TwoWire_General_Spec..

advertisement

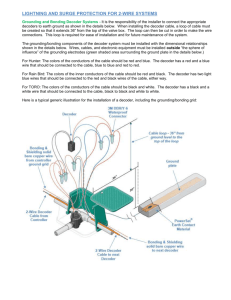

Baseline Two-wire Specification & Two-wire Device Specification Table of Contents PART 1 - Wire Specifications ...................................................................... 2 1.1 Two-Wire Specifications ............................................................................................................ 2 1.2 Wire Path .................................................................................................................................... 2 1.3 Wire Installation Details ............................................................................................................. 3 PART 2 - Connectors .................................................................................... 3 2.1 Direct Bury ................................................................................................................................. 3 2.2 Connector Installation Details .................................................................................................... 3 PART 3 - Field Decoders .............................................................................. 4 3.1 Valve Decoders .......................................................................................................................... 4 3.2 Valve Decoder Wiring and Installation ...................................................................................... 5 3.3 Flow Decoder Specifications ...................................................................................................... 5 3.4 Flow Decoder Wiring and Installation ....................................................................................... 6 3.5 Event Decoders........................................................................................................................... 7 3.6 Event Decoder Wiring and installation....................................................................................... 8 3.7 Outside Operation Button Decoders [Coach’s Button] .............................................................. 9 3.8 Outside Operation Button Decoder Wiring and Installation ....................................................... 9 3.9 Air Temperature Sensors ...........................................................................................................10 3.10 Air Temperature Sensor Wiring and Installation .......................................................................10 3.11 Pump Start/Stop Relay Switching Decoders .............................................................................11 3.12 Pump Start/Stop Relay Switching Decoder Wiring and Installation .........................................11 3.13 Compact Soil Moisture Sensors ................................................................................................12 3.14 Original Soil Moisture Sensors..................................................................................................12 3.15 Soil Moisture Sensor Wiring and Installation ...........................................................................13 Baseline Support: 866-294-5847 1 www.baselinesystems.com Baseline irrigation controllers shall use the following specifications for two-wire and twowire devices: PART 1 - Wire Specifications 1.1 Two-Wire Specifications A. The two-wire shall have the following operating voltage: 600 V RMS max B. The two-wire shall have the following temperature rating: 140°F (60°C) C. The two-wire shall meet one criterion within each of the following categories: 1. Outer Jacket a. High density polyethylene (HDPE) between 0.035” and 0.048” thick, conforming to ICEA S-61-402 and NEMA WC5 2. Conductors - two of the same gauge, conforming to ASTM B-33, B-3, or B-8 a. Bare copper b. Tin coated solid copper 3. Conductor Arrangement a. b. 4. Conductor Insulation a. b. 5. Low density, high molecular weight polyethylene (PE) with a thickness of 0.045” PVC conforming to UL-493 or UL-719 for thermoplastic-insulated style UF (Underground Feeder) Conductor Color Coding a. b. c. 1.2 Conductors that are twisted Conductors that are laid in parallel Black & red (recommended) Black & white Blue & red Wire Path A. The two-wire path may be looped, spliced, or branched permitting extensions of the path in multiple directions. B. The distance from the controller to the end of any one wire run shall not exceed the maximum distance specified for the gauge of wire. C. The distance from the controllers to the farthest device shall not exceed a distance of 5000 feet (1524 m) using 14-gauge wire or 8000 feet (2438.4 m) using 12-gauge wire. D. The total length of wire connected to any one controller shall not exceed 15,000 feet (4572 m) on 14-gauge or 16,000 feet (4876.8 m) on 12-gauge. Baseline Support: 866-294-5847 2 www.baselinesystems.com E. 1.3 All splices shall be made in a valve box. Wire Installation Details A. The two-wire shall be laid with the pressurized irrigation line between valve boxes and installed without damage including nicks, cuts, or abrasions to the outer jackets. There shall be a 24-inch (61 cm) slack loop at every valve box for making connections. B. The two-wire shall be tested before decoders are installed. PART 2 - Connectors 2.1 Direct Bury A. All two-wire connectors shall be a DBR/Y or equivalent direct bury splice, made for full submersion proof and shall effectively seal moisture from two or more conductors and installed per manufacturer’s specifications, and as specified herein. B. All twist connectors shall be a steel spring, metal shell, flame retardant PVC insulator. C. The outer tube shall be made of polypropylene. D. The internal gel shall be silicone electrical insulating gel. E. The voltage rating shall be a minimum of 600 volts. F. The operating temperature shall be -40°F to 221°F (-40°C to 105°C). 2.2 Connector Installation Details A. All connectors shall be installed per manufacturer’s specifications. B. The installer shall make all connections per manufacturer’s specifications. C. The installer shall verify that no loose, unshielded wiring shall touch the ground, water, or other copper conductor causing a leakage of current to the ground or a short circuit across wires. D. The installer shall make all connections fully submersion proof. E. All splices shall be made inside a valve box. F. The installer shall score the outer jacket of the wire 6 to 10 inches (15.24 cm to 25.4 cm) from each end without scoring conductor insulation. G. The installer shall strip 1 inch (2.54 cm) of insulation from conductor without scoring the conductor. Baseline Support: 866-294-5847 3 www.baselinesystems.com H. Installer shall bundle like conductors, twist them together, and trim off ½ inch (1.27 cm) of conductors. I. Installer shall twist a wire connector in a clockwise direction, and then place a fully submersion-proof DBR/Y tube over the top making sure connector is fully seated at the top of the tube. Snap the cover completely closed. J. Installer shall ensure that all connections are mounted in a vertical orientation to eliminate standing water inside the connector. K. Installer shall provide a strain relief to eliminate pressure on connector (for example, a loop knot in wire or a tie wrap). L. All splices shall be made inside a valve box. PART 3 - Field Decoders 3.1 Valve Decoders A. The valve decoders [BL-5201, BL-5202, BL-5204, BL-5201DC, BL-5202DC, BL-5201MV manufactured by Baseline Inc, in Boise, Idaho] shall be fully sealed, submersion proof, and direct bury to effectively seal moisture from the electronics and shall be installed as specified herein. 1. The BL-5201DC, BL-5202DC decoders shall be used with DC latching solenoids. 2. The BL-5201MV decoder shall be used as a master valve decoder. B. The valve decoder shall have true two-way communication. C. The valve decoder shall be capable of self identifying to the two-wire controller, and will report preconfigured unique serial numbers and zone addresses. D. The valve decoder shall have from one to four preconfigured serial numbers with the first address listed on the side of the decoder. E. Each valve decoder shall come with 23 inches (58.4 cm) of 16-gauge PVC jacketed solid core wire to connect to the two-wire. F. Each valve decoder shall come with 23 inches (58.4 cm) of 18-gauge PVC jacketed stranded core wire to connect to the valve wire. G. The valve decoder shall have communication collision detection on the two-wire and will resend any message experiencing an error. H. The valve decoder shall be able to search for a solenoid and report whether or not a solenoid is present. Baseline Support: 866-294-5847 4 www.baselinesystems.com I. 3.2 3.3 The valve decoder shall have a built-in amperage meter to accurately measure and diagnose valve solenoid electrical problems such as “no current,” “station short,” “over current,” etc. Valve Decoder Wiring and Installation A. The valve decoder shall be 1″ x 4″ x 2″ (2.54 cm x 10.16 cm x 5.08 cm) with 2 mounting tabs for attaching the decoder to the side of a valve box. B. The valve decoder shall be connected to the two-wire path and shall be mounted to the side of the valve box with the serial number face up. C. The valve decoders shall be attached to the valve wire using the connector specification in this document. All valve common wires shall be attached to white common wire of the valve decoder using the connector specification in this document. D. The valve decoders shall not share valve wires or common wires between valve decoders. E. The maximum wire run between a valve decoder and the controller shall be the same as stated in the manufacturer’s two-wire specifications. The maximum distance between the controller and the decoder is 8000 feet (2438.4 m). F. The maximum wire run between the valve decoder and the solenoid shall be 150 feet (45.7 m) using standard 14-gauge irrigation wire. G. Each decoder shall be polarized. H. The decoder shall be connected to the two-wire using the connector specification. I. Each valve wire shall be color coded relative to the serial numbers on the decoder. J. The valve decoder shall have built-in LEDs on the two-wire side that blink during communications. K. The valve decoder shall have a built-in LED on the valve side that is on when power is supplied to the valve. L. The valve decoder shall have enough current to run a typical solenoid up to 150 feet (45.7 m) away from valve decoder using standard 14-gauge irrigation wire. M. The valve decoder shall have enough power to run 2 typical solenoids per decoder concurrently on separate outputs. N. The valve decoder shall be installed in accordance with the manufacturer’s published instructions. O. The valve decoder shall carry a conditional 5-year warranty. Flow Decoder Specifications Baseline Support: 866-294-5847 5 www.baselinesystems.com A. The flow decoder shall be [BL-5308, BL-5309 manufactured by Baseline Inc, in Boise, Idaho] fully sealed, submersion proof, and direct bury that shall effectively seal moisture from the electronics and shall be installed as specified herein. 1. The BL-5308 flow decoder shall supply up to 17mA of current to the blue wire. The voltage on the blue wire is approximately 14.5v. 2. The BL-5309 flow decoder shall supply up to 50mA of current to the purple wire. The voltage on the purple wire is approximately 12v. a. The flow meter output wires of the BL-5309 flow decoder are powered by a DC-DC converter that has up to 1000 volts of isolation. B. The flow decoder shall have true two-way communication. C. The flow decoder shall be capable of self-identifying to the two-wire controller and will report preconfigured unique serial numbers and zone addresses. D. The flow decoder shall have one preconfigured serial number on the side of the decoder. E. Each flow decoder shall come with 23 inches (58.4 cm) of 16-gauge PVC jacketed solid core wire to connect to the two-wire. F. Each flow decoder shall come with 23 inches (58.4 cm) of 18-gauge PVC jacketed stranded core wire to connect to a pulse output flow meter. G. The flow decoder shall have collision detection on the two-wire and be able to resend messages if a collision is detected. H. The flow decoder shall read a minimum of a 5-millisecond low pulse at 200 hertz and a maximum of 200 pulses per second. I. The flow decoder shall be able to search for a flow meter. J. The flow decoder shall have a built-in amperage meter to accurately measure and diagnose flow meter electrical problems such as “no current,” “station short,” “over current,” etc. 3.4 Flow Decoder Wiring and Installation A. The flow decoder shall be 1″ x 4″ x 2″ (2.54 cm x 10.16 cm x 5.08 cm) with 2 mounting tabs for attaching the decoder to the side of a valve box or mounting to a wall near the hydrometer. B. The flow decoder shall be connected to the two-wire path and shall be mounted to the side of a valve box or a wall with the serial number facing up. C. The flow decoder shall be attached to the two-wire using the connector specification in this document. D. The flow decoder shall only be attached to one hydrometer. Baseline Support: 866-294-5847 6 www.baselinesystems.com E. The maximum wire run between flow decoder and the controller shall be the same as stated in the manufacturer’s two-wire specifications with a maximum distance of 8000 feet (2438.4 m) between the controller and the decoder. F. The maximum wire run between the flow decoder and the hydrometer shall be 1000 feet (304.8 m), using an isolated 2-conductor shielded 20 AWG UL type PTLC or larger stranded copper wire rated to 221°F (105°C). G. Each flow decoder shall be polarized. H. The flow decoder output wires shall be color coded for the connections to the hydrometer. I. The flow decoder shall be attached to the hydrometer using the manufacturer’s twowire specification. J. The flow decoder shall have built-in LEDs on the two-wire side that blink during communications. K. The flow decoder shall have built-in LEDs on the hydrometer side that are on when power is supplied to the hydrometer. L. The flow decoder shall be able to run a pulse output hydrometer up to 1000 feet (304.8 m) away using an isolated 2-conductor shielded 20 AWG UL type PTLC or larger stranded copper wire rated to 221°F (105°C). M. The hydrometer shall send low voltage digital pulses to the flow decoder and the decoder shall send the flow information back to the controller. N. The flow decoder shall have enough power to run one pulse output hydrometer per decoder. O. The flow decoder shall output 12 volts to the hydrometer. P. It is intended that the hydrometer shall be connected directly to the flow decoder and the decoder shall be connected directly to the two-wire. All wire connections shall be performed in a valve box per manufacturer’s specifications. Q. The flow decoder shall be installed in accordance with the manufacturer’s published instructions. R. The flow decoder shall carry a conditional 5-year warranty. 3.5 Event Decoders A. The event decoder [BL-5402 manufactured by Baseline Inc, in Boise, Idaho] shall be fully sealed, submersion proof, direct bury that shall effectively seal moisture from electronics and shall be installed as specified herein. B. The event decoder shall have true two-way communication. Baseline Support: 866-294-5847 7 www.baselinesystems.com C. The event decoder shall be capable of self-identifying to the two-wire controller and will report preconfigured unique serial numbers and zone addresses. D. The event decoder shall have one serial number listed on the side of the decoder. E. Each event decoder shall come with 23 inches (58.4 cm) of 16-gauge PVC jacketed solid core wire to connect to the two-wire. F. Each event decoder shall come with 23 inches (58.4 cm) of 18-gauge PVC jacketed stranded core wire to connect to a pause device. G. The event decoder shall have collision detection on the two-wire and will resend messages if a collision is detected. H. The event decoder shall be able to search for a pause device and report whether or not a device is present. I. The event decoder shall be able to interface and read any normally open pause device (this would include rain, wind, pressure, tank floats, and temperature). J. The event decoder shall work with any normally closed switch. K. The event decoder shall be able to detect a problem with the normally open switch and return a short or open to the controller. L. The event decoder shall have a built-in amperage meter to accurately measure and diagnose electrical problems such as “no current,” “station short,” “over current,” etc. 3.6 Event Decoder Wiring and installation A. The event decoder shall be 1″ x 4″ x 2″ with 2 mounting tabs for attaching the decoder to the side of a valve box or to a flat surface. B. The event decoder shall be connected to the two-wire path and shall be mounted to the side of the valve box or to a flat surface with the serial number face up. C. The event decoders shall be attached to the pause device wire using the connector specification in this document. D. Only one pause device may be attached to one event decoder. E. The maximum wire run between event decoder and the controller shall be the same as stated in the manufacturer’s two-wire specifications with a maximum distance of 8000 feet (2438.4 m) between the controller and the decoder. F. The maximum wire run between the event decoder and the pause device shall be a maximum distance of 250 feet (76.2 m) using standard 14-gauge irrigation wire. G. Each event decoder shall be polarized. Baseline Support: 866-294-5847 8 www.baselinesystems.com H. The event decoder shall be connected to the two-wire using the connector specification in this document. I. Each event decoder shall come with a preconfigured serial number for configuring it into the controller. J. The event decoder shall have built-in LEDs on the two-wire side that blink during communications. K. It is intended that the normally open pause device shall be connected directly to the event decoder and the event decoder shall be connected directly to the two-wire. All wire connections shall be performed in a valve box per manufacturer’s specifications. L. The event decoder shall be installed in accordance with the manufacturer’s published instructions. The event decoder shall carry a conditional 5-year warranty. 3.7 Outside Operation Button Decoders [Coach’s Button] A. The outside operation button decoder [BL-5401 manufactured by Baseline Inc, in Boise Idaho] shall be housed in a mountable enclosure that shall effectively seal moisture from electronics and be installed as specified herein. B. The outside operation button decoder shall provide a convenient way to pause irrigation from a remote location without having to access the controller. C. The outside operation button decoder shall have true two-way communication. D. The outside operation button decoder shall be capable of self-identifying to the twowire controller and will report preconfigured unique serial numbers and zone addresses. E. The outside operation button decoder shall have one built-in serial number. F. Each outside operation button decoder shall come with 23 inches (58.4 cm) of 16-gauge PVC jacketed solid core wire to connect to the two-wire. G. The outside operation button decoder shall have standard error collision detections built in on the two-wire and be able to detect collision and resend messages. 3.8 Outside Operation Button Decoder Wiring and Installation A. The outside operation button decoder shall be 5.11″ x 3.35″ x 3.36″ (13 cm x 8.5″ cm x 8.5 cm) with 4 mounting tabs for attaching the outside operation button to the side of a wall. B. The outside operation button decoder shall be connected to the two-wire path and shall be mounted to a flat surface. C. The maximum wire run between outside operation button decoder and the controller shall be the same as stated in the manufacturer’s two-wire specifications with a maximum distance of 8000 feet (2438.4 m) between the controller and the decoder. Baseline Support: 866-294-5847 9 www.baselinesystems.com D. Each outside operation button decoder shall be polarized. E. The outside operation button decoder shall be connected to the two-wire using the connector specification in this document. F. The outside operation button decoder shall have a built-in LED that flashes when the button is pressed. G. The outside operation button decoder shall be installed in accordance with the manufacturer’s published instructions. H. The outside operation button decoder shall carry a conditional 5-year warranty. 3.9 Air Temperature Sensors A. The air temperature sensor [BL-5303 manufactured by Baseline Inc, in Boise Idaho] shall be fully contained in a plastic or stainless steel enclosure that shall effectively seal moisture from the electronics and shall be installed as specified herein. B. The air temperature sensor shall be capable of measuring temperature within the effective operating range of -40°F to 140°F (-40°C to 60°C). C. The air temperature sensor shall have true two-way communication. D. The air temperature sensor shall be capable of self-identifying to the two-wire controller and will report a preconfigured unique serial number. E. Each air temperature sensor shall come with 23 inches (58.4 cm) of 16-gauge PVC jacketed solid core wire to connect to the two-wire. F. The air temperature sensor shall have collision detection on the two-wire and be able to resend messages if a collision is detected. 3.10 Air Temperature Sensor Wiring and Installation A. The air temperature sensor enclosure shall measure 4.5″ x 4.5″ x 2″ (11.4 cm x 11.4 cm x 5.1 cm) with 4 mounting tabs for attaching the enclosure to the side of a wall. B. The enclosure shall be mounted in a shaded area. C. The air temperature sensor shall be connected to the two-wire path using the connector specification from the manufacturer. D. The maximum wire run between the air temperature sensor and the controller shall be the same as stated in the manufacturer’s two-wire specifications with a maximum distance of 8000 feet (2438.4 m) between the controller and the sensor. E. Each air temperature sensor shall be polarized. F. The air temperature decoder shall carry a conditional 5-year warranty. Baseline Support: 866-294-5847 10 www.baselinesystems.com 3.11 Pump Start/Stop Relay Switching Decoders A. The pump start/stop relay switching decoder [BL-5201PR manufactured by Baseline Inc, in Boise Idaho] shall be fully sealed, submersion proof, direct bury that shall effectively seal moisture from electronics and shall be installed as specified herein. B. The pump start/stop relay switching decoder shall be capable of switching 24 VAC. C. The pump start/stop relay switching decoder shall switch a maximum of 2 amps. D. The pump start/stop relay switching decoder shall have true two-way communication. E. The pump start/stop relay switching decoder shall be capable of self-identifying to the two-wire controller and will report a preconfigured unique serial number. F. Each pump start/stop relay switching decoder shall come with 23 inches (58.4 cm) of 16-gauge PVC jacketed solid core wire to connect to the two-wire. G. The pump start/stop relay switching decoder shall have collision detection on the twowire and be able to resend messages if a collision is detected. 3.12 Pump Start/Stop Relay Switching Decoder Wiring and Installation A. The pump start/stop relay switching decoder shall measure 1″ x 4″ x 2″ with 2 mounting tabs for attaching the decoder to the side of a valve box or to a flat surface. B. The pump start/stop relay switching decoder shall be connected to the two-wire path and shall be mounted to the side of the valve box or to a flat surface with the serial number face up. C. The maximum wire run between the pump start/stop relay switching decoder and the controller shall be the same as stated in the manufacturer’s two-wire specifications with a maximum distance of 8000 feet (2438.4 m) between the controller and the decoder. D. The maximum wire run between the pump start/stop relay switching decoder and the 24 VAC load shall be a maximum distance of 250 feet (76.2 m) using standard 14-gauge irrigation wire. E. The pump start/stop relay switching decoder shall be connected to the two-wire using the connector specification in this document. F. Each pump start/stop relay switching decoder shall come with a preconfigured serial number for configuring it into the controller. G. The pump start/stop relay switching decoder shall have built-in LEDs on the two-wire side that blink during communications. H. The pump start/stop relay switching decoder shall have built-in LEDs on the load side. I. The pump start/stop relay switching decoder shall be installed in accordance with the manufacturer’s published instructions. Baseline Support: 866-294-5847 11 www.baselinesystems.com J. 3.13 The pump start/stop relay switching decoder shall carry a conditional 5-year warranty. Compact Soil Moisture Sensors A. The compact soil moisture sensor [BL-5311 manufactured by Baseline Inc, in Boise Idaho] shall be fully sealed, submersion proof, direct bury that shall effectively seal moisture from electronics and shall be installed as specified herein. B. The compact soil moisture sensor shall provide automatic and continuous measurements of soil moisture. C. 1. The compact soil moisture sensor shall be capable of measuring volumetric soil moisture changes of less than 0.1 percent. 2. The compact soil moisture sensor shall be capable of measuring volumetric soil moisture within ± 3 percent of the actual volumetric soil moisture content. The compact soil moisture sensor shall have a built-in temperature sensor (thermistor) that provides automatic and continuous measurements of temperature. 1. The thermistor in the compact soil moisture sensor shall be capable of reading temperatures between 33°F and 120°F (.56°C and 49°C). 2. The thermistor in the compact soil moisture sensor shall be capable of measuring temperature within ± 1.12°F (2°C) of the actual temperature. D. The compact soil moisture sensor shall have true two-way communication. E. The compact soil moisture sensor decoder shall be capable of self-identifying to the two-wire controller and will report its preconfigured unique serial number. F. Each compact soil moisture sensor decoder shall come with 50 feet (15.24 m) of 16gauge PVC jacketed solid core wire to connect to the two-wire. G. The compact soil moisture sensor decoder shall have standard error collision detections and will resend messages on the two-wire. H. The compact soil moisture sensor shall be a TDT (time domain transmissibility) technology sensor that accurately measures soil moisture. I. Salinity and/or other minerals in the soil shall not affect the compact soil moisture sensor readings. J. The compact soil moisture sensor shall be constructed of a multi-layer fiberglass stick. K. The compact soil moisture sensor blade shall be 3.2″ x 3.25″ x .075″ (8.1 cm x 8.3 cm x .19 cm). L. The compact soil moisture sensor logic module shall be 2" x 3" x 1" (5 cm x 7.6 cm x 2.5 cm). 3.14 Original Soil Moisture Sensors Baseline Support: 866-294-5847 12 www.baselinesystems.com A. The original soil moisture sensor [BL-5315B manufactured by Baseline Inc, in Boise Idaho] shall be fully sealed, submersion proof, direct bury that shall effectively seal moisture from electronics and shall be installed as specified herein. B. The original soil moisture sensor shall provide automatic and continuous measurements of soil moisture. C. 1. The original soil moisture sensor shall be capable of measuring volumetric soil moisture changes of less than 0.1 percent. 2. The original soil moisture sensor shall be capable of measuring volumetric soil moisture within ± 3 percent of the actual volumetric soil moisture content. The original soil moisture sensor shall have a built-in temperature sensor (thermistor) that provides automatic and continuous measurements of temperature. 1. The thermistor in the original soil moisture sensor shall be capable of reading temperatures between 33°F and 120°F (.56°C and 49°C). 2. The thermistor in the original soil moisture sensor shall be capable of measuring temperature within ± 1.12°F (2°C) of the actual temperature. D. The original soil moisture sensor shall have true two-way communication. E. The original soil moisture sensor decoder shall be capable of self-identifying to the twowire controller and will report its preconfigured unique serial number. F. Each original soil moisture sensor decoder shall come with 50 feet (15.24 m) of 16gauge PVC jacketed solid core wire to connect to the two-wire. G. The original soil moisture sensor decoder shall have standard error collision detections and will resend messages on the two-wire. H. The original soil moisture sensor shall be a TDT (time domain transmissibility) technology sensor that accurately measures soil moisture. I. Salinity and/or other minerals in the soil shall not affect the original soil moisture sensor readings. J. The original soil moisture sensor shall be constructed of a multi-layer fiberglass stick. K. The original soil moisture sensor blade shall be 14.95″ x 2″ x .075″ (38 cm x 5.1 cm x .19 cm). L. The original soil moisture sensor logic module shall be 2" x 3" x 1" (5 cm x 7.6 cm x 2.5 cm). 3.15 A. Soil Moisture Sensor Wiring and Installation The maximum wire run between soil moisture sensor and the controller shall be the same as stated in the two-wire specifications. Baseline Support: 866-294-5847 13 www.baselinesystems.com B. The soil moisture sensor shall be connected to the two-wire as indicated in the Connectors specification in this document. C. The soil moisture sensor shall be buried in an area of average water distribution between 2 sprinkler heads and placed off of the centerline that the sprinklers create. D. The soil moisture sensor shall be installed in a location representative of the zones that the sensor is controlling. E. The soil moisture sensor shall be installed 2-3 inches (5-8 cm) below the plant or in the top 1/3 of the root zone. F. The soil moisture sensor shall be buried with no air pockets around the sensor. G. The soil moisture sensor shall be marked to avoid damage during aeration. H. All splices shall be made inside the valve box with a DBR/Y or equivalent direct-burial waterproof connection. I. The soil moisture sensor shall carry a conditional 5-year warranty. REV 2.9.2016 Baseline Support: 866-294-5847 14 www.baselinesystems.com