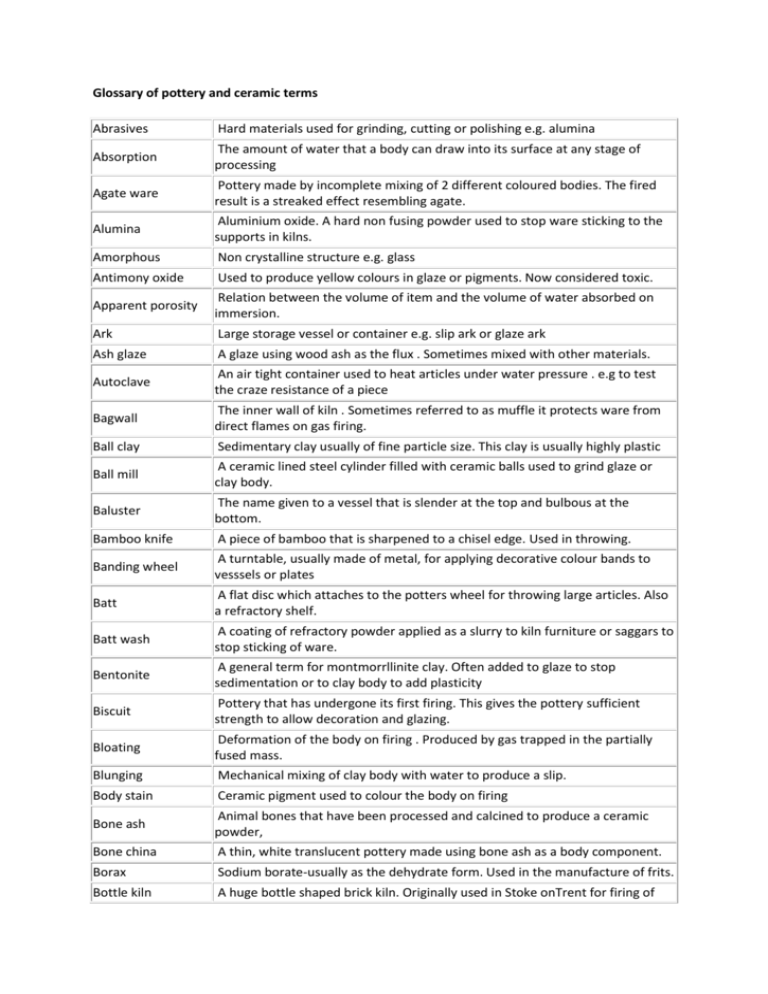

Glossary of pottery and ceramic terms

advertisement

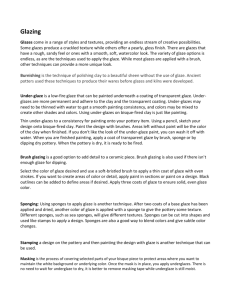

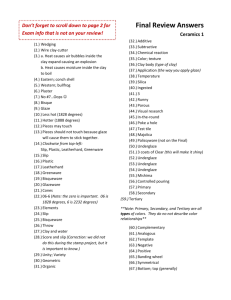

Glossary of pottery and ceramic terms Abrasives Hard materials used for grinding, cutting or polishing e.g. alumina Absorption The amount of water that a body can draw into its surface at any stage of processing Agate ware Pottery made by incomplete mixing of 2 different coloured bodies. The fired result is a streaked effect resembling agate. Alumina Aluminium oxide. A hard non fusing powder used to stop ware sticking to the supports in kilns. Amorphous Non crystalline structure e.g. glass Antimony oxide Used to produce yellow colours in glaze or pigments. Now considered toxic. Apparent porosity Relation between the volume of item and the volume of water absorbed on immersion. Ark Large storage vessel or container e.g. slip ark or glaze ark Ash glaze A glaze using wood ash as the flux . Sometimes mixed with other materials. Autoclave An air tight container used to heat articles under water pressure . e.g to test the craze resistance of a piece Bagwall The inner wall of kiln . Sometimes referred to as muffle it protects ware from direct flames on gas firing. Ball clay Sedimentary clay usually of fine particle size. This clay is usually highly plastic Ball mill A ceramic lined steel cylinder filled with ceramic balls used to grind glaze or clay body. Baluster The name given to a vessel that is slender at the top and bulbous at the bottom. Bamboo knife A piece of bamboo that is sharpened to a chisel edge. Used in throwing. Banding wheel A turntable, usually made of metal, for applying decorative colour bands to vesssels or plates Batt A flat disc which attaches to the potters wheel for throwing large articles. Also a refractory shelf. Batt wash A coating of refractory powder applied as a slurry to kiln furniture or saggars to stop sticking of ware. Bentonite A general term for montmorrllinite clay. Often added to glaze to stop sedimentation or to clay body to add plasticity Biscuit Pottery that has undergone its first firing. This gives the pottery sufficient strength to allow decoration and glazing. Bloating Deformation of the body on firing . Produced by gas trapped in the partially fused mass. Blunging Mechanical mixing of clay body with water to produce a slip. Body stain Ceramic pigment used to colour the body on firing Bone ash Animal bones that have been processed and calcined to produce a ceramic powder, Bone china A thin, white translucent pottery made using bone ash as a body component. Borax Sodium borate-usually as the dehydrate form. Used in the manufacture of frits. Bottle kiln A huge bottle shaped brick kiln. Originally used in Stoke onTrent for firing of pottery-now museum exhibits exist only. Bullers ring Special ceramic discs used to assess the firing in kilns. The measured contraction of the disc indicates the heat applied. Burnish Achieving a high sheen by polishing surface of piece with smooth tool marble or spoon when semi dry. Calcium carbonate Used a a glaze or frit component-also called limestone Calcination A high temperature heating process usually employed to change the crystalline form, e.g. flint Caliper A device for measuring the internal or external diameter of an object. Casting Forming pottery by pouring a slip into a porous mould Casting slip A very fluid slip of high solids content made of clay body, deflocculant and water. It is used in the casting process to form pottery shapes. Celadon A transparent green glaze pale in colour of Chinese origin Ceramic Derived from the Greek word 'Keramos' meaning earthen vessel. Used nowadays to describe many high temperature formed produced using ceramic materials. Cheesehard Also called leatherhard-a clay body that is dry enough to retain its shape. Chemically combined water Water that is chemically attached to materials e.g. clay and is only removed by high temperature firing China clay Also known as kaolin. Made from pegmatite and mined in Cornwall and other parts of the world. Chinastone Pegmatite. A feldspar and in its impure form the source china clay in the UK. Chrome oxide Used to produce yellow or green pigments or glazes Chuck Tube like former to hold a pot in position on the wheel while the foot is being trimmed. Chun A pale blue glaze used on stoneware Clay body The main pottery body composed of intimately mixed clays,feldspar,silica and other materials Cobalt oxide Used as a blue colorant in body glaze or decoration. Coefficient of expansion A measure of the reversible change of volume with temperature. can be quoted as linear or cubic expansion Coiling Rolled cylinders of clay build up to make a solid pottery form. Colloid A stable suspension of ultra fine particles. Cutting parallel lines in the clay or through slip. Combing Comminution Size reduction by breaking, crushing or grinding Compressive strength The ability of an article to withstand crushing loads Cones Sometimes called pyrometric cones, these ceramic pieces change shape and slump on exposure to heat. Used by potters as an indicator of a repeatable firing cycle. Copper oxide Used to produce green transparent colours in glaze. Under reducing fire can give bright red colours. Crackle Intentionally produced decorative crazing of the glaze. Crawling Shrinkage of the glaze leaving exposed body or pinholes after glaze firing-has many causes. Crazing Cracking of the glaze after firing. Caused by mismatch of body and glaze expansion. Cryptocrystalline Possessing crystals so small that they cannot be distinguished by optical microscope Cut glaze Bare areas on glazed ware caused by mechanical damage of the glaze prior to firing. Damper A crude device or small hinged refractory door to control the flow of gases from the kiln. De-airing Removal of air from clay either by wedging by hand or using a special chamber in the pug mill. Deflocculation The dispersion of clay slip or glaze by the addition of an electrolyte e.g. sodium silicate or soda ash Delft Opaque lead glazed earthenware often decorated by metal oxides prior to firing Devitrification Crystallisation of a vitreous glaze after firing. Often at the surface of the glaze. Dilatancy The property of a suspension whereby it gets thicker as it is stirred and thinner as it stands. Dipping The application of glaze or decoration slip by immersion and ten allowing excess to drain off. Dispersion The separation of the clusters of fine particles in water into individual particles. Draw Absorption of glaze by an unglazed surface during firing. Dropper Globules of glaze that are found on glazed pieces after firing. These are caused by drops from the kiln roof. Dunting Cracking pottery on cooling. Often caused by silica inversions in the body or too fast firing. Earthenware Originally a moderately porous pottery formed by firing a mixture of ball clay, flint , china clay and feldspar. Edge runner mill At ype of mill for mixing or grinding materials using 2 large stone rollers and a stone pan. Efforescence A growth on the surface of bricks or other articles due to the the presence of soluble salts. Electrical porcelain Type of porcelain used for producing electrical insulators. Typical formula 28 ball clay,22 china clay.quartz25,feldspar 25 Elutriation The separation of particles according to their size or density by a controlled velocity water stream. Enamel A fusible low temperature coating for metal or decoration for pottery. Engobe A white or coloured coating of clay slip applied to the body prior to glazing. Often used for technical or decorative reasons. Eutectic A set mixture of 2 components having a lowest melting point of any ratio of the individual components. Extrusion The process of forcing a clay body through an aperture or die to achieve a specific cross section or size. Faceting Cutting away the clay surface. Faience Style of tin glazed earthenware produced in Europe. Feathering Effect obtained by trailing a feather thro still wet slip decoration Feldspar A crystalline mineral caused by weathering of granite. Used as a high temperature flux in many bodies. Fettling The removal of the seams edges and blemishes from dried pots prior to glazing Fillers Minerals added to a body to give it rigidity or strength. Quartz and flint are termed as fillers. Filter cloth Used to filter press clay slip to produce solid filter cake Filter pressing Process used to change slip into solid clay. Clay slip is forced thro a special cloth to remove water. Fireclay Clay that is usedd for refractory items. some fireclays contain natural grogs to improve shock resistance. Firing The increase in temperature used to produce a ceramic item. Flocculation The aggregation of ceramic particles in a suspension. A divalent electrolyte such as CaCl2 is commonly used to create a thickening effect. Flambe A strong red glaze produced by a reduced copper glaze. Flatware Plates, saucers, trays etc Flint Calcined powdered silica often used in earthenware bodies. Fluting Cutting decorative grooves into clay in parallel lines, often on thrown ware. Flux A material added to a glaze body or colour to improve its melting properties Foot The base of the pot on which the piece stands. Frit A special glass ground to a powder and used to reduce the melting point of a glaze. Frizzling A decorating fault where the decoration curls or moves on firing. There are many causes. Fusibility The melting behaviour of a ceramic glaze, frit, flux or decoration with increase in temperature. Glaze a thin glaze coating formed on the surface of pottery to render it impermeable and provide decoration. Glaze-body fit The relationship between the thermal expansion of rhe body and glaze. Ideally the glaze should have a lower expansion than the body. Glaze stain A colouring pigment added to a glaze to produce a coloured glaze. Glost A glazed and fired piece is referred to as 'glost'. Greenware Clay pieces that have been formed but not fired. Grog Ceramic material that is relatively coarse compared to the rest of body components. Generally used to give texture or improved thermal shock properties. Gypsum Plaster of paris used to make moulds Hakeme Oriental technique of applying white slip with a brush made of straw-allows slip to be applied thickly. Handbuilding Constructing pottery from premade components. These components might be made by moulding, coiling or by hand. Hardening on A firing process normally 650-700C to remove organic components of underglaze decoration. Hot pressing Densification of a ceramic by simultaneous application of heat and pressure. Holloware cups, jugs, bowls etc Impressed A design stamped into the leatherhard clay using a die or tool Incised Pattern cut into the clay with a sharp tool Inlay Coloured clay rolled into the main body clay Jiggering Machine process using a mould to form the inside of the plate and the tool the outside Jolleying Machine process using a mould to form the outside of the pot and the tool the outside Kaolin Also called china clay. White firing clay used in many bodies. Kiln High temperature oven or furnace used for firing of pottery. Kiln furniture General term used to describe refractory pieces used to separate or support items during firing Kiln wash Refractory slurry applied to kiln furniture to stop sticking during firing Lamination A fault structure in clay before or after firing where the clay is aligned in layered clusters. Lawn A sieve Lead solubility The solubility of lead containing glaze or colour powders when exposed to aqueous hydrochloric acid Leatherhard Or cheesehard. Clay that has dried to a point where it retains its shape. Limestone Calcium carbonate-often used as a glaze component Lithograph A method of decoration involving transfers. Allows fine detailed printing. Loss on ignition The loss in weight of a clay body when fired to a high temperature (usually 1000C) expressed as a % Lustres A metallic thin film applied to pottery either as a glaze or decorative effect Lute To join 2 pottery surfaces together with slip Majolica The technique of applying low fired tin glazes with colours to produce a multi coloured effect. Manganese oxide Colouring oxide used in glaze or decoration to give brown to purple colours. Model The original or prototype article Modulus of elasticity The term used to define the extent a material can be distorted under stress without fracture. Modulus of rupture The term is used to define the strength of unfired clay body or the fired ceramic. Moisture expansion The extent to which a porous ceramic expands when it absorbs moisture or water vapour. Mould The shape usually made of plaster used to form the article either by casting or pressing. Muffle kiln A type of kiln where the ware is protected from the flame by an inner refractory box. Nickel oxide Used to produce brown, green or violet colours in glaze. Now considered toxic. Onglaze Decoration applied on top of the fired glaze. Overglaze or enamel terms are sometimes used. Opacifier An additive to the glaze to give opacity e.g. zircon or tin oxide Particle size The distribution of particle sizes either as a powder or a slurry. Important measure in manufacture of glaze or colour. Peeling A defect in glazed and fired ware. The glaze flakes off in pieces particularly on edges. Piercing Cutting through walls of pot Peephole Small hole in a kiln door for the potter to observe the progress of firing. Pinching Indenting a pot with fingers or thumb before it is hard. Pinholes A common fault in the body or glaze. Small holes appear in the glaze or body as gases erupt thro the surface. Pitchers Fired or broken scrap pottery (of course also a large jug) Plaster of paris Gypsum. Used to make moulds. Plasticity The property of clay which allows it to be moulded and retain its shape after the force is removed. Plucked ware A fault caused by the ware sticking to the refractory support during firing Porcelain A vitrified and white translucent ware made predominantly in Europe and Asia. Usually strong in use. Porosity The amount of pore space in a ceramic body-consists of closed and open pores. Pouncing The ancient technique known as pouncing is when 'pounce', powder graphite or charcoal, is rubbed through a series of small holes punched in a paper pattern to transfer a design to an item to be decorated. Press Mould/Hump Dropping sheet of clay over or into a plaster or bisque shape. Mould Pugging The intimate mixing and extrusion of plastic clay body. Also the machine used to carry out this process. Pulling Shaping a handle by hand to the correct size and shape. Pyrometer High temperature measuring device Pyrometric cones Special refractory cones placed next to the ware to confirm repeatable firing. Quenching Method of making a frit where the molten glass is poured into cold water to produce small granules of frit Raku Low fired glazed firing (1000oC). Produced normally by rapid firing. Raku is Japanese for 'enjoyment' and this type of pottery is used in the Japanese tea ceremony. Raw glaze A glaze in which no frit is present-normally a high fire glaze over 1100C Reducing atmosphere A kiln atmosphere which is deficient in free oxygen(more gas less air)-used to produce specific glaze colours or effects Refractory Ceramics that are able to withstand high temperatures without distortion. Rib A shaped tool to facilitate forming of a pot on a wheel. Saggars A fireclay or other refractory box used originally to protect the ware during firing Salt glaze Thin orange peel glaze produced on the surface of pottery-originally produced by throwing salt into the kiln and allowing it to vaporise. Sang-de- Boeuf Ox-blood colour used to describe deep red colour of some glazes Sedimentation The settling out over time of any clay or glaze slip. More noticeable in glazes low in clay content. Sgraffito The technique of scratching through an applied slip layer to reveal the colour of the body beneath. Shelling Same as peeling: A defect in glazed and fired ware. The glaze flakes off in pieces particularly on edges. Shivering Same as peeling: A defect in glazed and fired ware. The glaze flakes off in pieces particularly on edges. Sintering The adhesion and densification of particles on heating Slip A Liquid clay to which colour can be added in the form of oxides or body stains, slip can be marbled – feathering- trailer application- paper/wax/ latex- resists Slip decoration Application of contrasting coloured slip to a body as a form of decoration. Slabbing A building technique where slabs of clay are joined at edges to form an article. Slumping Soft clay shaped and altered by using gravity, dropping, tapping and folding Slurry/Slop Soft clay used to join leather hard, cross hatched clay together Silk screen A form of decoration where the colour paste is forced thro a decorative patterned screen either directly onto the ware or a transfer paper. Smoke Firing/Pit Firing Firing in newspaper Soak Allowing the pottery to remain at the peak temperature for a time period. This allows all positions in the kiln to reach approx the same temperature Spalling Flaking, cracking or disintegration of ceramics when subjected to rapid temperature changes. Specific surface area The total surface area of a all particles per unit weight of material Spitout Rapid desorption of moisture during the on glaze firing process causing a severe fault of small craters or pinholes. Spray drying A means of drying clay slips or other ceramic slurries by spraying the slurry into a large chamber of hot air Sprig Decorative pieces applied to leather hard pots Spur marks The marks left on pottery from refractory supports used to fire the piece. Stoneware A vitreous opaque pottery containing naturally vitrifying clay. Favoured by many studio potters Surface tension The tendency of a fluid to wet a surface. E.g. low surface tension= high wetting Tailings The portion of a material which does not pass thro a sieve or is returned for further processing Tenmoku A stoneware glaze deeply coloured by iron oxide. Colours can vary from yellow, green. red. blue or black Tensile strength The resistance of a material to being stretched by tension or pulling Terracotta Red eathenware body usually made with naturally red clays Thermal conductivity The rate at which heat passes through a material as measured by its rise in temperature. Thermal shock The failure of a ceramic article due to stresses created by rapid temperature change. -either hot to cold or cold to hot Thermocouple A device for measurement of temperature in a kiln. Usually in the form of a special metallic wires encased in a ceramic sheath. Thread Twisted wire sometimes used by potters for cutting pots of a wheel Throwing Making a pot on a potters wheel Tin glaze White opaque glaze produced with tin oxide in the glaze recipe. Titanium oxide Used in glazes to produce decorative crystalline effects Towing The smoothing of the outer edge of flatware in its green state. Transfer printing The method of applying a decoration to a pot. Slide off transfers using ceramic colours are applied to the glost ware and the refired to bond the decoration to the glaze. True porosity The sum of open and closed pores in a ceramic body. Tube lining A decorating technique where coloured slips are piped thro a small nozzle onto clay ware. This is often used as a border for further decoration. Tunnel kiln A kiln where the pottery moves progressively thro a heated zone to fire the pottery. Underglaze A decoration applied either directly to the clay or biscuit prior to glaze application and firing Viscosity The resistance of a fluid to flow. the reciprocal of fluidity Vitreous Glassy-having very low or zero porosity Vitrification The change from a porous to vitreous state of a ceramic Volatility The process of evaporation of materials on firing Wall pocket A vase usually with a flat back for attachment to a wall Water absorption A measure of the open porosity of a ceramic-determined by soaking the item in water for a set time Wax resist Wax applied to a pot to stop glaze or decoration sticking to these areas during application. Wedging A method of de-airing and dispersing moisture evenly in clay. The clay is worked by hand by repeated throwing of the clay onto the bench and folding over. Wetting agent A chemical used to help the application of glaze or colour to allow it to better cover uneven areas. Wheel Also potters wheel- a horizontal disc on a foot operated or motor driven shaft. Used for throwing of pots. Wreathing Ripples or waves on the inside of a cast pot after draining. Caused by variation in casting rate at different parts of the pot