12 CAN/CGSB-69.31-[M89]/ANSI/BHMA A156.15-[1981], Closer/Holder Release Device. .13 CAN/CGSB-69.32-[M90]/ANSI/BHMA A156.16-[1981], Auxiliary Hardware. .14 CAN/CGSB-69.33-[M90]/ANSI/BHMA A156.17-[1987], Self-closing Hinges and Pivots. .15 CAN/CGSB-69.34-[93]/ANSI/BHMA A156.18-[1987], Materials and Finishes. .16 CAN/CGSB-69.35-[M89]/ANSI/BHMA A156.19-[1984], Power Assist and Low Energy Power Operated Doors. .17 CAN/CGSB-69.36-[M90]/ANSI/BHMA A156.20-[1984], Strap and Tee Hinges and Hasps. .3 Canadian General Standards Board (CGSB) .1 CAN/CGSB-69 / ANSI/BHMA A156, Builders Finishing Hardware, Latest Editions. Page 22 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 1.2 REQUIREMENTS REGULATORY AGENCIES .1 Hardware for doors in fire separations and exit doors certified by a Canadian Certification Organization accredited by Standards Council of Canada. 1.4 HARDWARE LIST Existing Hardware is to be used for this project. 1.5 CLOSEOUT SUBMITTALS .1 Brief maintenance staff regarding proper care, cleaning, and general maintenance. 1.6 MAINTENANCE MATERIALS .1 Provide maintenance materials in accordance with accepted closeout practice. .2 Supply two sets of wrenches for each different type of hardware, including door closers, locksets and fire exit hardware. 1.7 DELIVERY AND STORAGE .1 Deliver, store, handle and protect materials in accordance with Section 016100 Common Product Requirements. .2 Store finishing hardware in locked, clean and dry area. .3 Package each item of hardware including fastenings, separately or in like groups of hardware, label each package as to item definition and location. 1.8 WARRANTY .1 For the work of this Section 087110 - Door Hardware - General, the 12 month warranty period is extended to 24 months. 1.9 WASTE DISPOSAL AND MANAGEMENT .1 Separate and recycle waste materials in accordance with Section 01 74 21 - Construction Waste Management And Disposal PART 2 Products 2.1 HARDWARE ITEMS PART 3 Execution 3.1 INSTALLATION INSTRUCTIONS Page 23 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .1 Furnish metal door and frame manufacturers with complete instructions and templates for preparation of their work to receive hardware. .2 Furnish manufacturers' instructions for proper installation of each hardware component. .3 Install hardware to standard hardware location dimensions in accordance with Canadian Metric Guide for Steel Doors and Frames (Modular Construction) prepared by Canadian Steel Door and Frame Manufacturers' Association. .4 Where door stop contacts door pulls, mount stop to strike bottom of pull. .5 Remove construction cores when directed by Engineer; install permanent cores and check operation of all locks. .6 Mitre or cope inside corners of weather stripping at junction of head to jamb. .7 Set thresholds in two continuous beads of sealant. Sealant in accordance with Section 079210 - Joint Sealing. 3.2 LOCKSET SCHEDULE .1 The project is to use existing locksets & closures. New hinges are to be supplied with new door and frame. DOOR LOCKSET SPECIFICATIONS ADDITIONAL NUMBER TYPE MANUFACTURER MODEL Existing locks are to be used on this project. END OF SECTION Page 24 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ JOINT SEALING - 07 92 10 PART 1 General 1.1 REFERENCES .1 Canadian General Standards Board (CGSB) .1 CAN/CGSB-19.2-[M87], Glazing Compound, Nonhardening, Modified Oil Type. .2 CGSB 19-GP-5M-[76], Sealing Compound, One Component, Acrylic Base, Solvent Curing. .3 CAN/CGSB-19.6-[M87], Caulking Compound, Oil Base. .4 CAN/CGSB-19.13-[M87], Sealing Compound, One-component, Elastomeric, Chemical Curing. .5 CGSB 19-GP-14M-[76], Sealing Compound, One Component, Butyl-polyisobutylene Polymer Base, Solvent Curing. .6 CAN/CGSB-19.17-[M90], One-Component Acrylic Emulsion Base Sealing Compound. .7 CAN/CGSB-19.18-[M87], Sealing Compound, One Component, Silicone Base, Solvent Curing. .8 CAN/CGSB-19.20-[M87], Cold-applied Sealing Compound, Aviation Fuel-resistant. .9 CAN/CGSB-19.21-[M87], Sealing and Bedding Compound Acoustical. .10 CAN/CGSB-19.22-[M89], Mildew Resistant, Sealing Compound for Tubs and Tiles. .11 CAN/CGSB-19.24-[M90], Multi-component, Chemical Curing Sealing Compound. .2 Department of Justice Canada (Jus) .1 Canadian Environmental Protection Act, 1999 (CEPA). .3 Health Canada/Workplace Hazardous Materials Information System (WHMIS) .1 Material Safety Data Sheets (MSDS). .4 Transport Canada (TC) .1 Transportation of Dangerous Goods Act, 1992 (TDGA). 1.2 SUBMITTALS .1 Submit product data in accordance with Submittal Procedures. .2 Manufacturer's product to describe. .1 Caulking compound. .2 Primers. Page 25 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .3 Sealing compound, each type, including compatibility when different sealants are in contact with each other. .4 Submit manufacturer's instructions in accordance with Submittal Procedures. .1 Instructions to include installation instructions for each product used. 1.3 MOCK-UP NA 1.4 DELIVERY, STORAGE, AND HANDLING .1 Deliver, handle, store and protect materials in accordance with Common Product Requirements. .2 Deliver and store materials in original wrappings and containers with manufacturer's seals and labels, intact. Protect from freezing, moisture, water and contact with ground or floor. 1.5 ENVIRONMENTAL AND SAFETY REQUIREMENTS .1 Comply with requirements of Workplace Hazardous Materials Information System (WHMIS) regarding use, handling, storage, and disposal of hazardous materials; and regarding labeling and provision of material safety data sheets acceptable to Labour Canada. .2 Conform to manufacturer's recommended temperatures, relative humidity, and substrate moisture content for application and curing of sealants including special conditions governing use. .3 Ventilate area of work as directed by Engineer by use of approved portable supply and exhaust fans. 1.6 WASTE MANAGEMENT AND DISPOSAL .1 Separate and recycle waste materials in accordance with Section 01 74 21 - Construction Waste Management And Disposal. .2 Place materials defined as hazardous or toxic waste in designated containers. .3 Ensure emptied containers are sealed and stored safely for disposal away from children. .4 Dispose of surplus chemical and finishing materials in accordance with federal, provincial and municipal regulations. .5 Place used hazardous sealant tubes and other containers in areas designated for hazardous materials. Page 26 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ PART 2 Products 2.1 SEALANT MATERIALS .1 Sealants and caulking compounds must: .1 Meet or exceed all applicable governmental and industrial safety and performance standards; and .2 Be manufactured and transported in such a manner that all steps of the process, including the disposal of waste products arising there from, will meet the requirements of all applicable governmental acts, by laws and regulations including, for facilities located in Canada, the fisheries Act and the Canadian Environmental Protection Act (CEPA). .2 Sealant and caulking compounds must not be formulated or manufactured with: aromatic solvents, fibrous talc or asbestos, formaldehyde, halogenated solvents, mercury, lead, cadmium, hexavalent chromium, barium or their compounds, except barium sulfate. .3 Sealant and caulking compounds must be accompanied by detailed instructions for proper application so as to minimize health concerns and maximize performance, and information describing proper disposal methods. .4 Caulking that emits strong odors, contains toxic chemicals or is not certified as mould resistant shall not be used in air handling units. .5 When low toxicity caulks are not possible, confine usage to areas which off gas to the exterior, are contained behind air barriers, or are applied several months before occupancy to maximize off-gas time. .6 In the selection of the products and materials of this section preference will be given to those with the following characteristics: low Volatile Organic Compound (VOC) content, manufactured without compounds which contribute to ozone depletion in the upper atmosphere, manufactured without compounds which contribute to smog in the lower atmosphere, does not contain methylene chloride, does not contain chlorinated hydrocarbons. .7 Sealants acceptable for use on this project must be listed on CGSB Qualified Products List issued by CGSB Qualification Board for Joint Sealants. Where sealants are qualified with primers use only these primers. Page 27 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ 2.2 SEALANT MATERIAL DESIGNATIONS .1 Sealant A: Polyurethane Elastomeric Sealant, Two Part to CAN/CGSB-19.24 .1 Non-sag or Self-Levelling as required by application .2 Shore “A” Hardness at 14 Days: Non-sag 25 +/- 5, Self Levelling 40 +/- 5 .3 Colours to match adjacent materials, and as selected by Engineer. .2 Sealant B: Silicone, One Part. .1 To CAN/CGSB-19.22 (Mildew resistant). .1 Non-sag, one component, moisture curing .2 Shore “A” Hardness at 14 Days: 25 +/- 5 .3 Non-staining and non-bleeding .4 Colours to match adjacent materials, and as selected by Engineer. .3 Sealant C: Polyurethane, One Part to CAN/CGSB-19.13 .1 Non-sag, one component, moisture curing .2 Shore “A” Hardness at 21 Days: 40 +/- 5 .3 Non-staining and non-bleeding .4 Colours to match adjacent materials, and as selected by Engineer. .4 Sealant D: Polyurethane, One Part Security Sealant .1 Non-sag, one component, moisture curing .2 Shore “A” Hardness at 21 Days: 50 +/- 5 .3 Non-staining and non-bleeding .4 Colours to match adjacent materials, and as selected by Engineer. .5 Pick Resistant .6 Acceptable Products: NO SUBSTITUTIONS .1 Tremco Permaquik 2252 .2 Pecora Dynapoxy EP-430 Fast .3 Sika AnchorFix 3 .4 BASF Epolith G .5 Sealant E: Acoustical Sealant to CAN/CGSB-19.21 .1 Non-sag, one component, moisture curing .2 Shore “A” Hardness at 14 Days: 25 +/- 5 .3 Non-staining and non-bleeding .4 Colours to match adjacent materials, and as selected by Engineer. .6 Preformed Compressible and Non-Compressible back-up materials. .1 Polyethylene, Urethane, Neoprene or Vinyl Foam. .1 Extruded closed cell foam backer rod. .2 Size: oversize 30 to 50 %. Page 28 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .2 Bond Breaker Tape. .1 Polyethylene bond breaker tape which will not bond to sealant. 2.3 JOINT CLEANER .1 Non-corrosive and non-staining type, compatible with joint forming materials and sealant recommended by sealant manufacturer. .2 Primer: as recommended by manufacturer. PART 3 Execution 3.1 PROTECTION .1 Protect installed work of other trades from staining or contamination. 3.2 PREPARATION OF JOINT SURFACES .1 Examine joint sizes and conditions to establish correct depth to width relationship for installation of backup materials and sealants. .2 Clean bonding joint surfaces of harmful matter substances including dust, rust, oil grease, and other matter which may impair work. .3 Do not apply sealants to joint surfaces treated with sealer, curing compound, water repellent, or other coatings unless tests have been performed to ensure compatibility of materials. Remove coatings as required. .4 Ensure joint surfaces are dry and frost free. .5 Prepare surfaces in accordance with manufacturer's directions. 3.3 PRIMING .1 Where necessary to prevent staining, mask adjacent surfaces prior to priming and caulking. .2 Prime sides of joints in accordance with sealant manufacturer's instructions immediately prior to caulking. 3.4 BACKUP MATERIAL .1 Apply bond breaker tape where required to manufacturer's instructions. .2 Install joint filler to achieve correct joint depth and shape, with approximately 30 % compression. 3.5 MIXING .1 Mix materials in strict accordance with sealant manufacturer's instructions. 3.6 APPLICATION .1 Sealant. .1 Apply sealant in accordance with manufacturer's written instructions. Page 29 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ .2 Mask edges of joint where irregular surface or sensitive joint border exists to provide neat joint. .3 Apply sealant in continuous beads. .4 Apply sealant using gun with proper size nozzle. .5 Use sufficient pressure to fill voids and joints solid. .6 Form surface of sealant with full bead, smooth, free from ridges, wrinkles, sags, air pockets, embedded impurities. .7 Tool exposed surfaces before skinning begins to give slightly concave shape. .8 Remove excess compound promptly as work progresses and upon completion. .2 Curing. .1 Cure sealants in accordance with sealant manufacturer's instructions. .2 Do not cover up sealants until proper curing has taken place. .3 Cleanup. .1 Clean adjacent surfaces immediately and leave work neat and clean. .2 Remove excess and droppings, using recommended cleaners as work progresses. .3 Remove masking tape after initial set of sealant. 3.7 SEALANT SELECTION .1 Sealant A: .1 Perimeters of exterior openings where frames meet exterior facade of building .2 Control and expansion joints in exterior surfaces of unit masonry walls .3 All exterior locations noted on drawings for sealant .3 Sealant C: .1 All interior joints between dissimilar materials. .2 All interior locations noted on drawings for sealant End of Section DOORS Three(3) doors – 2, 4, & 5. - APPROX - 3.0 X 7.0 X 13/4” One(1) door – 43. - APPROX - 3.0’ x 8.0’ One (1) Over Head Door –APPROX - 9.0’ x 8.0’ Page 30 of 31 SPECIFICATION FOR CONSTRUCTION FOR Exterior Doors, Windows and siding Waskesiu GOCB Building Waskesiu, Sask. _____________________________________________________________________________________ WINDOWS Three(3) – APPROX - 7.0’ x 4’ 3/16” Three(3) – APPROX - 8.0 ‘ X 4’ 3/16” ATTACHMENTS – Main Floor Drawing END OF GENERAL REQUIREMENTS Page 31 of 31