Stokes Law for Chuck Lewis - High

advertisement

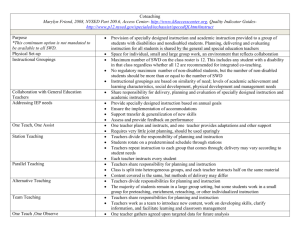

Pro-Fit Salt Water Disposal Plant Design An Engineered Approach to Steady State Plant Design INTRODUCTION The oil industry of the past can be characterized as an aging traditionalist group of companies trapped in their own paradigms. In 2014 the oil industry is vigorous, and made up of younger, better educated, fearless, far more flexible, imaginative, and aggressive professionals who have few if any paradigms. All that is lacking now is the knowledge of what is possible and how to achieve it. With water is at the forefront of most oil industry discussions today, managing water is one of the more pressing topics. In 2014 the industry is using more water than ever before in it massive frac jobs. Water sources are limited, and water re-use is a hot topic. In 2014 the industry produces over none times as much water as oil. All of that water has to come from someplace and it has to go someplace when it is expended. The common denominator is today’s salt water disposal plant, the “SWD”. However, thousands of SWDs already exist today. Most are older; unmanned, built before the advent of SCADA, and without an emphasis on oil recovery or EBITA economics. Hundreds of new SWDs are built every year. Many of these are built with a focus on low capital cost and ROI, with income treated like an annuity. The builders often copy other local plants rather than employing engineering expertise. And still, they make money! They do not, however, make near as much as they should! The Pro-Fit™ SWD System attacks this issue with a vengeance, maximizing performance, and increasing owner cash flow by at least 200%. Pro-Fit™ is a patented SWD process and plant design. It employs only state-ofthe art components. Each component is selected to compliment the next and to contribute to optimum overall plant performance. The result is a complete system, engineered to generate maximum cash flow and the highest profitability for the owner. Page 2 of 5 THE PRO-FIT™ PROCESS The Pro-Fit™ process was developed with three prime directives for any SWD plant: 1. Capture and sell every drop of available crude oil. 2. Clarify the water to the greatest extent possible within a controlled economic model. 3. Maximize disposal well life through automated fluid flow management in the plant. The common denominator and the condition necessary to achieve them is the “steady state” operation of the SWD Plant. Since gravity separation is in play in all SWD Plants, the separation of oil from water follows the physical laws of gravity separation. Chief among these is Stokes’ Law. Stokes’ Law quantifies the separation velocity, or flow rate, of two or more separating fluids according to their physical characteristics. Since dynamic separation has to do with flow velocities, enhancing separation has everything to do with controlling the fluid flow, with the aim to achieve a steady state where flow is constant. Steady state is difficult to achieve in any SWD Plant. In 2014 most water is trucked from the source to the SWD Plant in 130 barrel trucks. Trucks arrive at unpredictable intervals and numbers. The water received into the SWD Plant from these trucks is totally unpredictable both in terms of quantities or timing. This reality creates a real challenge for the steady-state design of any SWD plant. The goal of achieving the constant flow of fluids in an ever changing fluid flow environment is quite challenging, but it is far from impossible. The Pro-Fit™ System achieves this goal! To achieve steady-state in a SWD Plant, the inlet flow needs to be conditioned to a more constant flow condition. To do this all intermittent inlet flows need to “buffered”. Buffering flow rate changes can be accomplished by 1) dividing the flow, and 2) accumulating or storing the inlet water in an intermediate storage facility. By accumulating the inlet fluid in “buffer” tanks, the inlet flow rate peaks and valleys can be equalized using storage as a buffer to varying rates so the effluent from the buffer tanks can be controlled at the desired and constant flow rate. Next, with crude oil prices at or near $100/barrel, a primary SWD Plant process goal is to separate, capture, and sell every drop of crude oil present in the waste water being hauled to the SWD Plant. The first step in this process is to slow the flow rate of the inlet fluids as mentioned above. This is first done by equally dividing the inlet flow into the inlet buffer tanks via a flow dividing tank (aka DFSD™) so that the flow rate of the influent into any one buffer tank downstream is a fraction of the total inlet flow. The next step in this process is to design the buffer tanks so the influent stream in each buffer tank distributes uniformly in the entire tank, thus further slowing the overall flow and maximizing the retention time of the fluids within each buffer tank. Doing so obviously maximizes the opportunity for separation. The result is a pre-separation of oil and water, where some percentage of the oil entrained or dispersed in the water can and does separate in each buffer tank. Since it is virtually impossible to achieve ideal retention time in buffer tanks, only a Page 3 of 5 portion of the oil will separate there. As a key part of the Pro-Fit™ System flow distribution internals are installed in every Pro-Fit™ System buffer tank to maximize fluid distribution. Additionally, depending on the time that oil remains in the buffer tank, the crude oil may contain various quantities of contaminants. These contaminants are defined by the term BS&W, an acronym standing for “basic sediment and water”. For oil to be marketable, these contaminants must be reduced to very low concentrations. The allowable concentration varies geographically, generally in the 0.1% to 3% range, and averages 0.5% maximum. Steady state is the key to removing the oil borne BS&W contaminants. So, the Pro-Fit™ System uses smart level transmitters to detect the amount of oil in each tank, and to transfer it to oil storage tanks where no dynamic fluid movement occurs. This level of quiescence maximizes BS&W separation in the oil tanks, reducing BS&W levels to those acceptable to a crude oil buyer. The water leaving the buffer tanks is metered out of the buffer tanks by special low-shear liquid moving pumps. These specialty pumps are designed to avoid the mixing energy necessary to remix oil and water. These pumps move the buffered water, which entered the plant a various flow rates, out of the buffer tanks at a constant flow rate, achieving the desired “steady state” process condition. The water now flows in a steady state at a constant flow rate into an oil-water separation system designed for the maximum steady state flow rate of the SWD Plant. This separation system (aka HWSB™ Skim Tank) efficiently separates remnant crude oil from water, automatically sending separated crude oil to the crude oil storage tanks, and sending the separated oil-free water to a storage tank (aka surge tank) from which the water is eventually pumped through a filter bank and on to the deep disposal well. PRO-FIT™ “AUTO-OP™” AUTOMATION SOFTWARE The entire Pro-Fit™ system is computer controlled. Pro-Fit™ operating software manages the flow of fluids throughout the plant one these priorities: 1. Maintain the high pressure injection pump in a running condition whenever possible to minimize deep well formation damages from a start-stop condition. 2. Maintain near-constant flow through the oil-water separation system within a narrow band to optimize oil-water separation efficiency. In order to maintain water flow through this highly dynamic plant the Pro-Fit™ automation software manages the fluid flow through the plant under its many varying conditions. These are typified by the descriptions below: DAYTIME OPERATIONS Trucks are employed to move water from its remote sources to the SWD Plant. Most of this water hauling process occurs during daylight (normal working) hours, roughly from sun-up to sun-down. Since each SWD Plant services a grouping of source facilities within a given radius, truck traffic tends to group. This tends to happen in “activity waves”. Each wave results from the natural traffic flow for trucks going to the source, picking up a load of water, driving to the SWD Plant, dumping the water, and returning Page 4 of 5 to the source for another load. Trucks tend to typically arrive at SWD Plants in three waves; one in the morning, one around noontime, and one in the late afternoon. As these trucks begin to arrive in the morning the Pro-Fit™ automation software maximizes the throughput through the SWD plant to keep the buffer tanks as empty as possible. During any one wave of truck traffic, the varying inrush rate of water exceeds the constant disposal rate of water, so the buffer tanks gradually fill up. Sufficient tanks are included in the Pro-Fit™ process design so the tanks normally never fill completely. As the noontime wave occurs, the Pro-Fit™ software continues to manage total plant throughput at or near maximum. However, after the noontime wave the Pro-Fit™ software begins to automatically throttle back the outflow, managing the buffer tank storage space to just accommodate the late afternoon wave without overfilling any buffer tank, but allowing the buffer tanks to reach the near-full condition. This “managing” means that during the afternoon hours the disposal well pumping system is throttled back to achieve the ideal near-full storage condition desired after the final wave in the late afternoon. From the conclusion of the late afternoon final wave event until the next morning wave the next day, the Pro-Fit™ software slows the rate of fluid transfer from the buffer tanks through the separation (HWSB™) system and on to the surge tank. It also reduces the disposal pump to a software-determined rate so the buffer tanks are near empty when the first wave of the next day begins. The surge tank is the last tank in the system to empty, providing an additional buffer against the likelihood of a no-water-flow plant condition which would trigger the undesirable disposal pump system shutdown. In unusual conditions resulting from higher than normal water haul truck activity triggered by new well flowback water hauling 24/7 events, the Pro-Fit™ software determines that the wave events are not occurring normally, and adjusts accordingly to maximize throughput through the SWD Plant 24/7. Finally, the Pro-Fit™ software alerts the owner and his staff in the event of any unusual event. If a component malfunctions, Pro-Fit™ reports it electronically via SCADA communications so a technician can be dispatched pre-advised of the failure point so he travels to the SWD Plant site with the knowledge and parts he needs to execute the necessary repairs. Perhaps the most important unusual event for the SWD Plant owner is the custody transfer of his crude oil. This is the cash cow if his plant, generating the majority of the plant’s gross and net income. The Pro-Fit™ software allows the owner to permit such custody transfers via an encoded remote owner input, and alerts the owner and his staff in the event any unauthorized movement of plant crude oil is attempted. CONCLUSION The Pro-Fit™ SWD Plant Design and Pro-Fit™ software program combine to produce SWD plants which operate themselves to minimize human interfacing, maximize oil Page 5 of 5 recovery and oil quality, take effluent water quality to the highest possible level to avoid disposal well plugging, and allow for automatically maximized daily water throughput for complete SWD plant utilization under widely varying and reasonably unpredictable conditions. The result is a smarter plant with maximized cash flow in a 21st century environment where manned operation is unnecessary. ABOUT THE DEVELOPER OF THE PRO-FIT™ SYSTEM Bill Ball is the founder and owner of HTC, Inc. He has a long history of oilfield plant and separation system design development, which when coupled with his vast oilfield experience and career portfolio, make him one of the industry’s leading SWD Plant, Plant Automation, and Separation system authorities today. After his university studies his career began in a very challenging 1,000,000 b/d waterflood operation where he was responsible to evaluate and improve the performance of all surface facilities. Through this hands-on effort, he learned the modifications that help improve process efficiency, and those that do not. In the 50 years since Bill has accumulated a lifetime of knowledge and experience in oilfield separation, and now is the named inventor in several related patents. The culmination of this work are patents covering the Pro-Fit™ SWD Plant Design and Automation System, and components like the HEGB™ (high efficiency Gunbarrel), the DFSD© De-sanding, Degassing, Flow Splitting Tank, the HWSB© Skim Tank, and the Pro-Fit™ SWD Plant design. These and other unique components achieve the highest level of separation and hydraulic efficiency known to exist in any design, and make the Pro-Fit™ Plant design the best in the industry. The results are an unparalleled quality and quantity improvement in the effluent streams, and the most immediate ROI for investors in these technologies and intellectual properties. Today, HTC, Inc. is one of the industry’s leading low-cost surface facilities design firms. Bill surrounds himself with like minds. He and his team of seasoned veterans specialize in salt water disposal (aka SWD) plant, flowback water treatment plants, crude oil processing and dehydration plant designs, and many other endeavors worldwide. HTC affiliates blanket every field of engineering discipline making HTC a full service firm capable of complete turnkey designs.